Spacing weft fabric and its weaving method

A fabric, density technology, applied in the direction of fabrics, textiles, papermaking, textiles, etc., can solve the problems of lack of change, dull and monotonous appearance of fabrics, unfavorable personalized clothing, etc., to increase added value, easy to query, and ensure weaving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: a dense weft fabric is a fabric interwoven with warp yarns and weft yarns, and the distribution density of the weft yarns along the warp yarn direction changes according to a set rule; Length is the unit, and the number of weft yarns per unit length at the sparsest point is not more than 90% of the number of weft yarns per unit length at the densest point.

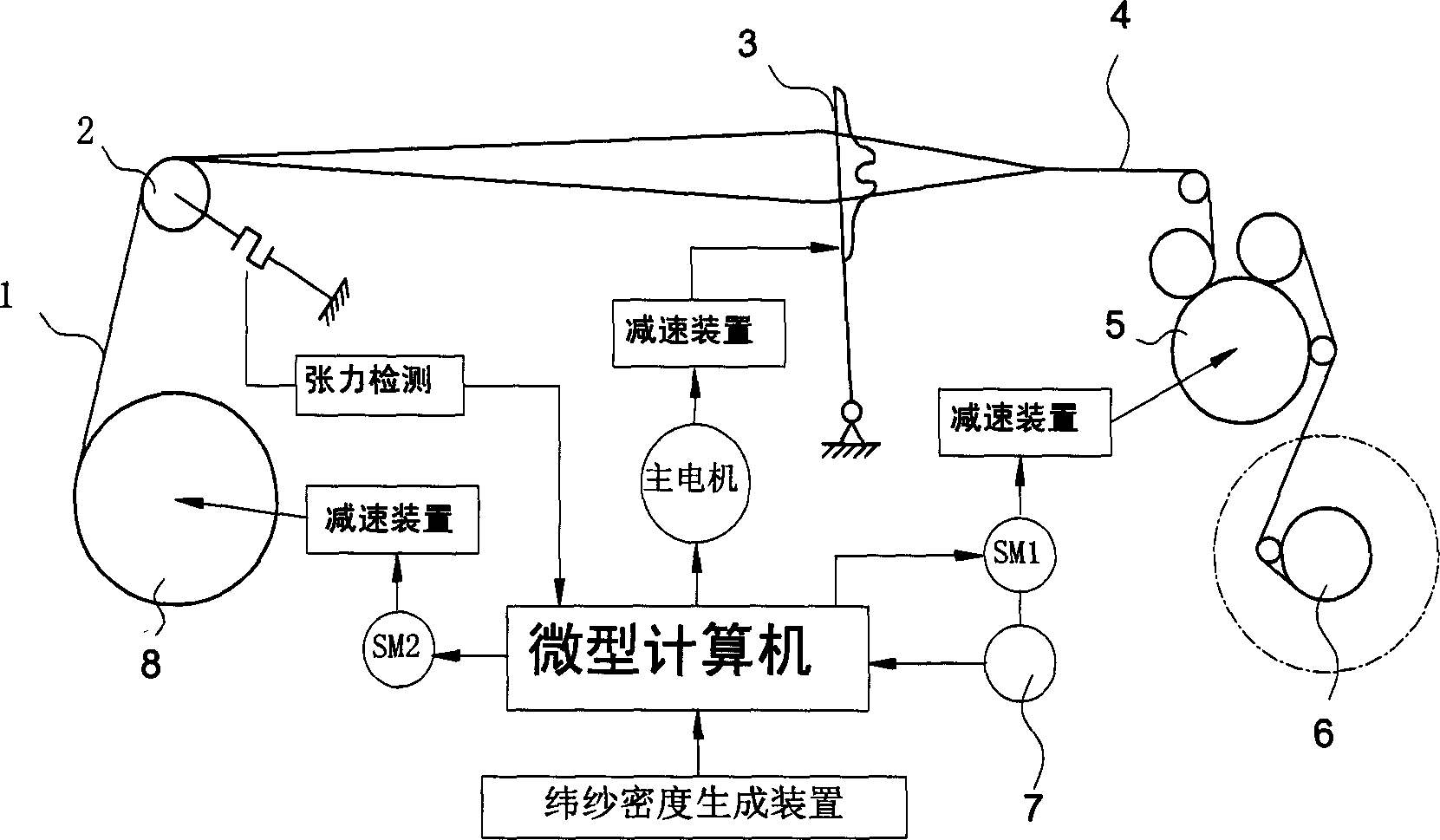

[0020] The weaving method of the sparse and dense weft fabric of this embodiment is realized by using a loom with an electronic take-up device, setting a weft density generating device in the loom control device, and using The weft density generating device converts the expected weft density into the current angular motion of the take-up roller, and controls the electronic take-up device so that the take-up roller rotates the angular motion, thereby realizing the expected change in weft density.

[0021] Wherein, the changing law of the weft yarn density is determined by a given formula, and the weft y...

Embodiment 2

[0025] Embodiment 2: a kind of density weft fabric, is the fabric that adopts warp yarn and weft yarn to interweave, and the distribution density of described weft yarn along the direction of warp yarn changes according to the law density of setting; Units of length.

[0026] The weaving method of the sparse and dense weft fabric of this embodiment is realized by using a loom with an electronic take-up device, setting a weft density generating device in the loom control device, and using The weft density generating device converts the expected weft density into the current angular motion of the take-up roller, and controls the electronic take-up device so that the take-up roller rotates the angular motion, thereby realizing the expected change in weft density.

[0027] Wherein, the change rule of the weft density is determined by a given table, the table includes the winding amount of each weft of at least one garment part length, and the weft density generating device include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com