Moisturizing microcrystalline lotion and preparation method thereof

A technology of microcrystalline and moisturizing agents, which is applied in pharmaceutical formulations, cosmetic preparations, dressing preparations, etc., can solve the problems of lack of long-term hydration, difficulty entering the dermis, and floating on the skin surface, etc., to achieve improved Moisturizing and water-locking effect, good-looking appearance, effect of improving moisture retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

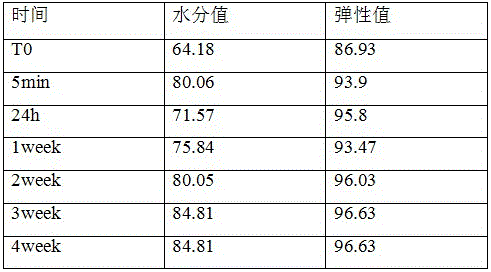

Examples

Embodiment 1

[0042] A moisturizing microcrystalline dew, comprising the following raw materials in parts by weight:

[0043] 80 parts of water

[0044] 1,3-propanediol 15 parts

[0045] Sea Grape Extract 2 parts

[0046] 0.5 parts of disodium EDTA

[0047] Chitosan Glycolate 2 parts

[0048] Acrylate cross-linked polymer 0.5 parts

[0049] Hydrogenated olive oil unsaponifiable matter 0.3 parts

[0050] Phenoxyethanol 0.3 parts

[0051] Chlorphenesin 0.058 parts

[0052] Ethylhexylglycerin 0.1 parts

[0053] Flavor 0.001 parts

[0054] Turkic rose flower oil 0.1 parts

[0055] Rosa rose flower water 0.5 parts.

[0056] The preparation method of the present invention is to mix water, 1,3-propanediol, disodium EDTA, chitosan glycolate and acrylate cross-linked polymer uniformly, dissolve at 80°C for 30 minutes, stir evenly, and then Homogenize, cool down to 40°C, add sea grape extract, essence, chlorphenesin, phenoxyethanol, ethylhexylglycerin, Turkic rose flower oil and rose rose ...

Embodiment 2

[0058] A moisturizing microcrystalline dew, comprising the following raw materials in parts by weight:

[0059] 85 parts of water

[0060] 3 parts glycerin

[0061] Sea Grape Extract 10 parts

[0062] Disodium EDTA 0.1 parts

[0063] Erythritol 10 parts

[0064] Acrylate crosslinked polymer 0.1 parts

[0065] Ethylhexyl Olivate - 3 parts

[0066] Phenoxyethanol 0.1 parts

[0067] Chlorphenesin 0.08 parts

[0068] Ethylhexylglycerin 0.051 parts

[0069] Flavor 0.01 parts

[0070] Turkic rose flower oil 0.01 parts

[0071] 1 part rose flower water.

[0072] The preparation method of the present invention is to mix water, glycerin, disodium EDTA, erythritol and acrylate cross-linked polymer uniformly, dissolve at 88°C for 20 minutes, stir evenly, then homogenize at 350MPa, cool to 50°C, and Grape extract, essence, phenoxyethanol, chlorphenesin, ethylhexylglycerin, Turkic rose flower oil and rose rose flower water were added according to the above proportions, stirred f...

Embodiment 3

[0074] A moisturizing microcrystalline dew, comprising the following raw materials in parts by weight:

[0075] 82 parts of water

[0076] Glyceryl ether-26 10 parts

[0077] Sea Grape Extract 7 parts

[0078] 0.3 parts of disodium EDTA

[0079] 2 parts erythritol

[0080] Chitosan Glycolate 3 parts

[0081] Acrylate cross-linked polymer 0.3 parts

[0082] 2.5 parts of deep sea chestnut seed oil

[0083] Phenoxyethanol 0.2 parts

[0084] Chlorphenesin 0.07 parts

[0085] Ethylhexylglycerin 0.07 parts

[0086] Flavor 0.005 parts

[0087] Turkic rose flower oil 0.05 parts

[0088] Rosa rose flower water 0.7 part.

[0089] The preparation method of the present invention is to mix water, glycerol polyether-26, EDTA disodium, erythritol, chitosan glycolate and acrylate cross-linked polymer uniformly, dissolve at 85°C for 25 minutes, and stir evenly , then homogenize at 370MPa, cool down to 45°C, add sea grape extract, essence, phenoxyethanol, chlorphenesin, ethylhexylgl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com