Reinforcing fabric for non-woven fabric heat-resisting filter material and application thereof

A filter material, heat-resistant technology, applied in the direction of filtration separation, chemical instruments and methods, separation methods, etc., can solve the problems of large elongation, high price, low strength of polytetrafluoroethylene fibers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

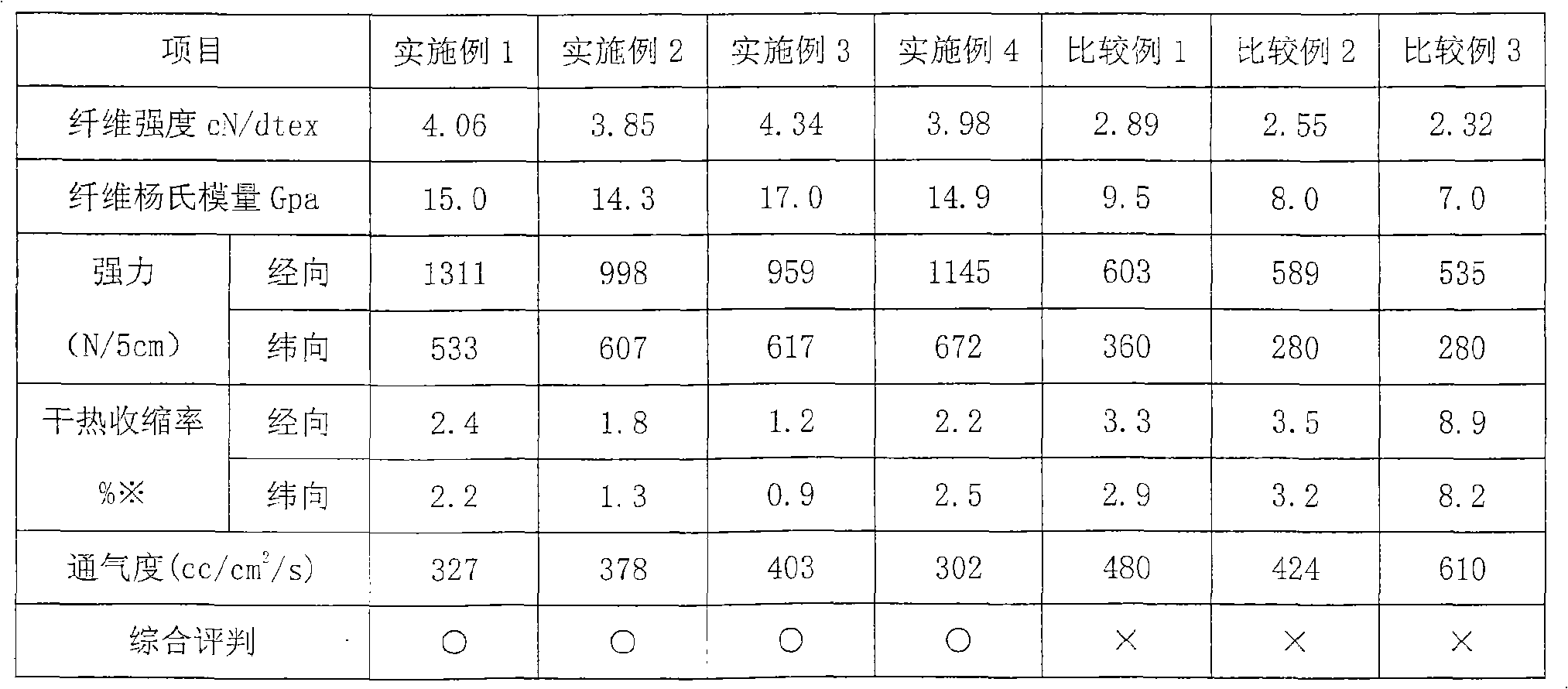

Embodiment 1

[0029] A reinforcing fabric for non-woven heat-resistant filter materials, using meta-aromatic polyamide high-strength short fibers (2.2dtex*51mm) as the raw material for reinforcing fabrics, through the process of opening → carding → drawing → slubbing →Fine spinning→doubling→twisting process to produce double-ply yarn with a linear density of 531 denier. The yarn is then subjected to processes such as heat setting, warping, and weaving to produce a reinforced fabric with a warp density of 35 threads / 2.54cm, a weft density of 15 threads / 2.54cm, and a cover factor of 1155. The results of some physical properties of the reinforced fabric are shown in Table 1 below.

Embodiment 2

[0031] A reinforcing fabric for non-woven heat-resistant filter materials, using meta-aramid high-strength short fibers (content 80%) and polytetrafluoroethylene short fibers (PTFE) (content 20%) as the reinforcing fabric Raw materials, through the process of opening → carding → drawing → slubbing → fine spinning → doubling → twisting, a single-ply yarn with a linear density of 760 denier is produced as a weft yarn with a linear density of 531 denier Er's double-ply yarn is used as warp yarn. The yarn is then subjected to processes such as heat setting, warping, and weaving to produce a reinforced fabric with a warp density of 30 threads / 2.54cm, a weft density of 13 threads / 2.54cm, and a cover factor of 1052. The results of some physical properties of the reinforced fabric are shown in Table 1 below.

Embodiment 3

[0033] A kind of reinforcing fabric for non-woven fabric heat-resistant filter material, choose meta-aromatic polyamide high-strength filament fiber (400 denier-100f) as the raw material of reinforcing fabric, through warping, weaving and other processes, A reinforced fabric with a warp density of 25 threads / 2.54cm, a weft density of 16 threads / 2.54cm and a cover factor of 907 was produced. The results of some physical properties of the reinforced fabric are shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com