Heat strengthening laminated glass

A technology of laminated glass and thermal strengthening, applied in glass/slag layered products, layered products, chemical instruments and methods, etc. The effect of good penetration performance and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12

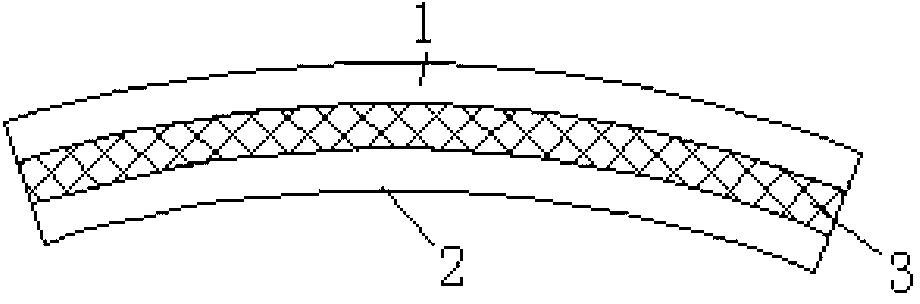

[0041] Such as figure 1 As shown, the thermally strengthened laminated glass in this embodiment includes a first glass plate 1, a second glass plate 2, and an interlayer film 3 sandwiched between the first glass plate 1 and the second glass plate 2, At least one of the first glass plate 1 and the second glass plate 2 is a heat-strengthened glass plate, and the heat-strengthened laminated glass includes a middle area 6 and an edge area 5, and the edge area 5 includes an edge compressive stress area 51 And the edge tensile stress region 52 adjacent thereto, characterized in that: the maximum edge compressive stress of the edge compressive stress region 51 is greater than 18MPa, the maximum edge tensile stress of the edge tensile stress region 52 is less than or equal to 7MPa, the The surface stress of heat strengthened laminated glass is greater than 6MPa and less than 14.8MPa. Among them, the first glass plate 1 and the second glass plate 2 of Examples 1 to 6 are transparent f...

Embodiment 13~24

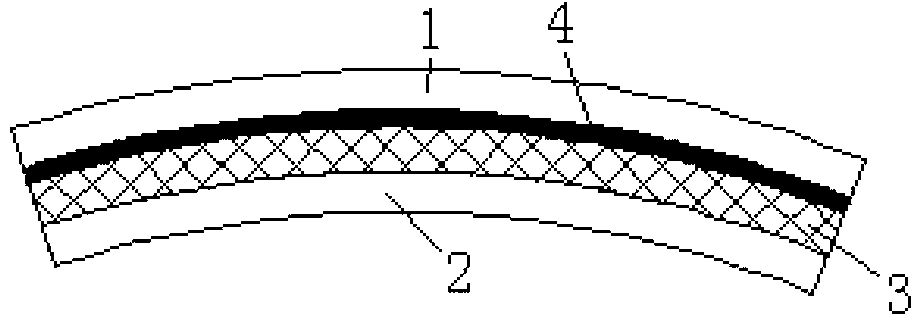

[0048] Such as figure 2 As shown, the thermally strengthened laminated glass in this embodiment includes a first glass plate 1, a second glass plate 2, and an interlayer film 3 sandwiched between the first glass plate 1 and the second glass plate 2, At least one of the first glass plate 1 and the second glass plate 2 is a heat-strengthened glass plate, and the heat-strengthened laminated glass includes a middle area 6 and an edge area 5, and the edge area 5 includes an edge compressive stress area 51 And the edge tensile stress region 52 adjacent thereto, characterized in that: the maximum edge compressive stress of the edge compressive stress region 51 is greater than 18MPa, the maximum edge tensile stress of the edge tensile stress region 52 is less than or equal to 7MPa, the The surface stress of heat strengthened laminated glass is greater than 6MPa and less than 14.8MPa. Wherein, the first glass plate 1 of embodiments 13-18 is a glass plate with a thickness of 2.1 mm, a...

Embodiment 25~27

[0058] Such as figure 2 and image 3As shown, a heat-strengthened low-emissivity coated laminated glass in this embodiment includes a first glass plate 1, a second glass plate 2, and is sandwiched between the first glass plate 1 and the second glass plate 2 The interlayer film 3, the first glass plate 1 and the second glass plate 2 are ordinary glass plates with a thickness of 2.1 mm, and the difference from Examples 1 to 24 is that the first glass plate 1 and the second glass plate of this example One of the glass plates 2 is a low-emissivity coated glass containing double silver layers, and the periphery of the coated glass is not coated with a low-emissivity coating to avoid damage to the coating under normal conditions. The low-emissivity coated glass is heat-strengthened using different process parameters, by applying convection heating in the heating zone and prolonging the heating time, and using local heating on the pressing forming zone to ensure that the temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface stress | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com