Capacitor aluminum shell coating and production and coating method thereof

A capacitor and film coating technology, used in polyester coatings, epoxy resin coatings, coatings, etc., can solve the problems of high insulation performance and heat resistance that cannot meet the requirements, low production efficiency, and high production costs, and achieve good resistance. The effect of softening ability, good breakdown resistance and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

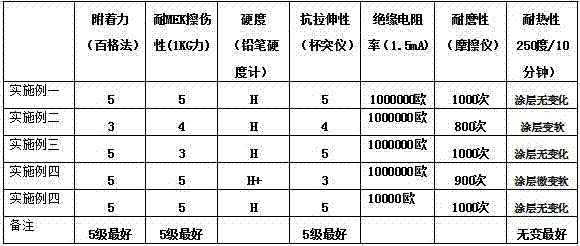

Examples

Embodiment 1

[0035] Capacitor aluminum casing coating, including composition A and composition B; said composition A includes the following materials in parts by mass: 40 parts of polyester resin, 15 parts of epoxy resin, 10 parts of S100# solvent naphtha, 20 parts of PMA, 1 part of dispersant, 3 parts of organosiloxane defoaming and leveling agent, 0.3 parts of acid catalyst, 5 parts of high insulation carbon black, 5 parts of mica powder; described composition B comprises the following by mass parts Substances: 20 parts of permethyl ether amino resin, 5 parts of high methylene amino resin, 30 parts of butyl acetate, 3 parts of butoxy cellosolve.

[0036] Produced as follows:

[0037] 1) Preparation of composition A: Mix polyester resin, epoxy resin, S100# solvent oil, PMA, dispersant, acid catalyst, organosiloxane defoaming and leveling agent, and stir at 500~800rpm for 10~ 15min; reduce the rotation speed to 200~300rpm, then add insulating carbon black and mica powder in turn, and then...

Embodiment 2

[0041] Capacitor aluminum shell coating, including composition A and composition B; said composition A includes the following materials in parts by mass: 65 parts of polyester resin, 10 parts of epoxy resin, 20 parts of S100# solvent oil, 10 parts of PMA, 2 parts of dispersant, 3 parts of organosiloxane defoaming and leveling agent, 0.5 part of acid catalyst, 3 parts of high insulation carbon black, 8 parts of mica powder; Described composition B comprises by mass parts as follows Substances: 15 parts of permethyl ether amino resin, 6 parts of high methylene amino resin, 15 parts of butyl acetate, 5 parts of butoxy cellosolve.

[0042] Production is carried out in the manner of Example 1, and the film-coating coating for the capacitor aluminum shell is obtained.

Embodiment 3

[0044] Capacitor aluminum casing coating, including composition A and composition B; said composition A includes the following materials in parts by mass: 45 parts of polyester resin, 12 parts of epoxy resin, 15 parts of S100# solvent naphtha, 15 parts of PMA, 1.5 parts of dispersant, 2 parts of organosiloxane defoaming and leveling agent, 0.4 part of acid catalyst, 4 parts of high insulating carbon black, 6 parts of mica powder; Described composition B comprises the following by mass parts Substances: 22 parts of permethyl ether amino resin, 5 parts of high methylene amino resin, 17 parts of butyl acetate, 4 parts of butoxy cellosolve.

[0045] Production is carried out in the manner of Example 1, and the film-coating coating for the capacitor aluminum shell is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com