Flexible reinforced composite material and preparation method thereof

A composite material and flexible technology, which is applied in the direction of bridge reinforcement, chemical instruments and methods, and synthetic resin layered products, can solve problems such as threats to the safety of personnel and material equipment, inability to perform rapid repairs, and damage to engineering structures, etc. Explosion shock ability, improved anti-explosion and anti-penetration ability, large coverage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A flexible reinforced composite material such as figure 1 As shown, the flexible reinforced composite material includes a polyurea coating 1 on the surface of the woven fabric, and a three-dimensional orthogonal woven fabric 2 impregnated with a mixed slurry padding liquid; the thickness of the three-dimensional orthogonal woven fabric is 6mm, and the length is 20m. The width is 1.5m; the weft yarn is Toray’s T620SC-24K-50C carbon fiber, and the linear density is 1850tex; the warp yarn is Japanese Teijin’s aramid (3220dtex / 2000f) fiber, and the Z-direction yarn is DyneemSK-66 from the Dutch DSM company; The 6 layers of warp yarns pass through the improved loom in a straightened state, and 7 weft yarns are fed into the gaps between the warp yarns, and the Z-direction yarns are fixed by using the up and down movement of the healds.

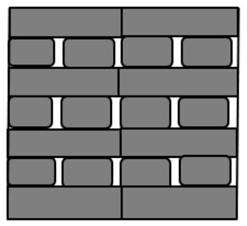

[0050] The front rendering of the three-dimensional orthogonal woven fabric is as follows figure 2 shown. The warp density and weft densi...

Embodiment 2

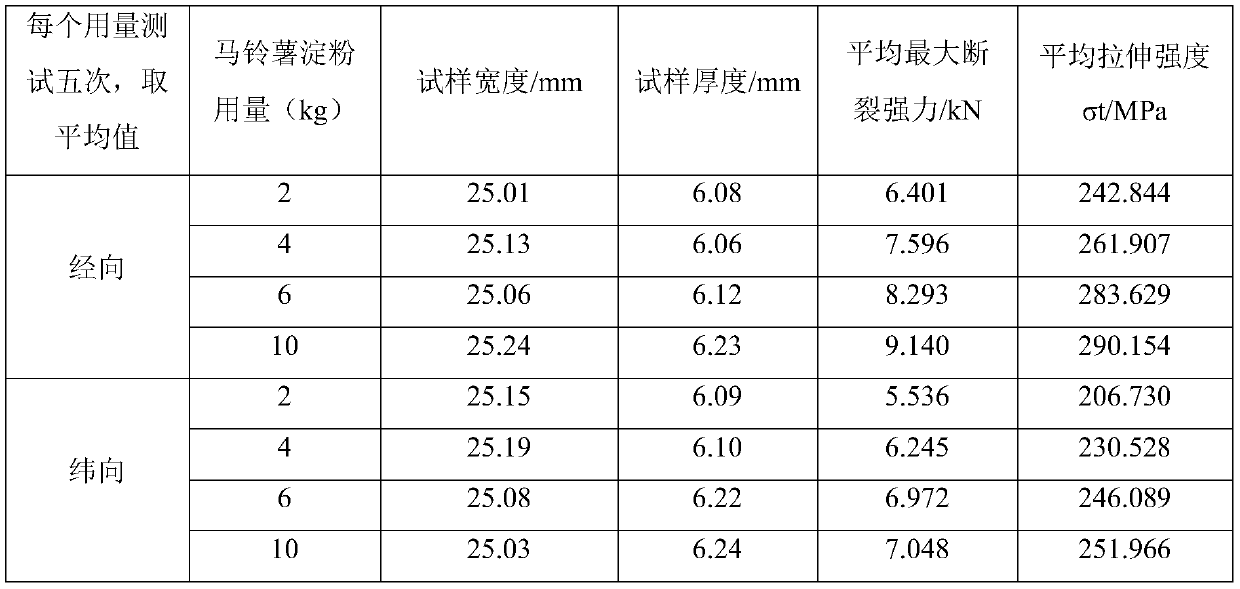

[0060] Referring to Example 1, the amount of potato starch was replaced by 2kg, 4kg, 6kg, and 10kg respectively, and other conditions remained unchanged, and a pretreated woven fabric was prepared, which was then compounded with polyurea to obtain a flexible and reinforced composite material. The specific test results are shown in Table 1, Table 2, and Table 3; Table 1 shows the tensile performance results of woven fabrics pretreated with different potato starch dosages; Table 2 shows the penetration performance results of flexible reinforced composite materials prepared with different potato starch dosages; Table 3 is the rigid-flexibility results of flexible reinforced composites under different potato starch content.

[0061] Table 1 Tensile properties of woven fabrics pretreated with different potato starch dosages

[0062]

[0063] Table 2 Penetration properties of flexible reinforced composites prepared with different amounts of potato starch

[0064]

[0065] Tab...

Embodiment 3

[0069] Referring to Example 1, the solid content of the water-based polyurethane emulsion was changed to 5%, 10%, 20%, and 30% respectively, and other conditions remained unchanged, to prepare a flexible and reinforced composite material. See Table 4 and Table 5 for specific results.

[0070] The results of tensile properties of woven fabrics pretreated with solid content of different water-based polyurethane emulsions in table 4

[0071]

[0072] Table 5 Penetration performance results of flexible reinforced composites prepared with different solid contents of aqueous polyurethane emulsions

[0073]

[0074] Table 6 Rigid-flexible results of flexible reinforced composites prepared with solid content of different aqueous polyurethane emulsions

[0075]

[0076] It can be seen from Table 4 that with the increase of the solid content of the aqueous polyurethane emulsion, the stretchability of the impregnated fabric increases, but when the solid content of the aqueous p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com