Packaging winding film

A technology of wrapping film and mineral fiber, applied in the field of wrapping wrapping film, can solve the problems of poor tensile strength and puncture resistance of wrapping film materials, unstable film production, uneven product quality, etc. The effect of penetration performance, simple manufacturing process, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

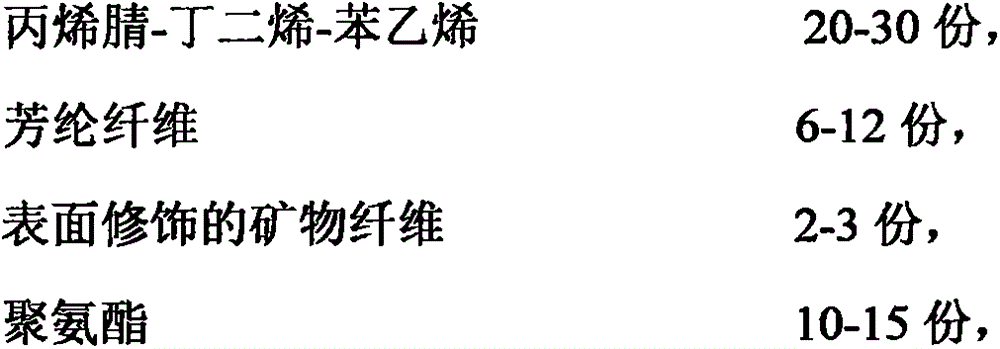

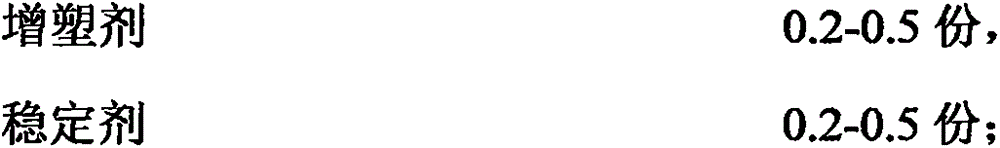

[0026] A packaging stretch film is prepared from the following components by weight:

[0027]

[0028] Wherein, the preparation method of the surface-modified mineral fiber is realized through the following steps: adding 100 g of trimethylolmethylaminoethanesulfonic acid to 1000 g of chloroform suspended with 200 g of mineral fiber with a diameter of 5 μm, and ultrasonically vibrating for 20 min , and then let it stand still for 20 minutes, took it out, washed it with chloroform, and placed it in a vacuum drying oven at 70° C. for 24 hours to obtain surface-modified mineral fibers.

[0029] A preparation method for packaging stretch film, comprising the steps of:

[0030] 1) Add the corresponding weight parts of raw materials into the mixer for mechanical mixing, stir and mix at a speed of 800r / min for 70min, and obtain material A;

[0031] 2) Use a twin-screw extruder to extrude material A at high temperature to obtain material B. The twin-screw extrusion temperature is d...

Embodiment 2

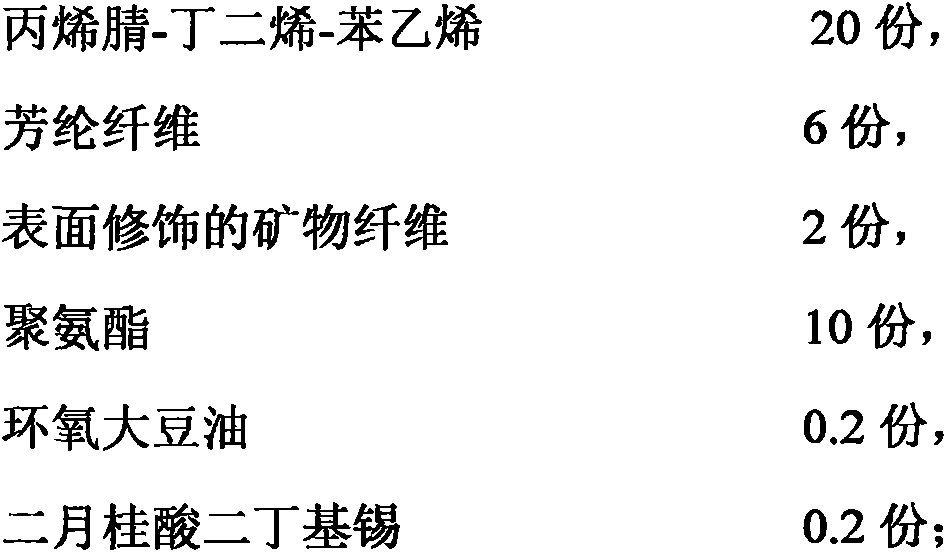

[0034] A packaging stretch film is prepared from the following components by weight:

[0035]

[0036] Wherein, the preparation method of the surface-modified mineral fiber is realized through the following steps: adding 100 g of trimethylolmethylaminoethanesulfonic acid to 1200 g of chloroform suspended with 300 g of mineral fiber with a diameter of 10 μm, and ultrasonically vibrating for 30 min , and then let it stand still for 25 minutes, took it out, washed it with chloroform, and placed it in a vacuum drying oven at 75° C. for 18 hours to obtain surface-modified mineral fibers.

[0037] A preparation method for packaging stretch film, comprising the steps of:

[0038] 1) Put the corresponding weight parts of raw materials into the mixer for mechanical mixing, stir and mix at a speed of 1000r / min for 56min, and obtain material A;

[0039] 2) Use a twin-screw extruder to extrude material A at high temperature to obtain material B. The twin-screw extrusion temperature is...

Embodiment 3

[0042] A packaging stretch film is prepared from the following components by weight:

[0043]

[0044] Wherein, the preparation method of the surface-modified mineral fiber is realized through the following steps: adding 100 g of trimethylolmethylaminoethanesulfonic acid to 1500 g of chloroform suspended with 400 g of mineral fiber with a diameter of 15 μm, and ultrasonically vibrating for 35 min , and then let it stand still for 26 minutes, took it out, washed it with chloroform, and placed it in a vacuum drying oven at 77° C. for 21 hours to obtain surface-modified mineral fibers.

[0045] A preparation method for packaging stretch film, comprising the steps of:

[0046] 1) Put the corresponding weight parts of the raw materials into the mixer for mechanical mixing, stir and mix at a speed of 1100r / min for 60min, and obtain material A;

[0047] 2) Use a twin-screw extruder to extrude material A at high temperature to obtain material B. The twin-screw extrusion temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com