Unilateral anti-delamination sandwich plate with oblique rib plate and application, connection and preparation method thereof

A technology of sandwich panels and oblique ribs, which is applied to hull paneling, transportation and packaging, and ship parts, etc., and can solve problems such as delamination of sandwich panels, affecting the service life and safety of ships, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

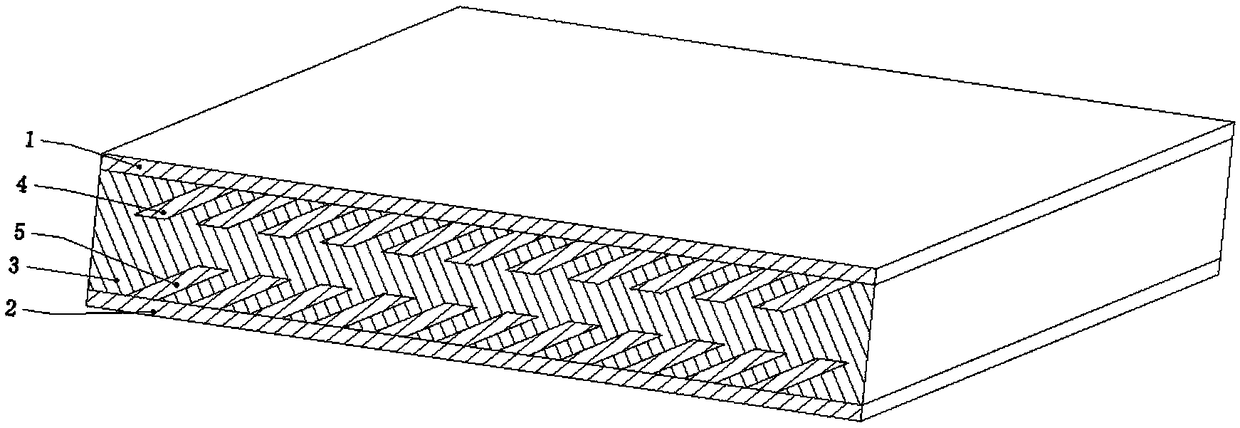

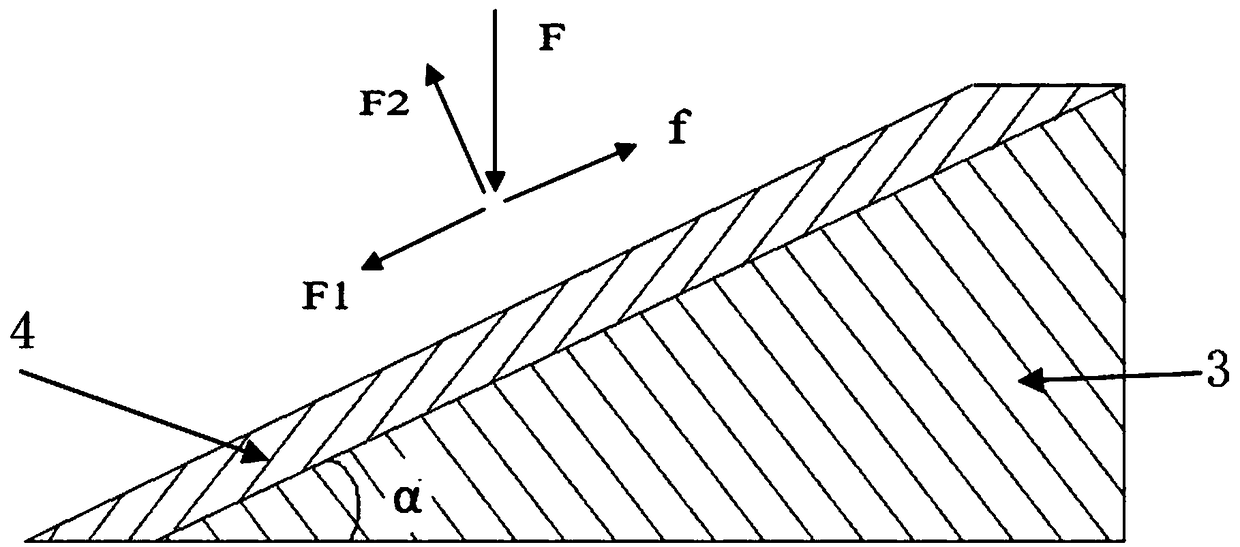

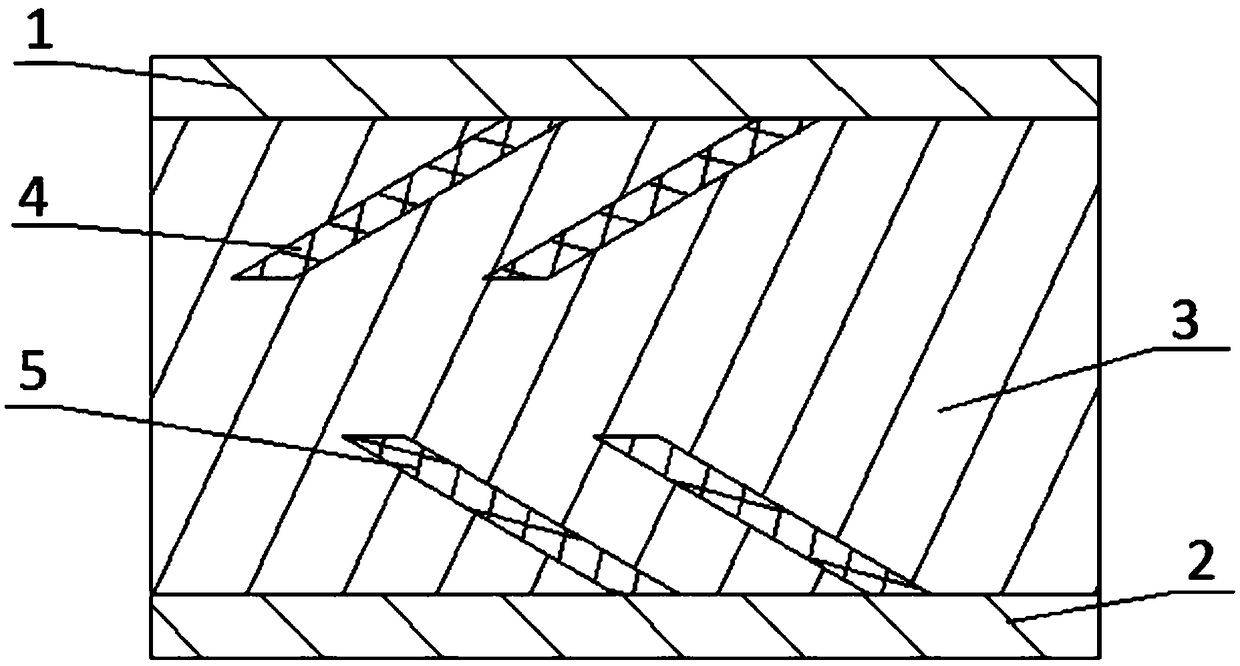

[0087] Such as Figure 8 As shown, the single-sided anti-delamination sandwich panel with oblique ribs in Example 1 includes an upper panel 1 , a lower panel 2 , a core material 3 , an upper rib 4 and a lower rib 5 . Among them, several upper ribs 4 are arranged obliquely and parallelly on the inner side of the upper panel 1, and several lower ribs 5 are arranged obliquely and parallelly on the inner side of the lower panel 2, the connection mode of the upper ribs 4 and the upper panel 1 And the connection mode of lower rib 5 and upper panel 2 is welding. The core material 3 is poured into the gap between the upper and lower panels and the upper and lower ribs, so that the components of the sandwich panel are combined to form a whole.

[0088] Wherein the upper panel 1 and the lower panel 2 are all selected A3 steel plate, the core material 3 of the present invention is selected nylon material, and the upper rib 4 and the lower rib 5 of the present invention are also selected...

Embodiment 2

[0093] Such as image 3 As shown, the single-sided anti-delamination sandwich panel with oblique ribs in Example 2 includes an upper panel 1 , a lower panel 2 , a core material 3 , an upper rib 4 and a lower rib 5 . Among them, several upper ribs 4 are arranged obliquely and parallelly on the inner side of the upper panel 1, and several lower ribs 5 are arranged obliquely and parallelly on the inner side of the lower panel 2, the connection mode of the upper ribs 4 and the upper panel 1 And the connection mode of lower rib 5 and upper panel 2 is pouring. The core material 3 is poured into the gap between the upper and lower panels and the upper and lower ribs, so that the components of the sandwich panel are combined to form a whole.

[0094] Wherein the upper panel 1 and the lower panel 2 are all selected A3 steel plate, the core material 3 of the present invention is selected nylon material, and the upper rib 4 and the lower rib 5 of the present invention are also selected ...

Embodiment 3

[0099]The sandwich panel in Example 3 includes an upper panel 1 , a lower panel 2 , a core material 3 , an upper rib 4 and a lower rib 5 . Among them, several upper ribs 4 are arranged obliquely and parallelly on the inner side of the upper panel 1, and several lower ribs 5 are arranged obliquely and parallelly on the inner side of the lower panel 2, the connection mode of the upper ribs 4 and the upper panel 1 And the connection mode of lower rib 5 and upper panel 2 is pouring. The core material 3 is poured into the gap between the upper and lower panels and the upper and lower ribs, so that the components of the sandwich panel are combined to form a whole.

[0100] The dimensions of the sandwich panels in Example 3 are as follows: the thickness of the upper panel 1 and the lower panel 2 is 1.0 mm, the thickness of the upper rib 4 and the lower rib 5 is 2 mm, the distance between two adjacent ribs is 15 mm, and the height of the ribs is 1.0 mm. is 10mm, the oblique angle α a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com