Crop-harvesting apparatus

A technology for harvesting devices and crops, which is applied in the direction of harvesters, agriculture, cutters, etc., can solve the problems of labor hours and other problems, and achieve the effects of reducing labor hours, improving workability, and suppressing unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

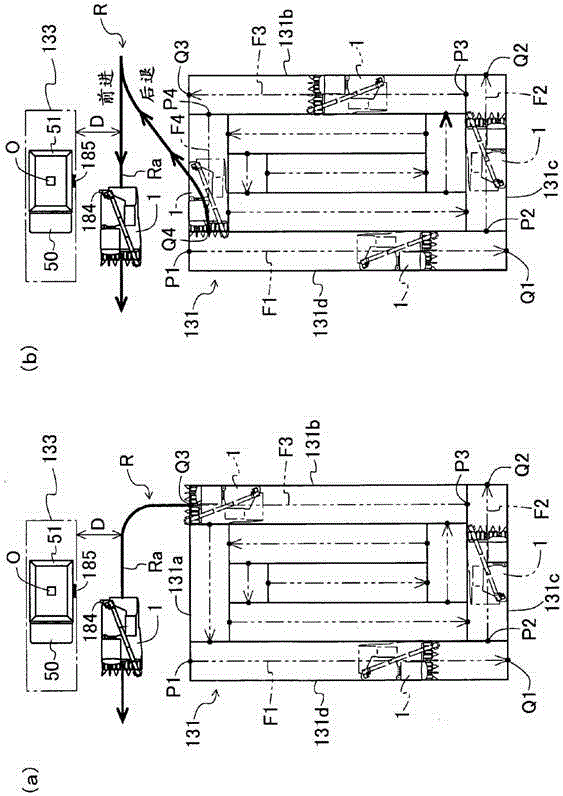

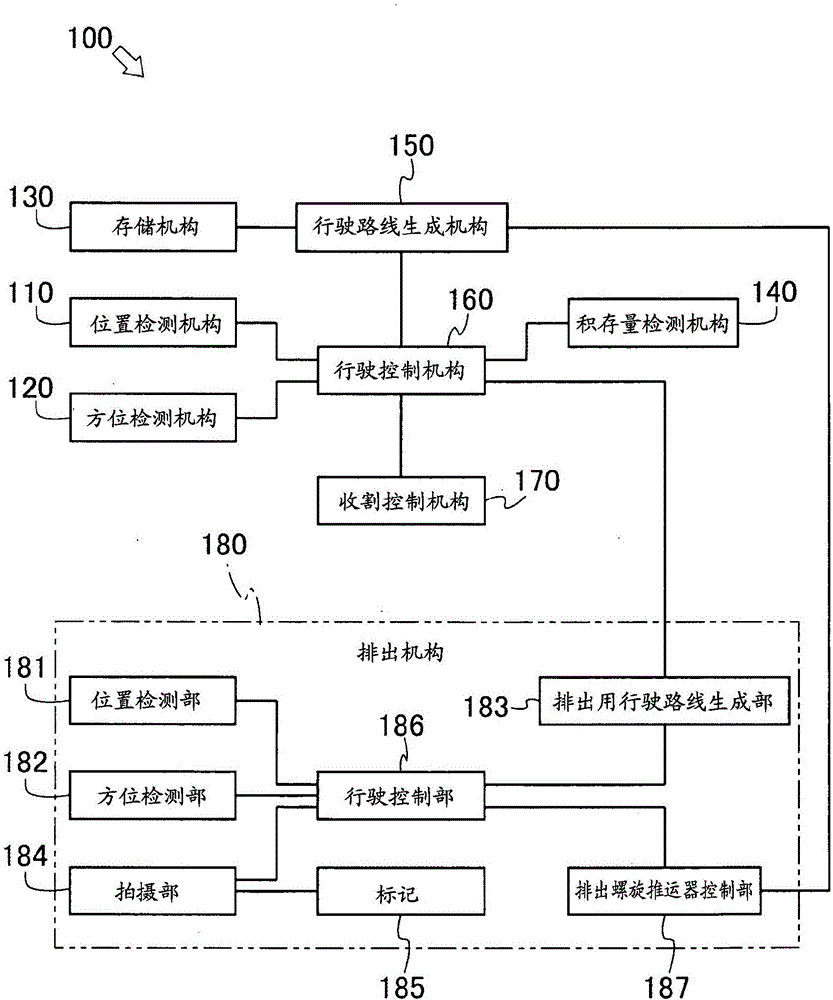

[0058] [Driving route generation]

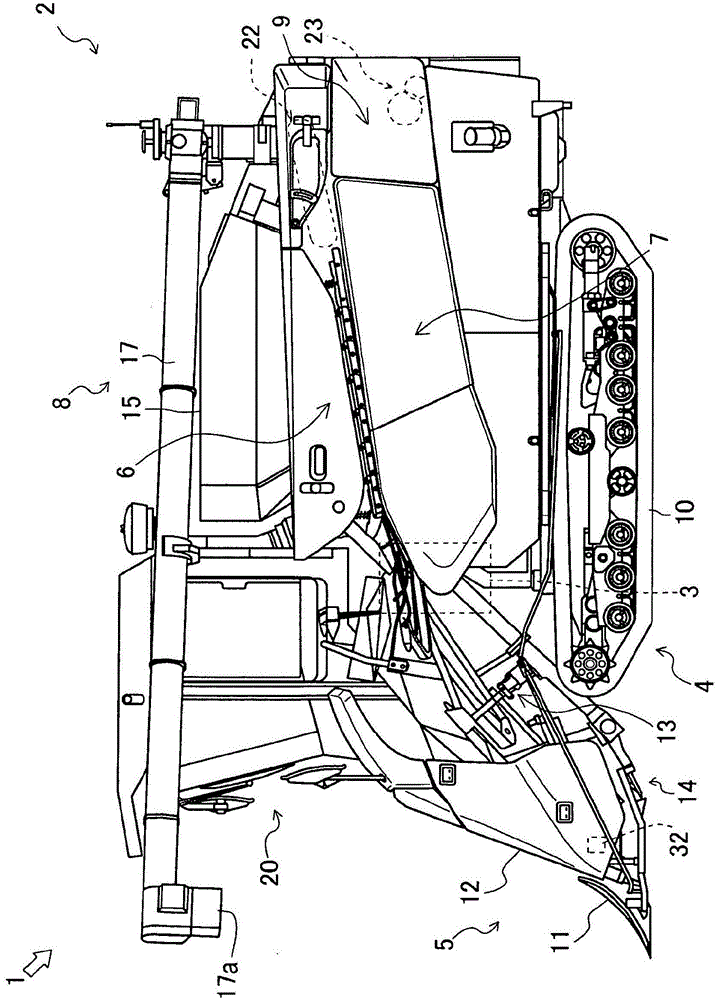

[0059] First, the combine harvester 1 which is an example of a traveling type harvester is demonstrated.

[0060] Such as figure 1 As shown, the combine harvester 1 has the engine 3, the traveling part 4, the reaping part 5, the threshing part 6, the sorting part 7, the grain discharge part 8, and the grass discharge processing part 9.

[0061] The combine harvester 1 transmits the motive power of the engine 3 to the traveling part 4, the reaping part 5, the threshing part 6, the sorting part 7, the grain discharge part 8, and the weed disposal part 9, and drives these each parts. The combine harvester 1 which is a traveling type harvester can reap agricultural crops (grain) while traveling.

[0062] The running part 4 is arranged at the lower part of the machine body 2 . The traveling unit 4 includes: a transmission mechanism (HST (Hydraulic Continuously Variable Transmission) or the like) 3a for changing the speed of power from the engi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com