Pushing device for stacking silicon steel sheets of transformer iron core

A transformer core and push device technology, applied in the direction of inductance/transformer/magnet manufacturing, electrical components, circuits, etc., can solve the problems of inability to guarantee stacking efficiency, height difference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

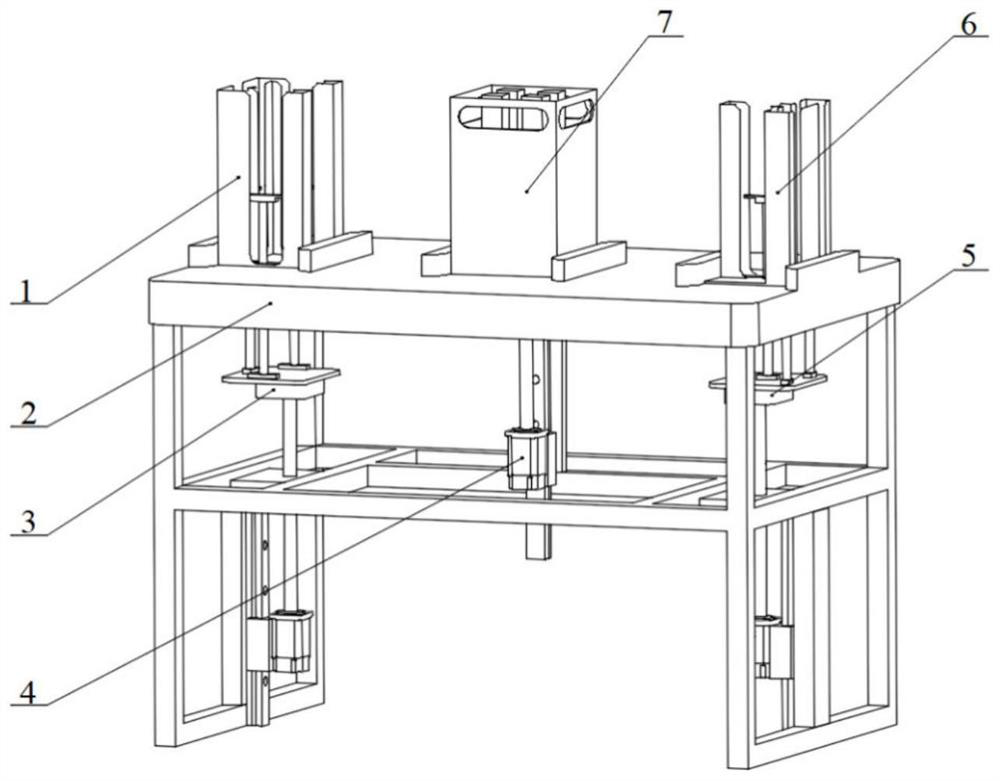

[0082] A pushing device for stacking silicon steel sheets of transformer iron core. Described casing and pushing device such as figure 1 As shown, it is composed of left silicon steel sheet case 1, frame 2, left push device 3, workpiece push device 4, right push device 5, right silicon steel sheet case 6 and workpiece case 7.

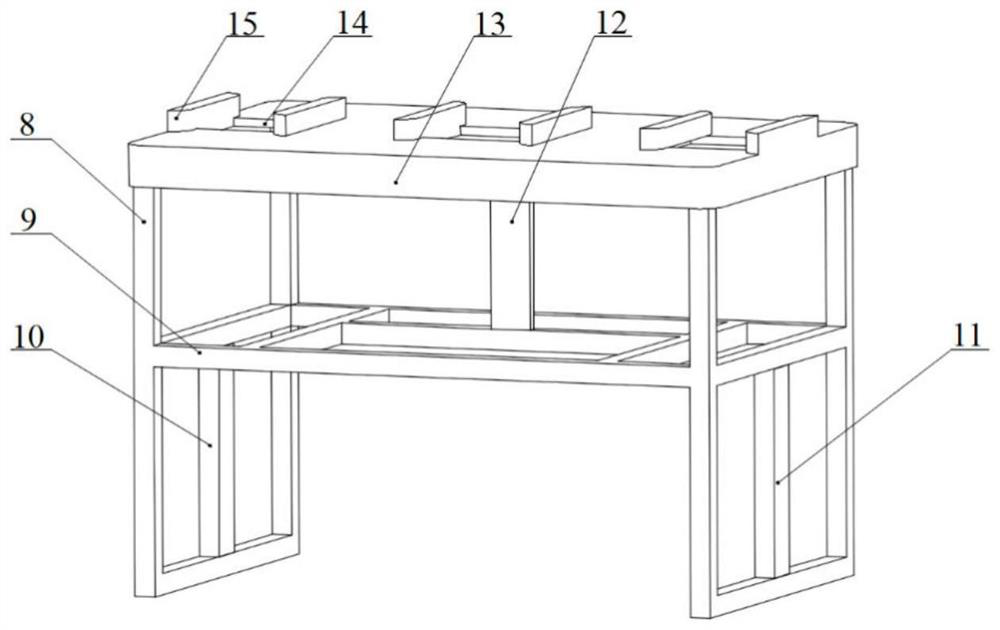

[0083] Rack 2 as figure 2 As shown, it includes an upper mounting plate 13, a lower mounting frame 9, four columns 8, a left mounting plate 10 and a right mounting plate 11; the upper ends of the four columns 8 are respectively vertically fixed at the four corners of the upper mounting plate 13, and the four columns The middle part of 8 is horizontally fixed with the lower mounting frame 9, and the bottom of the left end of the lower mounting frame 9 and the bottom of the right end are correspondingly fixed with the left side mounting plate 10 and the right side mounting plate 11; A middle mounting plate 12 is vertically fixed at the middle position,...

Embodiment 2

[0123] A pushing device for stacking silicon steel sheets of transformer iron core. Except for the following technical parameters, the rest are the same as Example 1:

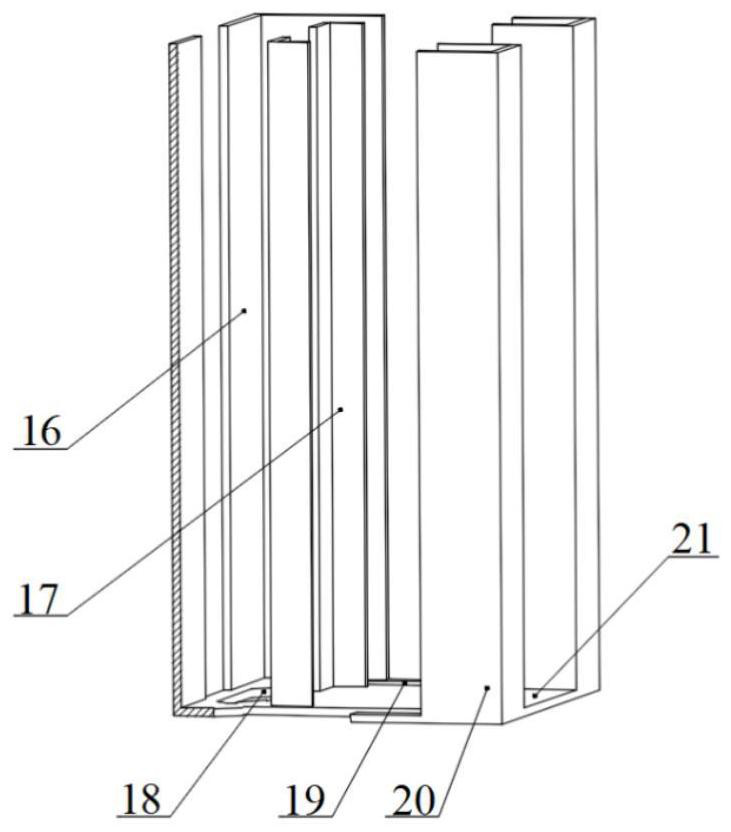

[0124] Such as Figure 4 As shown, the left vertical right-angle outer panel 16 is a mutually perpendicular whole composed of the outer panel along the left-right direction and the outer panel along the front-rear direction, the length of the outer panel along the left-right direction L061=0.35×L0, The length L062=0.35*B0 of the outer plate of direction; Described left vertical right-angled inner plate 17 is to be by the inner plate along left-right direction and by the inner plate along front-rear direction the mutually perpendicular integral body that is made up of, the inner plate along left-right direction The length L051=L061-Bg-δ, the length of the inner plate along the front-rear direction L052=L062-Bg-δ; the length of the side plates on both sides of the left long vertical channel plate 20 is L07=0.25×...

Embodiment 3

[0133] A pushing device for stacking silicon steel sheets of transformer iron core. Except for the following technical parameters, the rest are the same as Example 1:

[0134] Such as Figure 4 As shown, the left vertical right-angle outer panel 16 is a mutually perpendicular whole composed of the outer panel along the left-right direction and the outer panel along the front-rear direction, the length of the outer panel along the left-right direction L061=0.40×L0, The length L062=0.40*B0 of the outer plate of direction; Described left vertical right-angle inner plate 17 is to be by the inner plate along left-right direction and by the inner plate along front-rear direction the mutually perpendicular integral body that is made up of, the inner plate along left-right direction The length L051=L061-Bg-δ, the length of the inner plate along the front-to-back direction L052=L062-Bg-δ; the length of the side plates on both sides of the left long vertical channel plate 20 is L07=0.3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com