Production method of low-formaldehyde-releasing impregnating resin film paper

A technology of impregnated film paper and low formaldehyde release, which is applied in paper, papermaking, paper coating, etc., can solve problems such as not being able to meet market demand, and achieve the goal of ensuring surface physical and chemical properties, improving quality and applicability, and ultra-low formaldehyde release Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of urea-formaldehyde resin:

[0031] Formula: 100kg of formaldehyde with a concentration of 37%, 76kg of urea with a concentration of 98%, 15kg of water, and 7kg of compound additives. The molar ratio of formaldehyde to urea, F / U=0.99

[0032] method:

[0033] (1) Put 100kg of formaldehyde into the reactor at one time, put in 32.7kg of urea, add 15kg of water, and adjust the pH to 8.0 with sodium hydroxide solution;

[0034] (2) Open the oil valve and raise the temperature to 80°C, stop the heat supply, let it automatically rise to 85°C, keep warm for 30 minutes, add formic acid solution, control the pH value at 4.5, and carry out polycondensation reaction at 92°C;

[0035] (3) Add 7kg of compound additives and adjust the pH to 7.0 when the glue solution appears dense white mist in 20°C water, and add 24.3kg of urea when the temperature is lowered to 85°C;

[0036] (4) Cool down to 65°C and add 19kg of urea, adjust the pH to 7.0, continue to cool down to ...

Embodiment 2

[0054]The difference between the impregnated film paper described in this embodiment and Example 1 is: the total amount of urea added during the preparation of urea-formaldehyde resin is 78kg, the molar ratio of formaldehyde to urea, F / U=0.96; in the preparation step of urea-formaldehyde resin The add-on of the first batch of urea in (1) is 33.5kg; The add-on of the second batch of urea in the urea-formaldehyde resin preparation step (3) is 25kg; The add-on of the third batch of urea in the urea-formaldehyde resin preparation step (4) is 19.5kg; if there is a parameter range, the middle value of the corresponding parameter range is taken; others are the same as in Example 1.

Embodiment 3

[0056] The difference between the impregnated film paper described in this embodiment and Example 1 is: the total amount of urea added during the preparation of urea-formaldehyde resin is 80kg, the molar ratio of formaldehyde to urea, F / U=0.94; in the preparation step of urea-formaldehyde resin The addition amount of the first batch of urea in (1) is 34.4kg; the addition amount of the second batch of urea in the urea-formaldehyde resin preparation step (3) is 25.6kg; the addition amount of the third batch of urea in the urea-formaldehyde resin preparation step (4) It is 20kg; if there is a parameter range, take the end value of the corresponding parameter range (Example 1 takes the first end value). Others are the same as in Example 1.

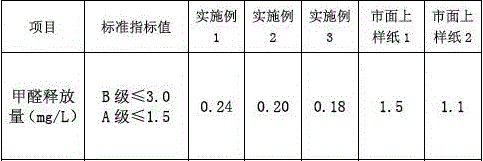

[0057] Table 1

[0058] Example 1-3 is compared with the detection value of formaldehyde emission of impregnated film paper on the market as shown in Table 1

[0059]

[0060] It can be seen from Table 1 that the formaldehyde emission of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com