Electro-acoustic actuator and method for manufacture

An actuator, electro-acoustic technology, applied in electret electrostatic transducers, sensors, electrical components, etc., can solve the problems of high resonance frequency, field restrictions, high unit price, and achieve cost saving, power saving cost, unit price low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

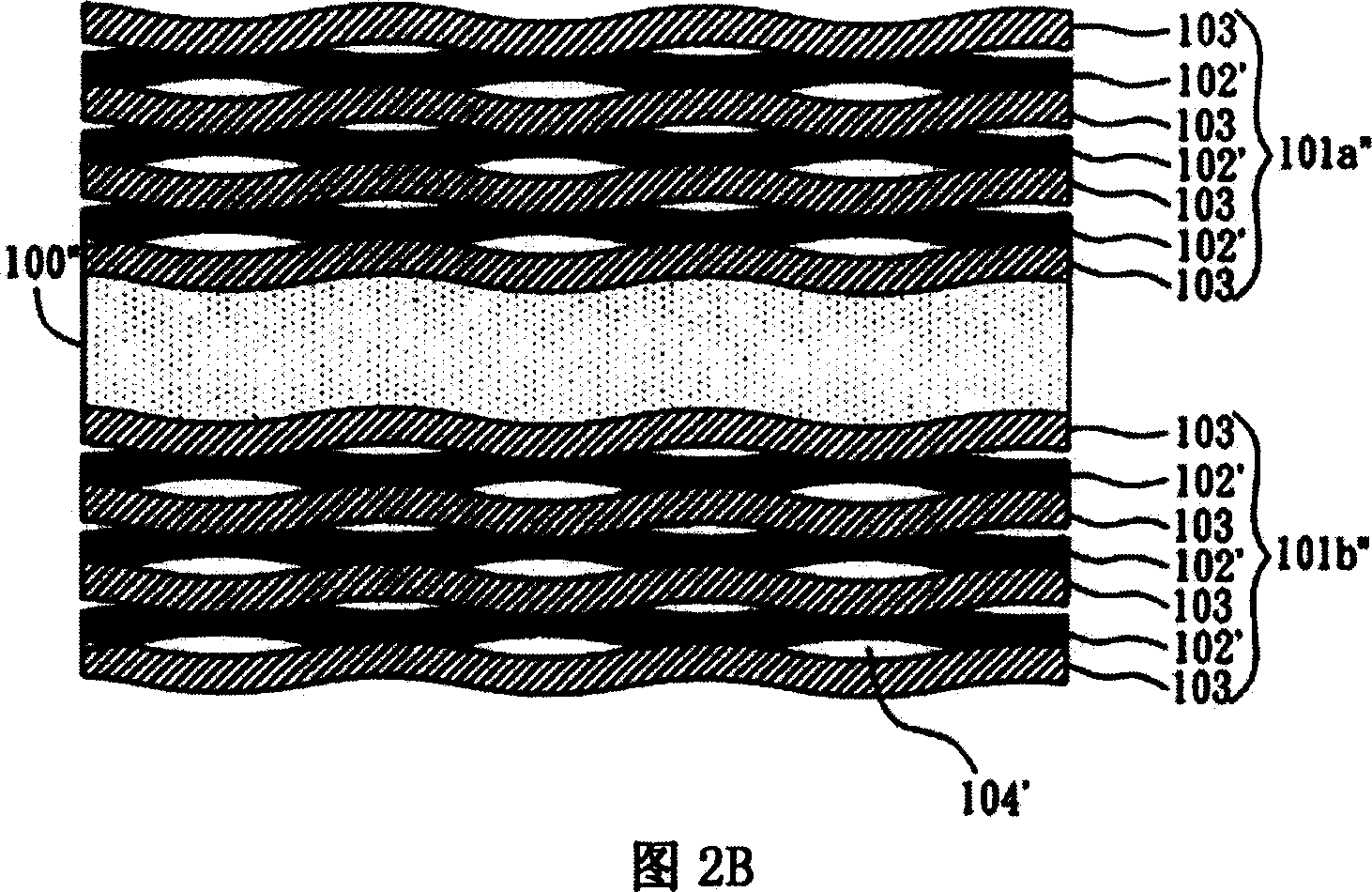

[0017] Fig. 1, Fig. 2A and Fig. 2B, Fig. 3A and Fig. 3B are related drawings of the electroacoustic actuator of the present invention, and these drawings cooperate to describe the embodiment of the electroacoustic actuator of the present invention in detail. It should be noted that these drawings are all simplified diagrams, illustrating the basic structure of the present invention in a schematic manner. Therefore, these drawings only show components related to the present invention, and the components shown are not drawn with the number, shape and size ratio of the actual implementation, and the number, shape and size ratio of the actual implementation are a kind of selective design , its component layout shape may be more complex.

[0018] Fig. 1 is the sectional structural diagram of electroacoustic actuator of the present invention, and electroacoustic actuator 1 of the present invention emits sound after receiving two in-phase or anti-phase AC audio voltages output by an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com