High performance air conditioning aluminum foil and method for preparing same

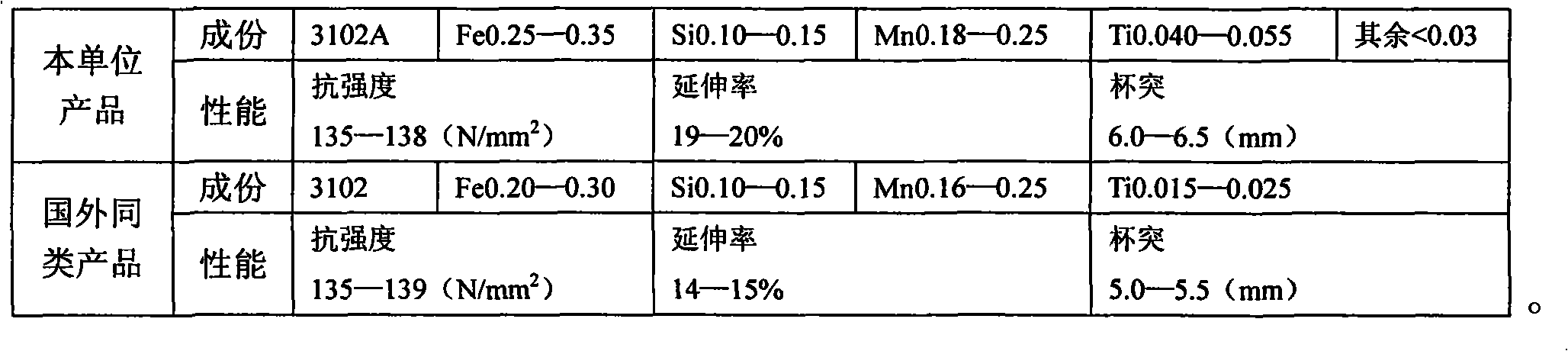

A high-performance, aluminum foil technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of low plasticity of thin aluminum foil, low sprint flanging height, etc., to achieve high cupping value, high sprint flanging, The effect of fine and uniform tissue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

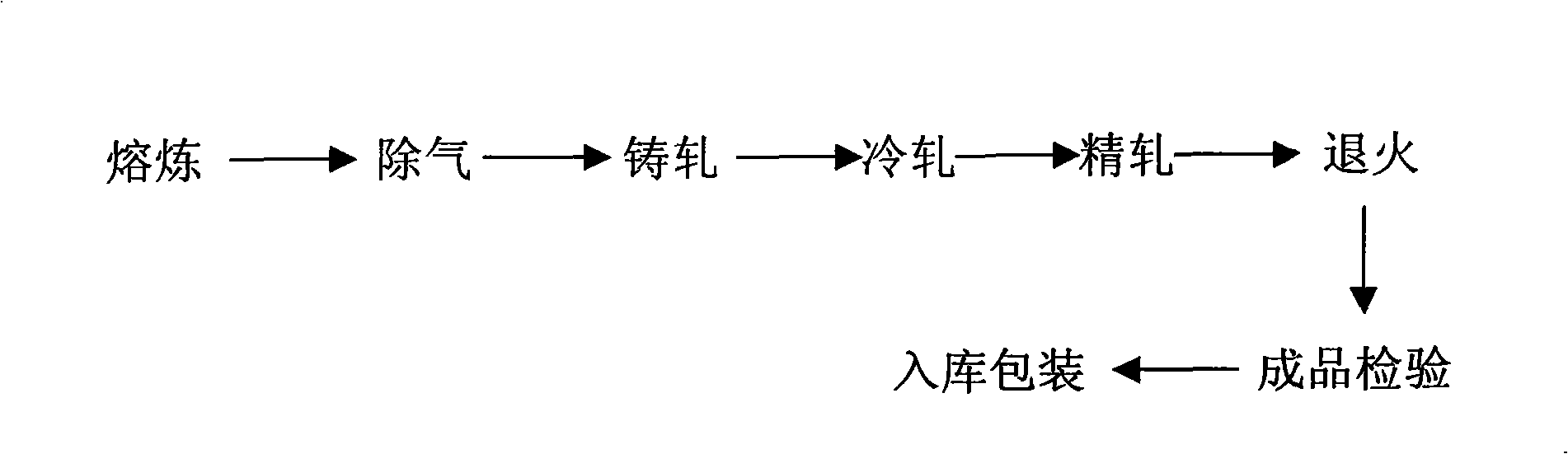

Method used

Image

Examples

Embodiment 1

[0027] Step 1, smelting, refining, heat preservation

[0028] Put each raw material in a smelting furnace for smelting according to the ratio. The smelting temperature is 740℃~750℃. Refining starts after the raw materials are melted. Refined once every 3 hours, and then introduced into the holding furnace with a holding temperature of 745°C to 760°C. Ti is added in the form of AlTiB wire (Ti content in AlTiB wire is 5%, B content is 1%), AlTiB wire is added at the entrance of the degassing box, and the feeding speed of AlTiB wire is about 220mm / min;

[0029] Step two, casting and rolling

[0030] For casting and rolling, the nozzle temperature is controlled at 730°C, the temperature of the degassing box is at 720°C, the temperature of the front box is 690°C, the length of the casting and rolling zone is 48mm, and the rolling speed is 1000m / min.

[0031] Step 3, cold rolling, edge trimming

[0032] The cold rolling is carried out in seven steps, as follows: 6.9mm→4.6mm→2.3mm...

Embodiment 2

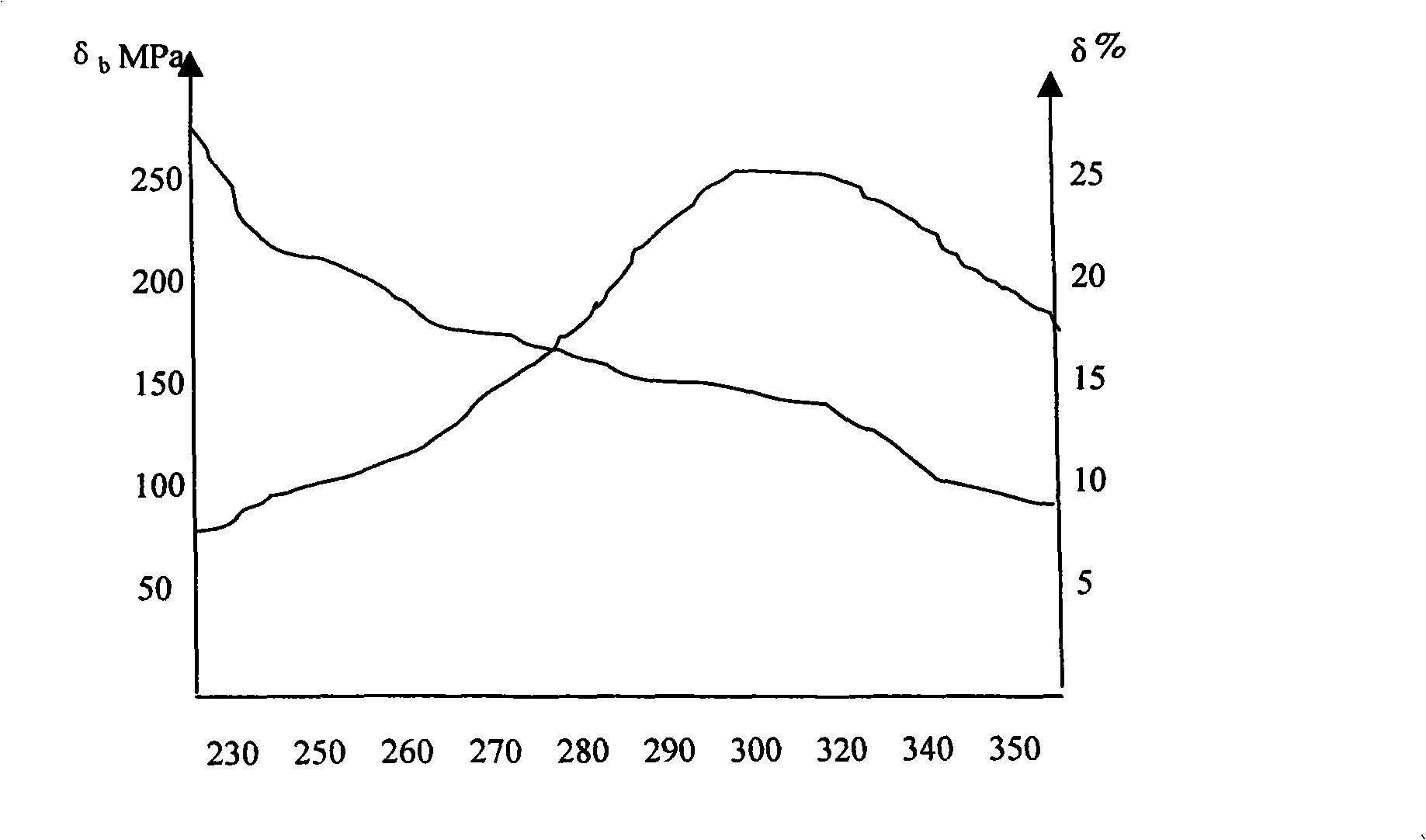

[0042] The difference between this embodiment and Embodiment 1 is that the annealing step adopts an industrial furnace experiment. The temperature setting adopts the method of setting the furnace gas temperature and the workpiece temperature. The mechanical properties are measured by different temperature ranges, and the temperature range of 290-305°C / 255-265°C×26h is more suitable (note that 290-305°C is the furnace Air temperature, 255~265℃ is the metal temperature), the average tensile strength of the product is 135~145MPa, and the elongation is 14~16%, which fully meets the needs of users. However, it should be noted that the actual temperature of the industrial furnace is different from that of the experimental furnace. Because the experimental furnace heats up quickly, the sample heats up quickly and reaches temperature quickly. The recovery process is too late to take place during the heating period,

[0043] The lattice distortion can be maintained at a relatively hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com