Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

77results about How to "Avoid lack of toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

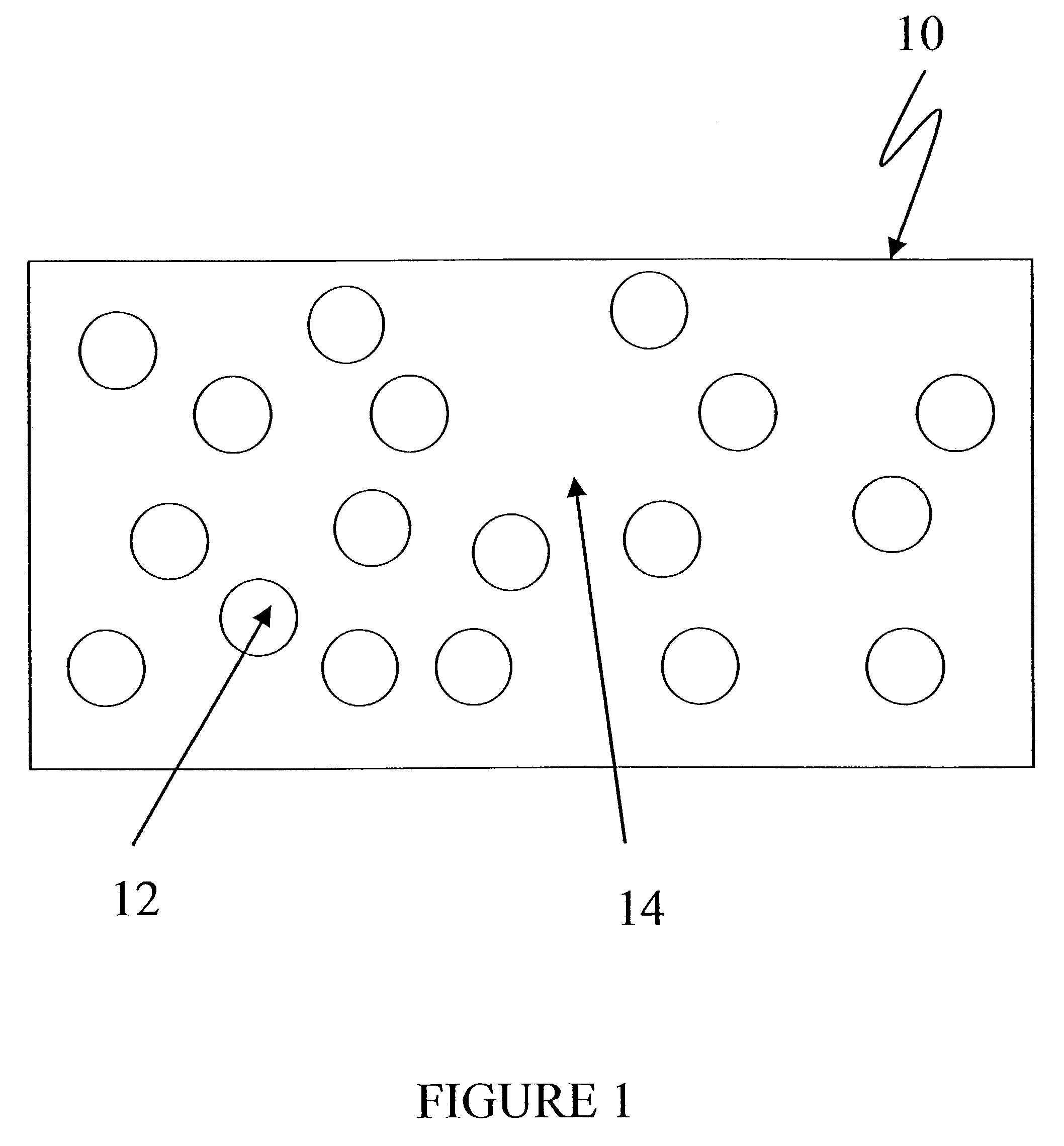

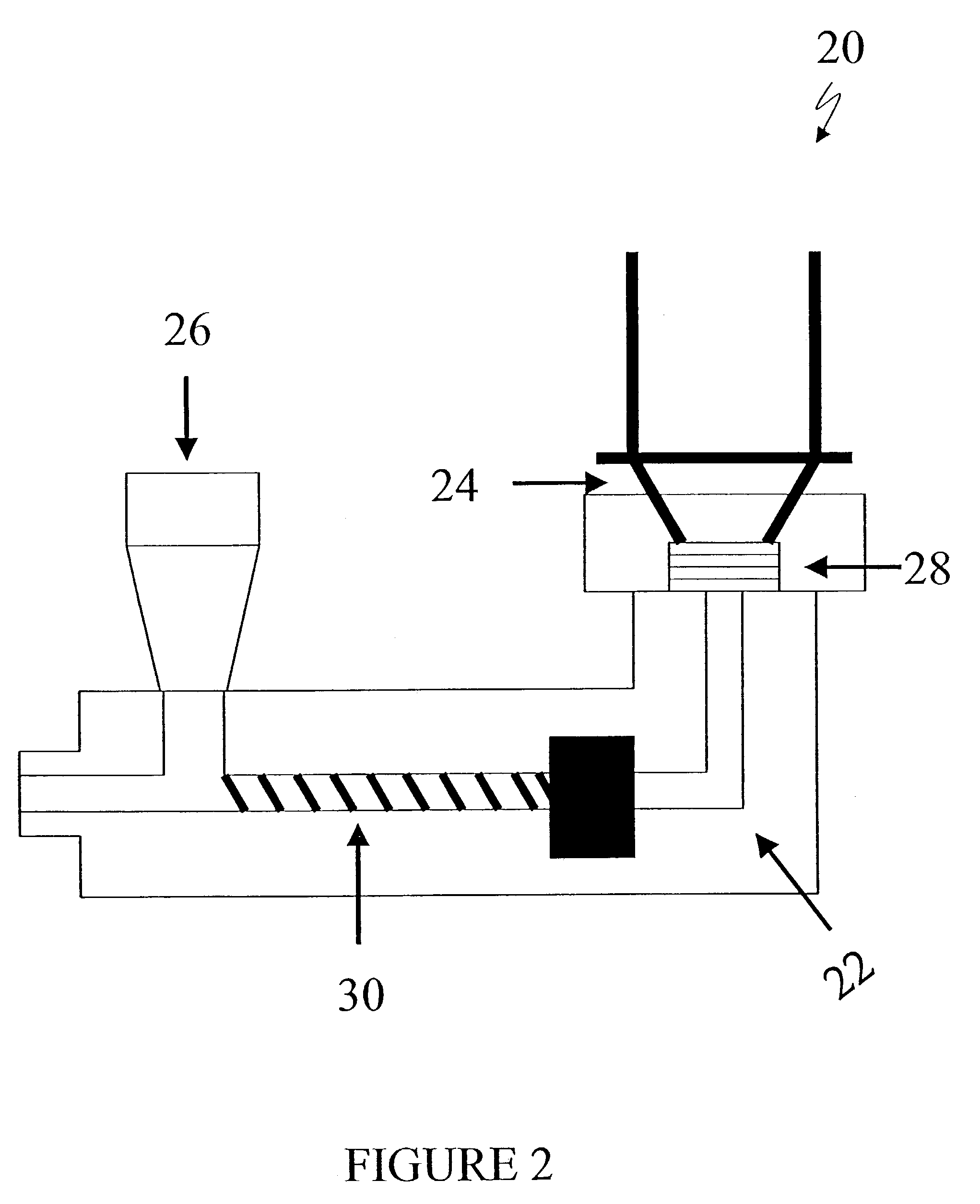

Compositions for manufacturing fiber-reinforced, starch-bound articles having a foamed cellular matrix

InactiveUSRE39339E1Avoid lack of toughnessHigh strengthClosure lidsSolid waste managementPolymer sciencePaperboard

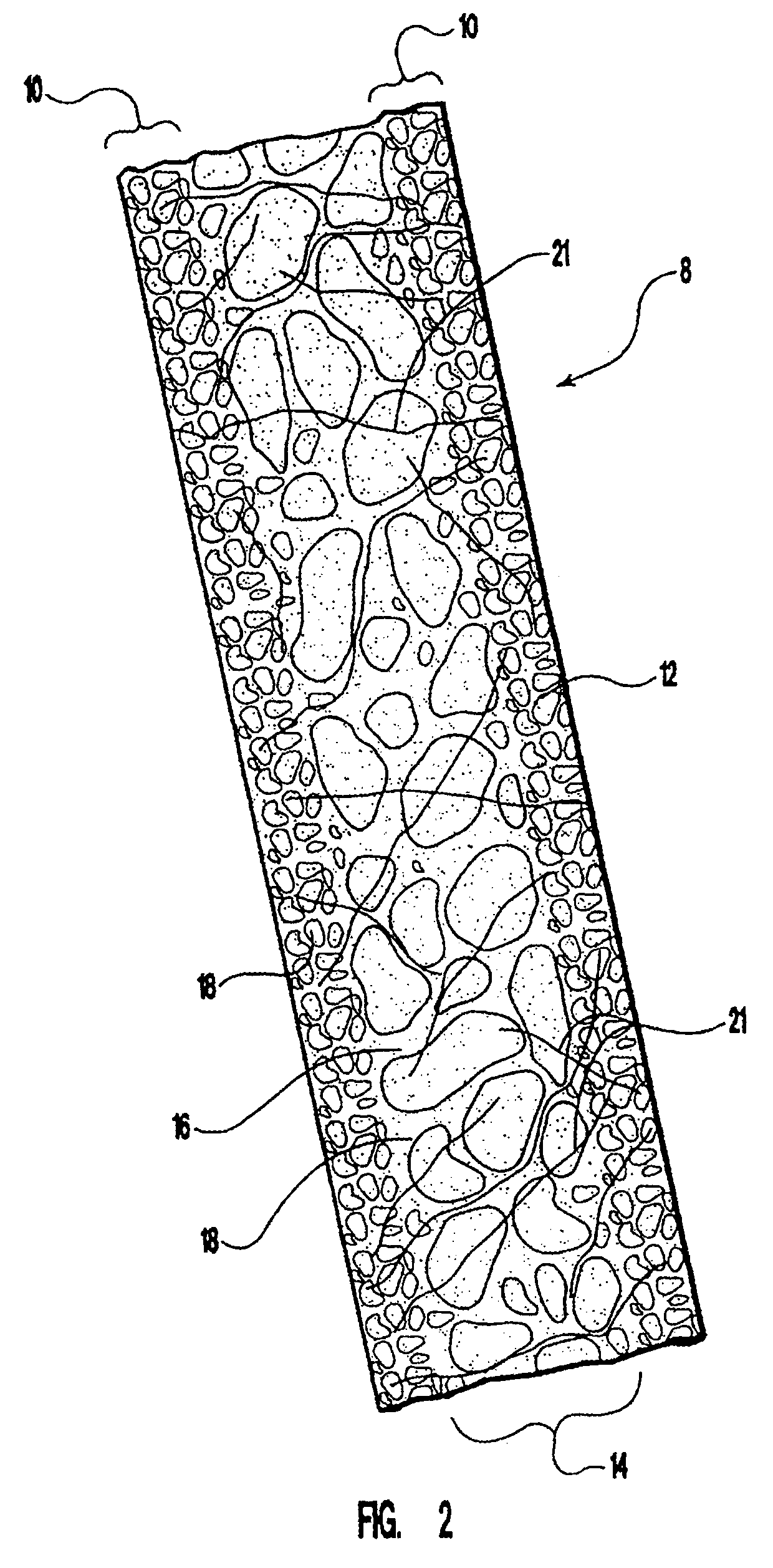

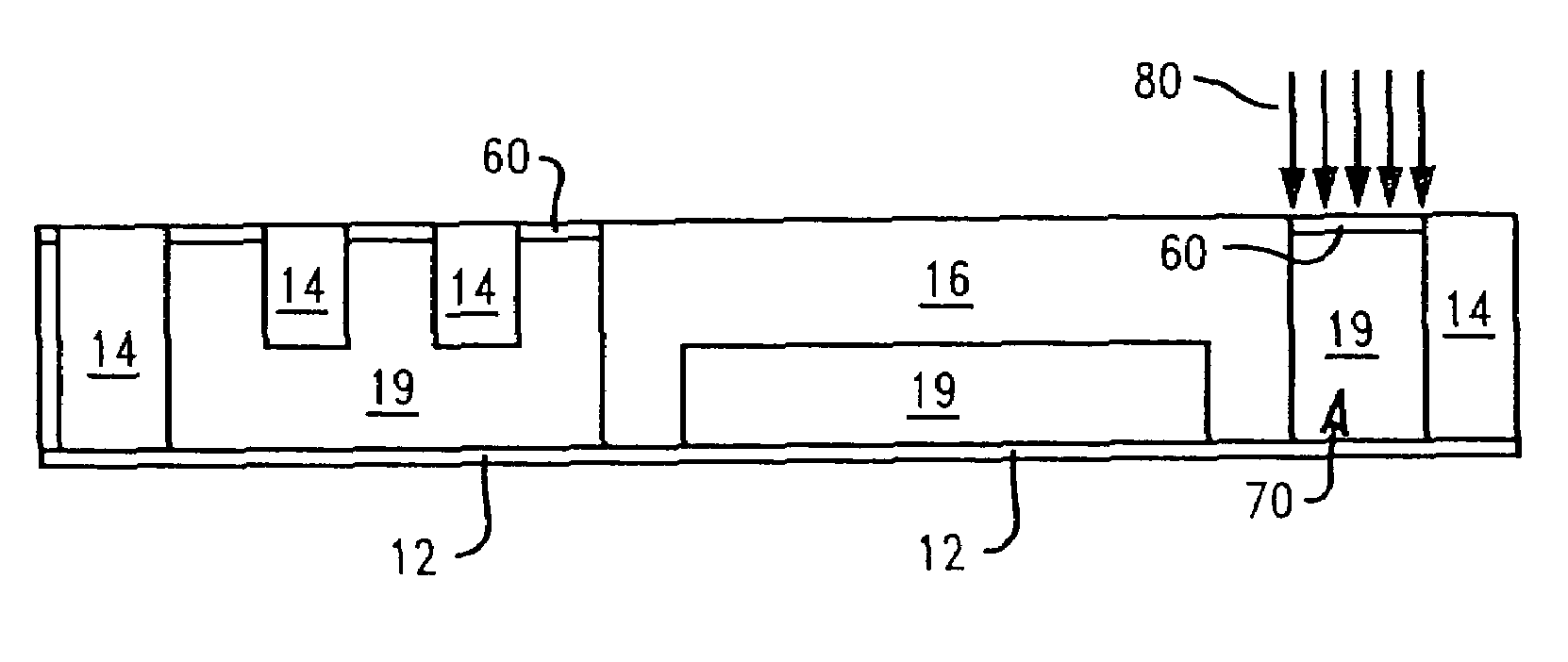

Compositions, methods, and systems for manufacturing articles, particularly containers and packaging materials, having a fiber-reinforced, starch-bound cellular matrix. Suitable mixtures used to form the articles are prepared by first preparing a viscous preblended mixture comprising water, a gelatinized starch-based binder, and fibers having an average length greater than about 2 mm. The highly viscous preblended mixture effectively transfers the shearing forces of the mixer to the fibers. The final moldable mixture is then prepared by mixing into the preblended mixture the remaining starch-based binder, water, and other desired admixtures, e.g., mold-releasing agents, inorganic filler rheology-modifying agents, plasticizers, coating materials, and dispersants, in the correct proportions to form an article which has the desired performance criteria. The moldable mixtures are heated between molds at an elevated temperature and pressure to produce form-stable articles having a desired shape and a selectively controlled foamed structural matrix. The articles may be manufactured to have properties substantially similar to articles presently made from conventional materials like paper, paperboard, polystyrene, plastic, or other organic-based materials and have especial utility in the mass-production of containers, particularly food and beverage containers.

Owner:EARTHSHELL SPE

Method of fabricating composite tooling using closed-loop direct-metal deposition

ActiveUS20050038551A1Maximize performance service lifeAvoid lack of toughnessAdditive manufacturing apparatusRadiation applicationsWear resistantClosed loop

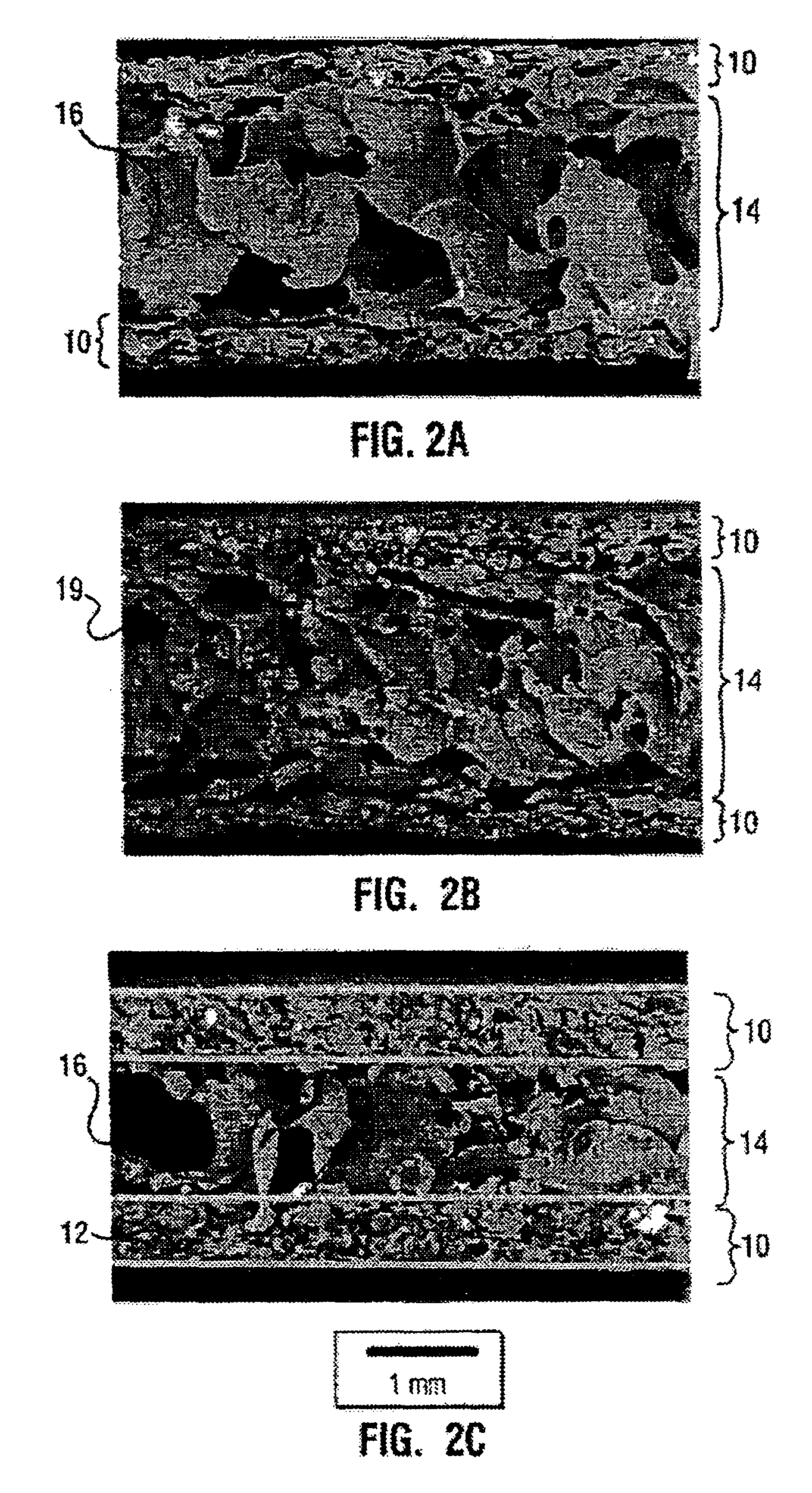

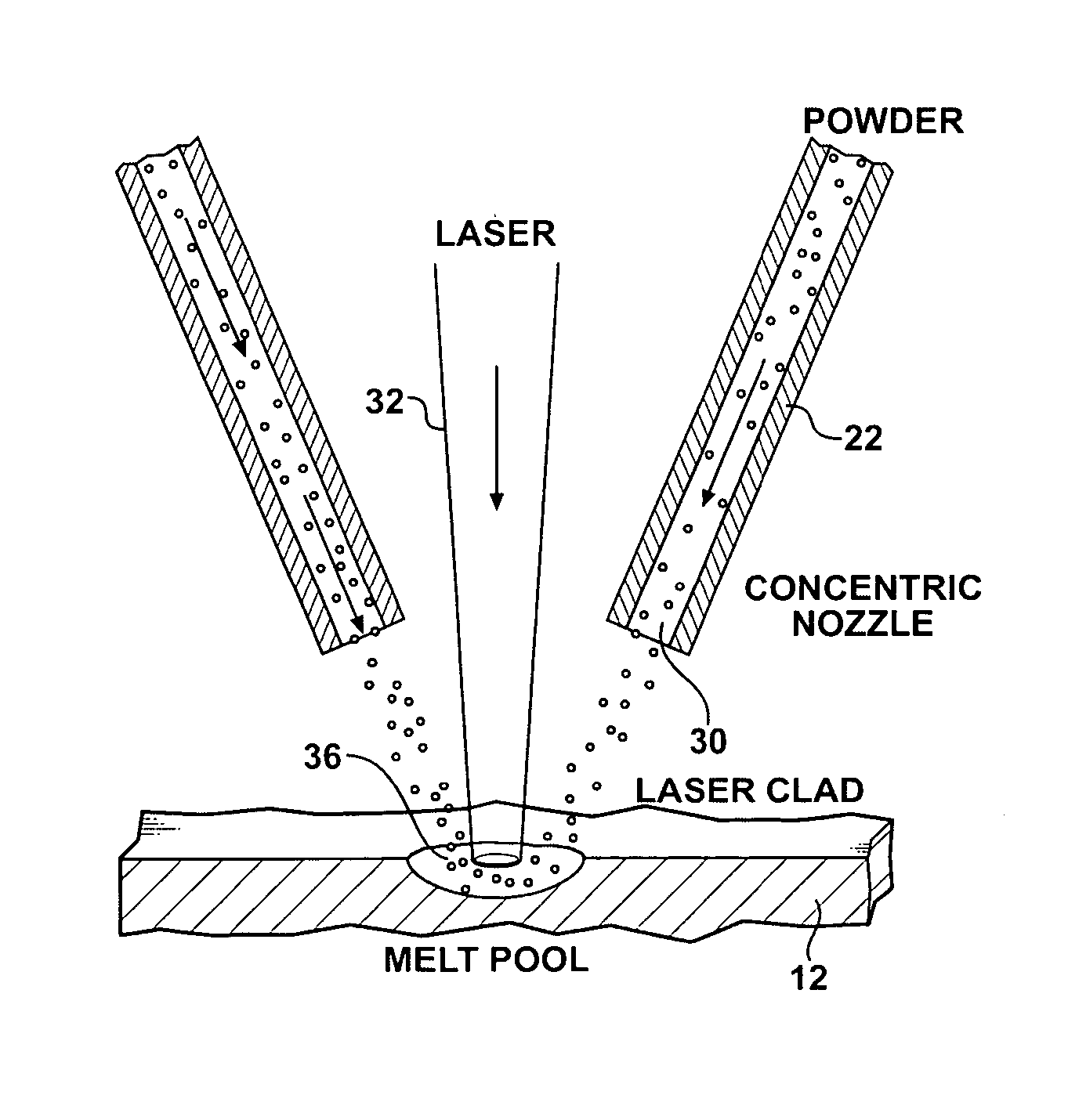

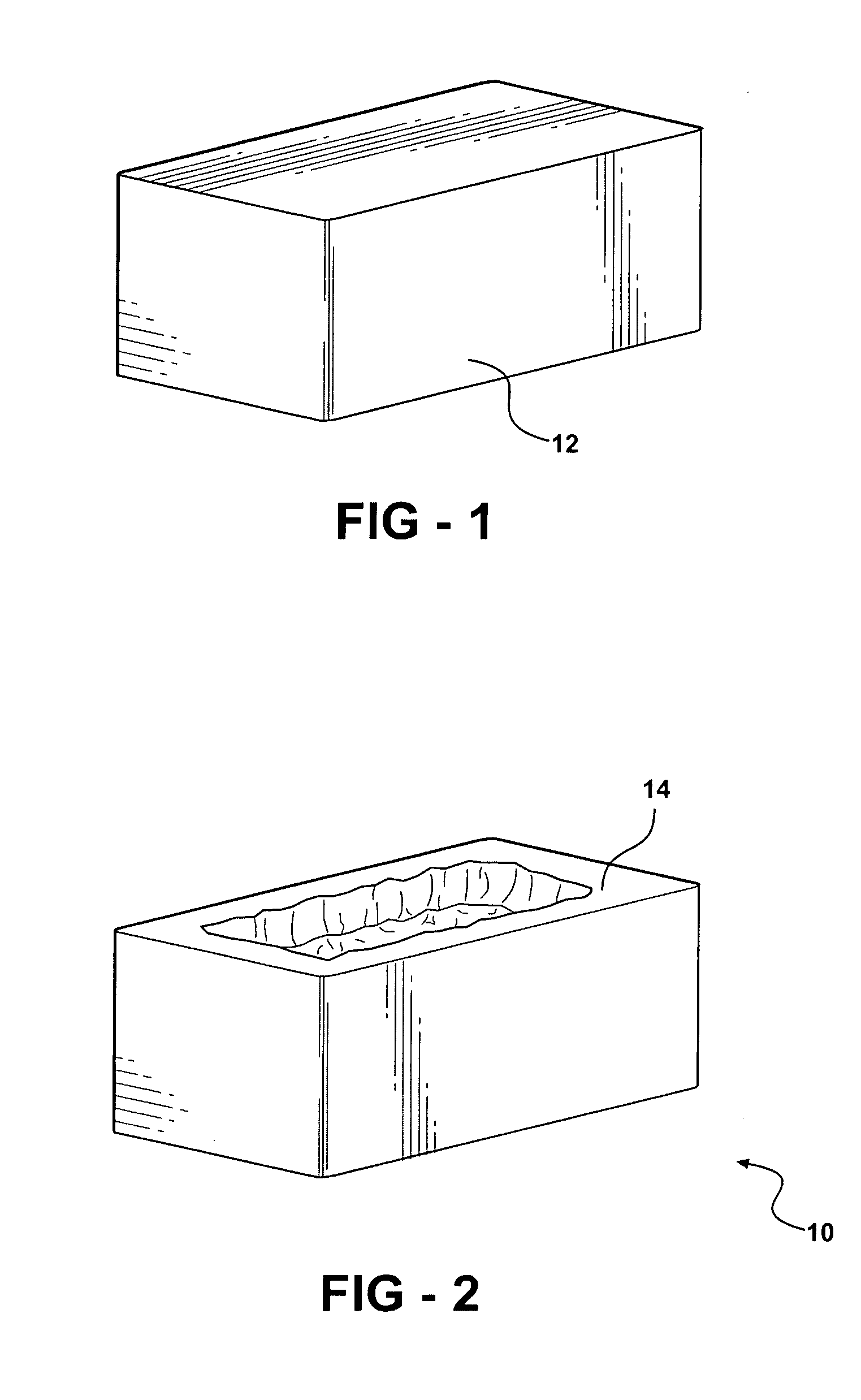

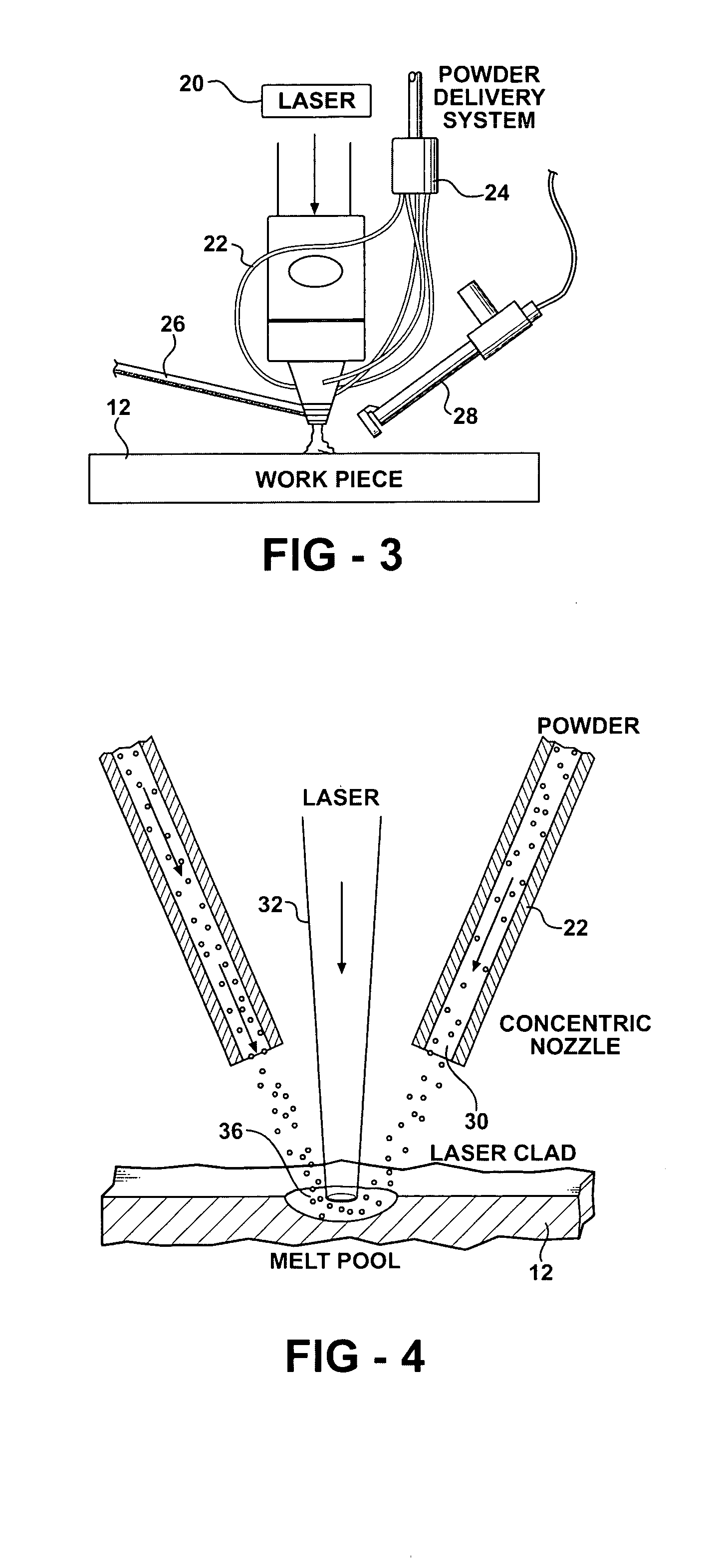

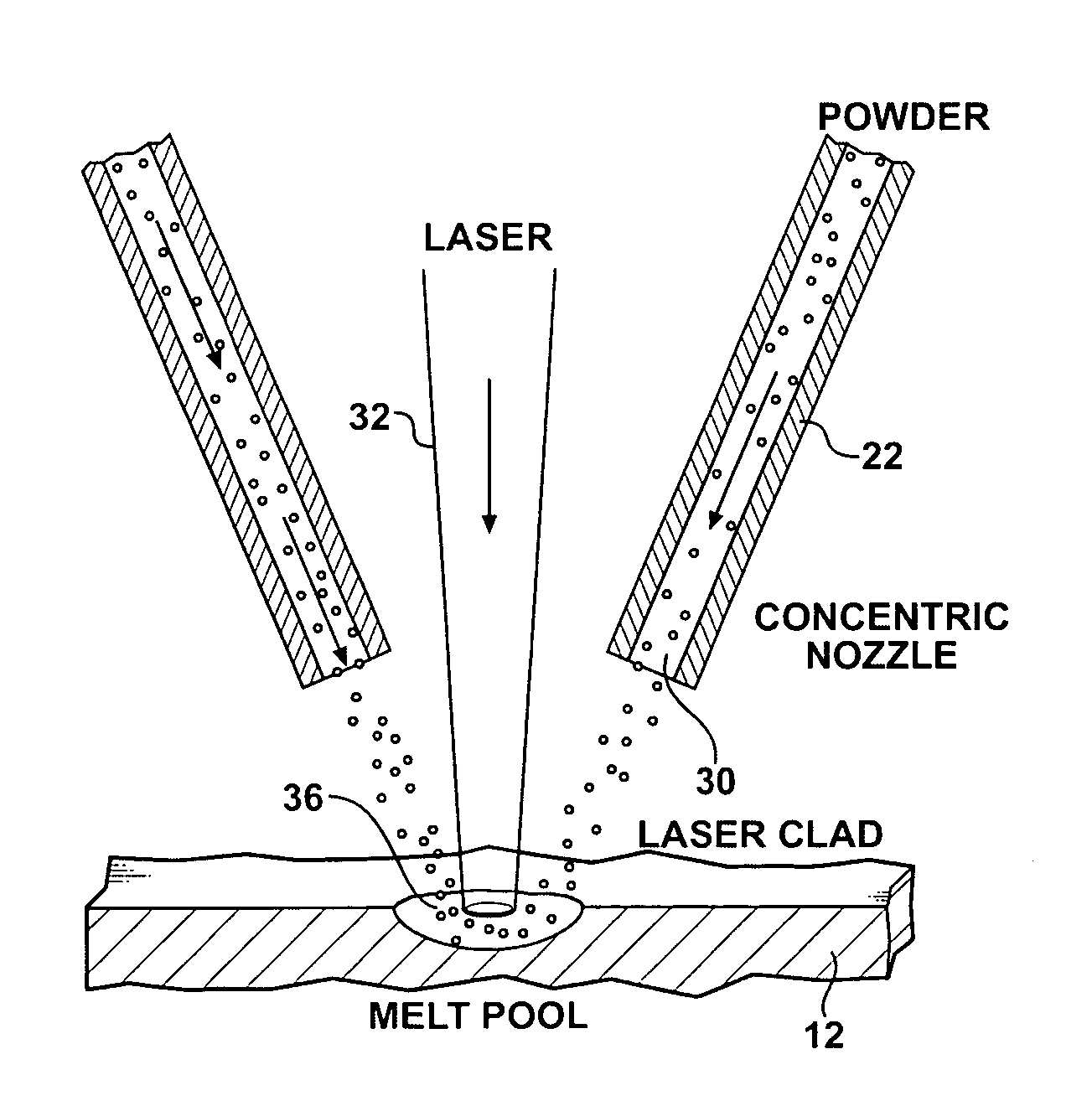

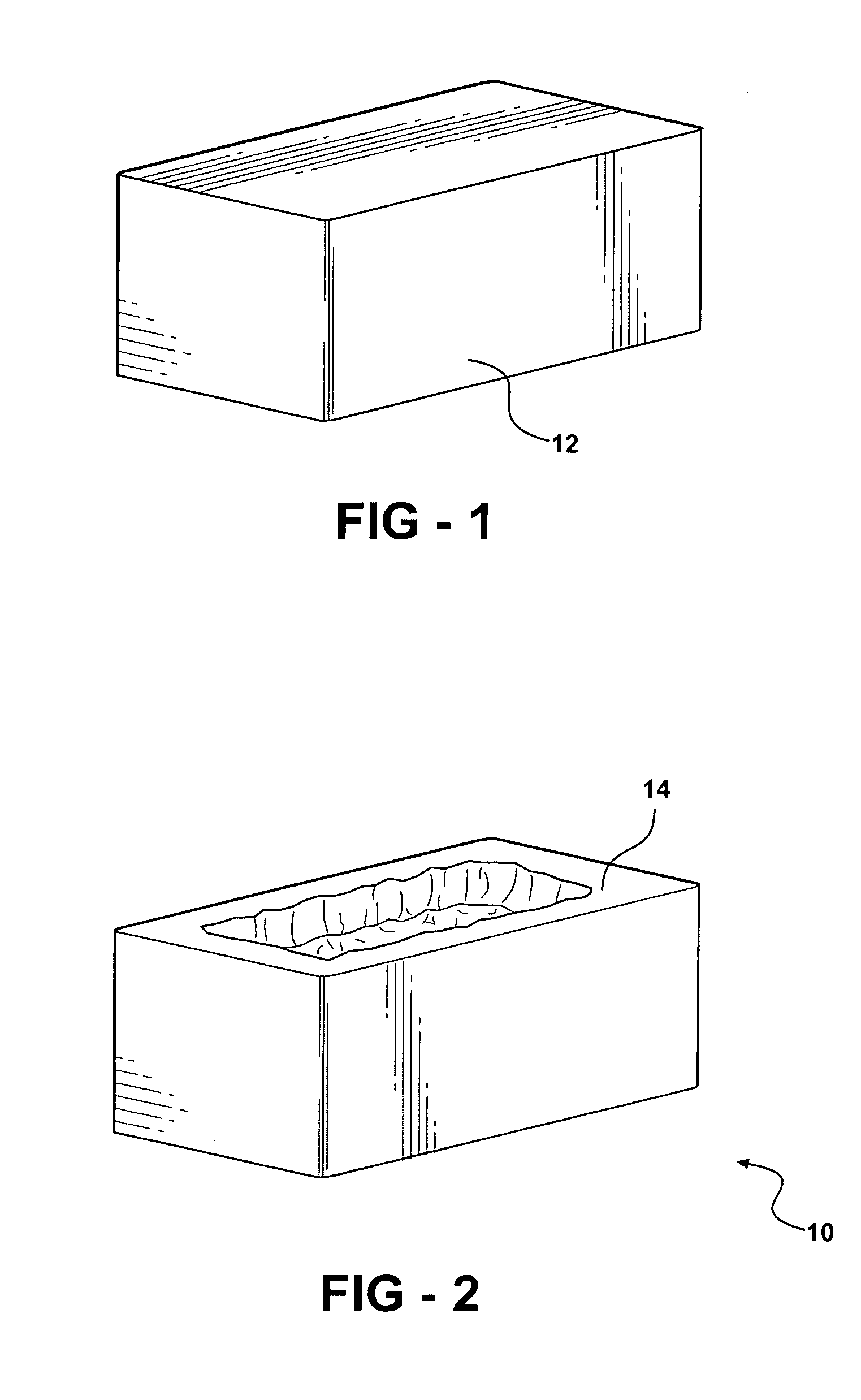

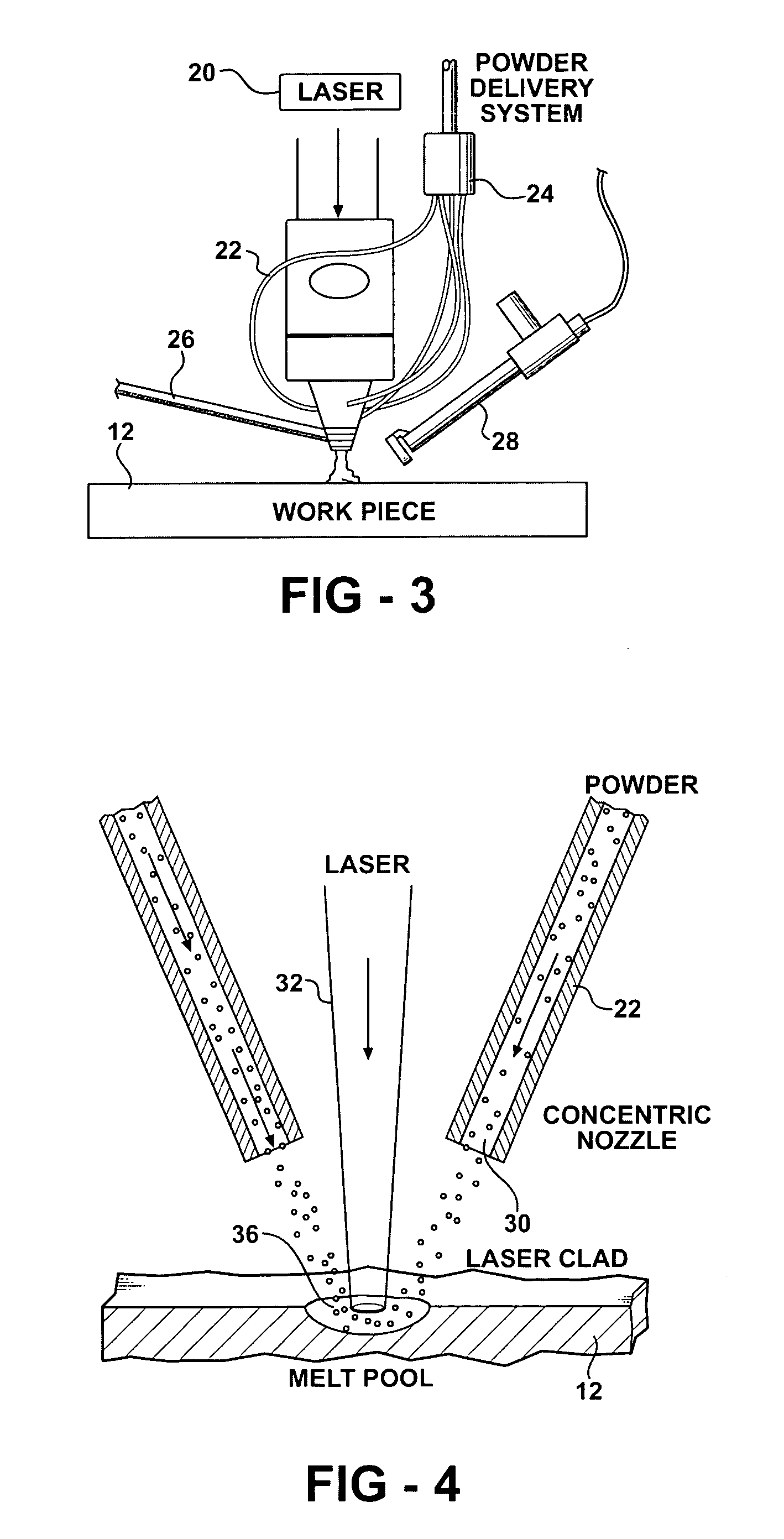

Manufacturing tools having a base and a working surface, such as trim steels, flange steels and die inserts, are formed by fabricating or casting a substrate out of a relatively ductile, low wear-resistant metal and forming the working surfaces such as cutting edges, flanging surfaces, die surfaces and die inserts by depositing layers of relatively hard, wear-resistant materials to the substrate by closed-loop direct-metal deposition or laser cladding. A multi-axis numerically controlled robot may be used to position and move a beam and deposition material over large substrates in forming such tooling.

Owner:MAZUMDER JYOTI +1

Polyolefin based films with improved water vapor transmission rates

InactiveUS20130295364A1Eliminate water droplet condensationAvoid lack of toughnessPigmenting treatmentNon-fibrous pulp additionPolymer sciencePolyolefin

The present invention provides a film suitable for applications requiring high water vapor transmission rates. The film comprises a polyolefin polymer together with from 1 to 30 percent by weight of the film of a hydrophilic polymer and from 30 to 75 percent by weight of the film of a filler having a hydrophilic surface functionality.

Owner:DOW GLOBAL TECH LLC

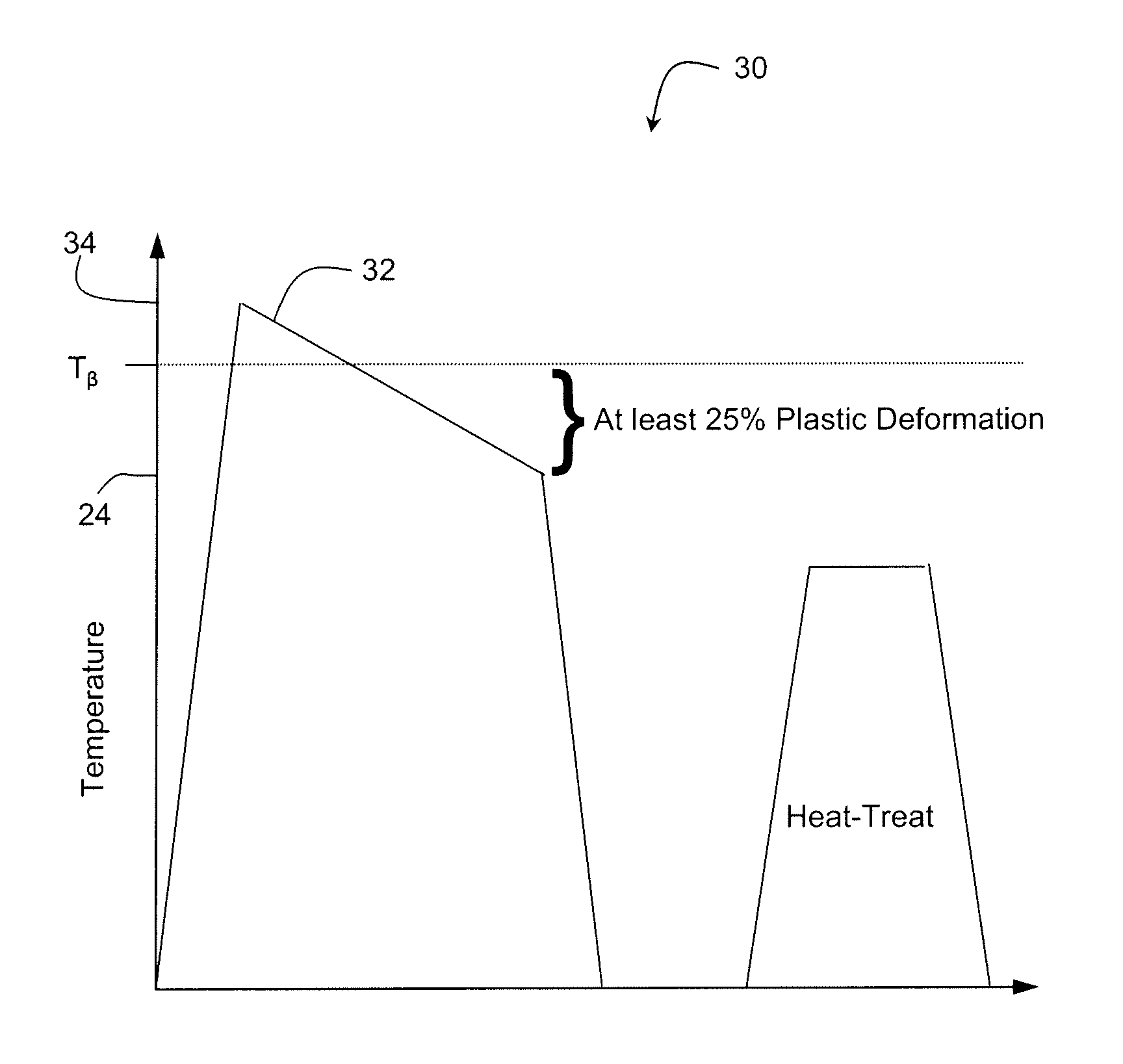

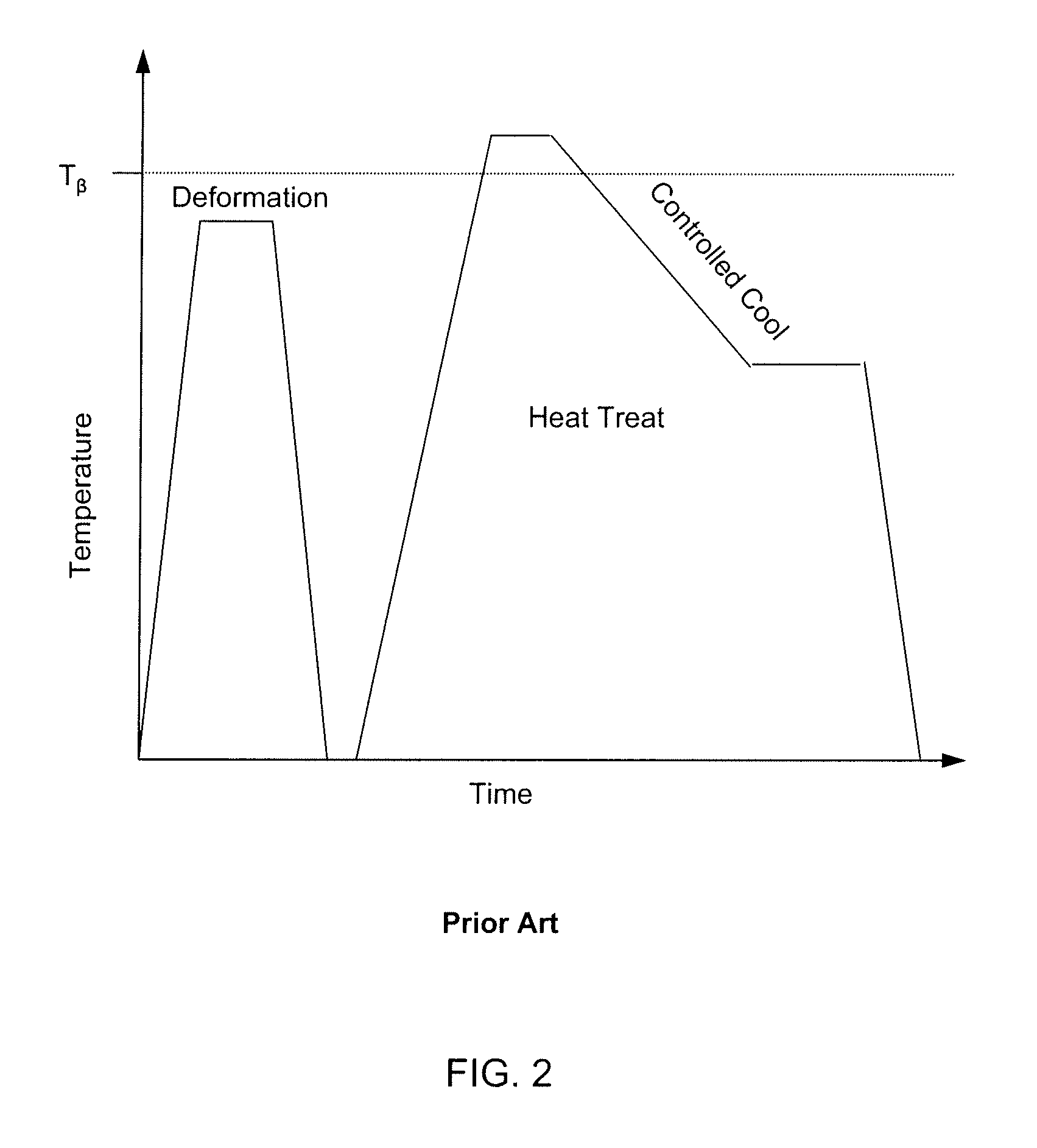

Production of high strength titanium

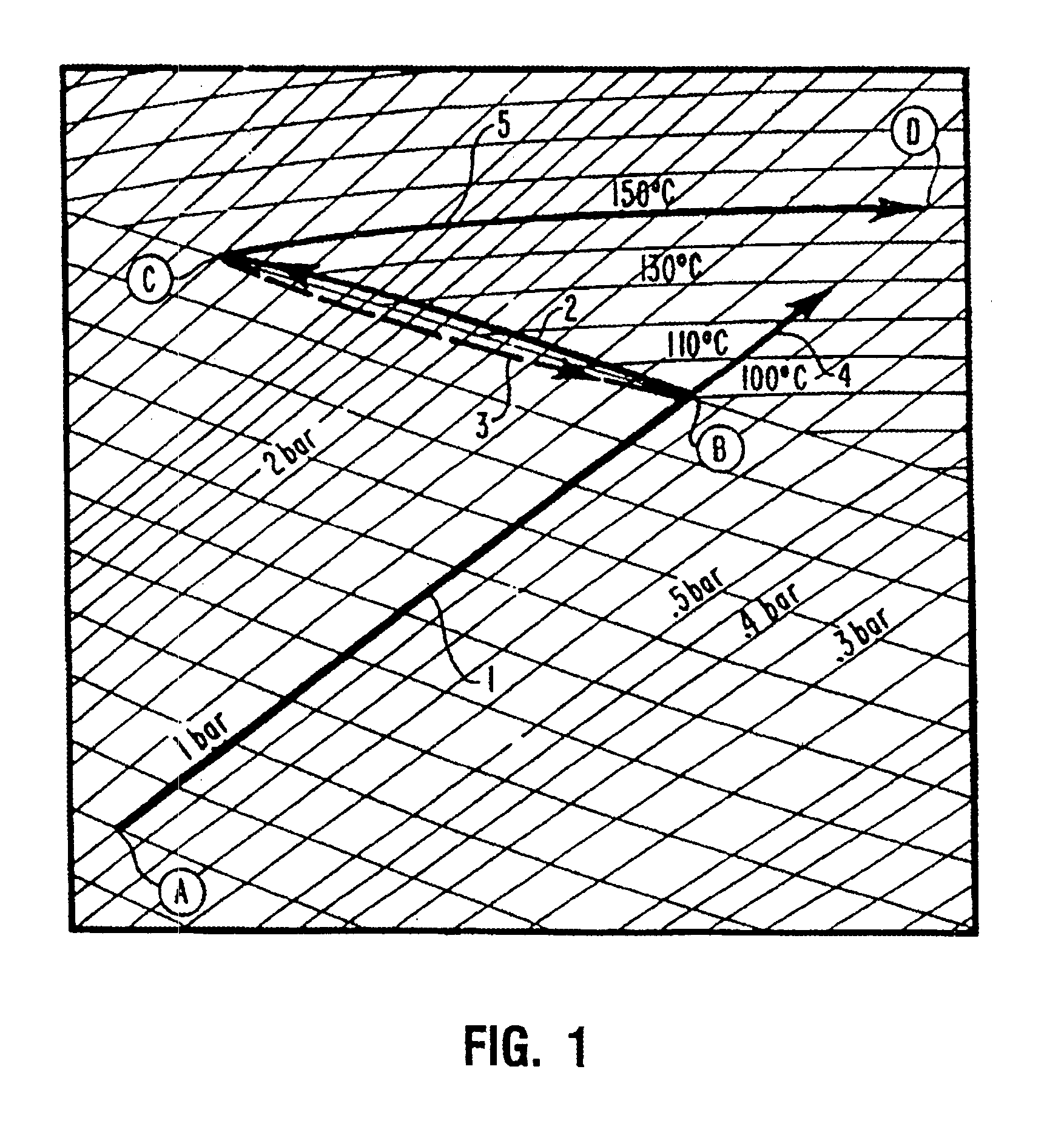

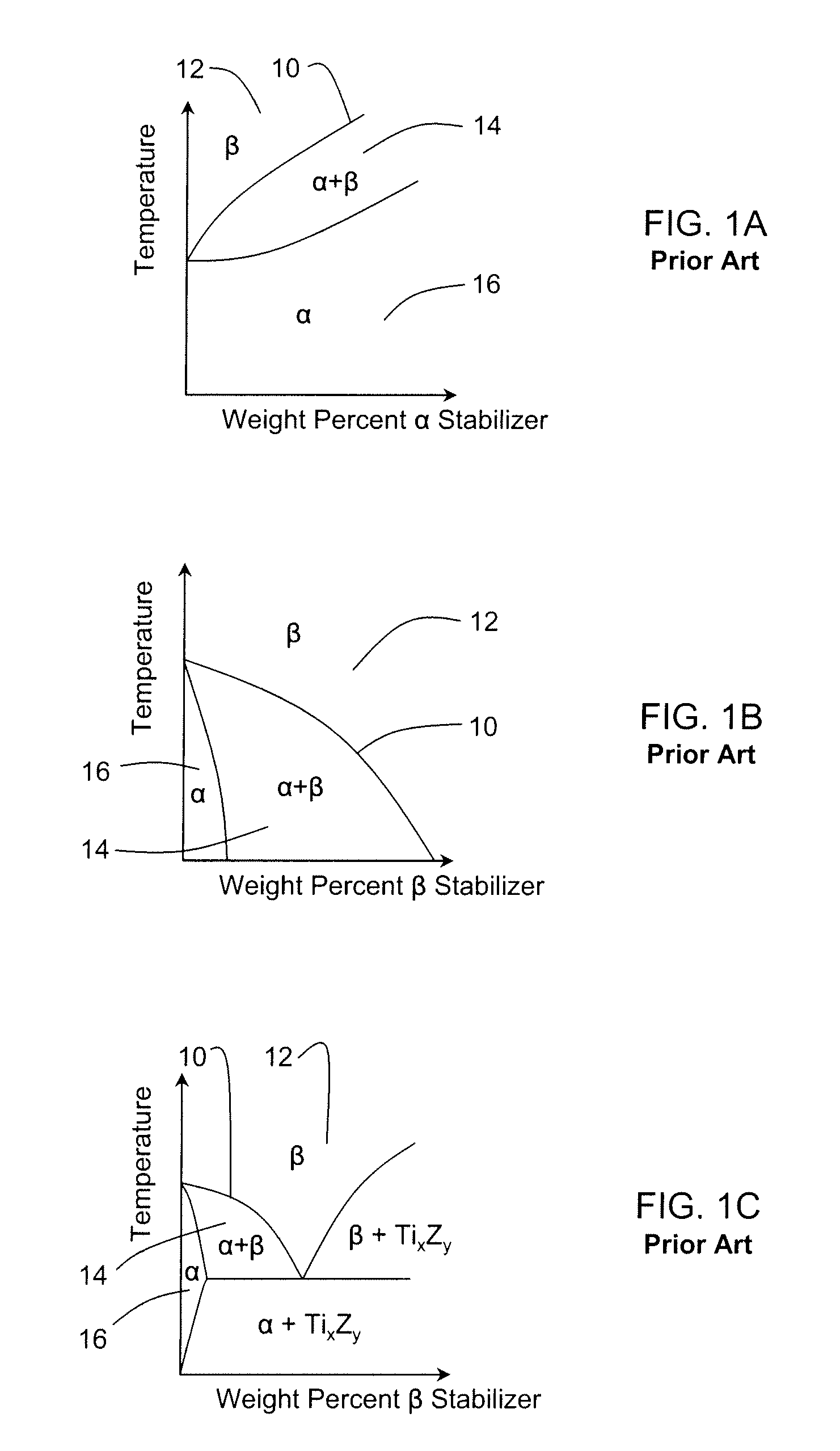

Certain embodiments of a method for increasing the strength and toughness of a titanium alloy include plastically deforming a titanium alloy at a temperature in an alpha-beta phase field of the titanium alloy to an equivalent plastic deformation of at least a 25% reduction in area. After plastically deforming the titanium alloy in the alpha-beta phase field, the titanium alloy is not heated to or above the beta transus temperature of the titanium alloy. After plastic deformation, the titanium alloy is heat treated at a heat treatment temperature less than or equal to the beta transus temperature minus 20° F. (11.1° C.).

Owner:ATI PROPERTIES LLC

Method of fabricating composite tooling using closed-loop direct-metal deposition

InactiveUS7139633B2Maximize performance service lifeAvoid lack of toughnessAdditive manufacturing apparatusRadiation applicationsWear resistantClosed loop

Manufacturing tools having a base and a working surface, such as trim steels, flange steels and die inserts, are formed by fabricating or casting a substrate out of a relatively ductile, low wear-resistant metal and forming the working surfaces such as cutting edges, flanging surfaces, die surfaces and die inserts by depositing layers of relatively hard, wear-resistant materials to the substrate by closed-loop direct-metal deposition or laser cladding. A multi-axis numerically controlled robot may be used to position and move a beam and deposition material over large substrates in forming such tooling.

Owner:MAZUMDER JYOTI +1

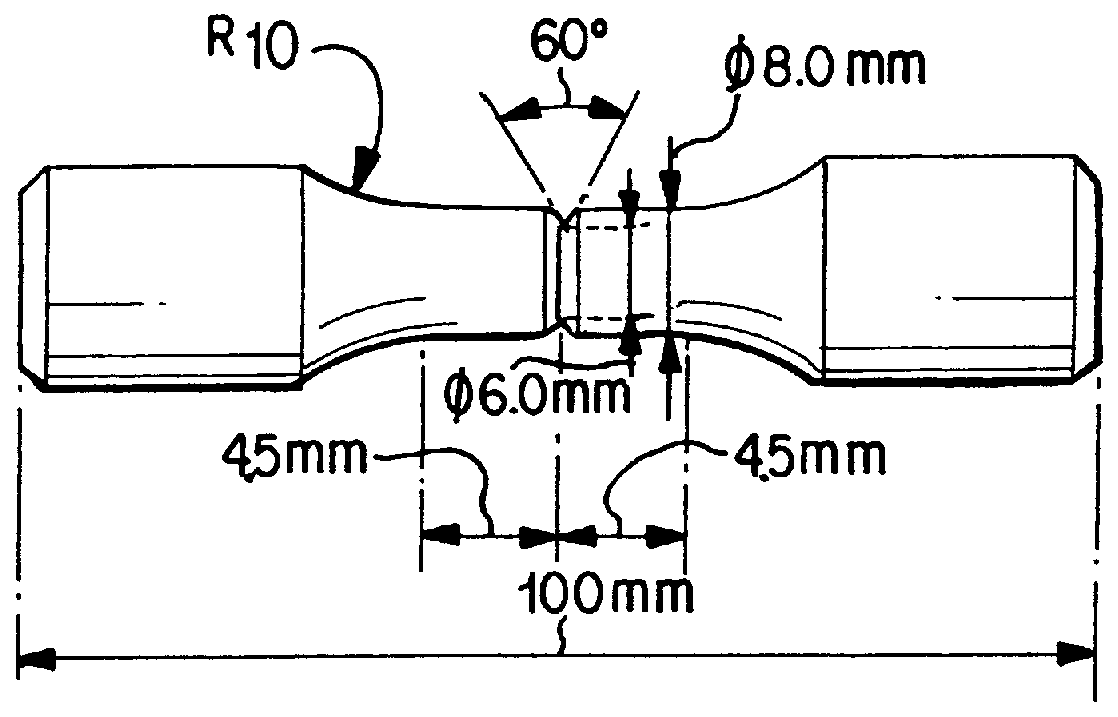

High toughness spring steel

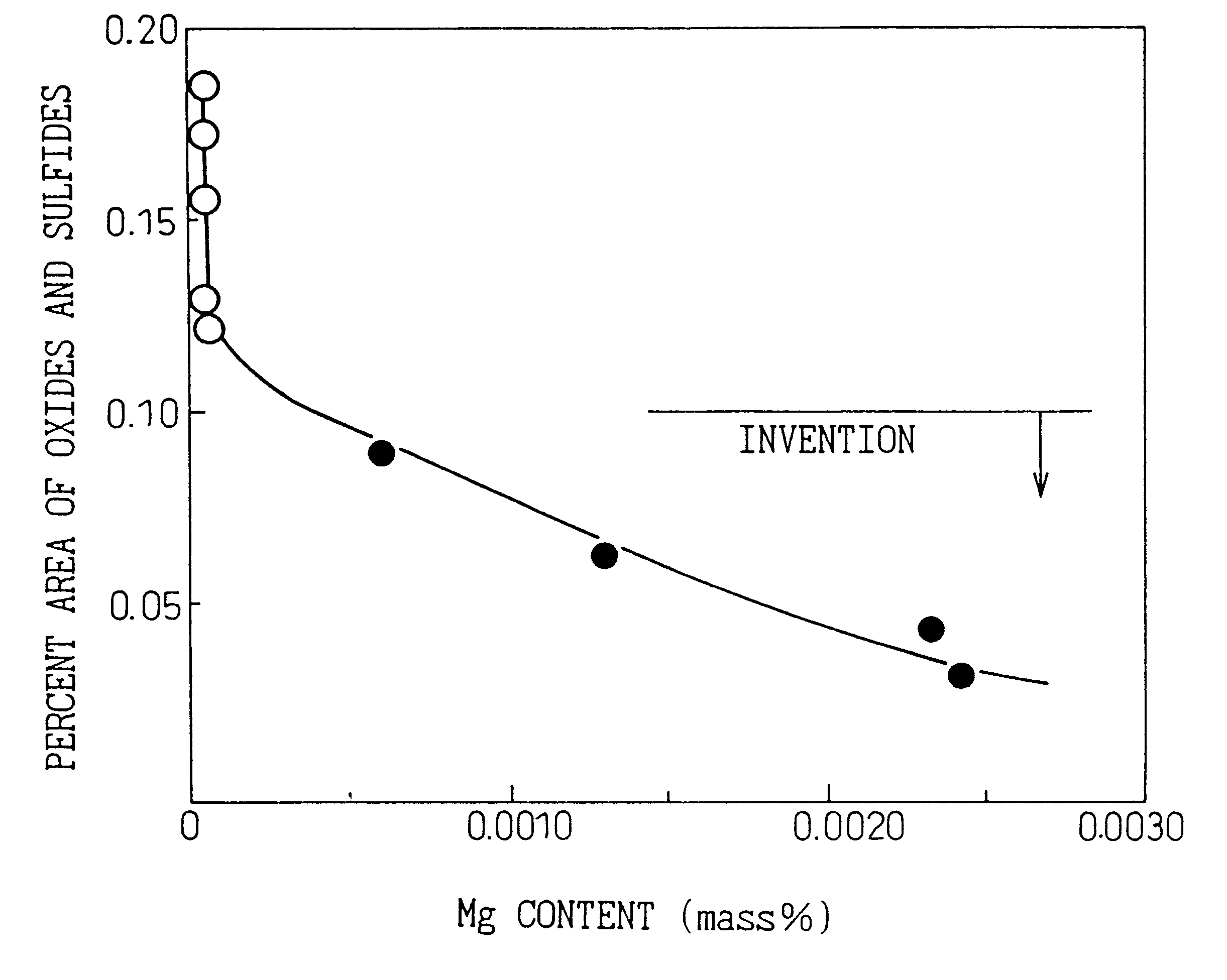

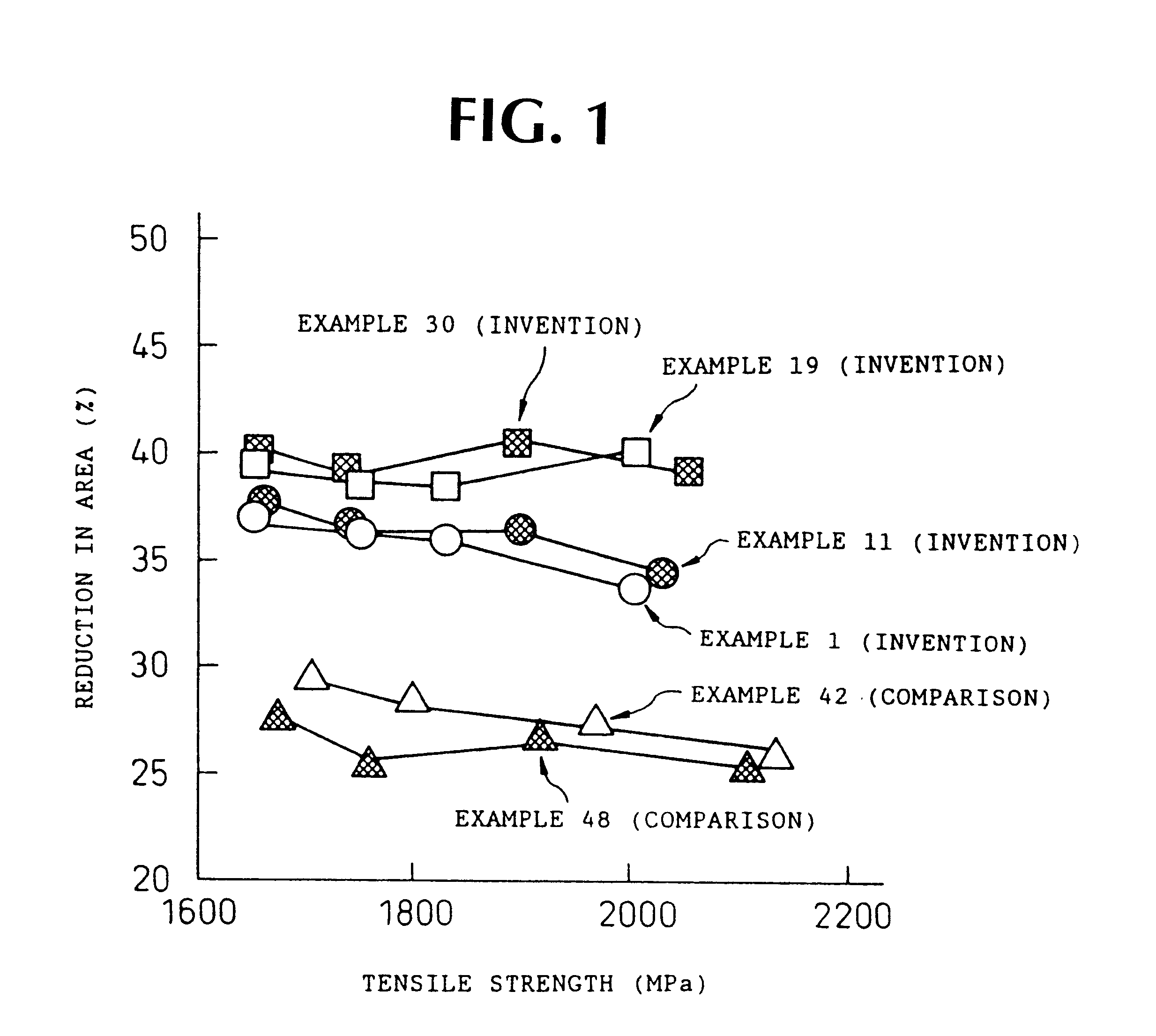

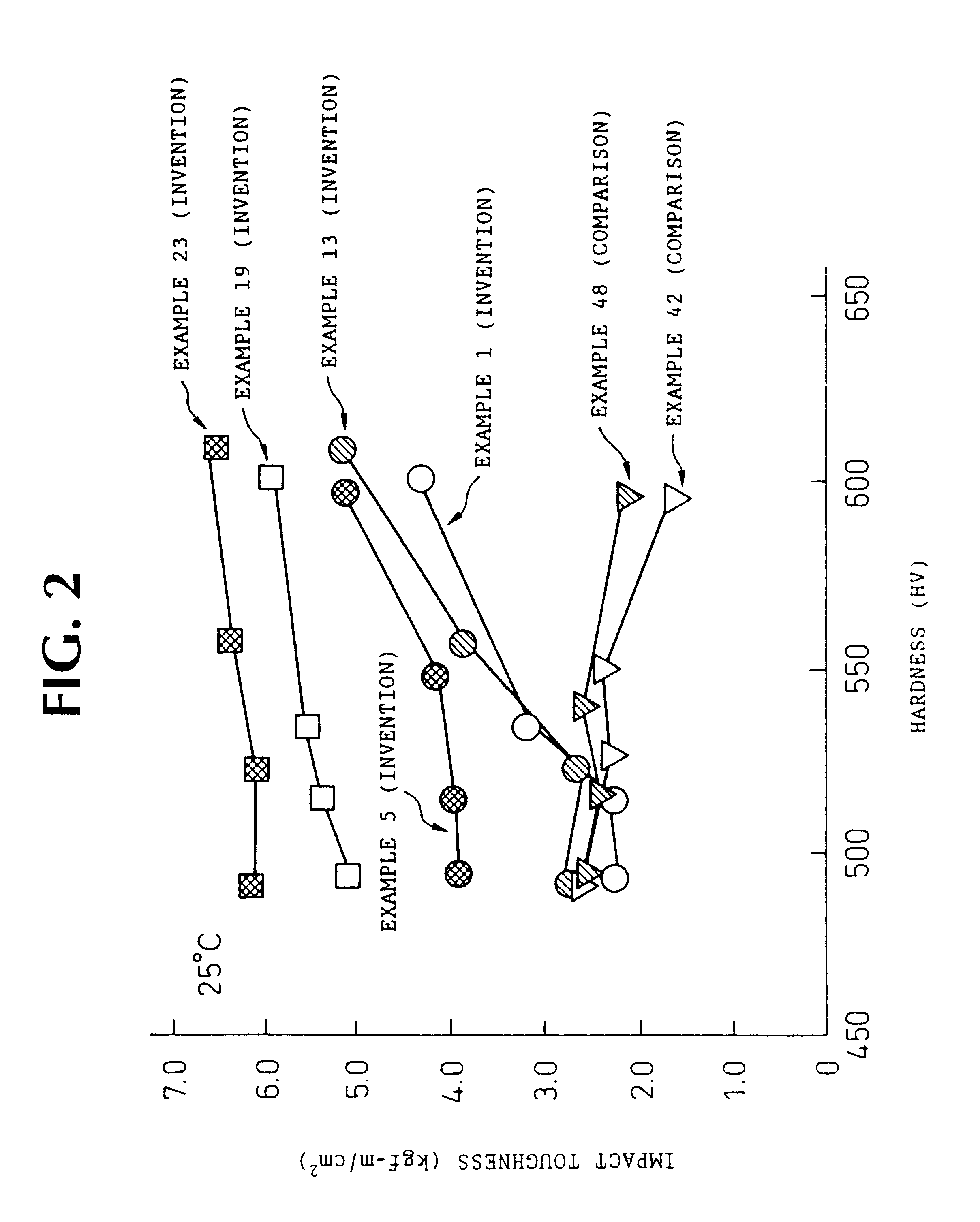

InactiveUS6406565B1Solve the lack of ductilityAvoid lack of toughnessFurnace typesHeat treatment furnacesSulfideSpring steel

The present invention provides a spring steel showing a sufficient reduction in area and an impact toughness while the steel has a high strength, in particular a tensile strength as high as at least 1,500 Mpa. A high toughness spring steel according to the present invention comprises, based on mass, 0.45 to 0.85% of C, 0.9 to 2.5% of Si, 0.1 to 1.2% of Mn, 0.1 to 2.0% of Cr, 0.005 to 0.07% of Ti, 0.001 to 0.007% of N, the Ti content being greater than four times the N content in terms of percent by mass, 0.0005 to 0.0060% B, at least one of 0.0005 to 0.01% Mg, 0.0005 to 0.01% La, and 0.0005 to 0.01% Ce, P and S with restrictive contents of less than 0.020% and less than 0.020%, respectively, and the balance of Fe and unavoidable impurities, and selectively contains V, Nb, Ni, Mo and Cu. The percent area of oxides and sulfides is not more than 0.1%.

Owner:NIPPON STEEL CORP

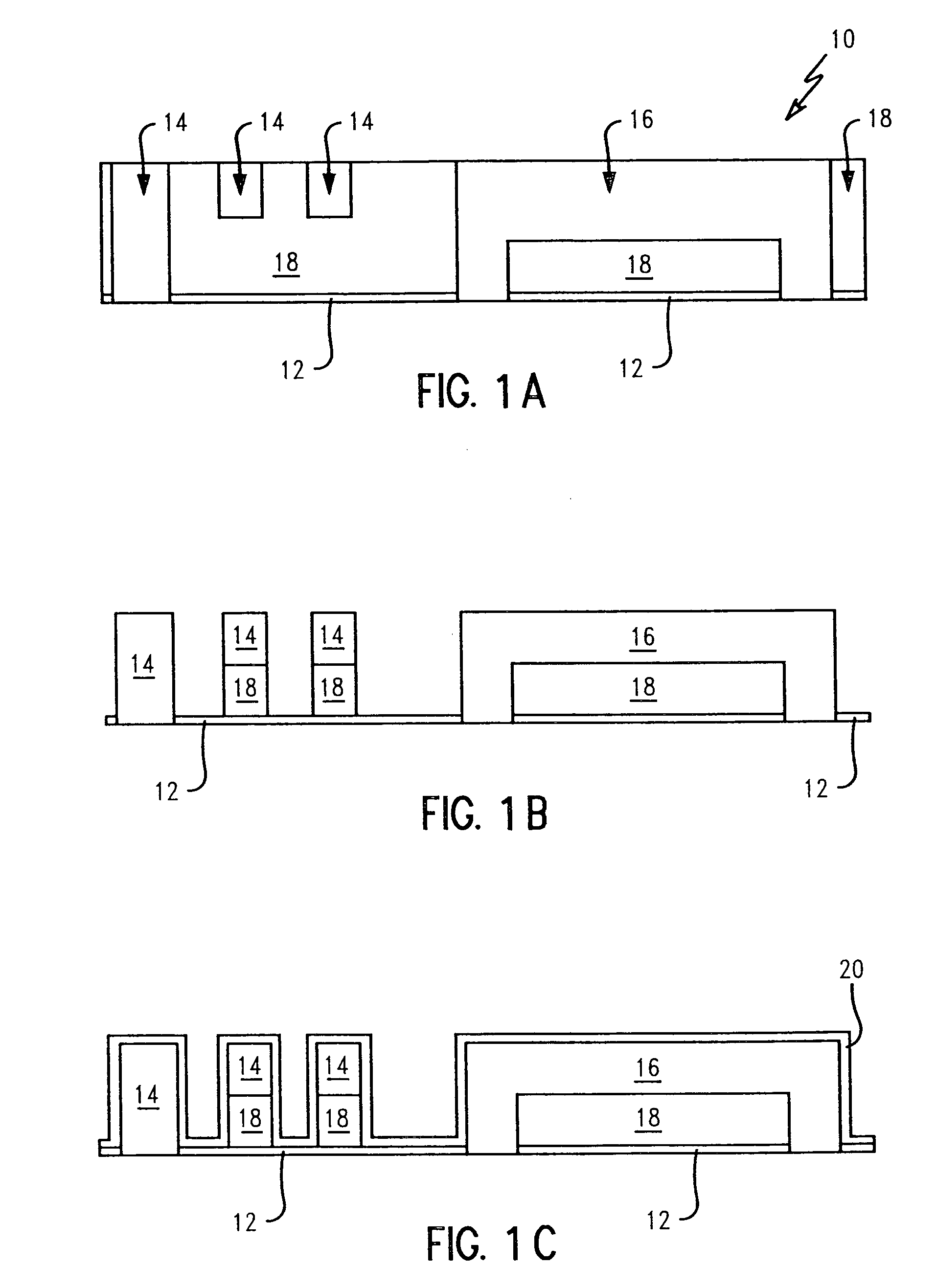

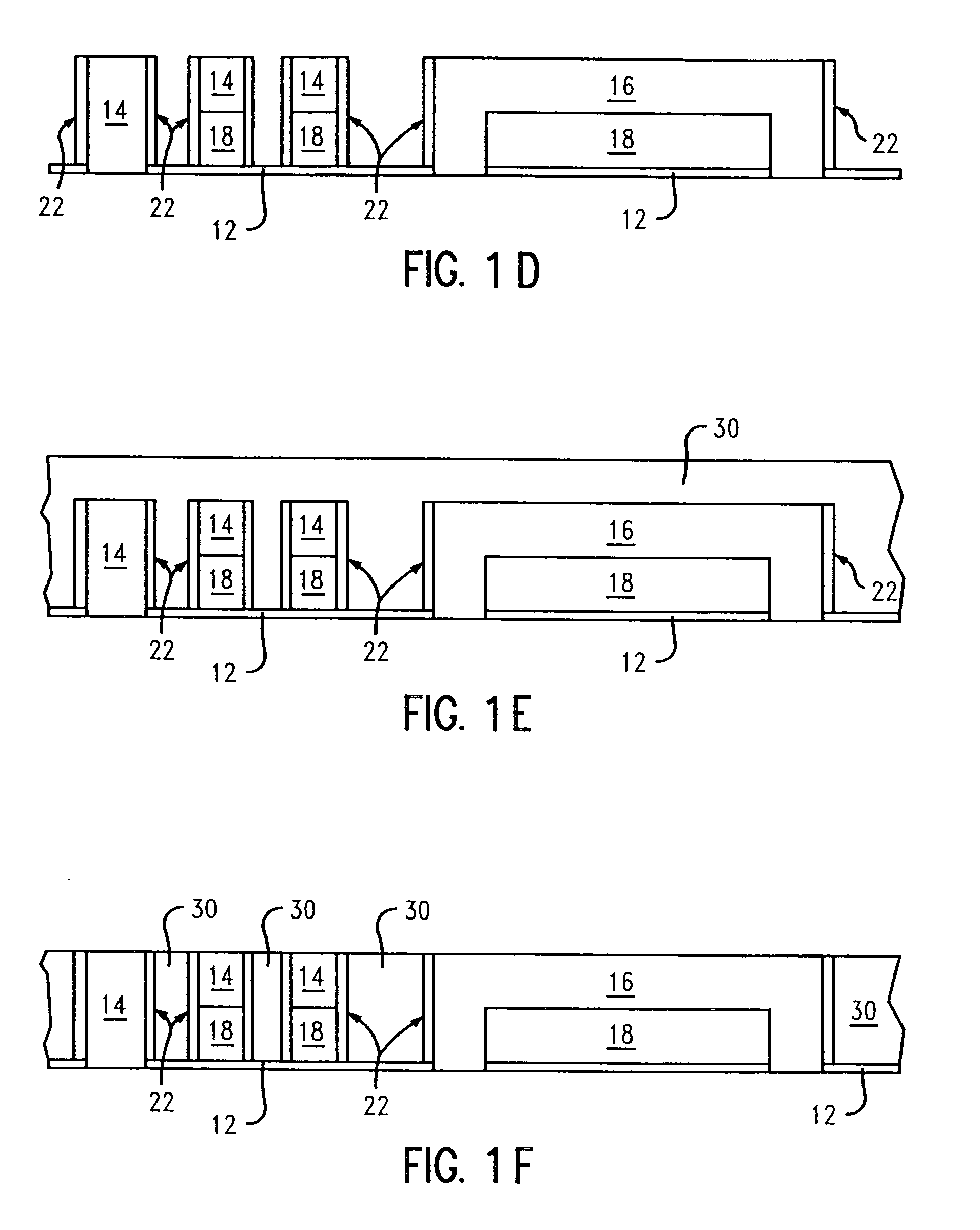

Crackstop with release layer for crack control in semiconductors

InactiveUS7109093B2Avoid crackingReduce crackingLiquid surface applicatorsSemiconductor/solid-state device detailsEngineeringVertical channel

Methods of forming and the integrated circuit device structure formed having vertical interfaces adjacent an existing crack stop around a perimeter of a chip, whereby the vertical interface controls cracks generated during side processing of the device such as dicing, and in service from penetrating the crack stop. The vertical interface is comprised of a material that prevents cracks from damaging the crack stop by deflecting cracks away from penetrating the crack stop, or by absorbing the generated crack energies. Alternatively, the vertical interface may be a material that allows advancing cracks to lose enough energy such that they become incapable of penetrating the crack stop. The present vertical interfaces can be implemented in a number of ways such as, vertical spacers of release material, vertical trenches of release material or vertical channels of the release material.

Owner:GLOBALFOUNDRIES INC

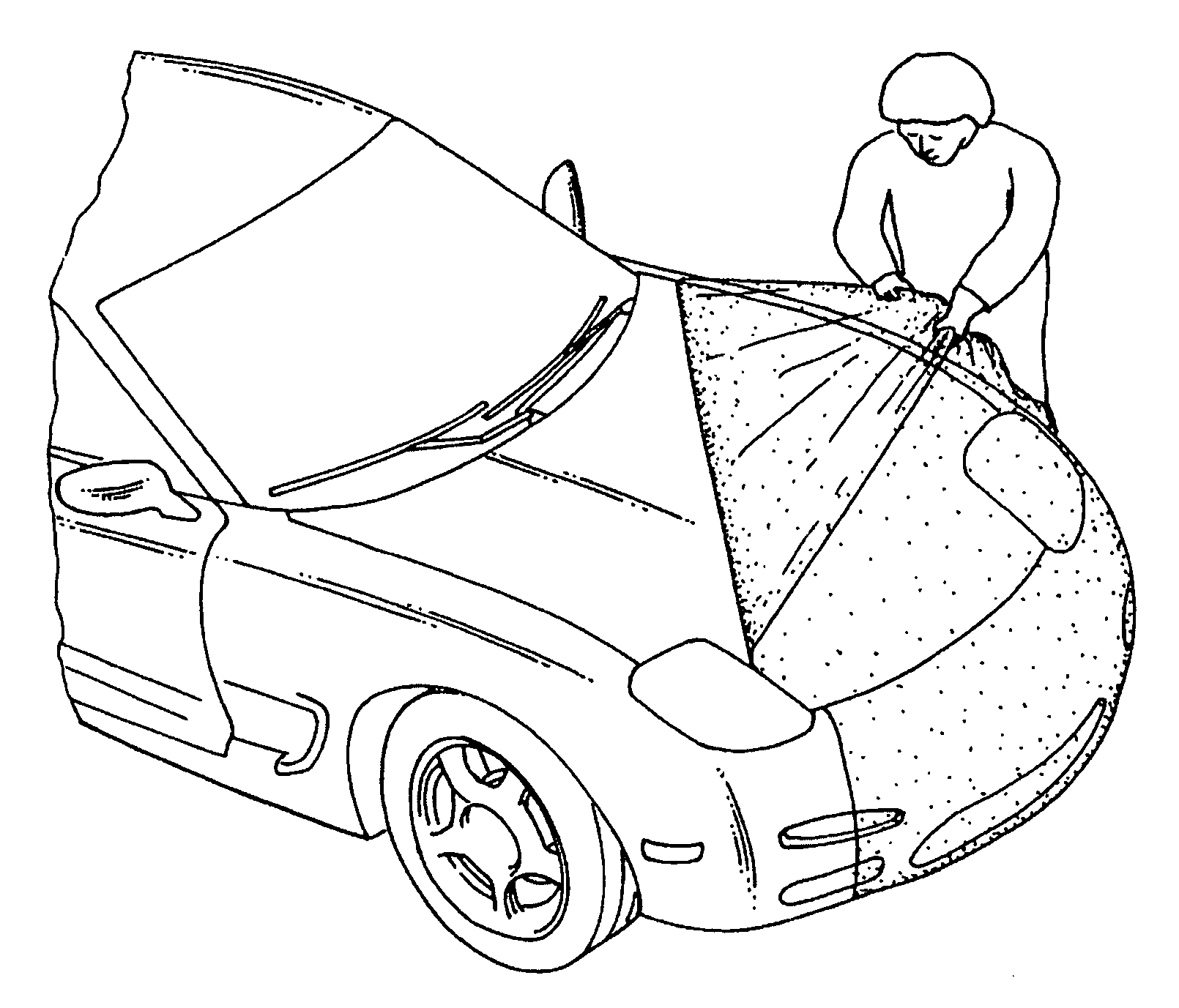

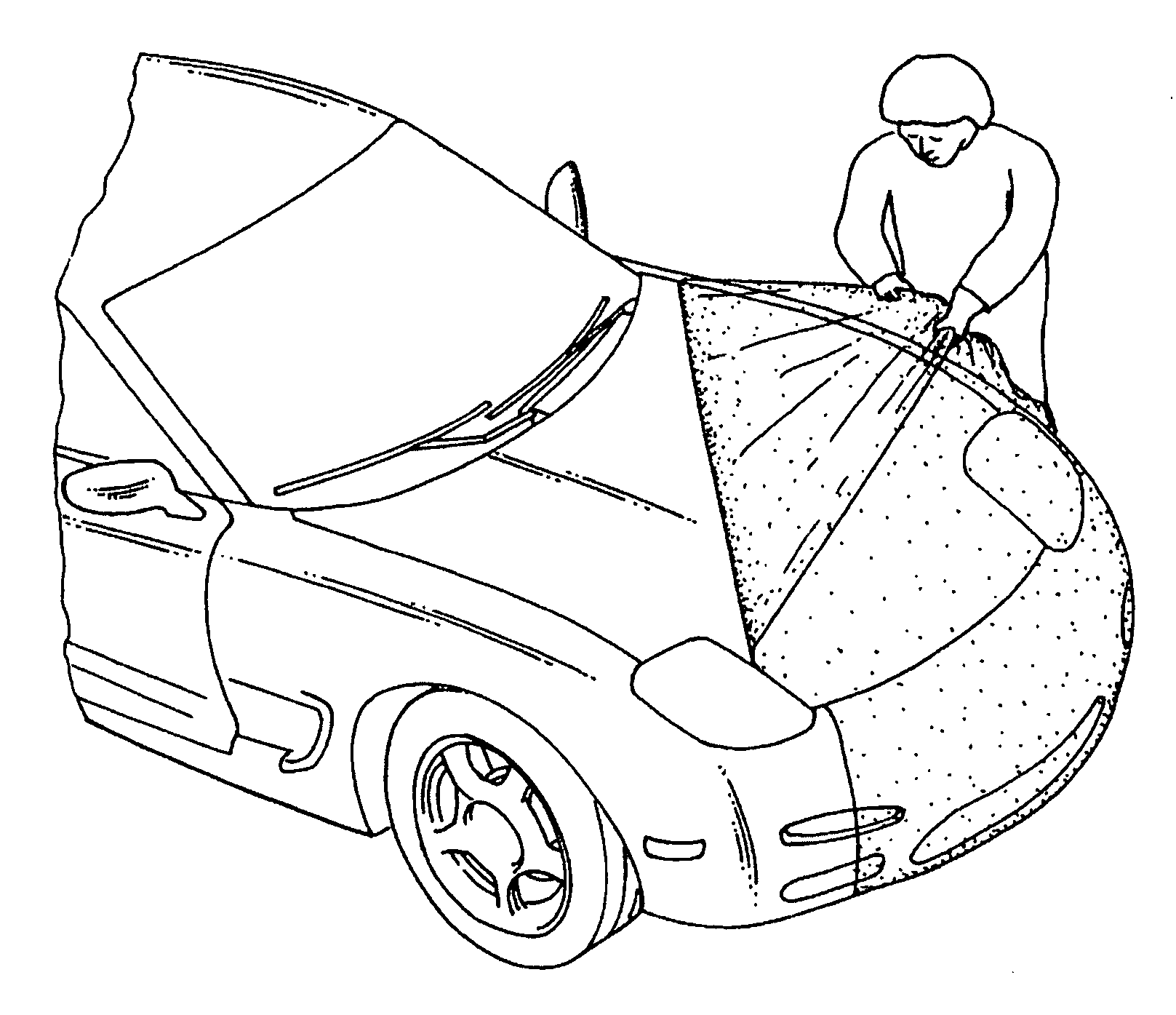

Peel-off coating compositions

ActiveUS8263231B2Easy to disassembleLow costNon-fibrous pulp additionAlkaline-earth metal silicatesEmulsionAcid rain

Methods and compositions are provided for protecting exterior surfaces of automobiles and other products, or components of products, against abrasion, abrasive dust, water, acid rain, etc. The methods involve applying to a surface a protective coating composition comprising a polyvinyl butyrate emulsion and a relatively inert extender. The emulsion is dried to form a water-resistant protective coating that can be removed from the underlying surface by peeling when no longer desired.

Owner:CAL WEST SPECIALTY COATINGS

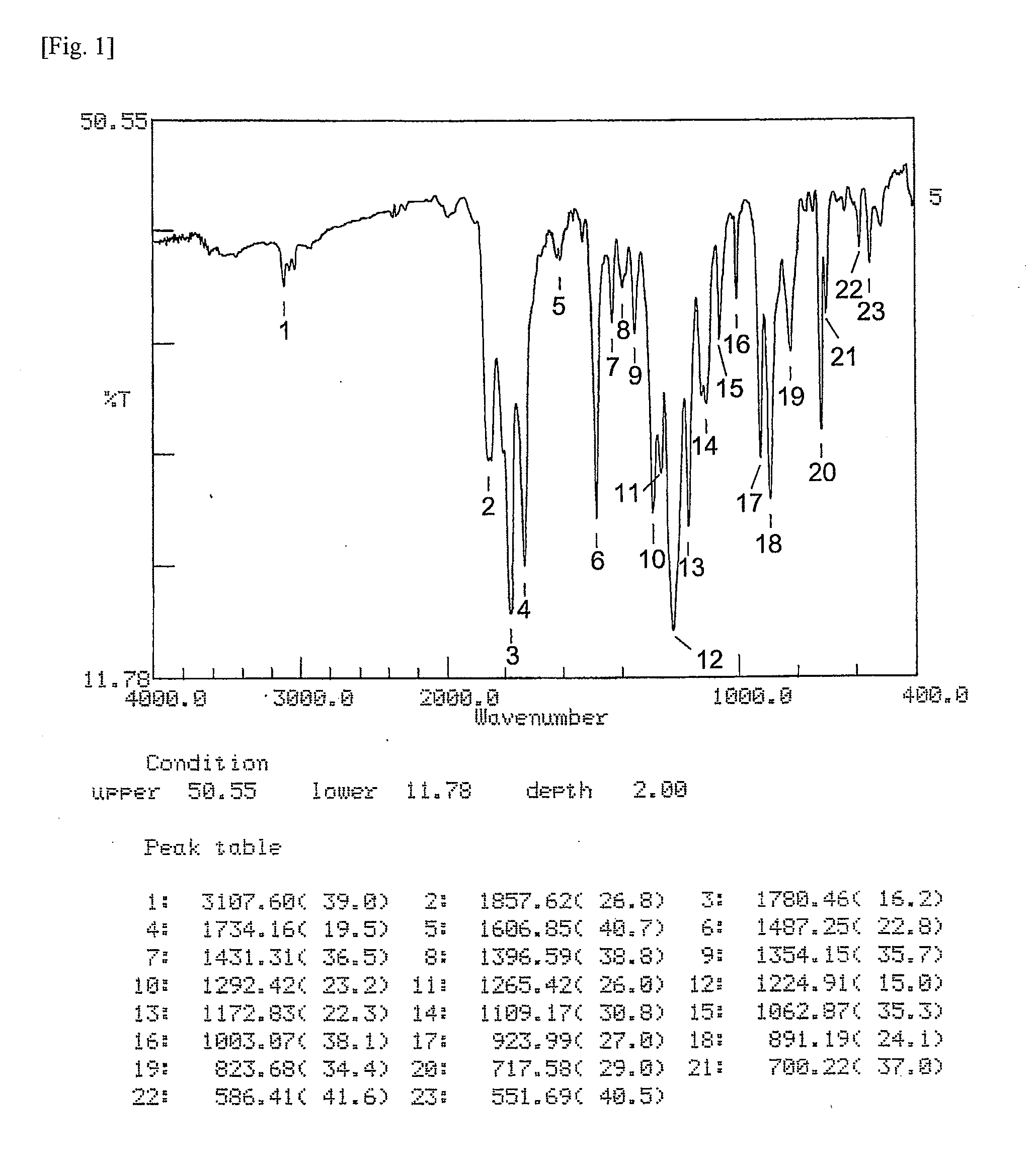

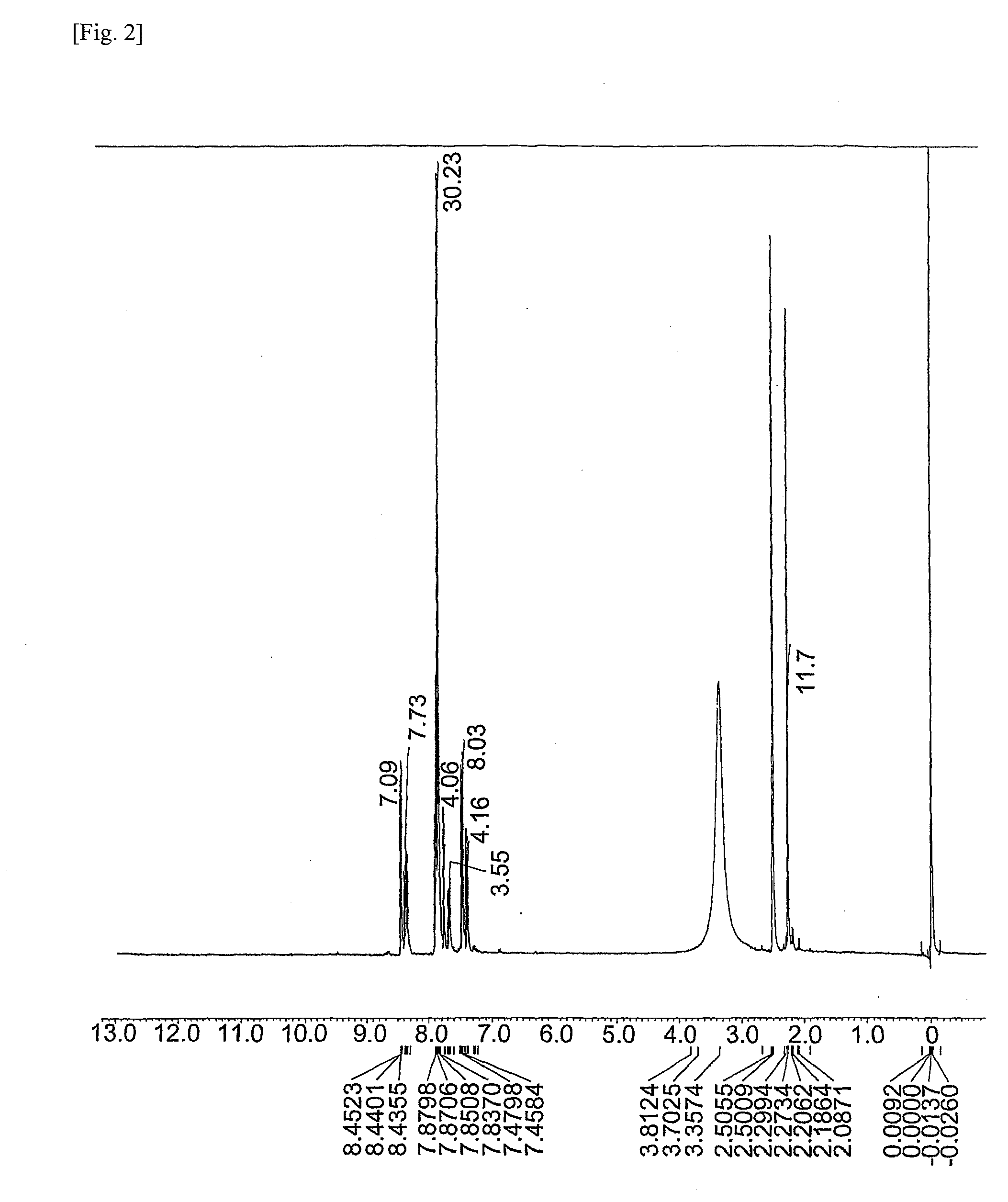

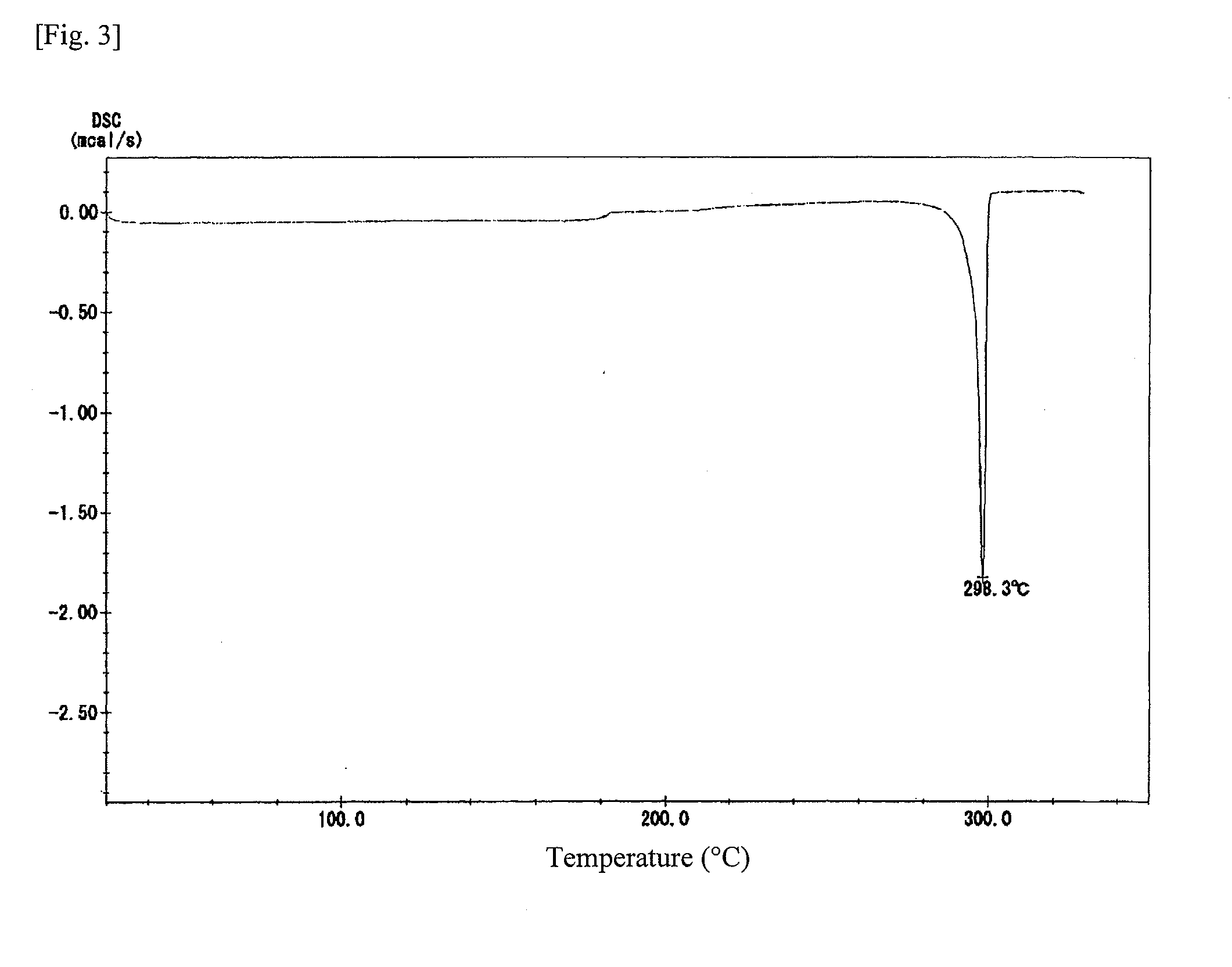

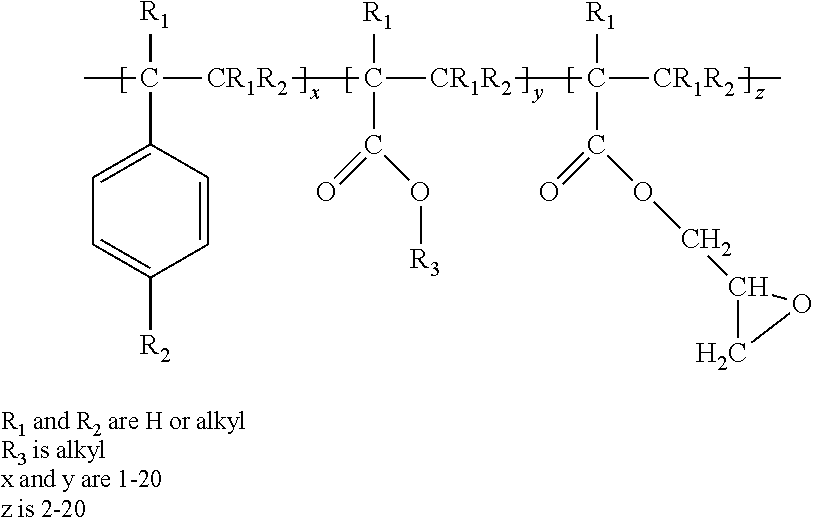

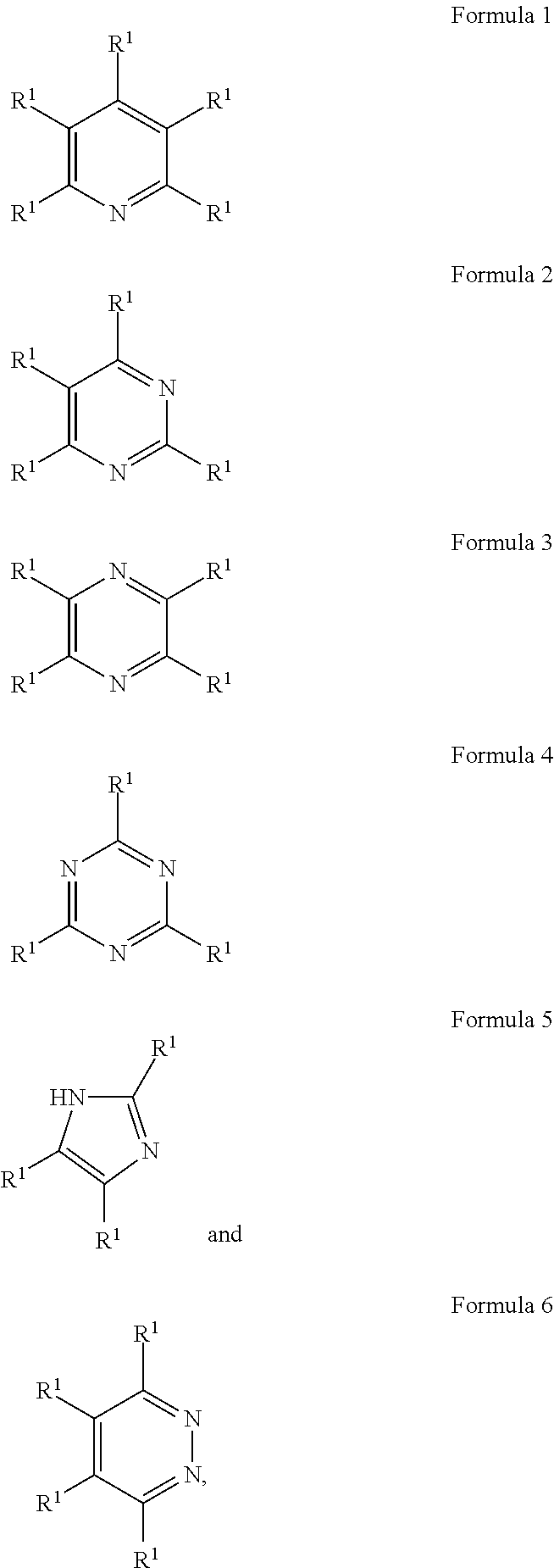

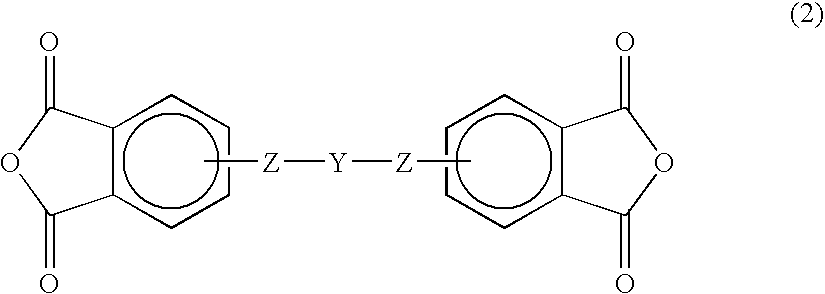

Novel ester group-containing tetracarboxylic acid dianhydride, novel polyesterimide precursor derived therefrom, and polyesterimide

ActiveUS20090306329A1High glass transition temperatureLow linearityOrganic chemistryPrinted circuitsPolyimideWater absorption coefficient

Provided are a polyimide that demonstrates low coefficient of hygroscopic expansion and low water absorption coefficient when used as an insulation film, as well as an ester group-containing tetracarboxylic acid dianhydride expressed by the general formula below, and a novel polyesterimide precursor derived therefrom and polyesterimide, for use in the production of such polyimide:In the formula, each R is independent and represents a straight or branched-chain alkyl group with 1 to 6 carbon atoms or straight or branched-chain alkoxyl group with 1 to 6 carbon atoms, n is an integer of 0 to 4, and m is an integer of 2 to 4, with the proviso that if m=2, n is an integer of 1 to 4.

Owner:HONSHU CHEM INDAL

Low Glass Transition Polyhydroxyalkanoates for Modification of Biodegradable Polymers

ActiveUS20150147929A1Improve propertiesHigh strengthWoven fabricsNon-woven fabricsPolytetramethylene terephthalateVitrification

Compositions of biobased polymer blends of polymers of polybutylene succinate (PBS) or polybutylene-adipate-terephthalate (PBAT) and a polyhydroxyalkanoate copolymer are described. In certain embodiments, the copolymer is a multiphase copolymer blend having one phase a glass transition temperature of about −5° C. to about −50° C. Methods of making the compositions of the invention are also described. The invention also includes articles, films and laminates comprising the compositions.

Owner:CJ CHEILJEDANG CORP

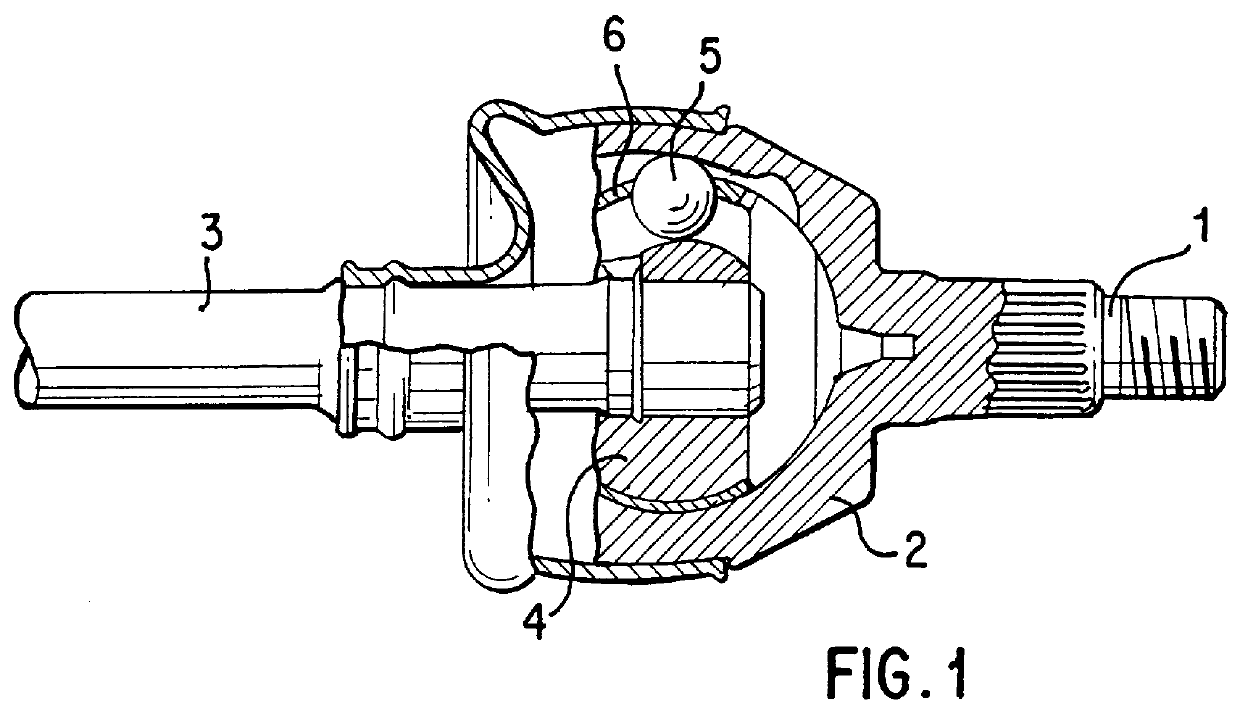

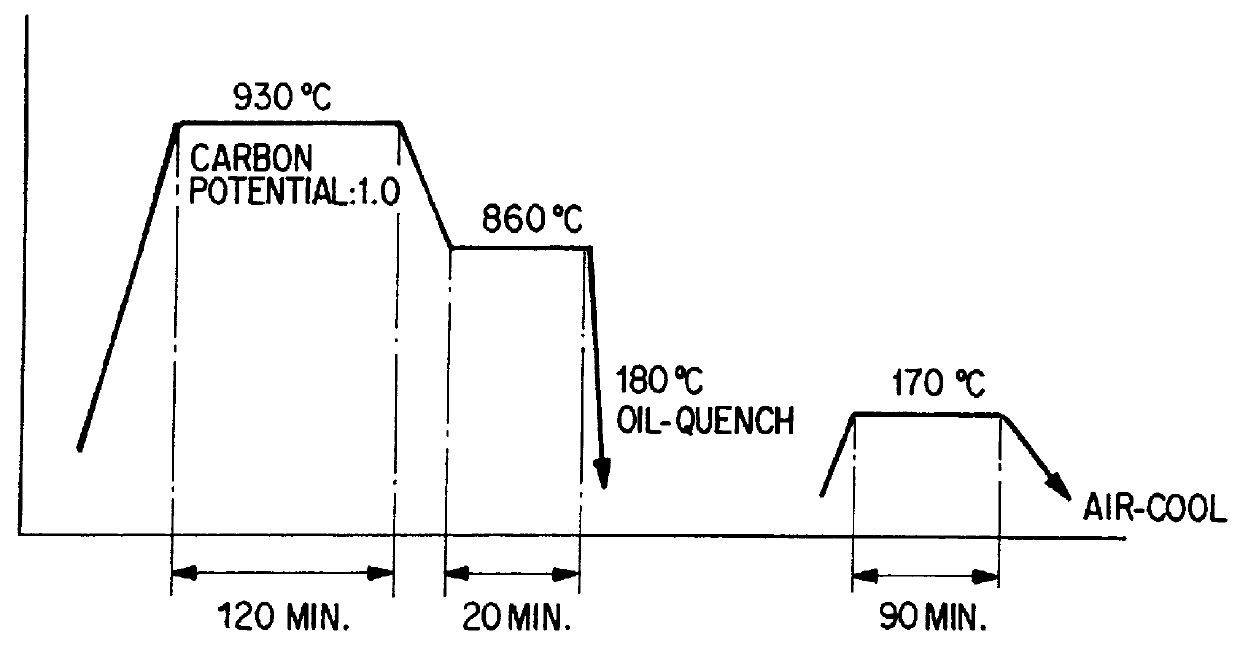

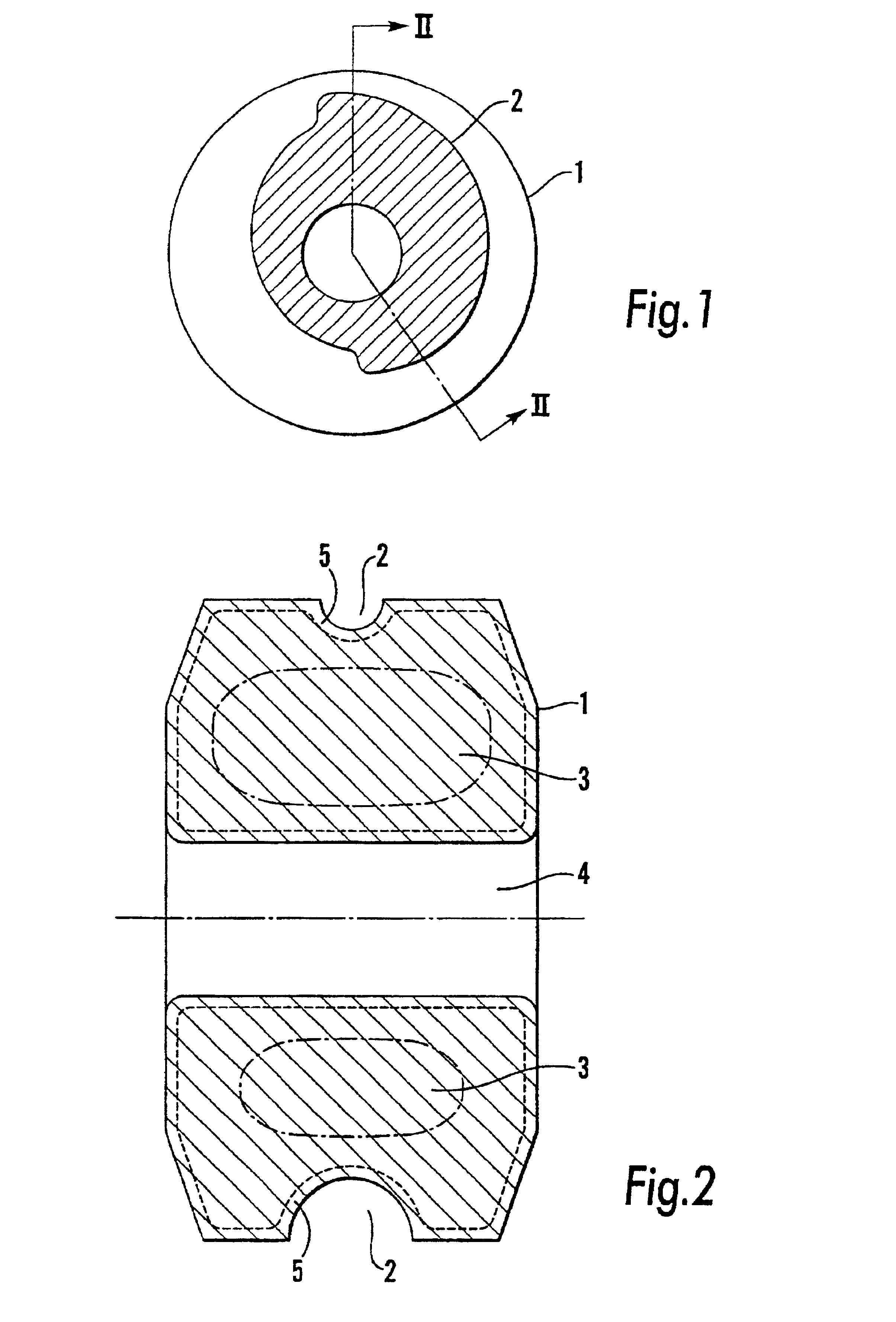

Carburizing steel and steel products manufactured making use of the carburizing steel

InactiveUS6126897AImproving rolling contact fatigue resistanceHigh strengthYielding couplingSolid state diffusion coatingChemical compositionUniversal joint

A carburizing steel having the following chemical composition: C: 0.1 to 0.25%, Si: 0.2 to 0.4%, Mn: 0.3 to 0.9%, P: 0.02% or less, S: 0.001 to 0.15%, Cr: 0.5 to 0.9%, Mo: 0.15 to 1%, Al: 0.01 to 0.1%, B: 0.0005 to 0.009%, N: less than 0.006%, and the balance of Fe and incidental impurities, wherein % is on a weight basis. Also disclosed are a method for the manufacture of the carburizing steel, parts of constant velocity universal joints for drive shafts made of the carburizing steel, as well as a method for the manufacture of such parts. The carburizing steel may further contain Ni: 0.3-4.0%, and one or more elements selected from the group consisting of Ti, Nb, V and Zr: 0.01-0.3% for each. The parts of constant velocity universal joints for drive shafts are manufactured using the carburizing steel of the present invention as a material. When they are carburized and quenched, they exhibit a surface hardness (Hv) of 650-800, core hardness (Hv) of 250-450, and carburized case depth of 0.2-1.2 mm.

Owner:SUMITOMO METAL IND LTD +1

Biobased Rubber Modified BioDegradable Polymer Blends

ActiveUS20150132512A1Improve material performanceReduce crystallinityPigmenting treatmentOrganic dyesPolymer scienceGlass transition

Compositions of biobased polymer blends of polymers and a polyhydroxyalkanoate copolymer are described. In certain embodiments, the copolymer is a multiphase copolymer blend having one phase a glass transition temperature of about −5° C. to about −50° C. Methods of making the compositions of the invention are also described. Also articles, films and laminates made from the compositions are described.

Owner:CJ CHEILJEDANG CORP

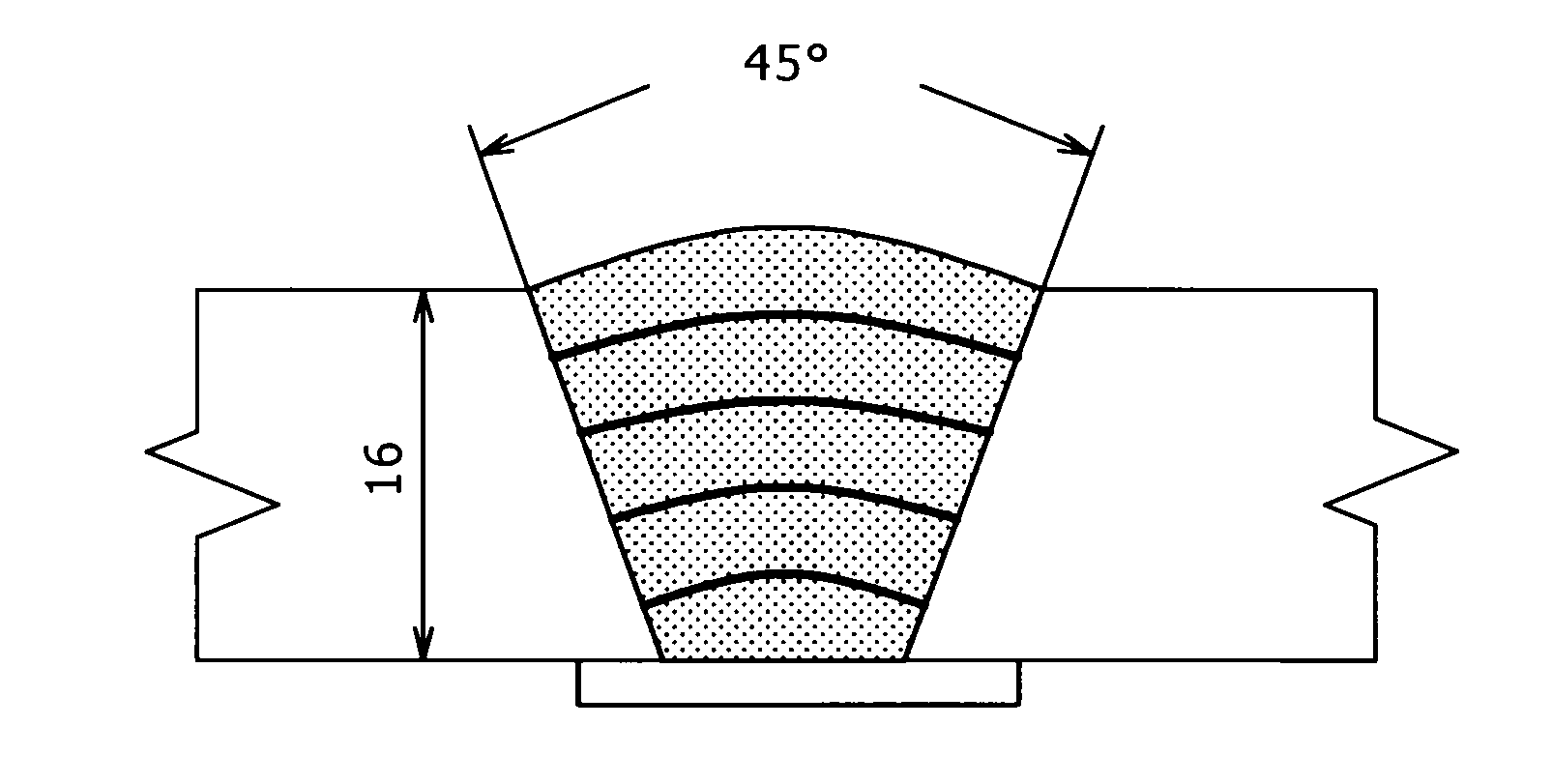

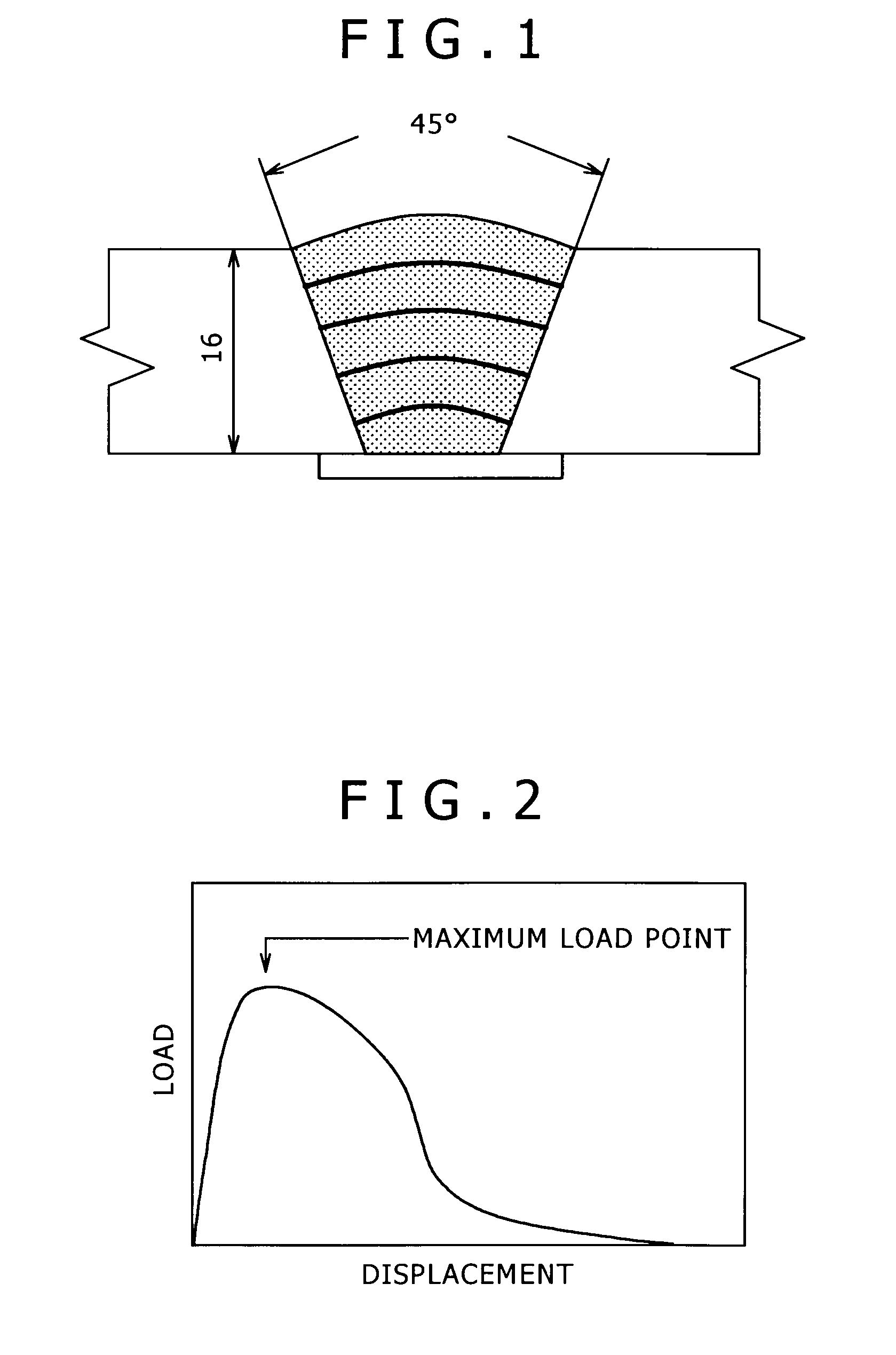

Welding solid wire

ActiveUS20100206130A1Sufficient low-temperature toughnessHigh absorption energyElectric discharge heatingWelding/cutting media/materialsManganeseOxygen

It is an object of the present invention to provide a similar composition metal type welding solid wire capable of forming a welded joint having excellent cryogenic characteristics, such as ensuring a low-temperature toughness equivalent to that of the cryogenic base metal, and in addition, further having a high crack initiation resistance, and a weld metal thereof. The welding solid wire of the present invention is an iron base welding solid wire including carbon: 0.10 mass % or less (not inclusive of 0%), silicon: 0.15 mass % or less (not inclusive of 0%), nickel: 8.0 to 15.0 mass %, manganese: 0.10 to 0.80 mass %, and Al: 0.1 mass % or less (not inclusive of 0%), and oxygen in an amount of 150 ppm or less (inclusive of 0), characterized by including: a REM: 0.005 to 0.040 mass %, or chromium: 4.0 mass % or less (not inclusive of 0%).

Owner:KOBE STEEL LTD

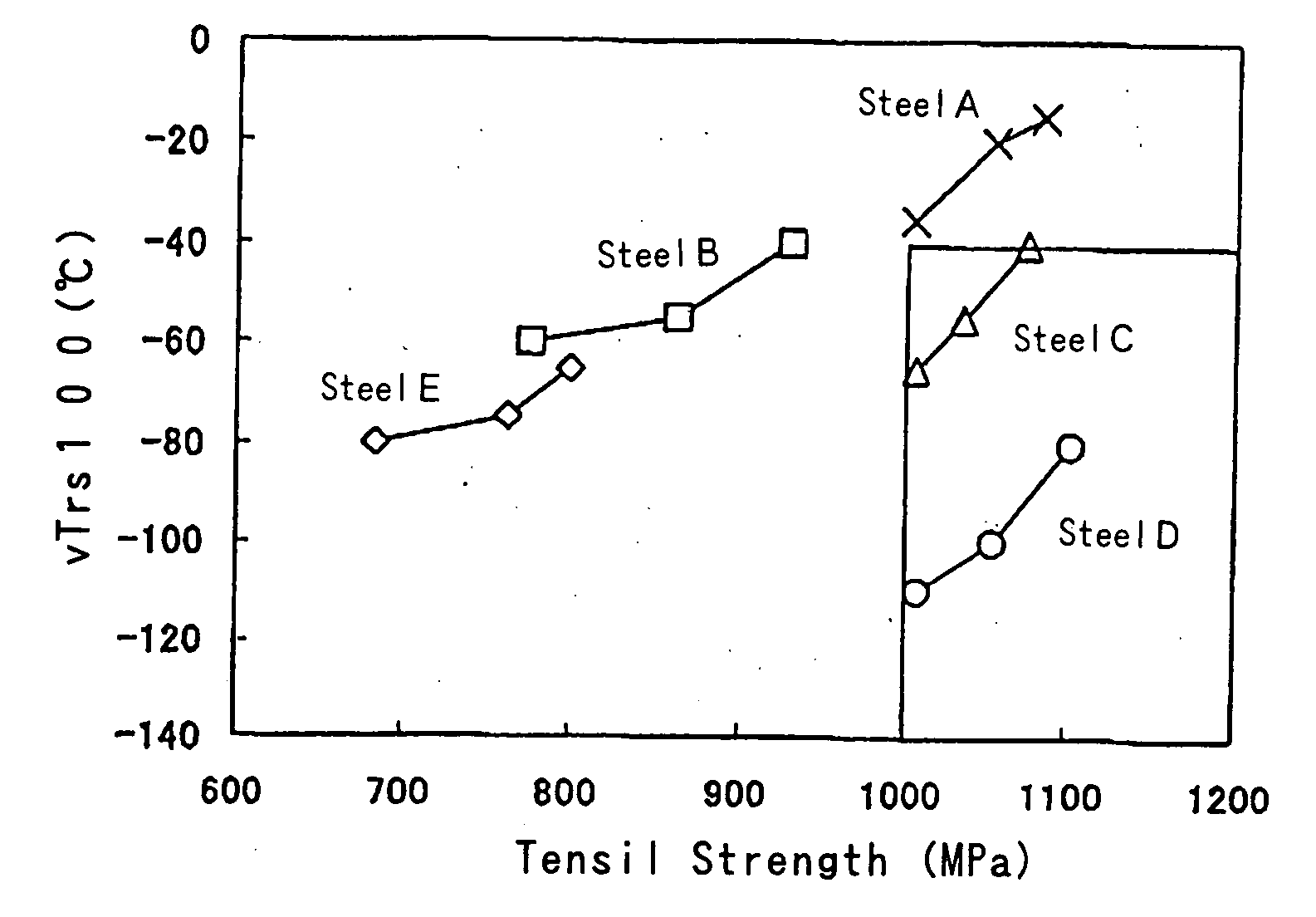

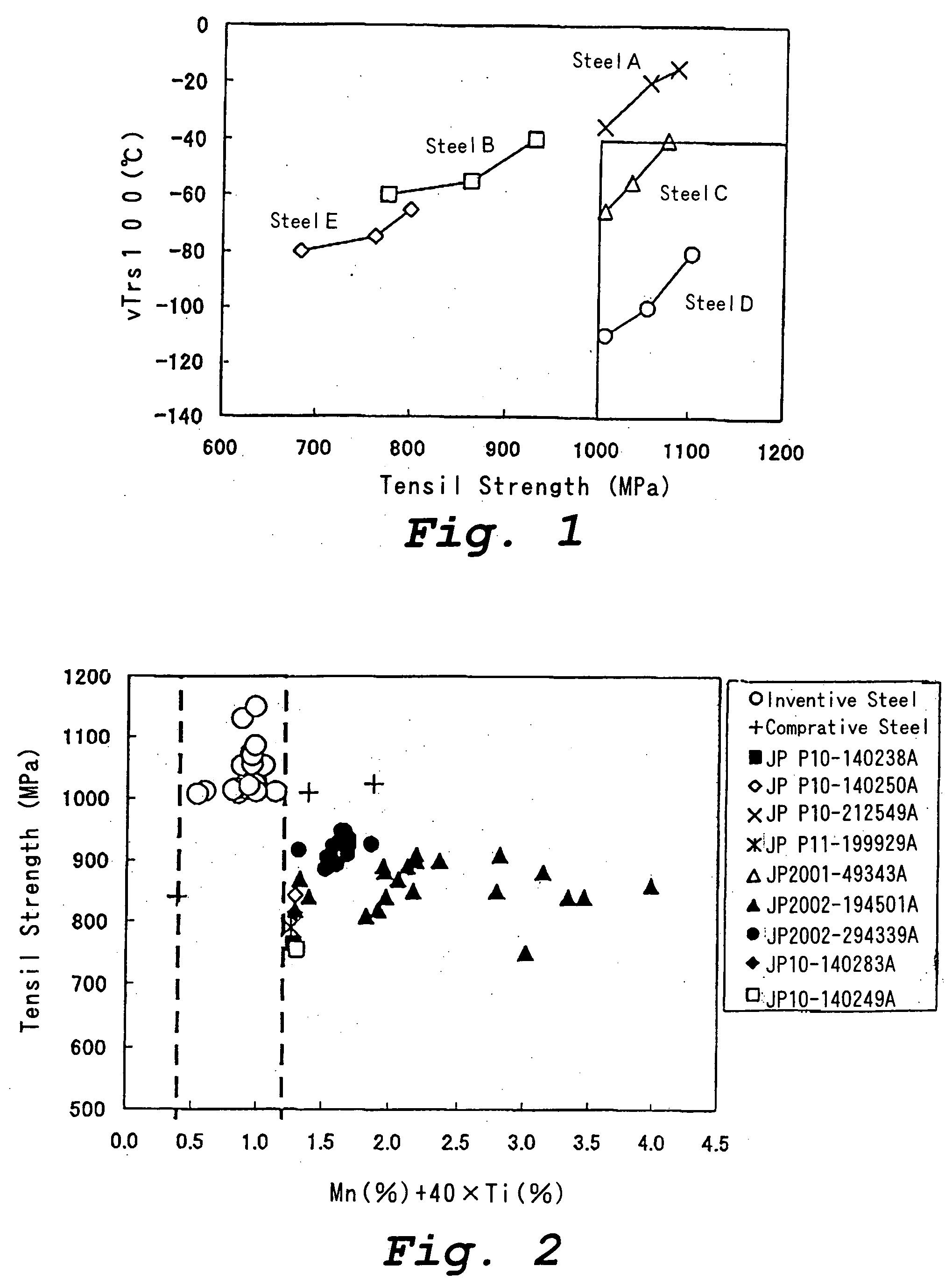

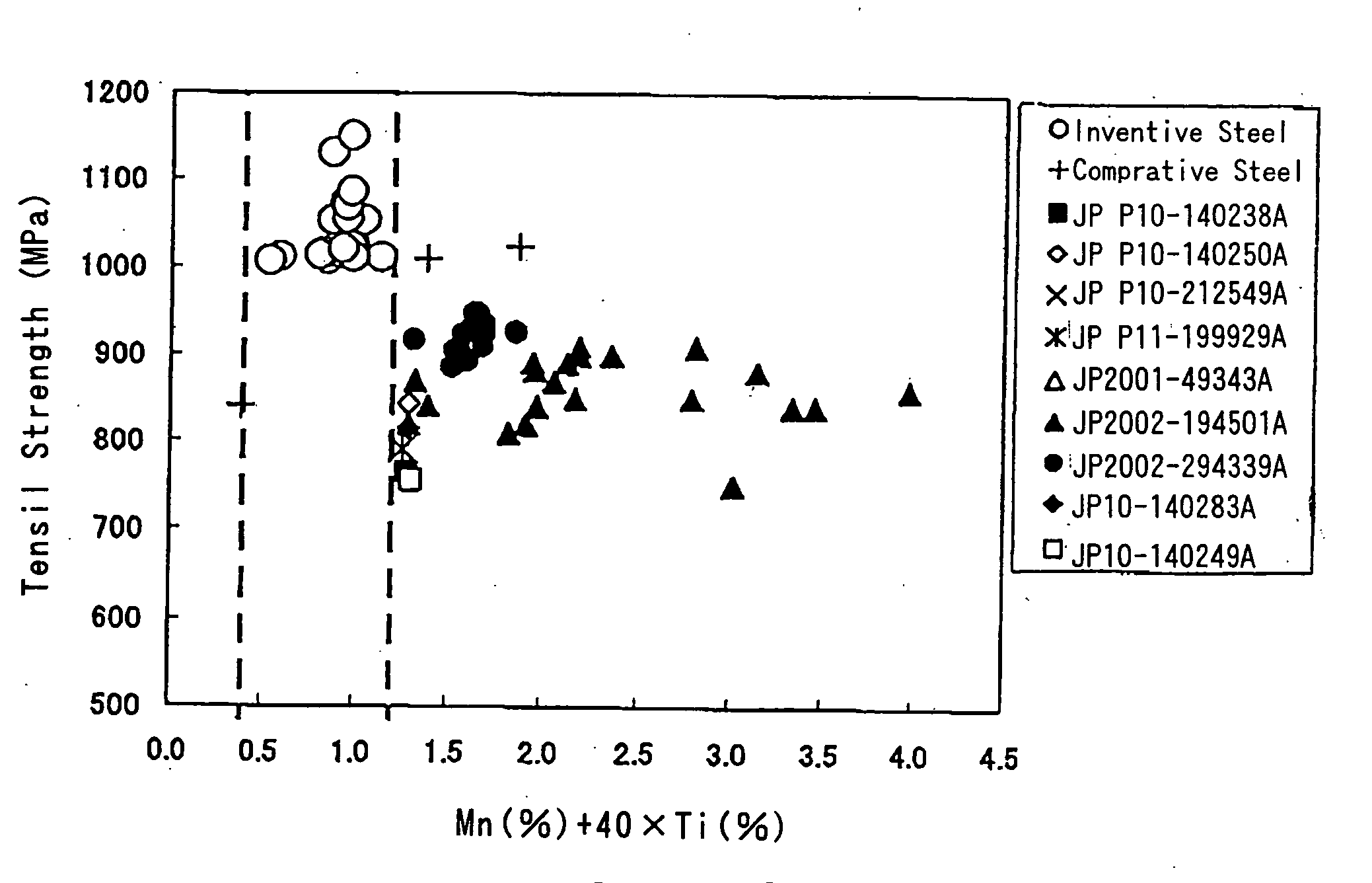

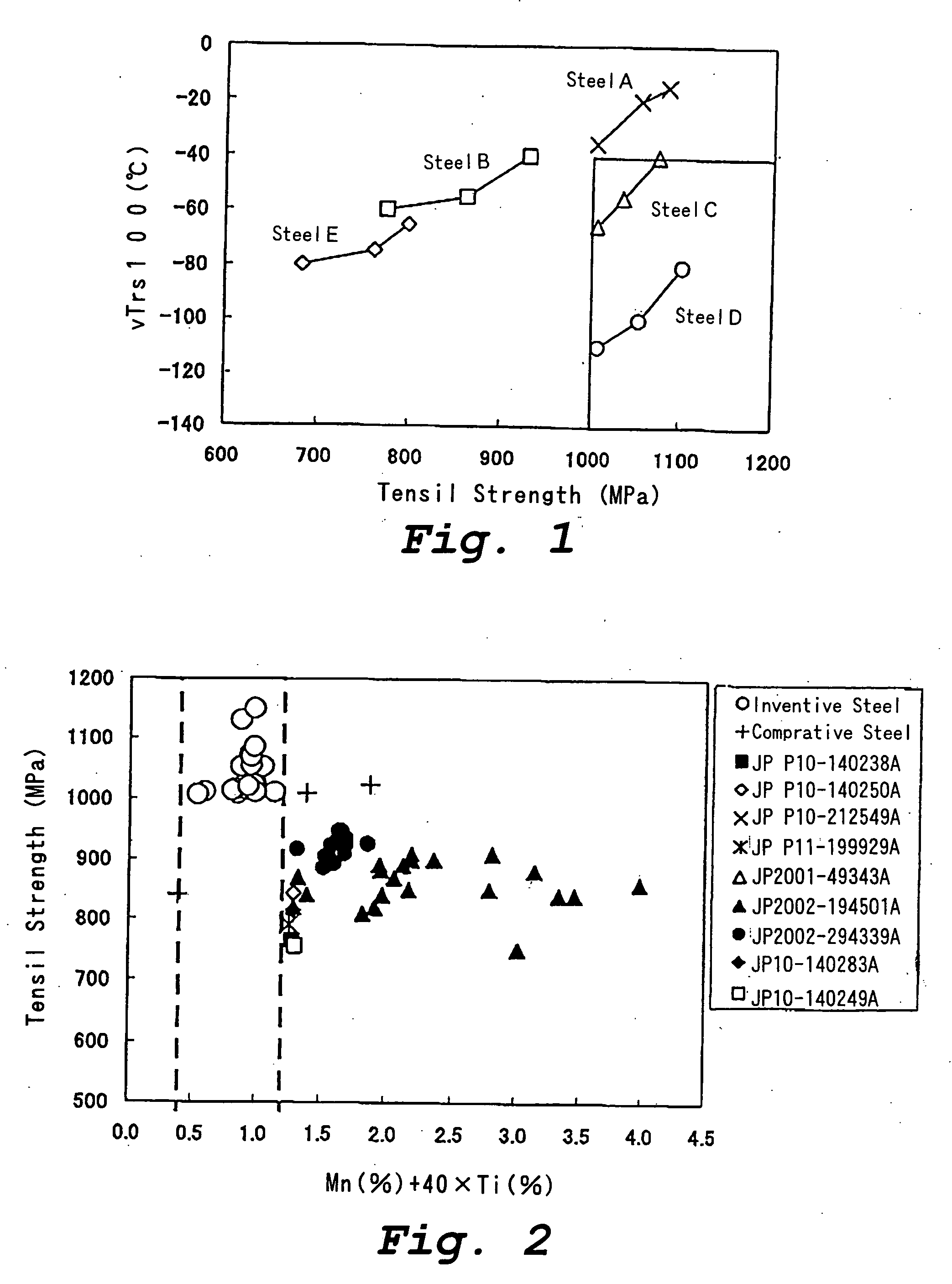

Steel pipe for an airbag system and a method for its manufacture

InactiveUS20050000601A1High strengthImprove toughnessPedestrian/occupant safety arrangementFurnace typesAirbagQuenching

A high strength steel pipe for an airbag system has a steel composition comprising C: 0.05-0.20%, Si: 0.1-1.0%, P; at most 0.025%, S: at most 0.010%, Cr: 0.05-1.0%, Al: at most 0.10% at least one of Ti and Mn satisfying (1) Ti≦0.02% and (2) 0.4%≦Mn+40Ti≦1.2%, and a remainder of Fe. The composition may further include one or more of (i) at least one of Mo: 0.05-0.50%, Ni: 0.05-1.5%, V: 0.01-0.2%, and B: 0.0003-0.005%, (ii) at least one of Cu: 0.05-0.5% and Nb: 0.003-0.1%, and (iii) at least one of Ca: 0.0003-0.01%, Mg: 0.0003-0.01%, and REM: 0.0003-0.01%. The steel pipe can be manufactured by forming a pipe from the above-described steel composition to obtain prescribed dimensions, heating to at least the Ac1 transformation point and quenching, and then tempering at the Ac1 transformation point or below.

Owner:SUMITOMO METAL IND LTD

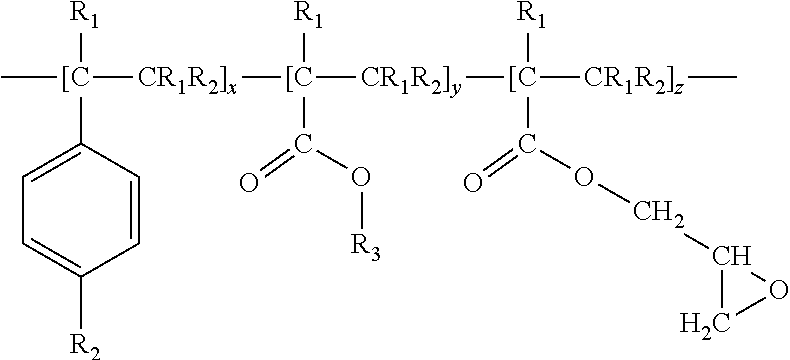

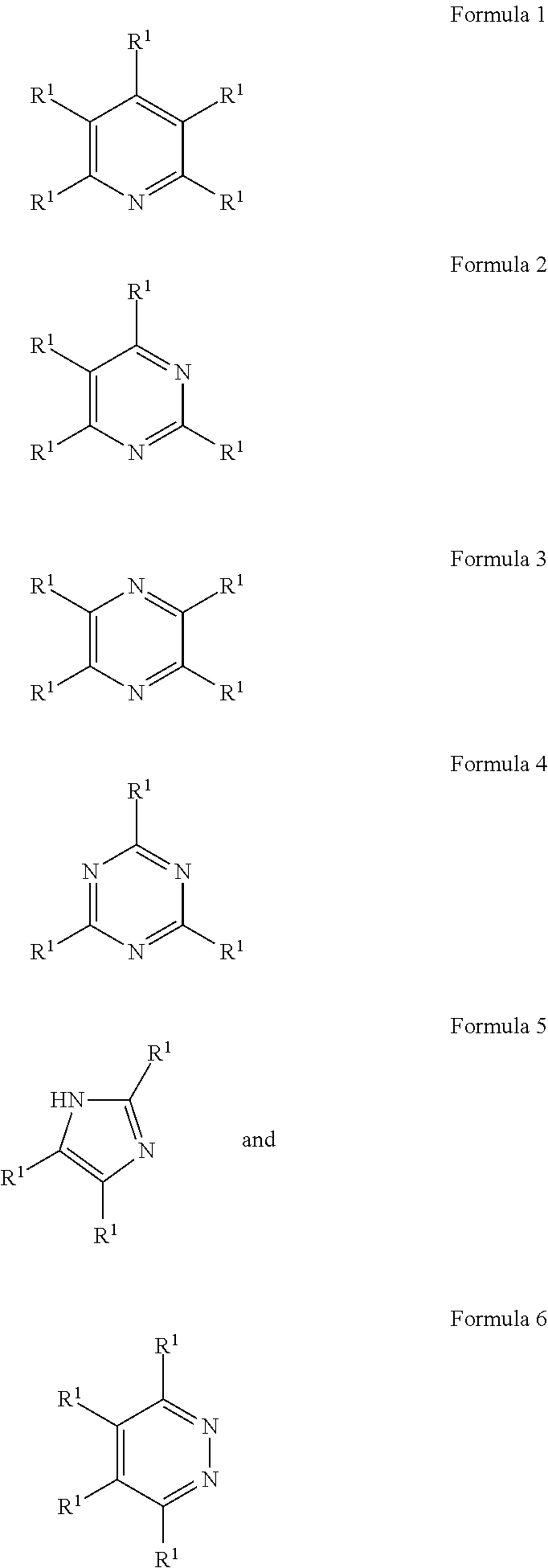

Curable composition, cured article obtained therefrom and process for preparation of the same

ActiveUS8859642B2Improve stabilityHighly stateOrganic non-macromolecular adhesiveDevelopersVolume averageToughness

Fine polymer particles are dispersed as primary particles in a vinyl monomer to provide a high quality composition in which the dispersed state and stability of the particles are regulated to a high degree and to provide a curable composition being excellent in handleability and using fine polymer particles as a toughness-imparting agent. For the above, the curable composition of the present invention comprises 100 parts by weight of a vinyl monomer (A) and 0.1 to 100 parts by weight of fine polymer particles (B) having a volume average particle size of 0.05 to 1 m, in which the fine polymer particles (B) are dispersed in the form of primary particles in the vinyl monomer (A).

Owner:KANEKA CORP

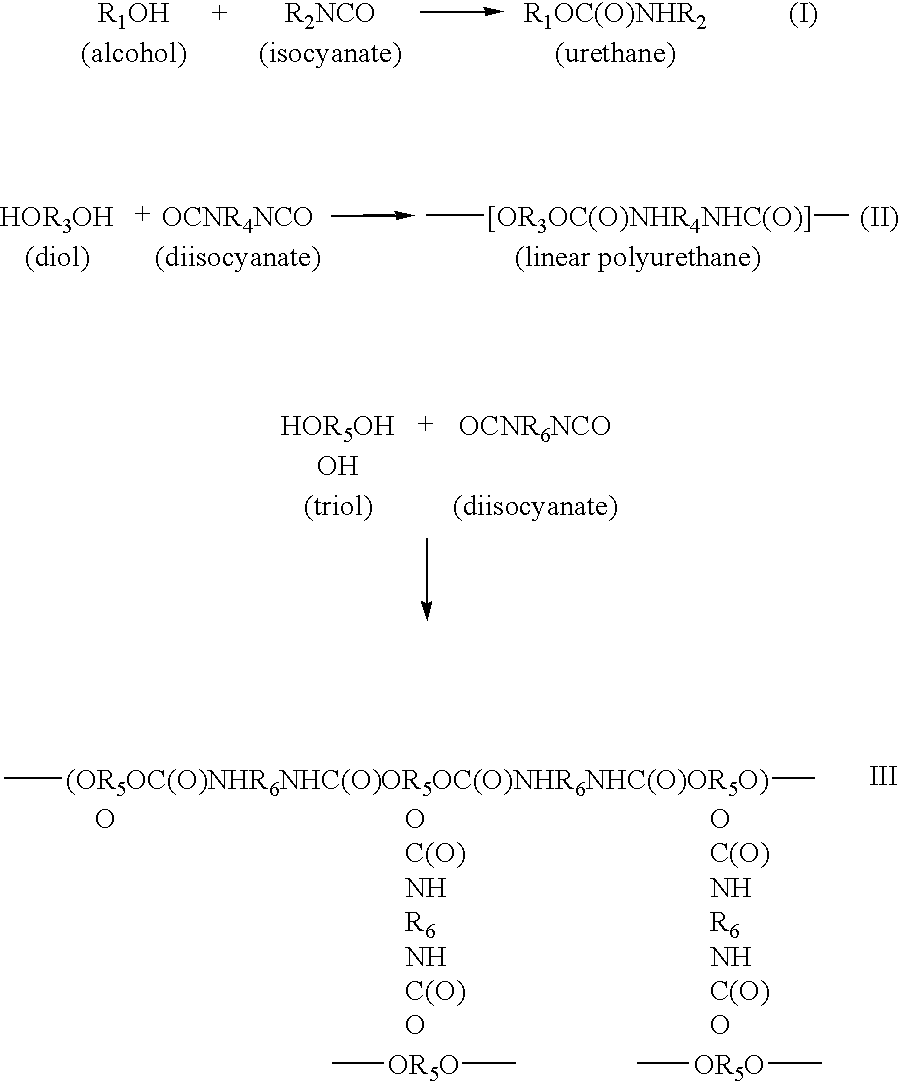

Robust nontoxic antifouling elastomers

InactiveUS20030113547A1Reduce the amount requiredModulus is reducedAntifouling/underwater paintsSynthetic resin layered productsPolyurethane elastomerYoung's modulus

The invention herein pertains to a method for reducing adhesion of marine organisms to a substrate and an article that is a substrate having thereon a solid coating of a fluorinated polyurethane elastomer. The elastomer is tough and has antifouling and release properties in reference to marine organisms. The method includes the steps of providing a liquid mixture of the fluorinated polyurethane elastomer, applying the elastomer mixture to said substrate, and curing the elastomer mixture to a solid coating of the fluorinated polyurethane elastomer, the elastomer having surface energy (which is a function of fluorine content) of 15-30 milli J / m2, Young's modulus of elasticity of 2-15 MPa, and fluorine content of 3-25%.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

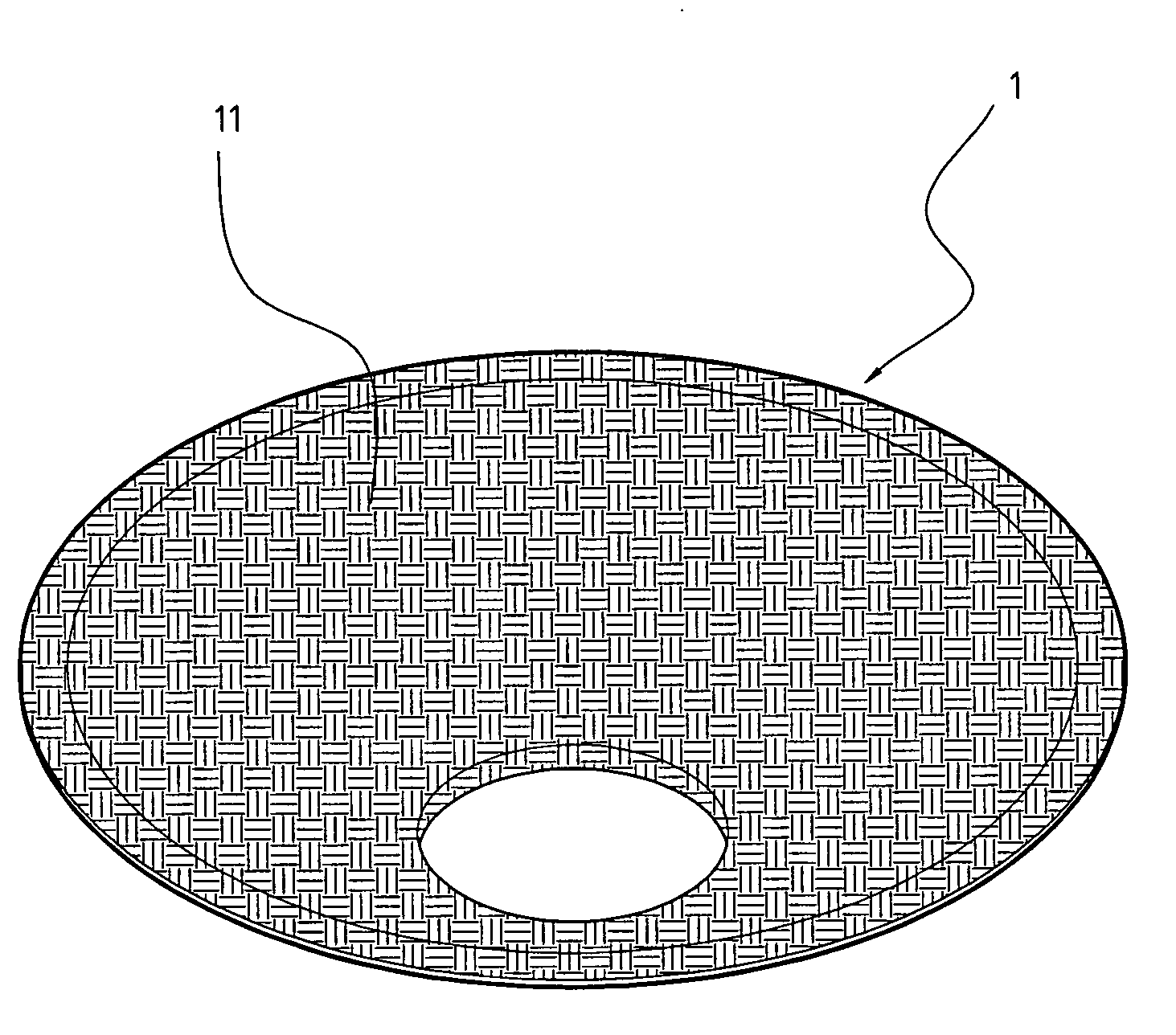

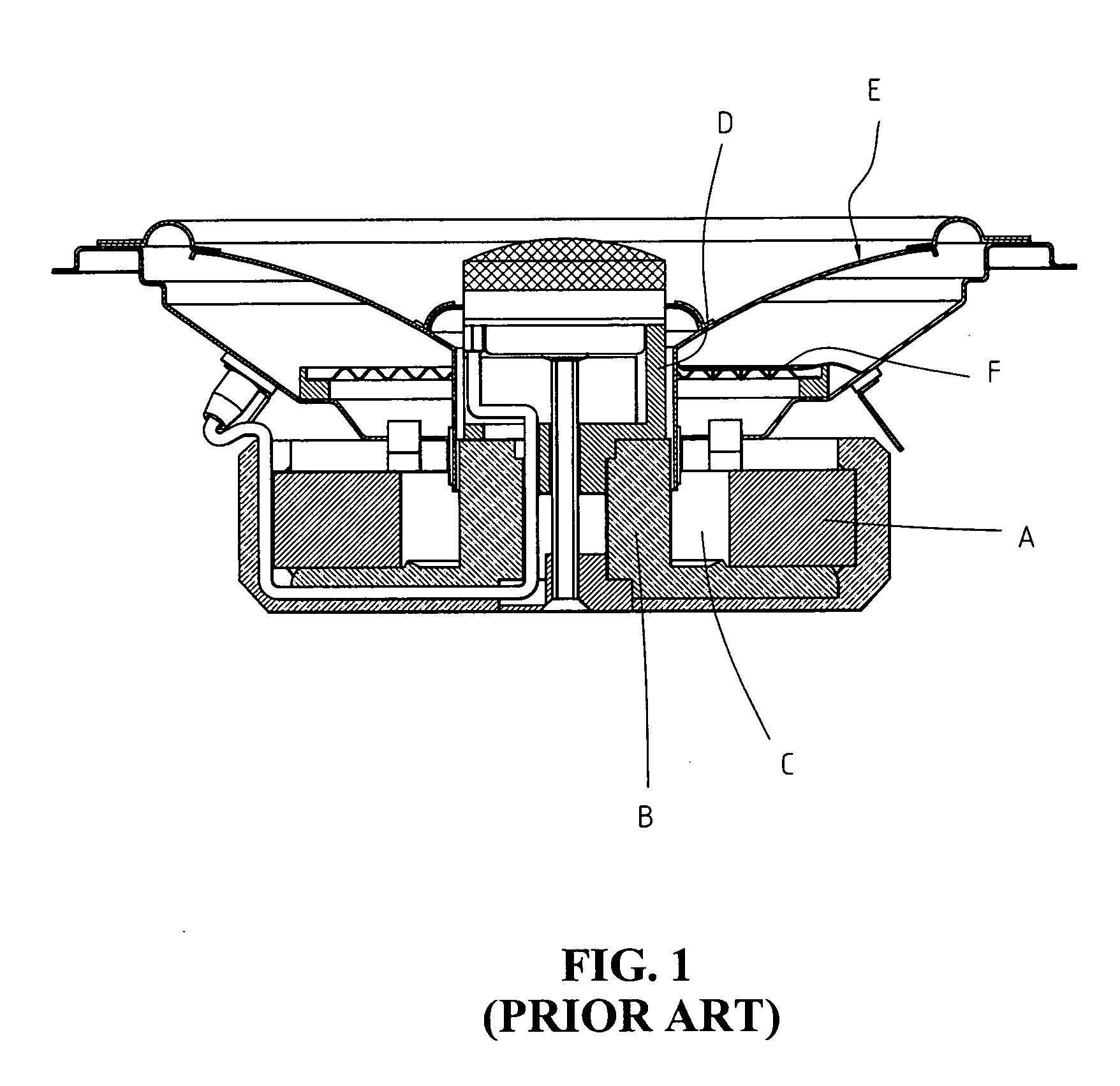

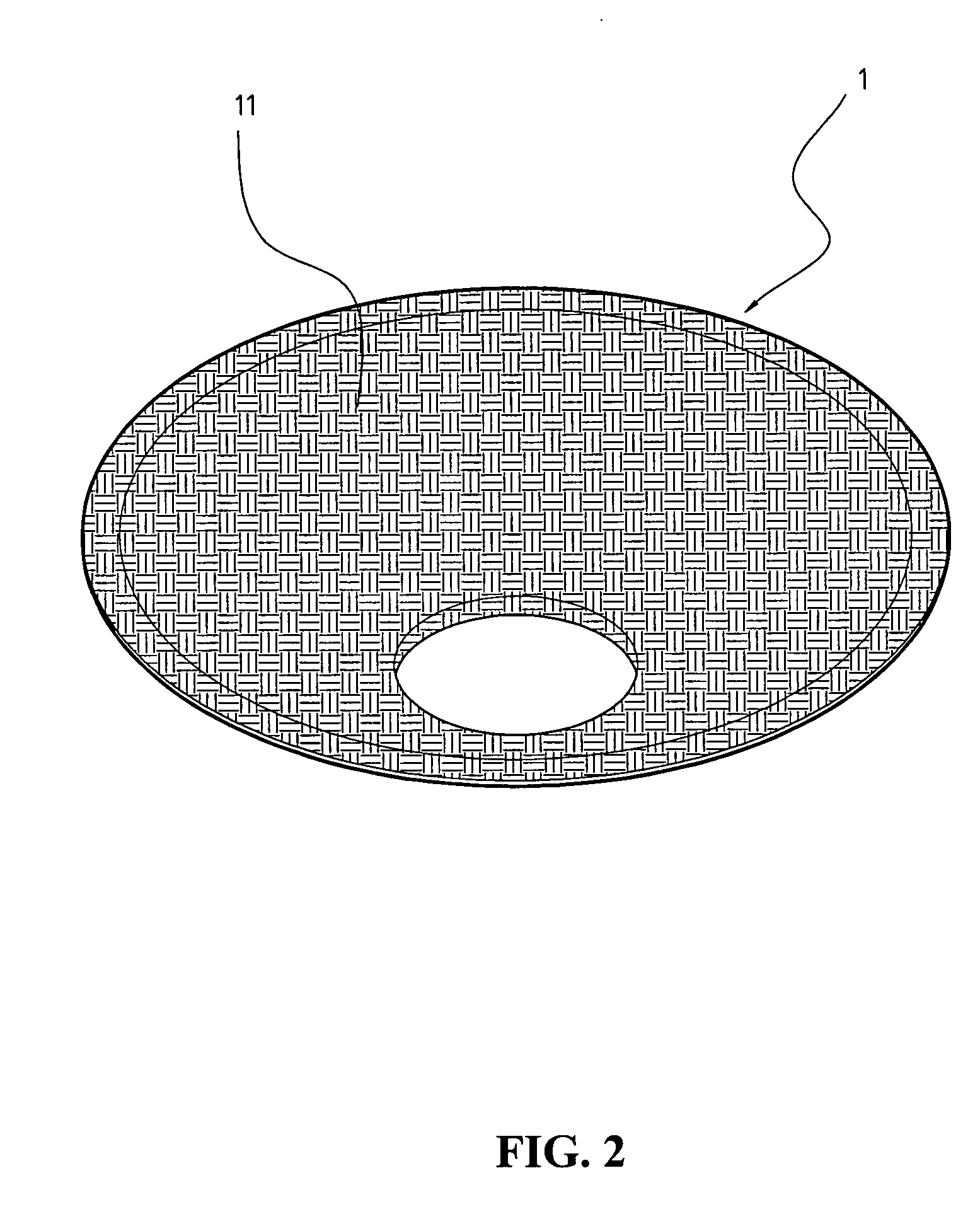

Loudspeaker cone including plated fabric

InactiveUS20070177758A1Low costEasy to transformTransducer detailsNon-planar diaphragms/conesEngineeringHigh pressure

A loudspeaker cone including a plated fabric is provided. The material of the loudspeaker cone is produced by laminating an interweaved plated fabric, and a light-weight and tough cloth together, and then a loudspeaker cone is produced by molding the material of the loudspeaker cone under high temperature and high pressure. The produced loudspeaker cone is light-weight, tough, pressure-resistant, not easily deformed, and can be used for a long term.

Owner:OHARA HIROSHI

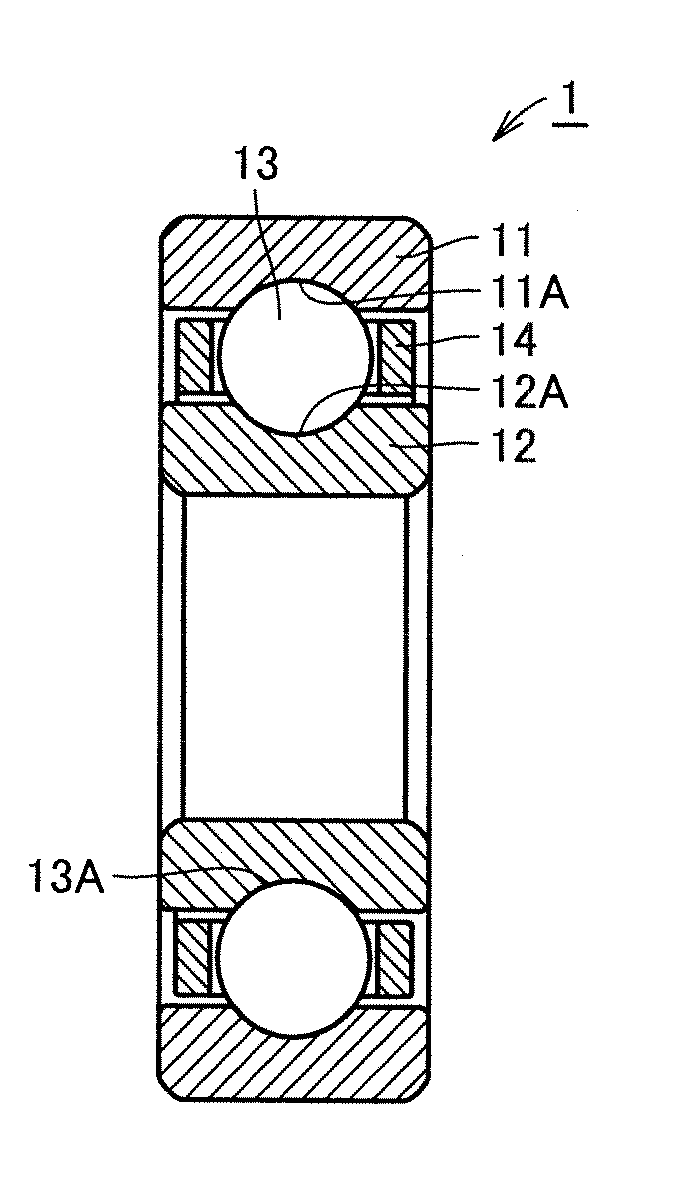

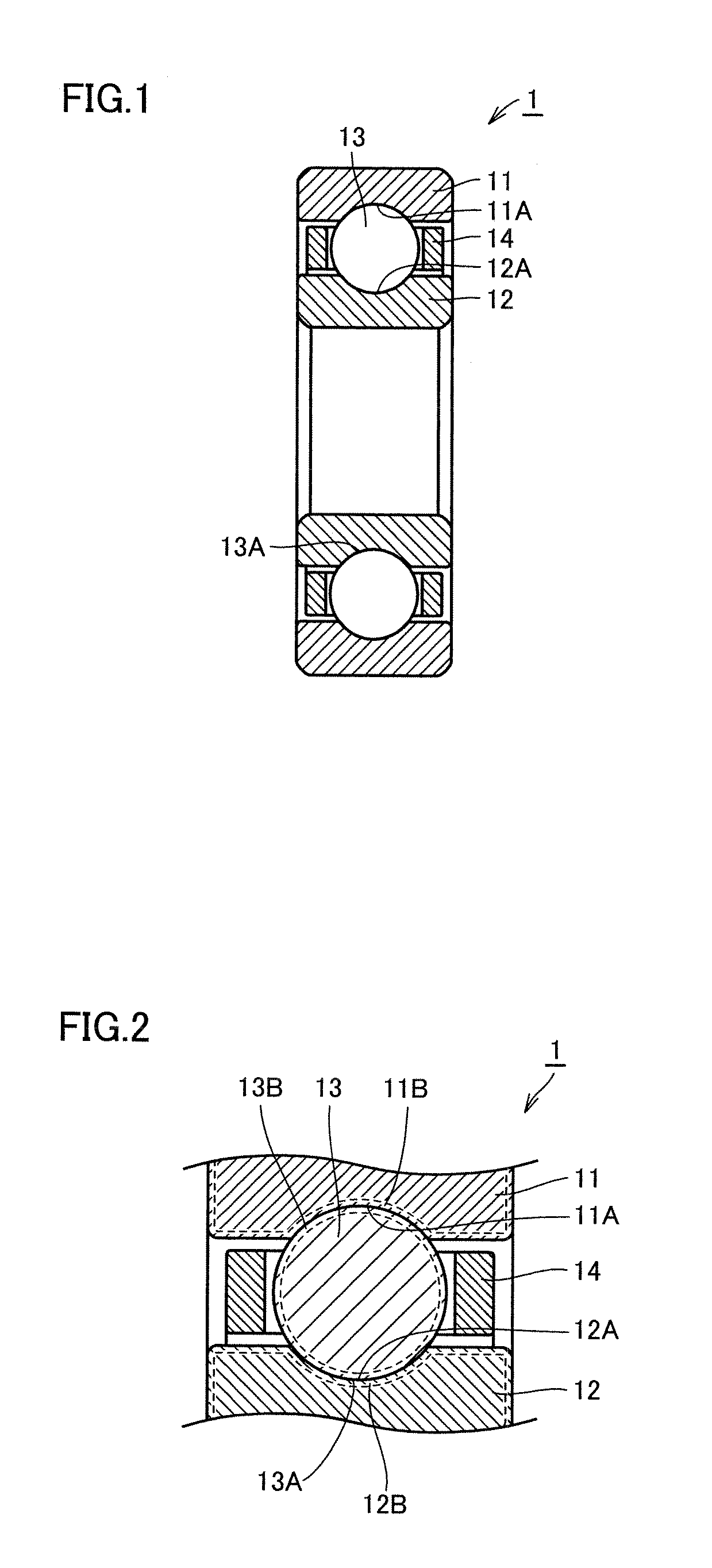

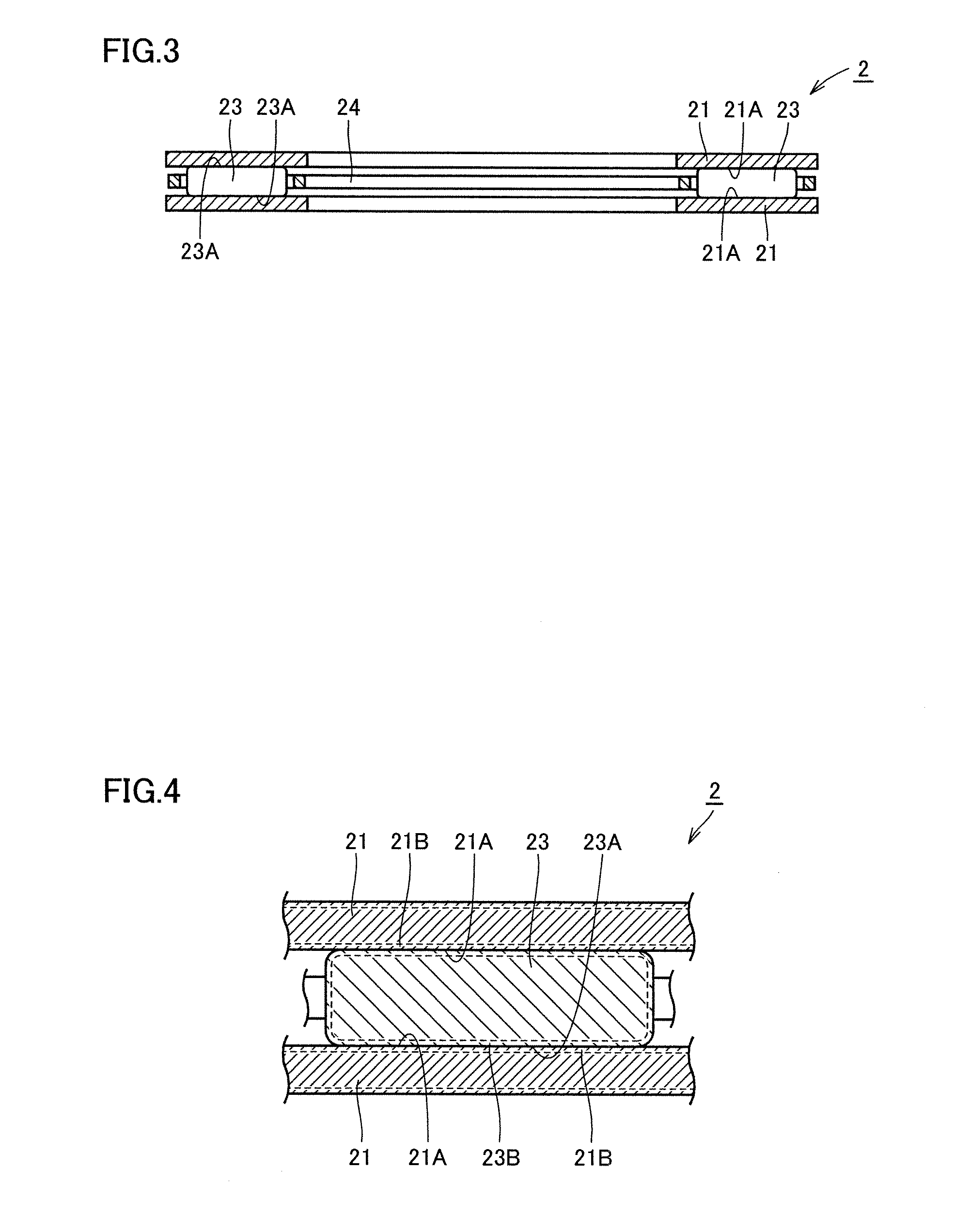

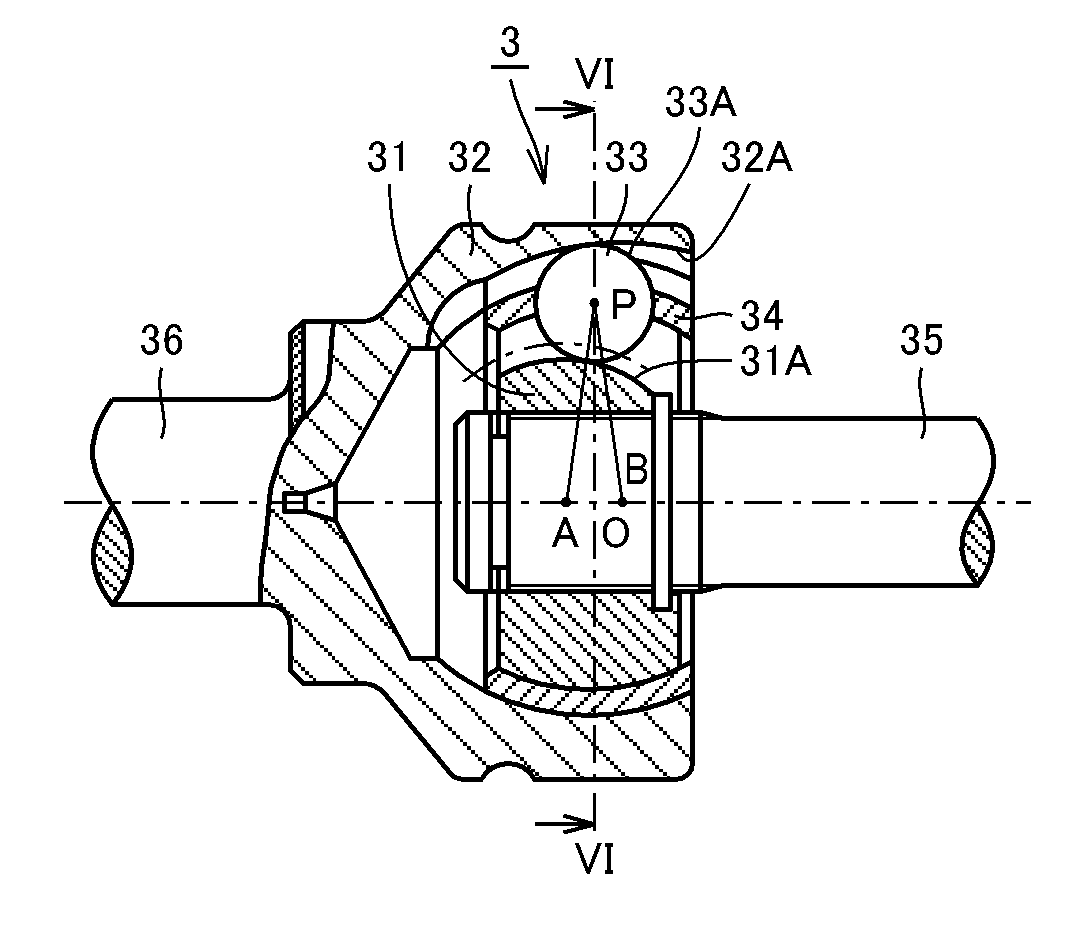

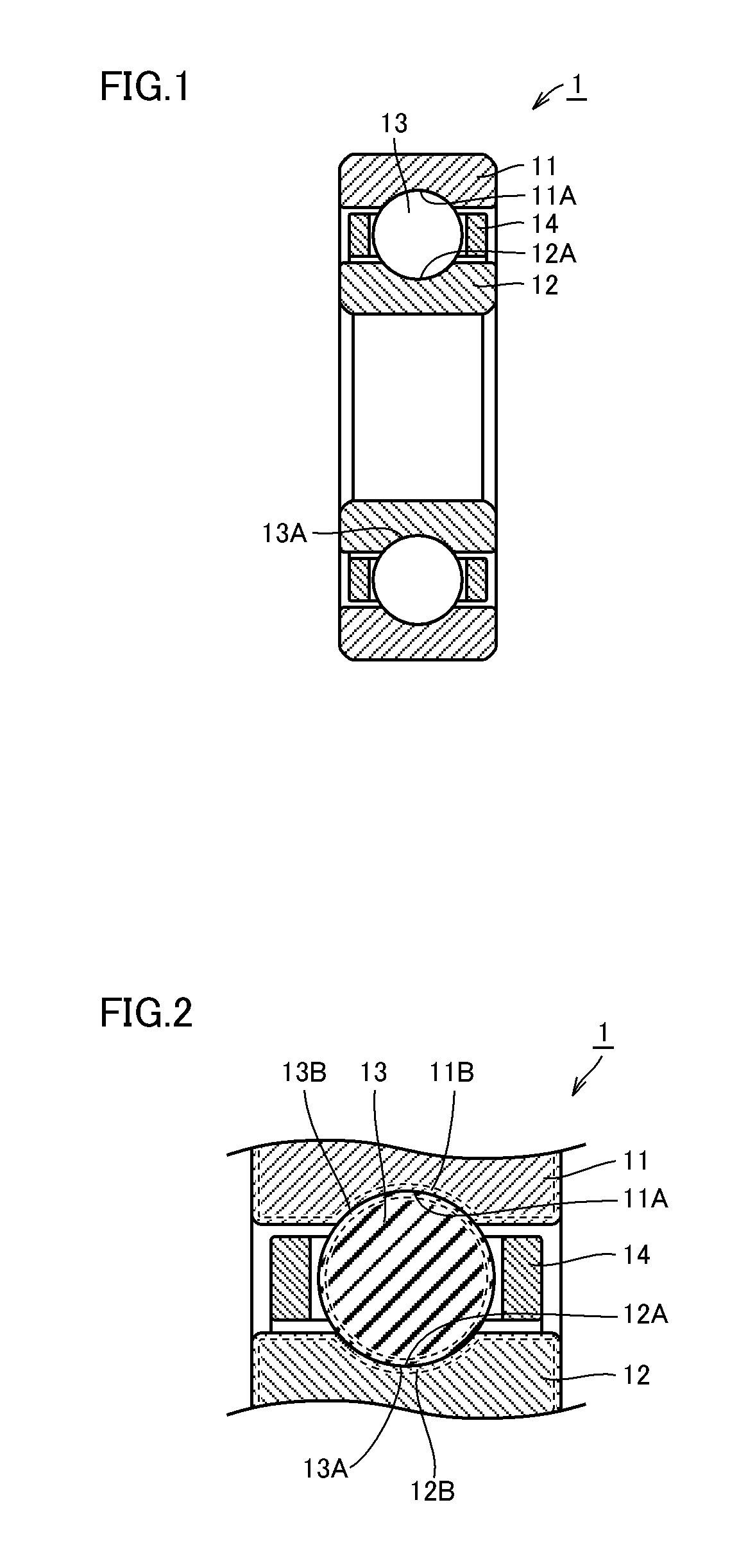

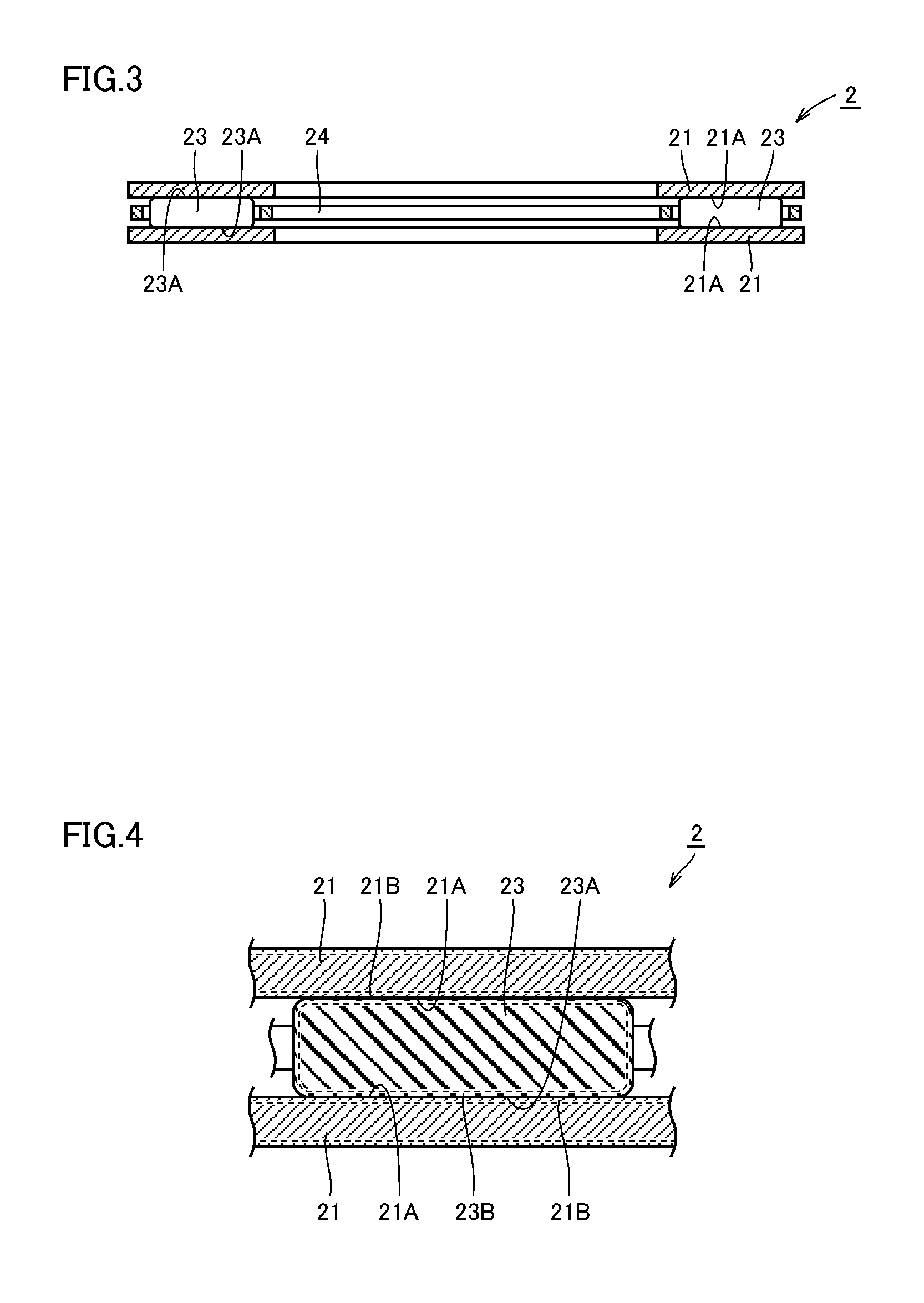

Mechanical component and rolling bearing

ActiveUS20120014635A1Reduce hardnessSolve the lack of resistanceClutchesYielding couplingBall bearingMechanical components

An outer ring, an inner ring and a ball serving as mechanical components configuring a deep groove ball bearing are formed of steel containing at least 0.77 mass % and not more than 0.85 mass % of carbon, at least 0.01 mass % and not more than 0.25 mass % of silicon, at least 0.01 mass % and not more than 0.35 mass % of manganese, at least 0.01 mass % and not more than 0.15 mass % of nickel, at least 3.75 mass % and not more than 4.25 mass % of chromium, at least 4 mass % and not more than 4.5 mass % of molybdenum and at least 0.9 mass % and not more than 1.1 mass % of vanadium with a remainder consisting of iron and impurity, and have raceway / rolling contact surfaces, the surface being included in a region having a nitrogen enriched layer having a nitrogen concentration of at least 0.05 mass %, the nitrogen enriched layer having a carbon concentration and the nitrogen concentration, in total, of at least 0.82 mass % and not more than 1.9 mass %.

Owner:NTN CORP

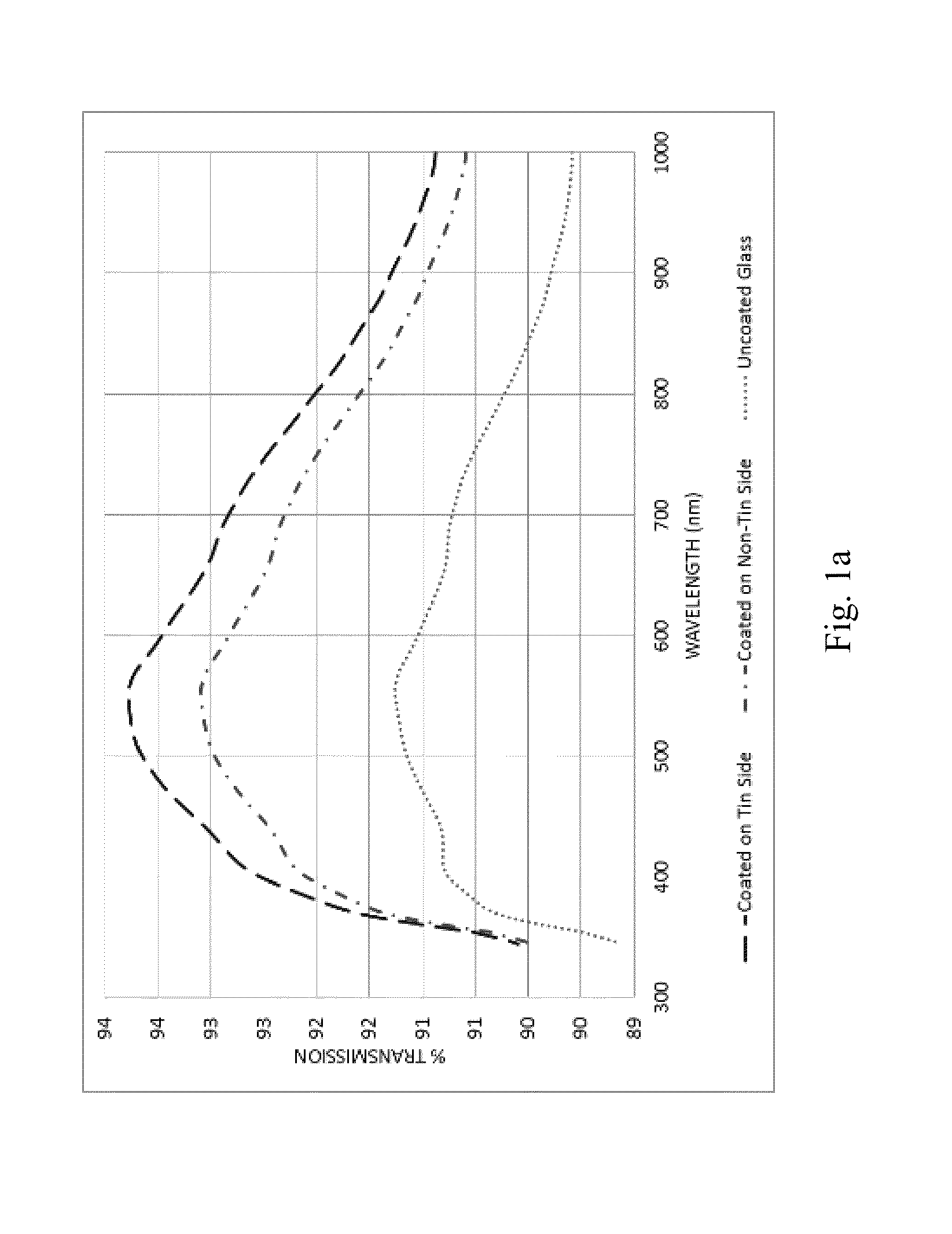

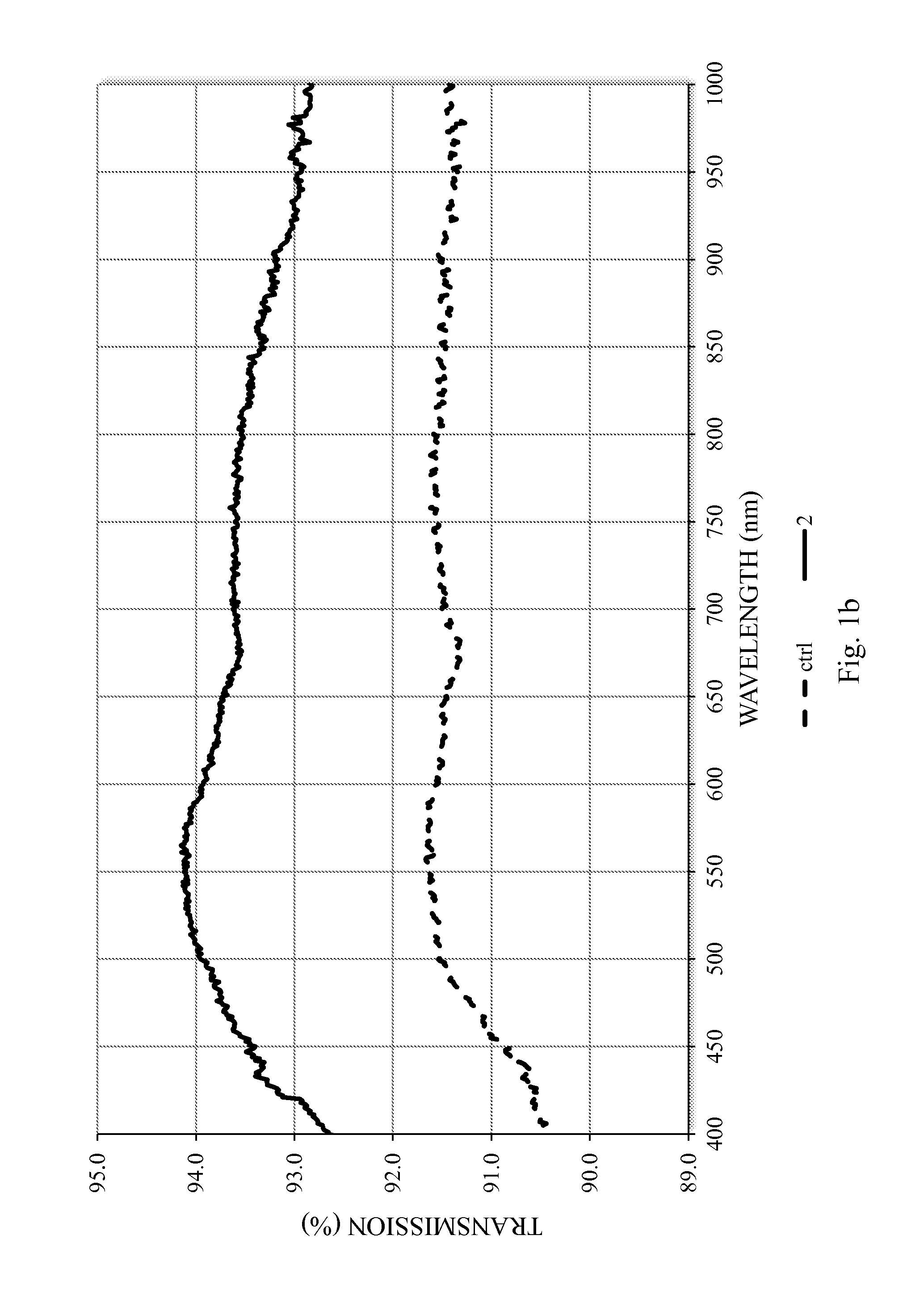

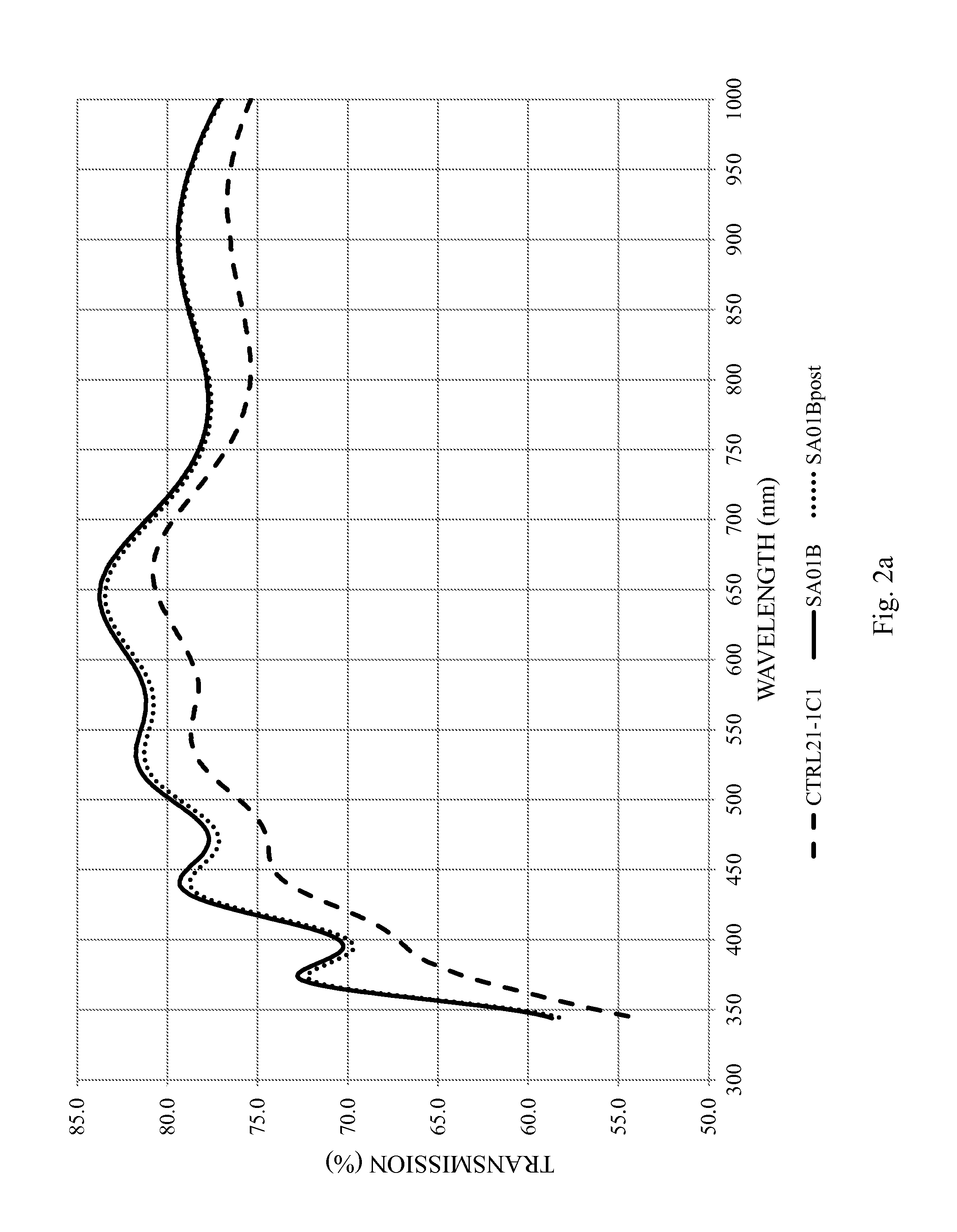

Optical enhancing durable Anti-reflective coating

ActiveUS20160083620A1High light transmittanceReduce light reflectionFilm/foil adhesivesPretreated surfacesAnti-reflective coatingRefractive index

Disclosed herein are polysilsesquioxane based anti-reflective coating (ARC) compositions, methods of preparation, and methods of deposition on a substrate. In embodiments, the polysilsesquioxane of this disclosure is prepared in a two-step process of acid catalyzed hydrolysis of organoalkoxysilane followed by addition of tetralkoxysilane that generates silicone polymers with >40 mol % silanol based on Si-NMR. These high silanol siloxane polymers are stable and have a long shelf-life in the polar organic solvents at room temperature. Also disclosed are low refractive index ARC made from these compositions with and without additives such as porogens, templates, Si—OH condensation catalyst and / or nano-fillers. Also disclosed are methods and apparatus for applying coatings to flat substrates including substrate pre-treatment processes, coating processes including flow coating and roll coating, and coating curing processes including skin-curing using hot-air knives. Also disclosed are coating compositions and formulations for highly tunable, durable, highly abrasion-resistant functionalized anti-reflective coatings.

Owner:FIRST SOLAR INC (US)

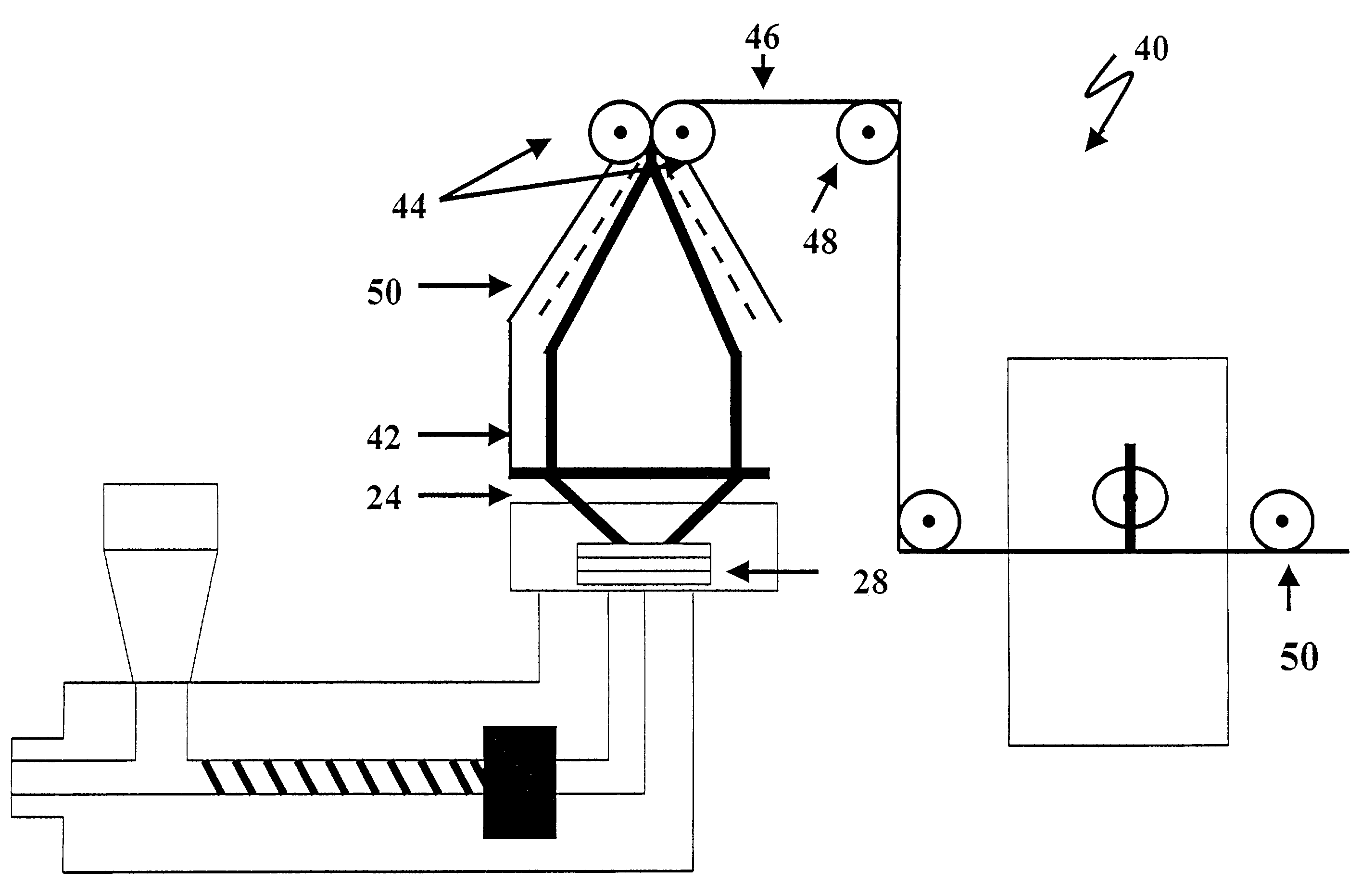

Method of manufacturing foamed polyethylene films and related products

InactiveUS7341683B2Avoid lack of toughnessHigh strengthEnvelopes/bags making machineryBag making operationsThermoplasticPolymer science

Owner:VINXI

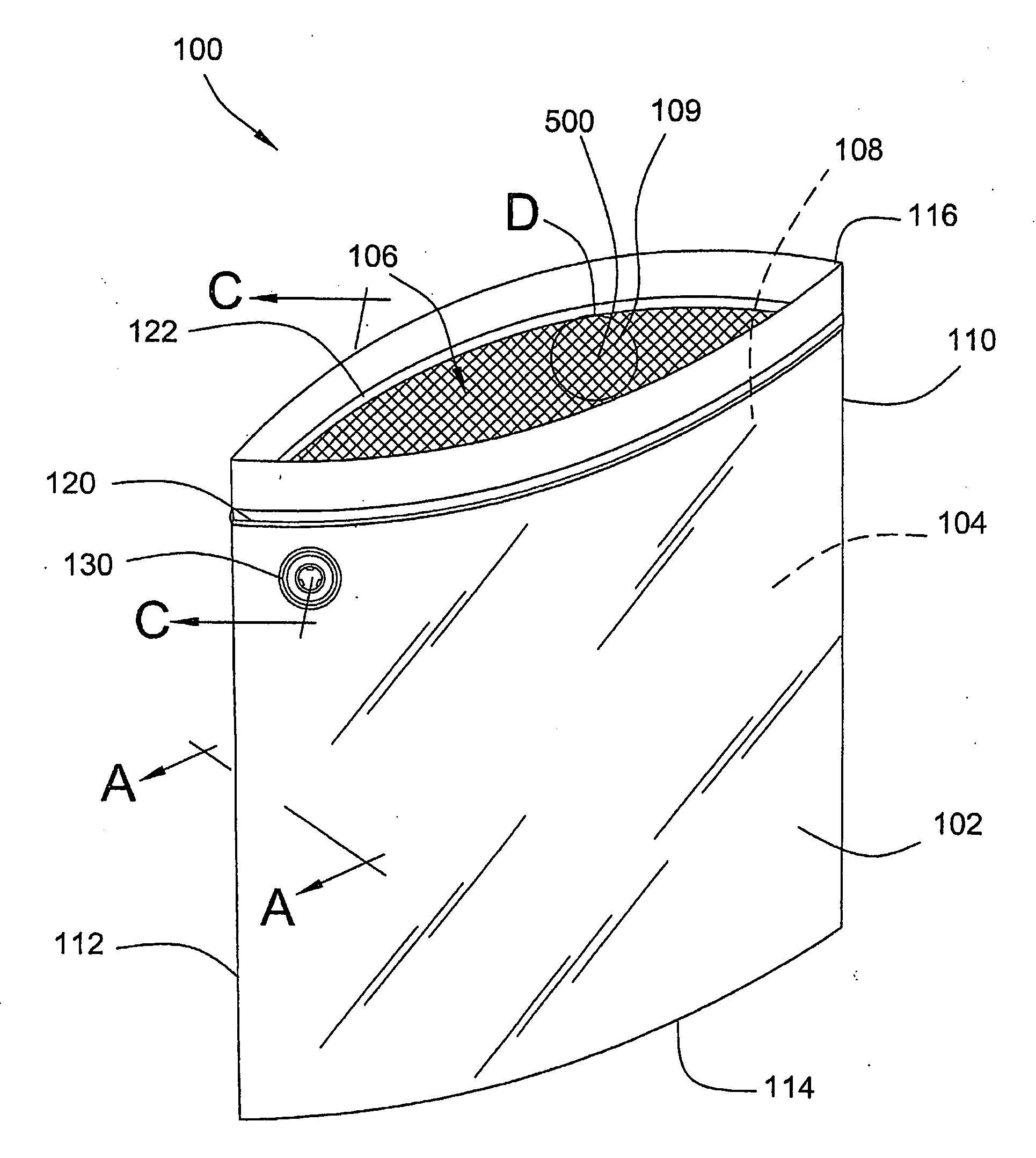

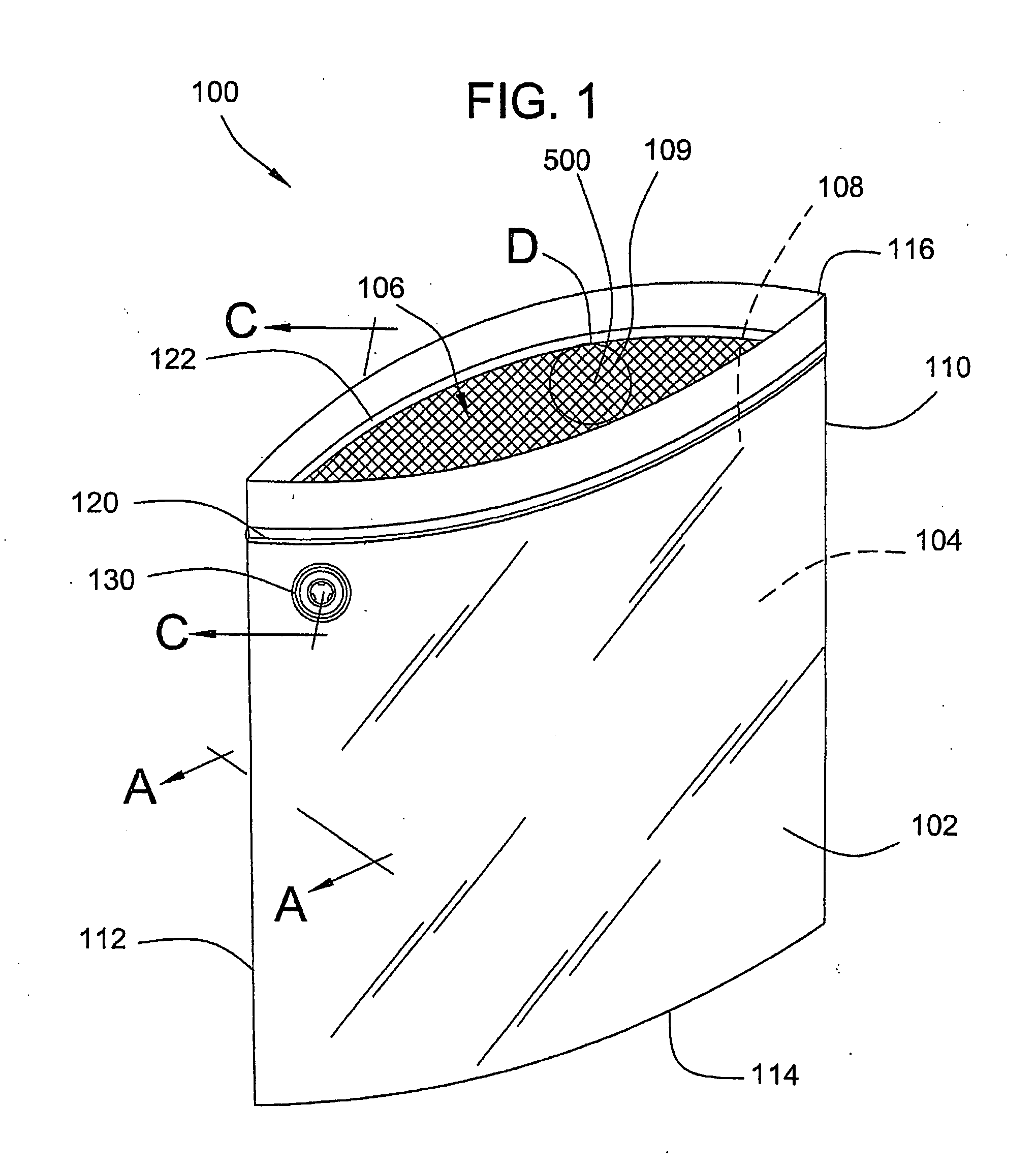

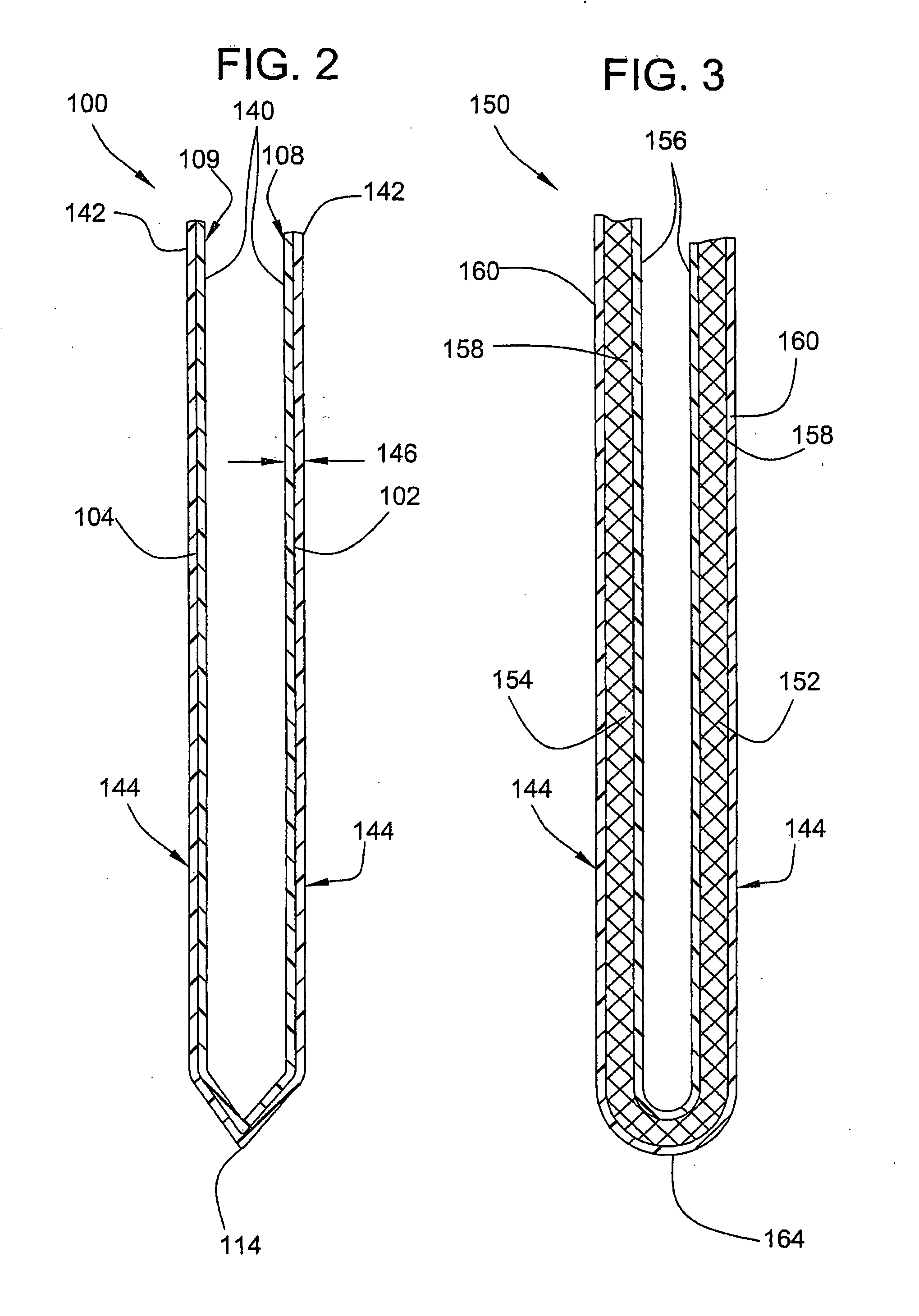

Vacuum storage bag

InactiveUS20100014789A1Improve manufacturabilitySufficient toughnessBagsSacksHigh-density polyethyleneLow-density polyethylene

A vacuum storage bag providing an interior volume for storing food items in an evacuated condition has air flexible sidewalls made of a gas permeable material. The gas permeable sidewalls can be made of multiple layers including a heat sealing innermost layer and a relatively stronger, outwardly disposed gas permeable layer. The heat sealing layer can be low density polyethylene to facilitate forming of the bag with heat seals and the stronger gas permeable layer can be high density polyethylene to provide the bag with sufficient strength and toughness. In various embodiments, the storage bag can include interlocking closure strips for releasably closing an opening, a one-way vacuum valve for evacuating the interior volume, and a textured portion along one sidewall to facilitate evacuation.

Owner:BINGER SCOTT +1

Steel pipe for an airbag system and a method for its manufacture

ActiveUS20060130945A1High strengthImprove toughnessPedestrian/occupant safety arrangementFurnace typesAirbagQuenching

A high strength steel pipe for an airbag system has a steel composition comprising C: 0.05-0.20%, Si: 0.1-1.0%, P: at most 0.025%, S: at most 0.010%, Cr: 0.05-1.0%, Al: at most 0.10%, at least one of Ti and Mn satisfying (1) Ti≦0.02% and (2) 0.4%≦Mn+40Ti≦1.2%, and a remainder of Fe. The composition may further include one or more of (i) at least one of Mo: 0.05-0.50%, Ni: 0.05-1.5%, V: 0.01-0.2%, and B: 0.0003-0.005%, (ii) at least one of Cu: 0.05-0.5% and Nb: 0.003-0.1%, and (iii) at least one of Ca: 0.0003-0.01%, Mg: 0.0003-0.01%, and REM: 0.0003-0.01%. The steel pipe can be manufactured by forming a pipe from the above-described steel composition to obtain prescribed dimensions, heating to at least the Ac1 transformation point and quenching, and then tempering at the Ac1 transformation point or below.

Owner:NIPPON STEEL CORP

Mechanical component and rolling bearing

ActiveUS20100239205A1High hardnessIncreased durabilityClutchesYielding couplingBall bearingManganese

An outer ring, an inner ring and a ball serving as mechanical components configuring a deep groove ball bearing are formed of steel containing at least 0.77 mass % and not more than 0.85 mass % of carbon, at least 0.01 mass % and not more than 0.25 mass % of silicon, at least 0.01 mass % and not more than 0.35 mass % of manganese, at least 0.01 mass % and not more than 0.15 mass % of nickel, at least 3.75 mass % and not more than 4.25 mass % of chromium, at least 4 mass % and not more than 4.5 mass % of molybdenum and at least 0.9 mass % and not more than 1.1 mass % of vanadium with a remainder consisting of iron and impurity, and have raceway / rolling contact surfaces, the surface being included in a region having a nitrogen enriched layer having a nitrogen concentration of at least 0.05 mass %, the nitrogen enriched layer having a carbon concentration and the nitrogen concentration, in total, of at least 0.82 mass % and not more than 1.9 mass %.

Owner:NTN CORP

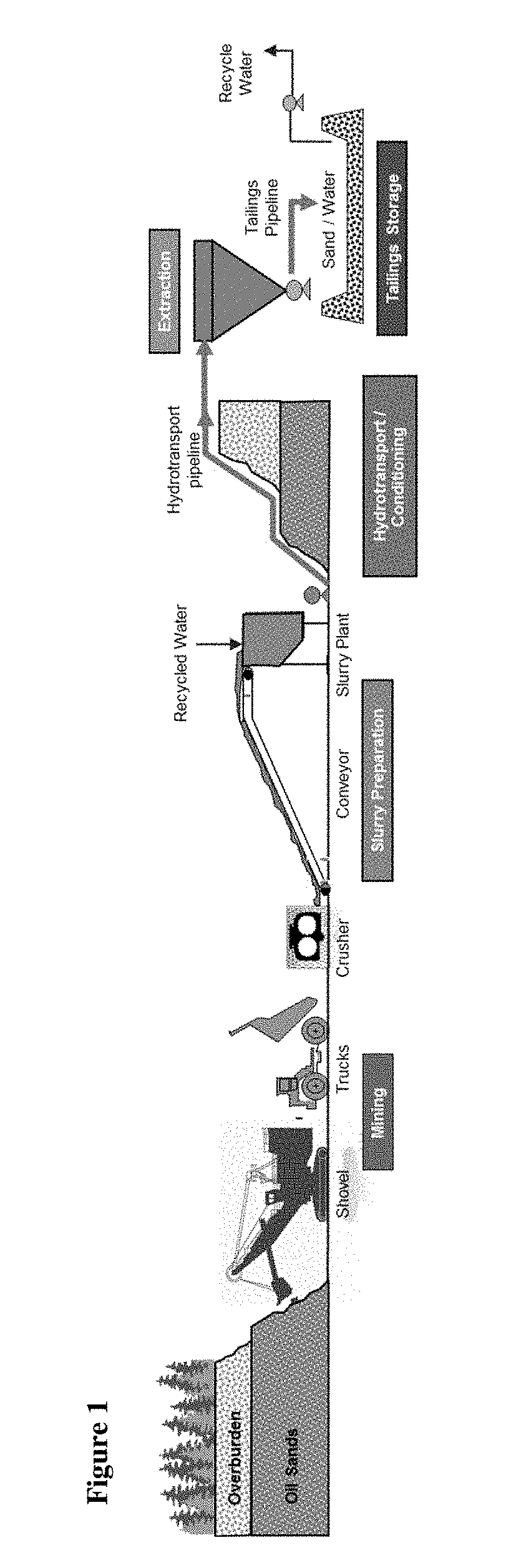

High manganese steel pipe with step-out weld zone erosion-corrosion resistance and method of making the same

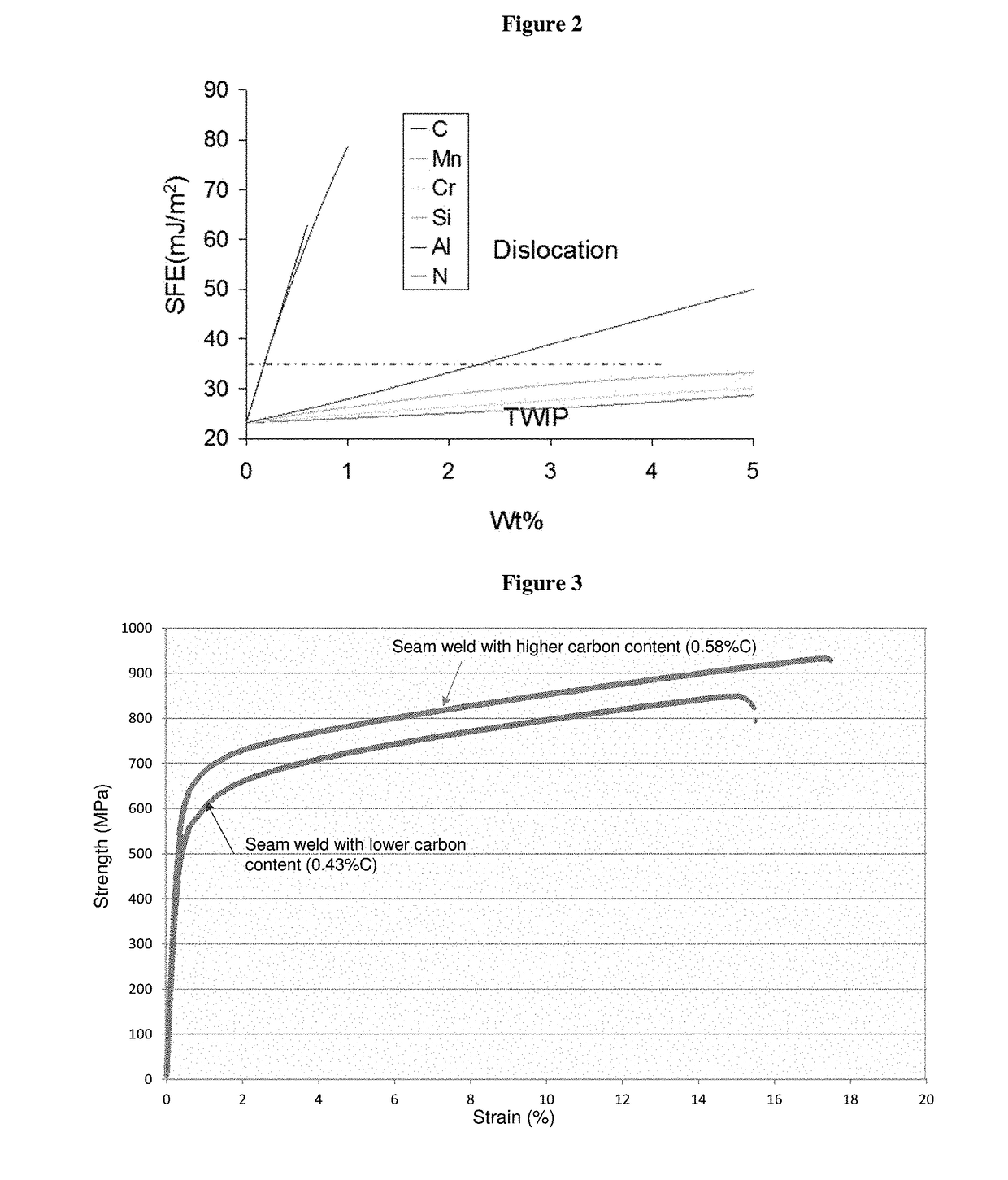

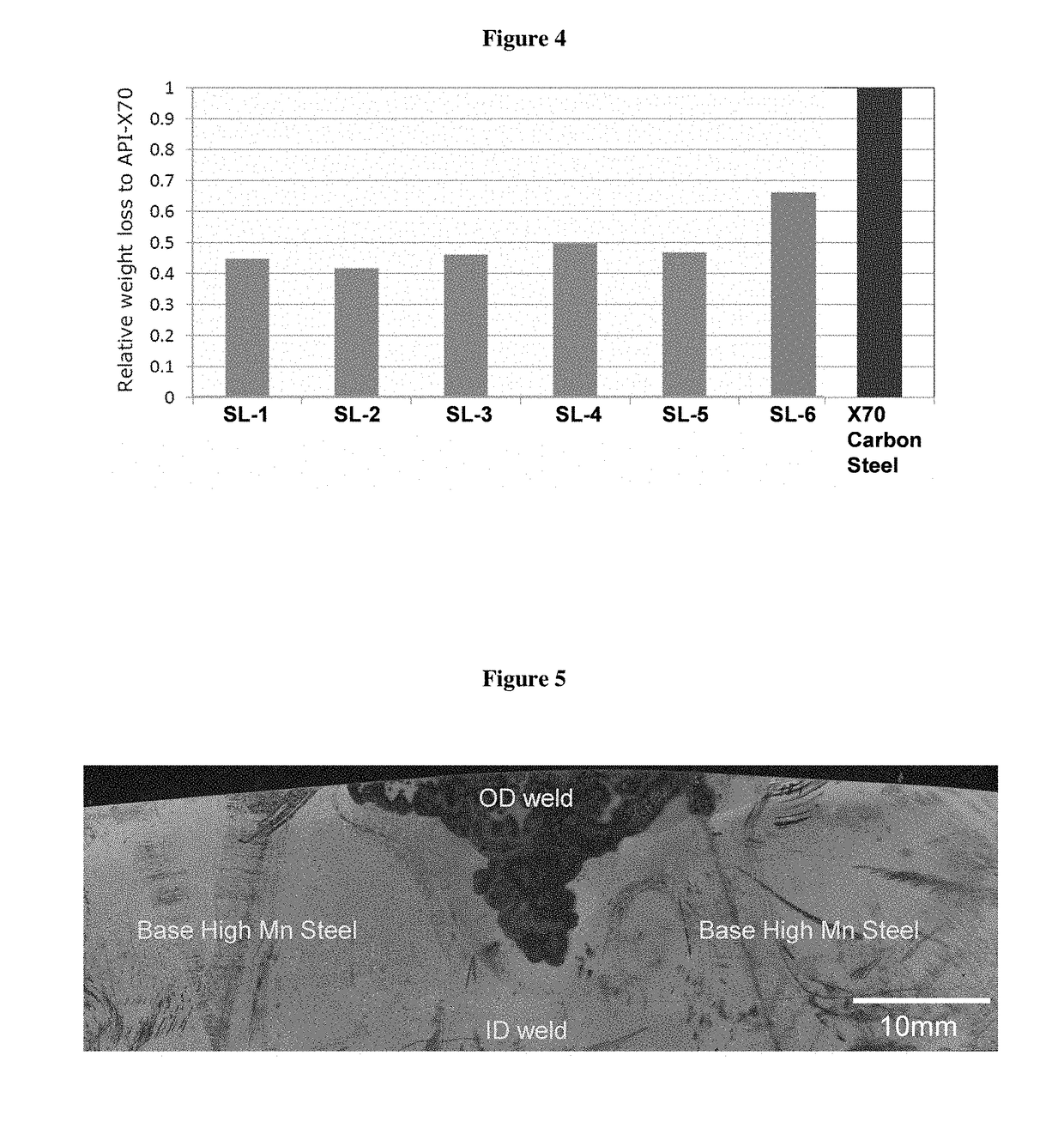

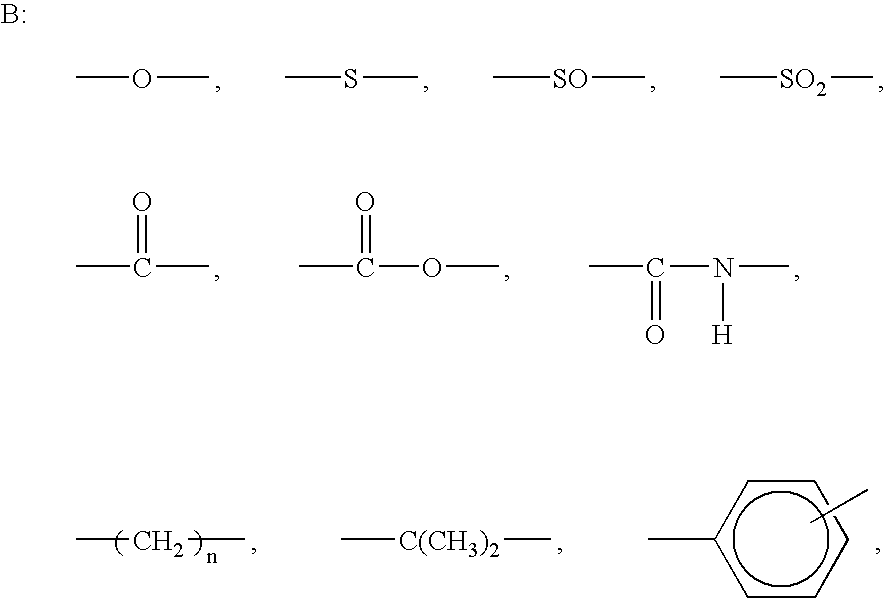

ActiveUS20170312861A1Adequate strengthAdequate toughnessArc welding apparatusWelding/cutting media/materialsCorrosion resistantErosion corrosion

Improved steel welds, article for making the same, and methods of making the same are provided. The present disclosure provides advantageous erosion, corrosion and / or cracking resistant weld metal. More particularly, the present disclosure provides high manganese (Mn) weld metal compositions having enhanced erosion, corrosion and / or cracking resistance, articles for the production of the high manganese weld metal compositions having enhanced erosion, corrosion, and / or cracking resistance, and methods for fabricating high manganese weld metal compositions having enhanced erosion, corrosion and / or cracking resistance.

Owner:POSCO

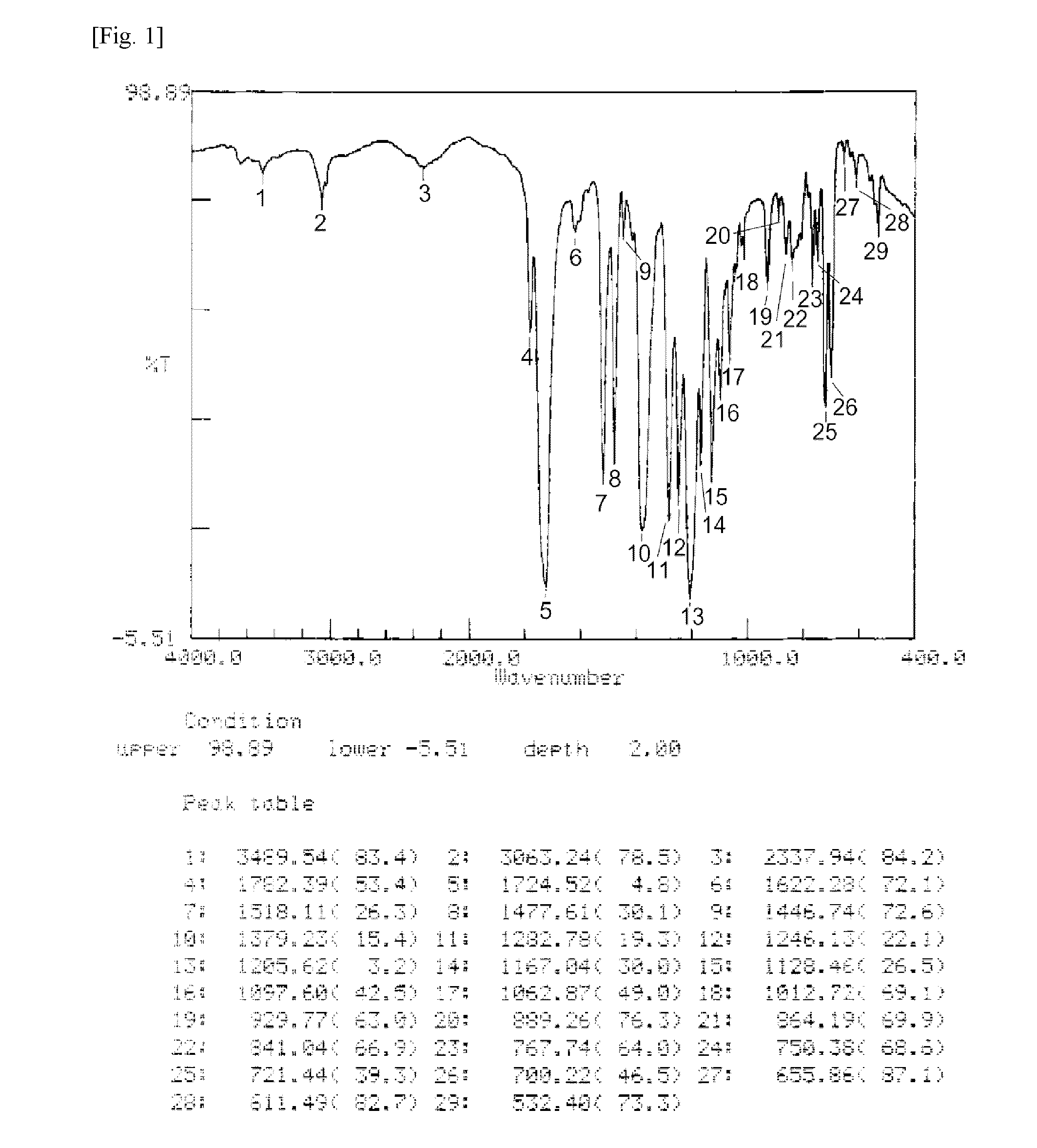

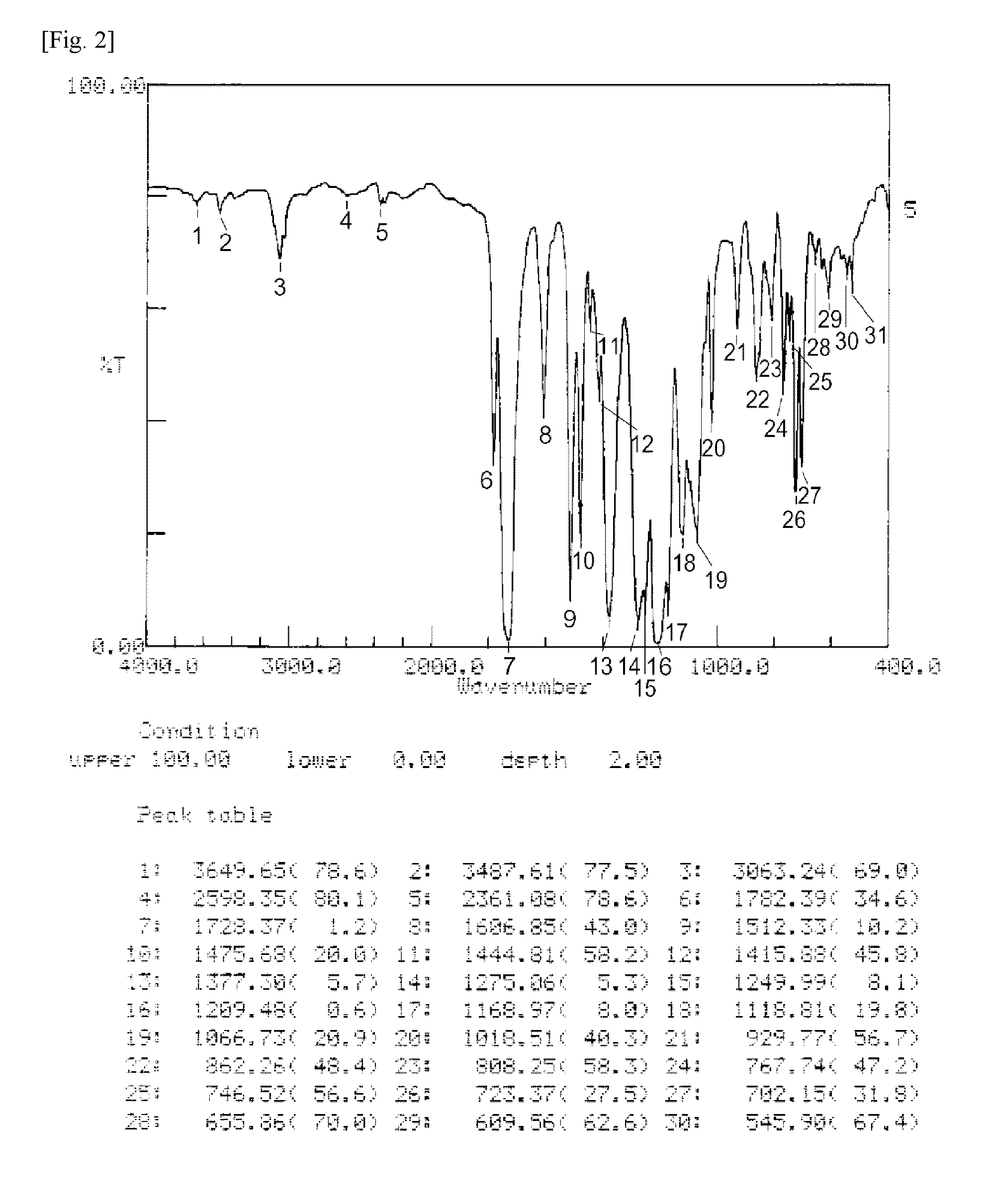

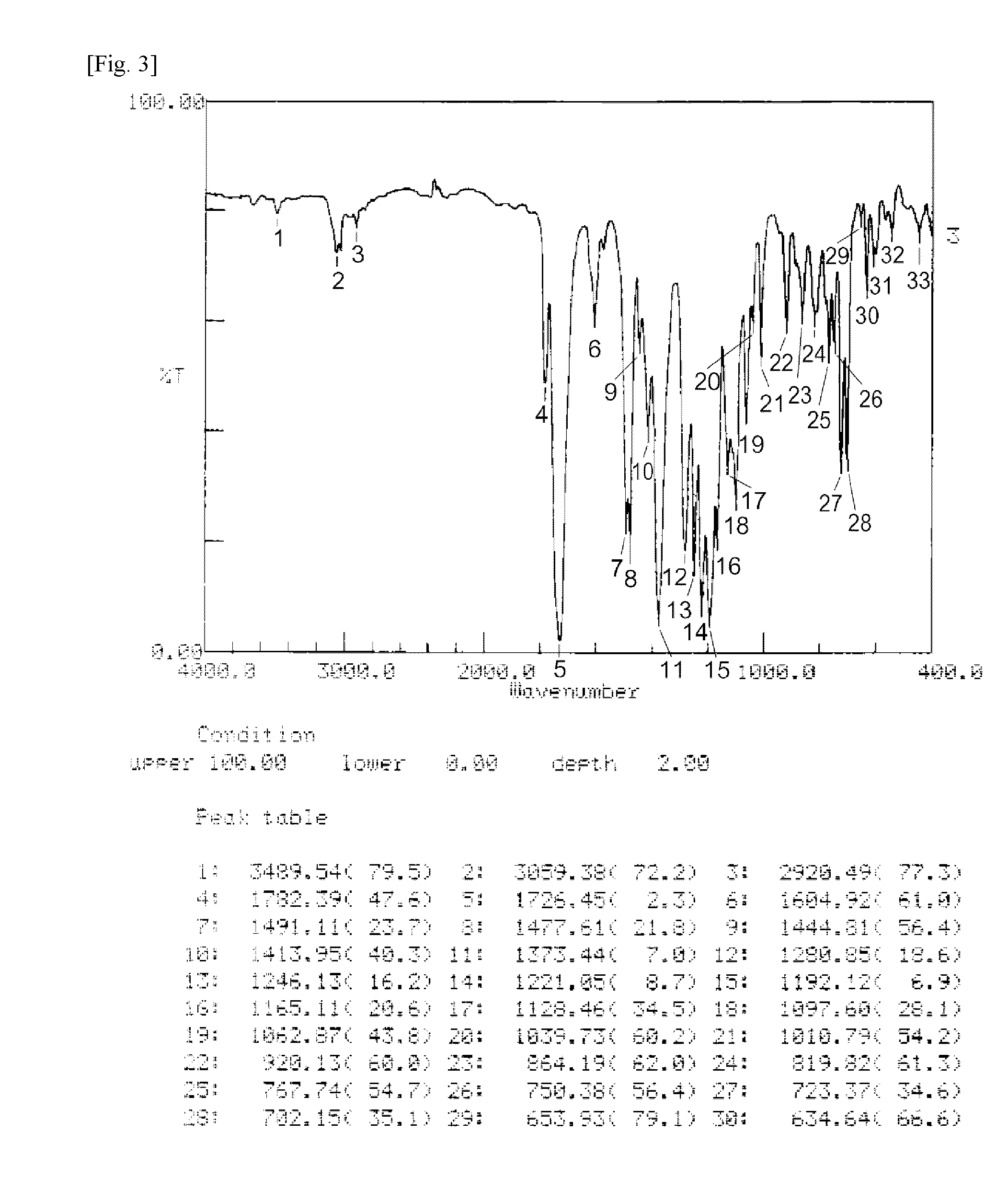

Polyimide film and process for producing the same

InactiveUS7247367B2Avoid lack of toughnessSynthetic resin layered productsSpecial tyresImidePolyamic acid

The polyimide film of the present invention is produced in the following manner: polyamic acid made of a combination of a specific acid anhydride constituent and a specific diamine constituent are heated under a low-pressure circumstance for heat imidation, and the obtained imide is dissolved again in a solvent to be polyimide solution, then the polyimide solution is formed to be a film. In this manner, it is possible to provide a polyimide film essentially transparent and colorless, and has sufficient toughness to prevent occurrences of a crack or a break when the film is folded and creased by hand.

Owner:KANEKA CORP

Low specific gravity steel for forging use excellent in machineability

Steel for forging having high strength and superior machinability due to controlled cooling immediately after shaping by hot forging followed by tempering and having a lower specific gravity than ordinary steel for forging use, the steel containing C: 0.05 to 0.50%, Si: 0.01 to 1.50%, Mn: 3.0 to 7.0%, P: 0.001 to 0.050%, S: 0.020 to 0.200%, Al: 3.0 to 6.0%, Cr: 0.01 to 1.00%, and N: 0.0040 to 0.0200% and having a balance of Fe and unavoidable impurities.

Owner:NIPPON STEEL CORP

Ester group-containing tetracarboxylic acid dianhydride, polyester polyimide precursor, polyesterimide, and methods for producing same

ActiveUS20120029164A1Good physical propertiesHigh polymerization reaction propertyOrganic chemistryPrinted circuit aspectsPolyesterPhenyl group

Disclosed is a polyesterimide having a repeating unit expressed by the formula below, and also provides the manufacturing methods thereof:wherein R represents a phenyl group, R1 represents an alkyl group with 1 to 6 carbon atoms or alkoxy group with 1 to 6 carbon atoms, n each independently takes a value of 0 to 4, a each independently takes a value of 0 to 4, and m represents an integer of 2 to 4, where not all n's are 0 at the same time and 0≦n+a≦4 is satisfied by each phenylene group, and X is a divalent aromatic group and / or aliphatic group.

Owner:HONSHU CHEM INDAL

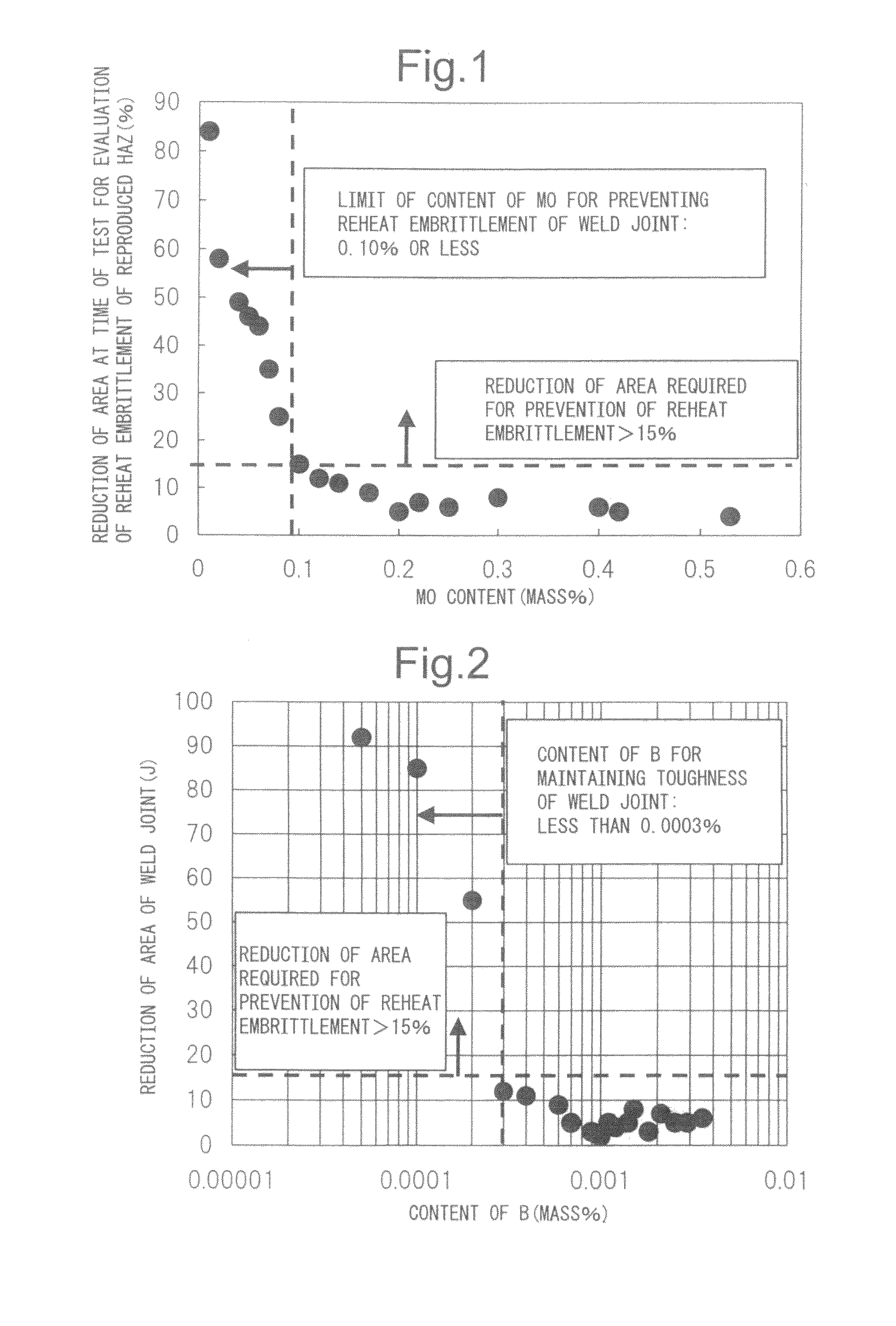

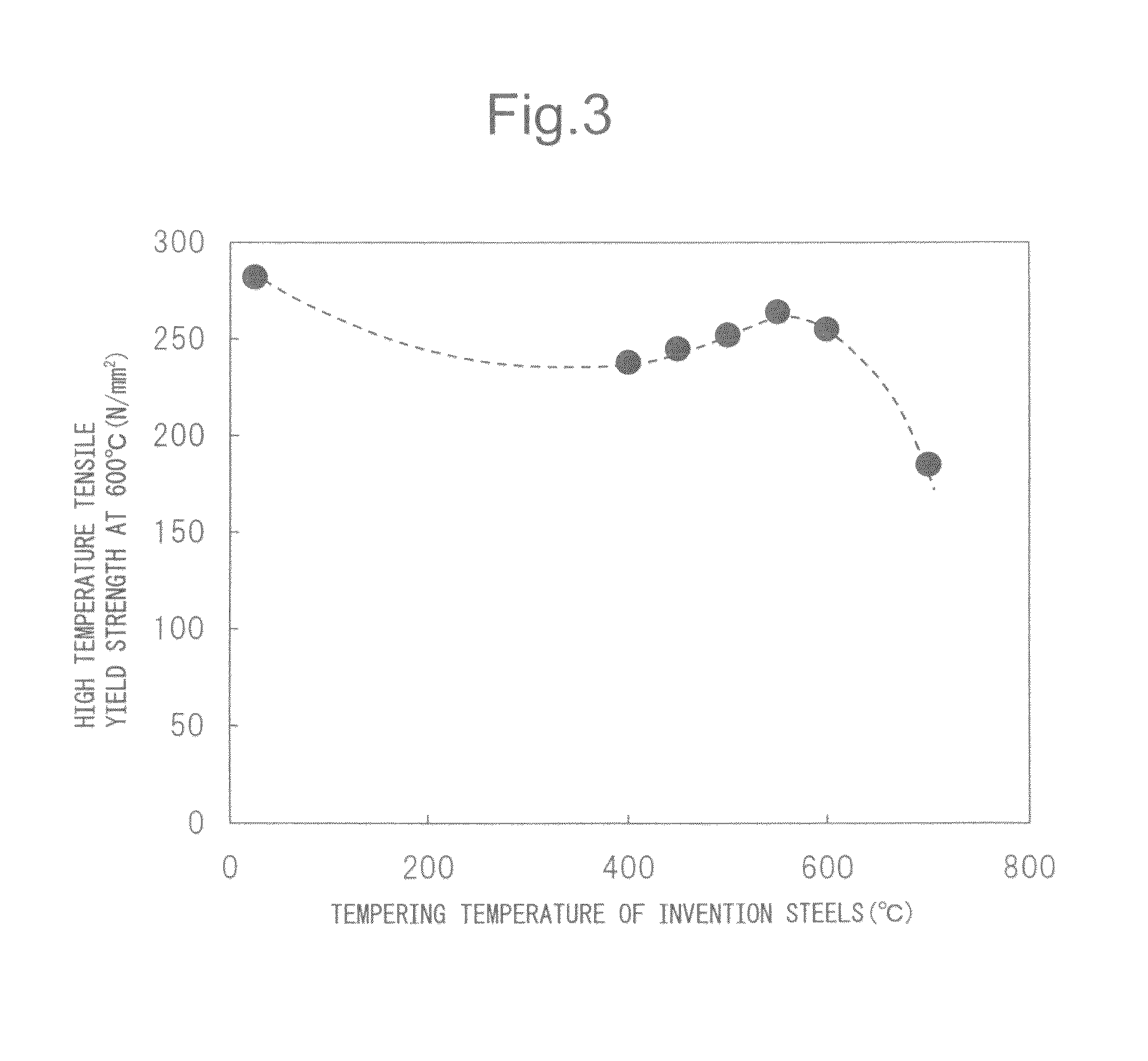

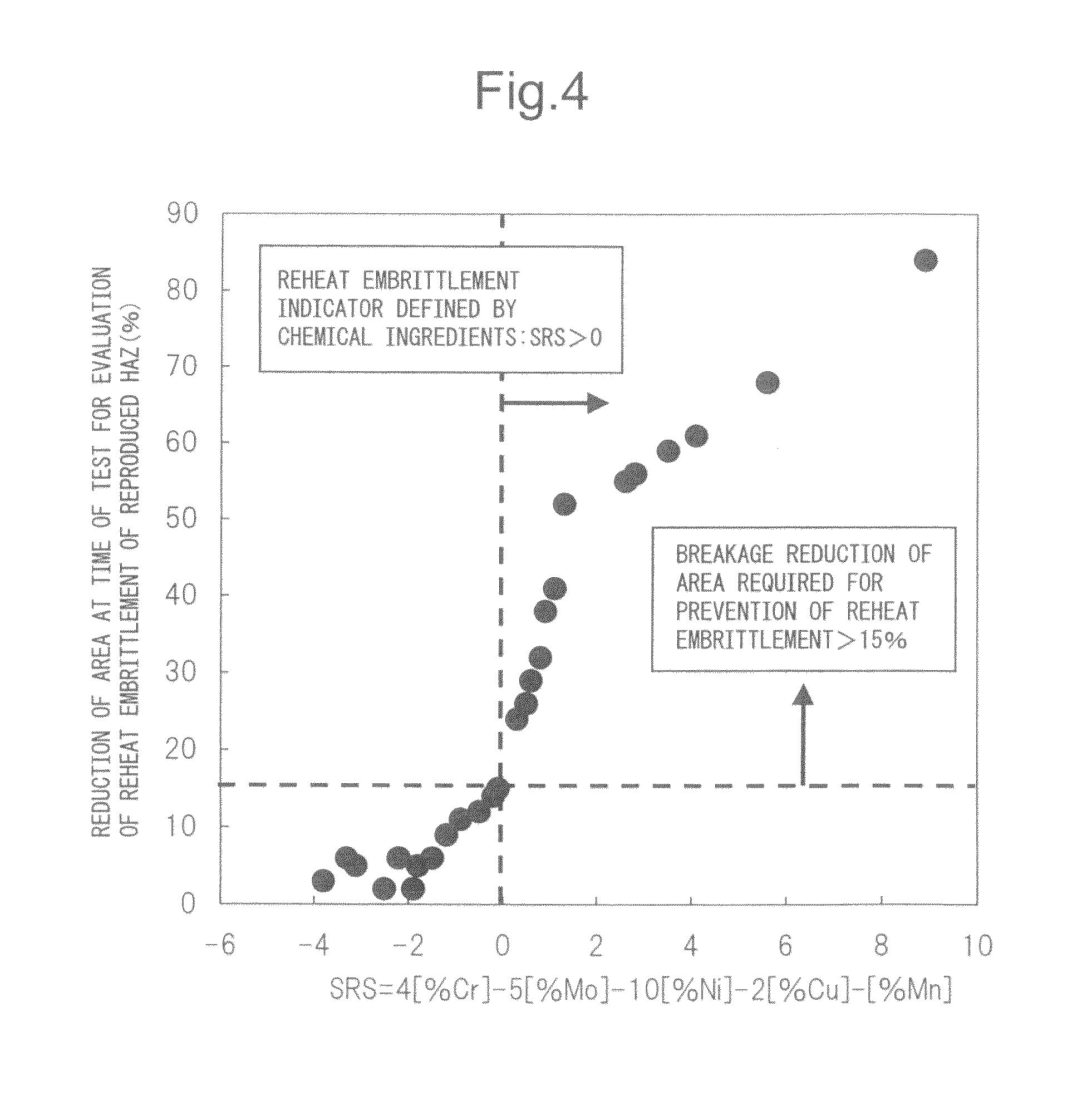

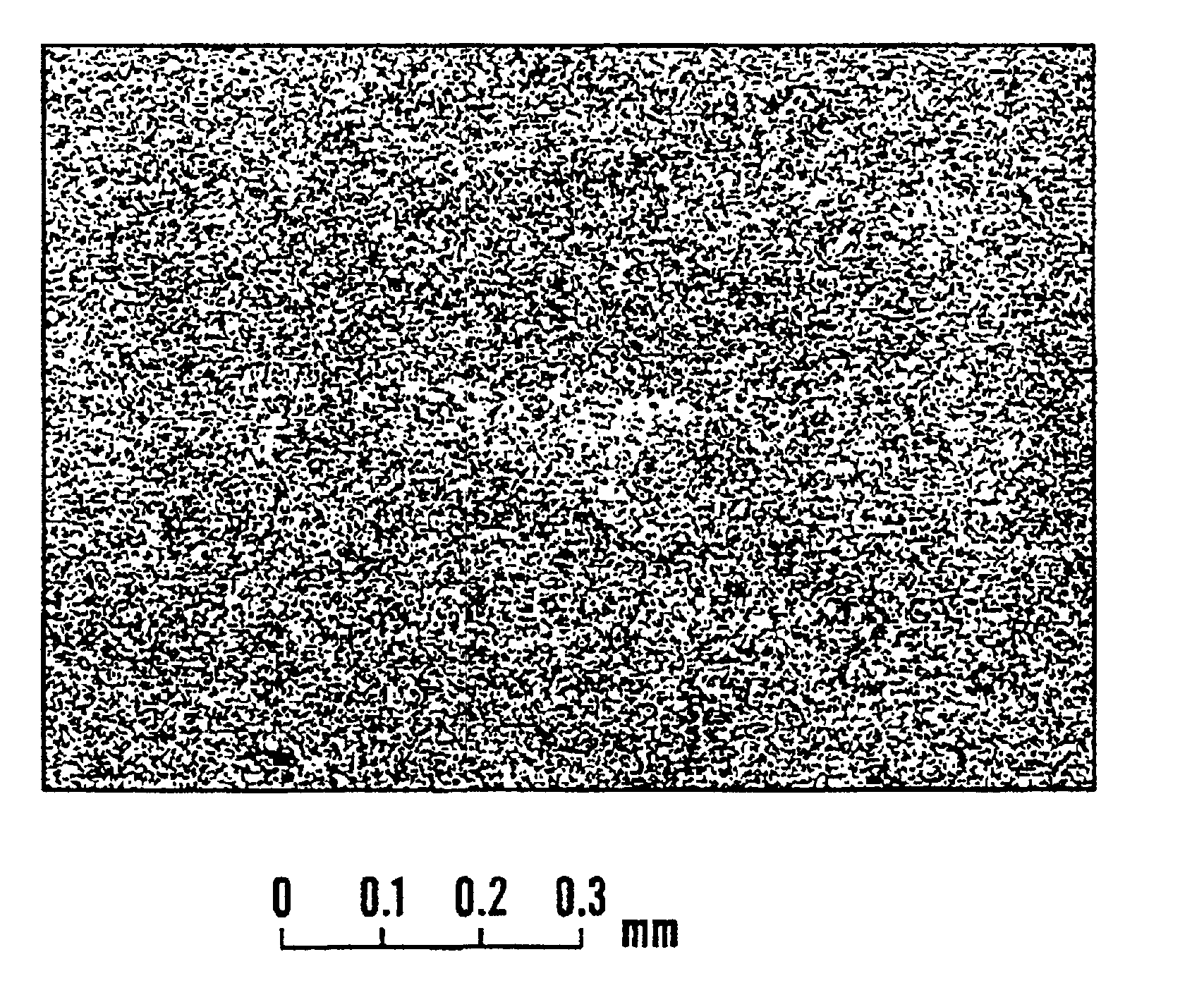

Fire-resistant steel superior in weld joint reheat embrittlement resistance and toughness and method of production of same

InactiveUS8715432B2Avoid lack of toughnessHigh temperature strengthFurnace typesHeat treatment furnacesRoom temperatureToughness

Owner:NIPPON STEEL CORP

Steel cold work tool, its use and manufacturing

InactiveUS6837945B1Avoid lack of toughnessImprove wear resistanceFurnace typesRollsChemical compositionCarbide

The invention concerns a steel article, which consists of an alloy having a chemical composition, which contains in weight-%: 1.2 to 2.5 C; 0.8 to 2.0 Si, which partly can be replaced by aluminium, which may exist in an amount of max 1.0%; 0.1 to 1.5 Mn; 0.5 to 1.5 Cr; 1.2 to 5.0 (V+Nb / 2), however max 1.0 Nb; balance iron and impurities in normal amounts, and having a microstructure which contains 4 to 12 volume-% of MC-carbides. The steel article can be used for manufacturing of cold-work tools, particularly pilger rolls for cold rolling of tubes. The invention also relates to a method of manufacturing the article.

Owner:UDDEHOLM TOOLING

Transparent plastic material

The invention discloses a transparent plastic material. The transparent plastic material is prepared from, by weight, 20-30 parts of ABS plastic, 10-20 parts of phenolic resin, 30-35 parts of PE, 5-15 parts of polyether sulfone resin and 5-10 parts of an additive. The transparent plastic material has higher toughness under the condition of high transparency, the problem of the insufficient toughness of an existing transparent plastic product is avoided, the quality of the plastic product is greatly improved, and the service life is also greatly prolonged. In addition, the plastic product further has good chemical resistance and flame retardant performance, and the comprehensive performance of the product is improved obviously.

Owner:林建文

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com