Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Solve the lack of ductility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

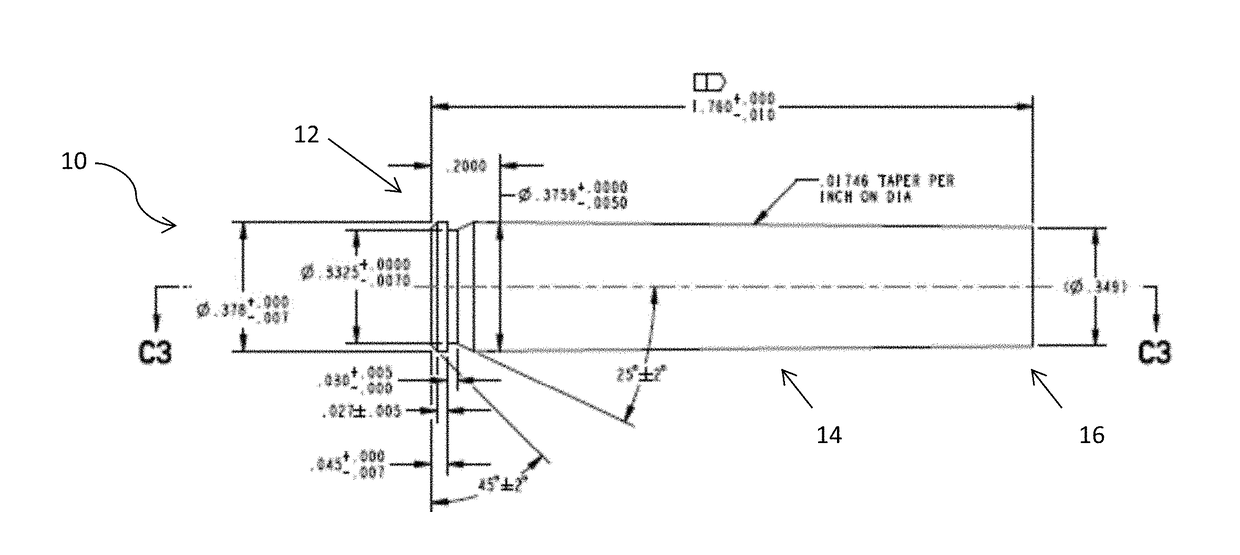

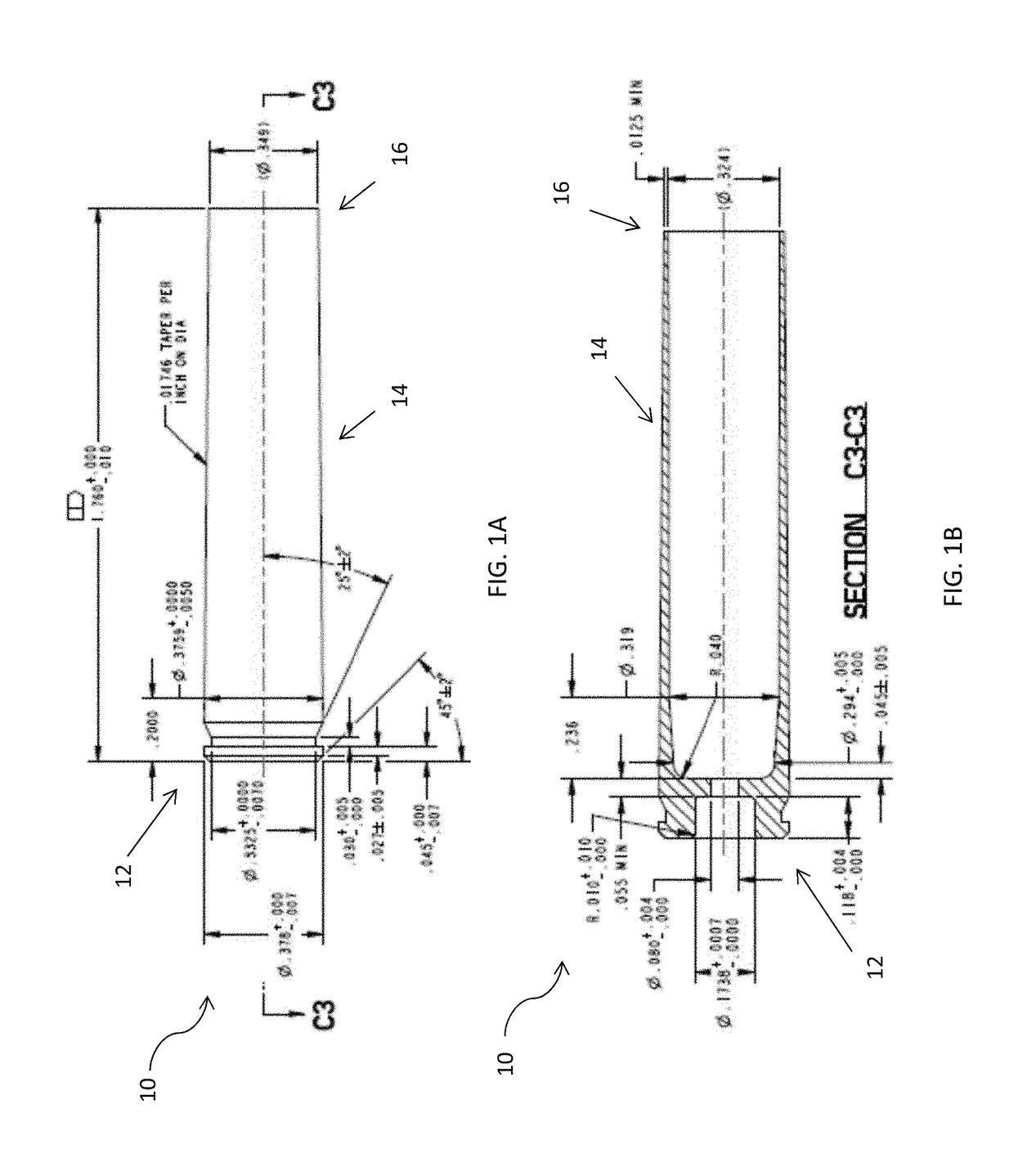

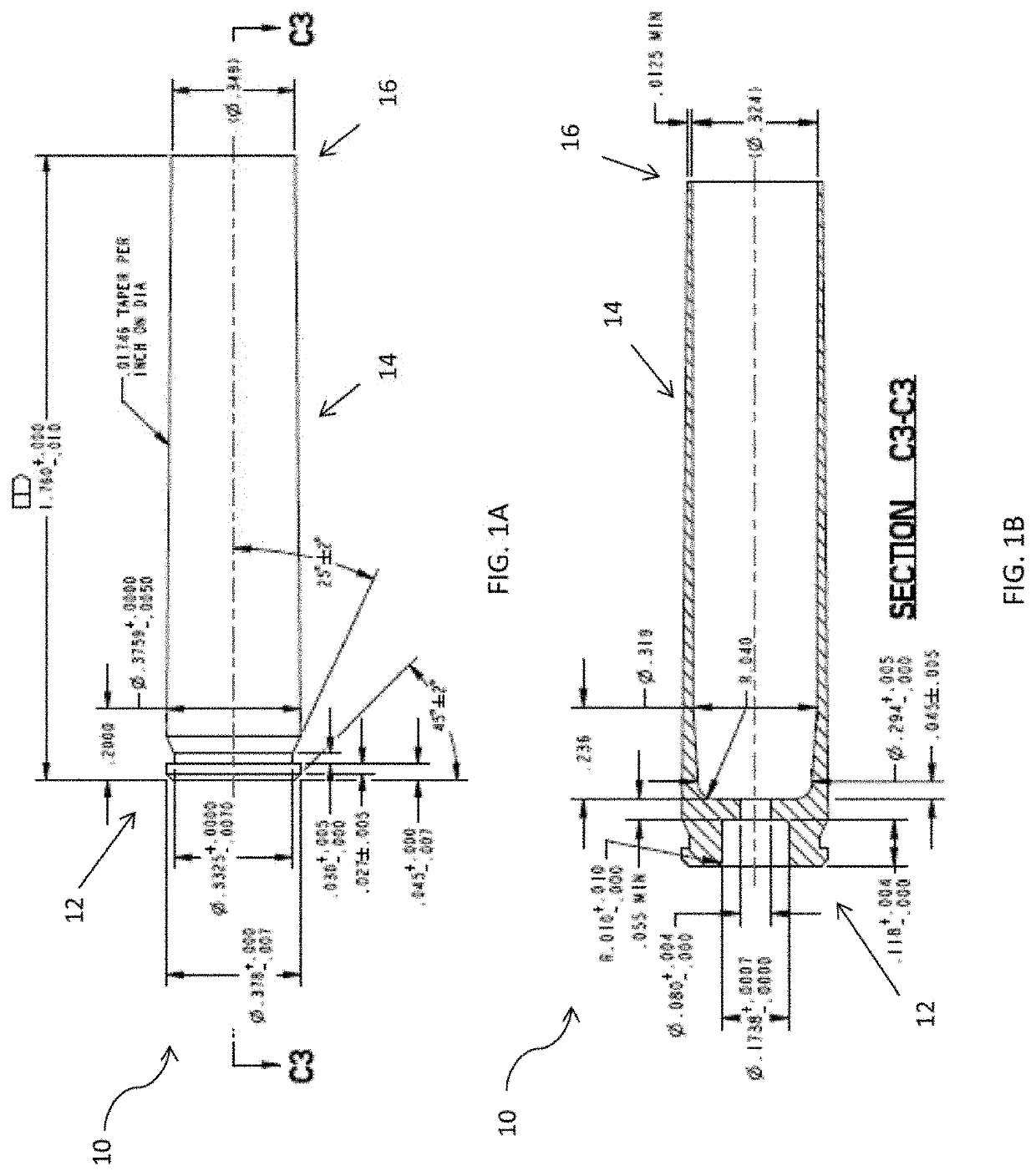

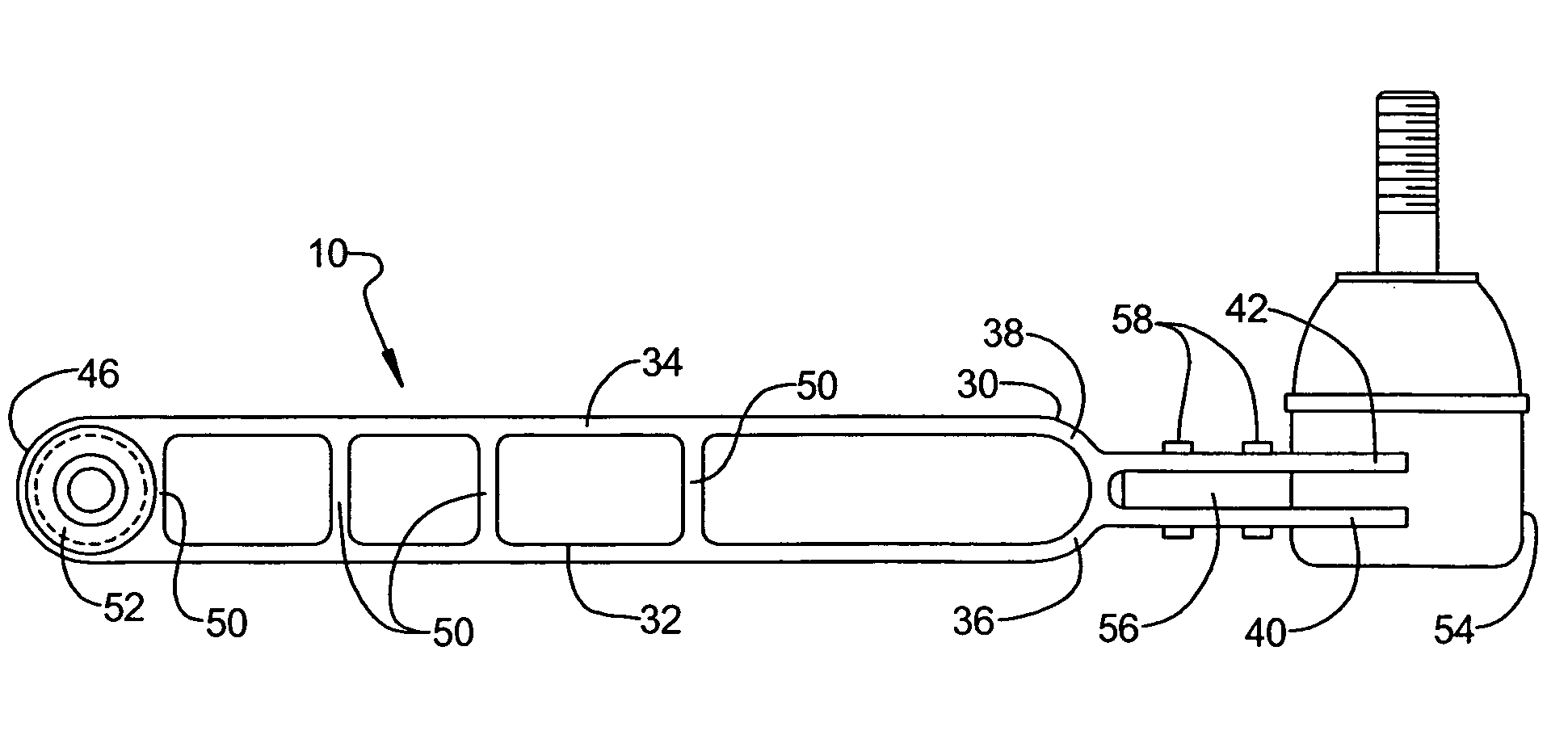

Metal Injection Molded Cased Telescoped Ammunition

ActiveUS20180066925A1Promote generationLight weightTransportation and packagingMetal-working apparatusMetal alloySlug

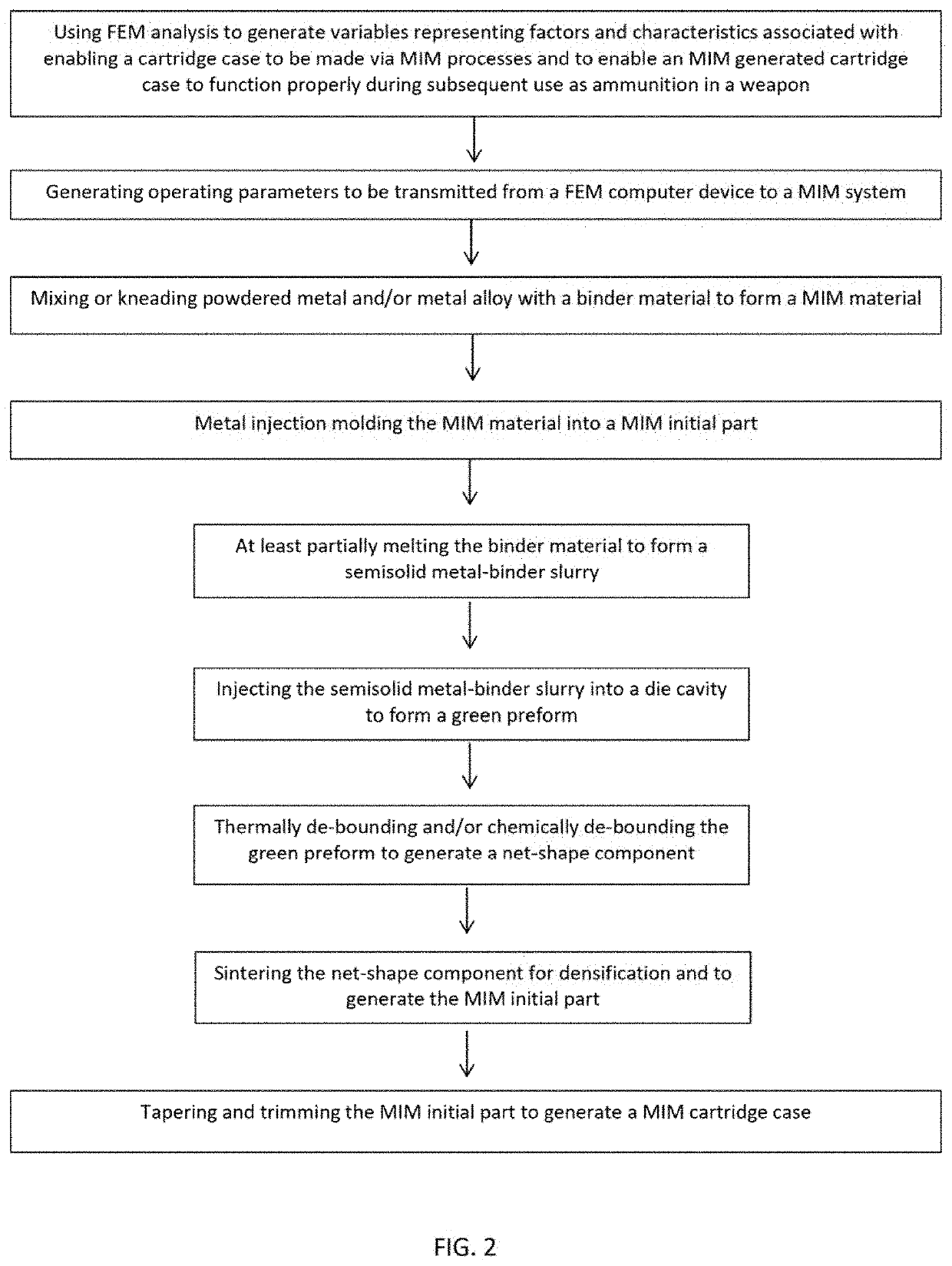

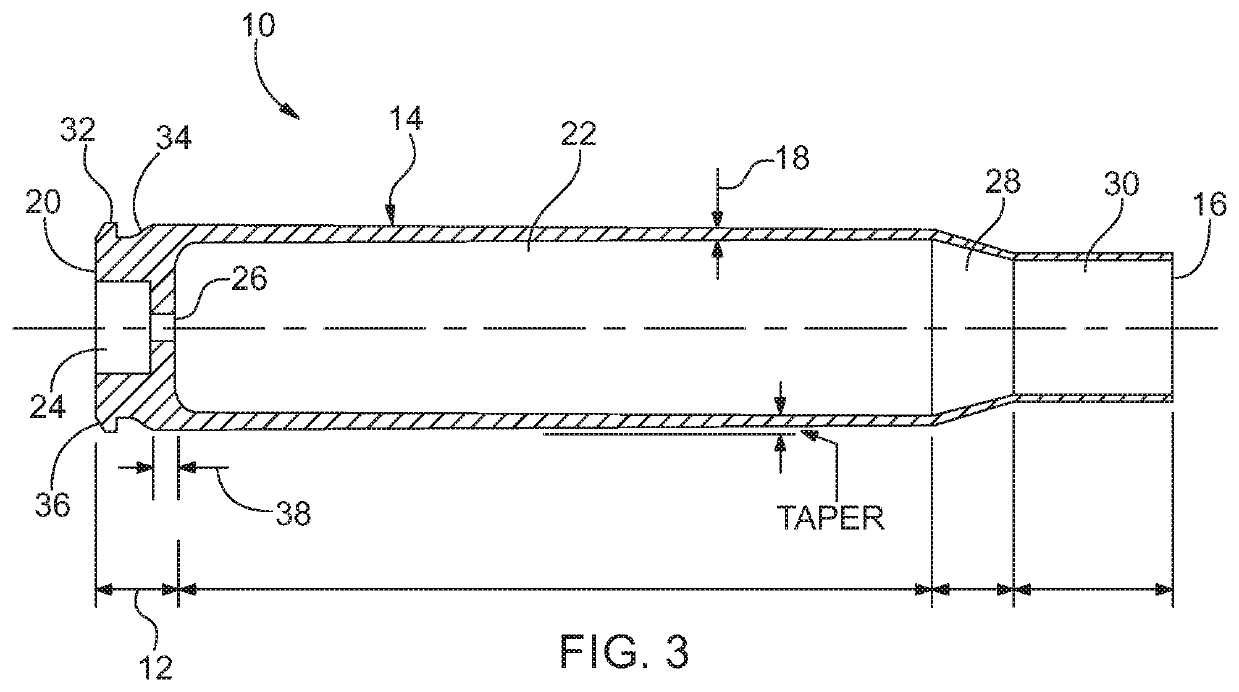

Disclosed is a cartridge case for various caliber ammunition that can consist essentially of a powdered metal and / or powdered metal alloy(s) that is formed into the cartridge case through an injection mold processing. Also disclosed is a method for forming a cartridge case, which may include use of Metal Injection Molding (“MIM”) processes to produce the cartridge case which retains a primer, propellant, and / or a bullet. Also disclosed are embodiments related to a case telescoped cartridge that may include a cap and a body. The body can consist essentially of or consists entirely of a powdered metal and / or powdered metal alloy(s) that has been formed through MIM. The cap can comprise plastic that has been formed through plastic molding or comprise powdered metal and / or powdered metal alloy(s) that has been formed through MIM.

Owner:CONCURRENT TECH

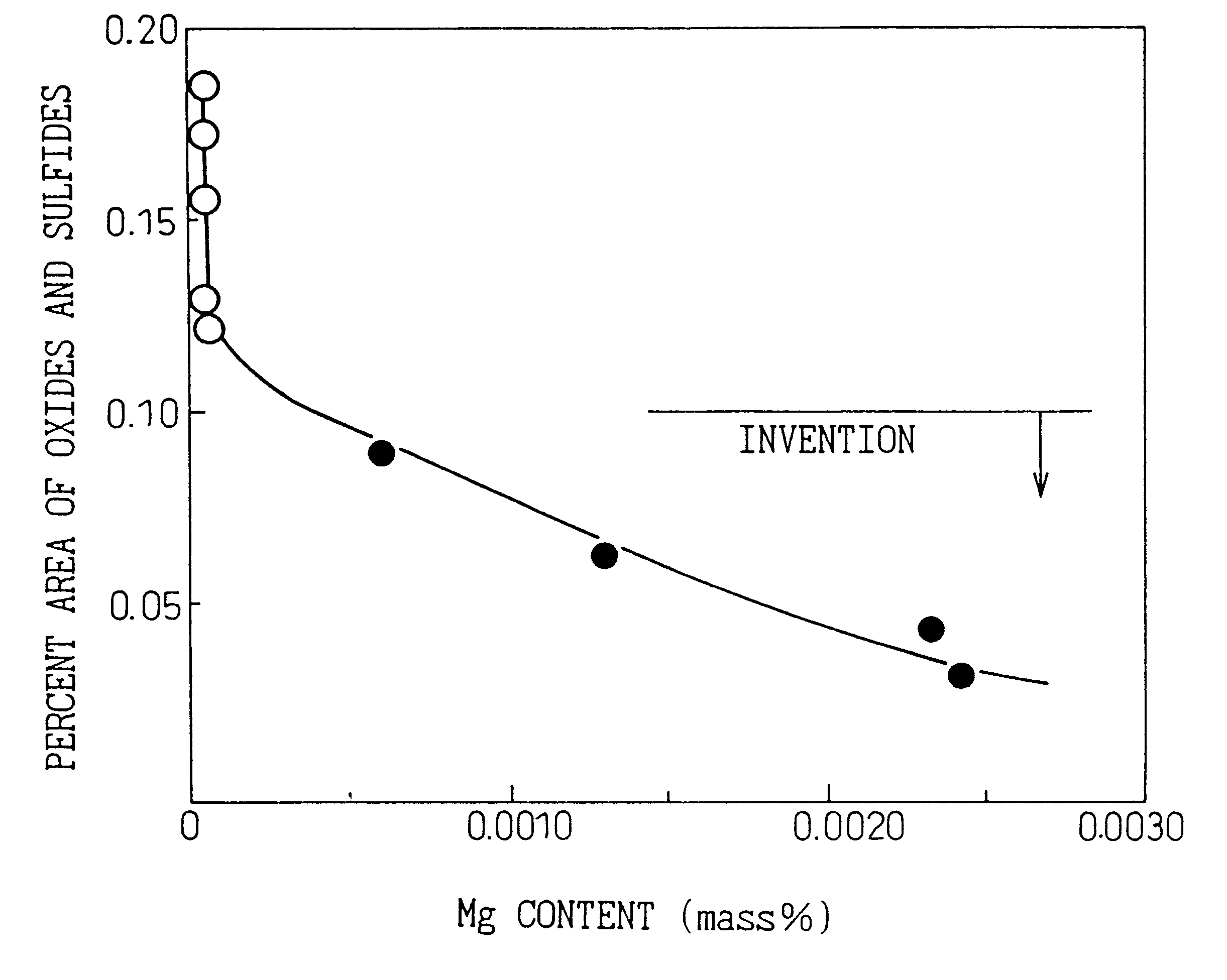

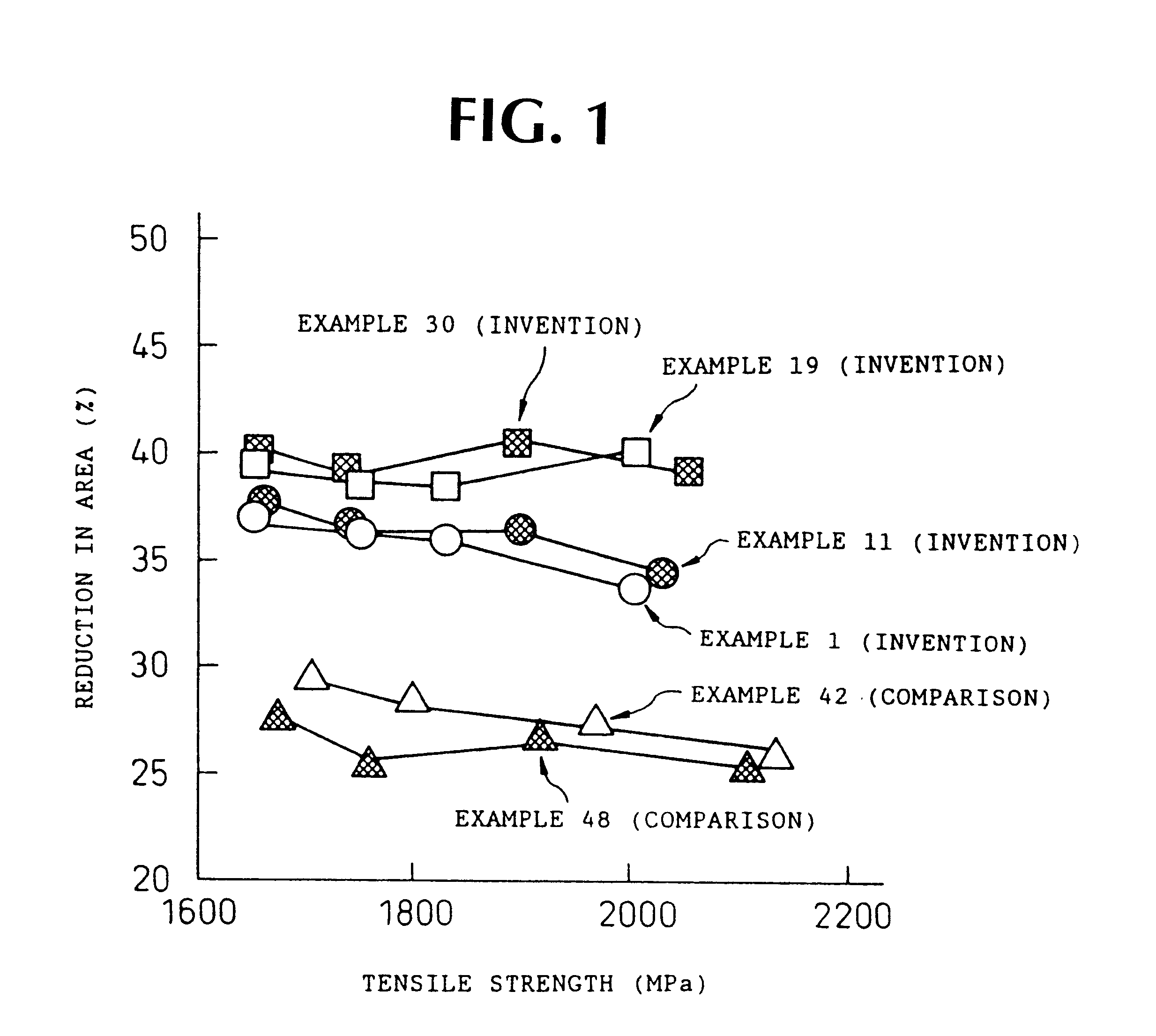

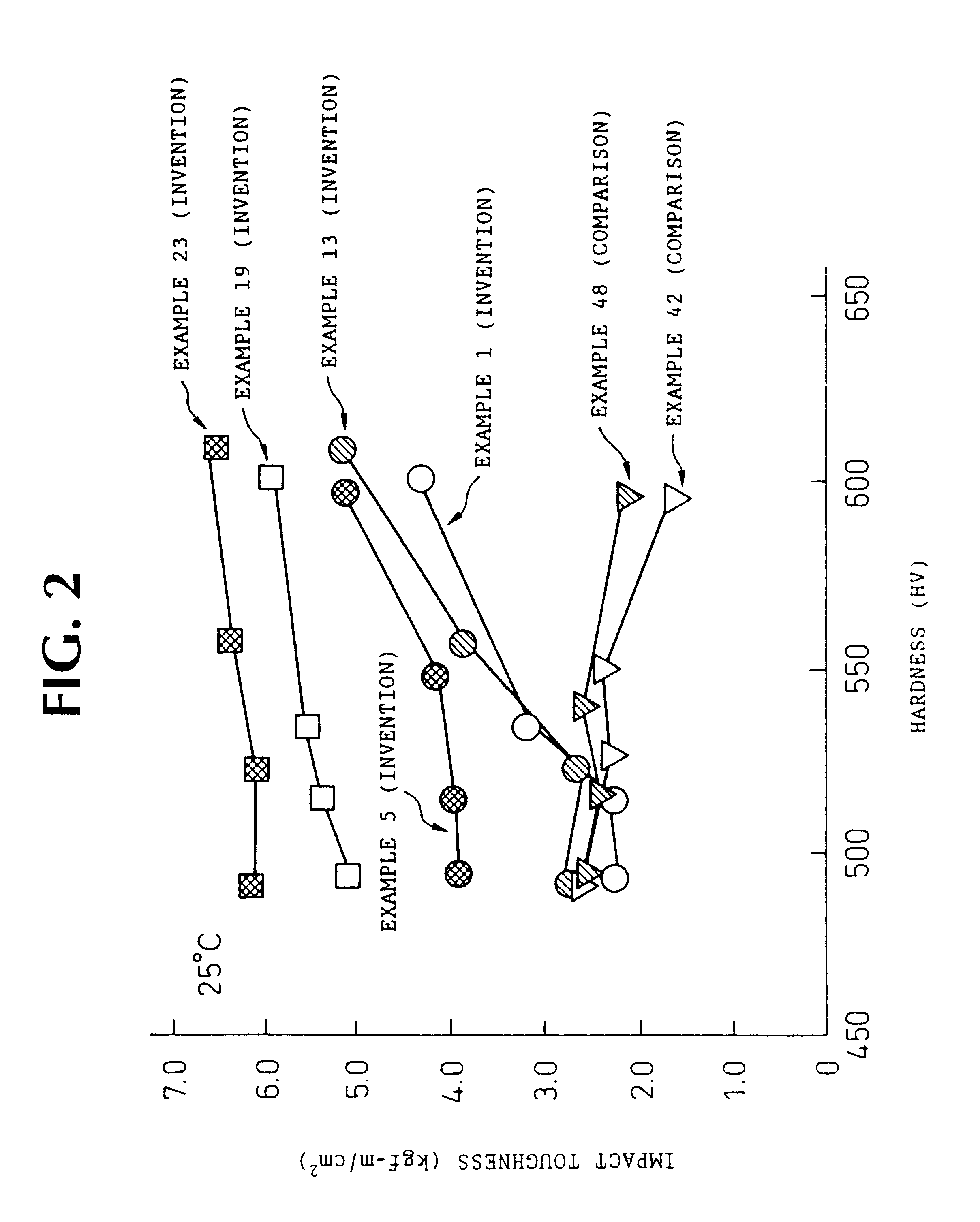

High toughness spring steel

InactiveUS6406565B1Solve the lack of ductilityAvoid lack of toughnessFurnace typesHeat treatment furnacesSulfideSpring steel

The present invention provides a spring steel showing a sufficient reduction in area and an impact toughness while the steel has a high strength, in particular a tensile strength as high as at least 1,500 Mpa. A high toughness spring steel according to the present invention comprises, based on mass, 0.45 to 0.85% of C, 0.9 to 2.5% of Si, 0.1 to 1.2% of Mn, 0.1 to 2.0% of Cr, 0.005 to 0.07% of Ti, 0.001 to 0.007% of N, the Ti content being greater than four times the N content in terms of percent by mass, 0.0005 to 0.0060% B, at least one of 0.0005 to 0.01% Mg, 0.0005 to 0.01% La, and 0.0005 to 0.01% Ce, P and S with restrictive contents of less than 0.020% and less than 0.020%, respectively, and the balance of Fe and unavoidable impurities, and selectively contains V, Nb, Ni, Mo and Cu. The percent area of oxides and sulfides is not more than 0.1%.

Owner:NIPPON STEEL CORP

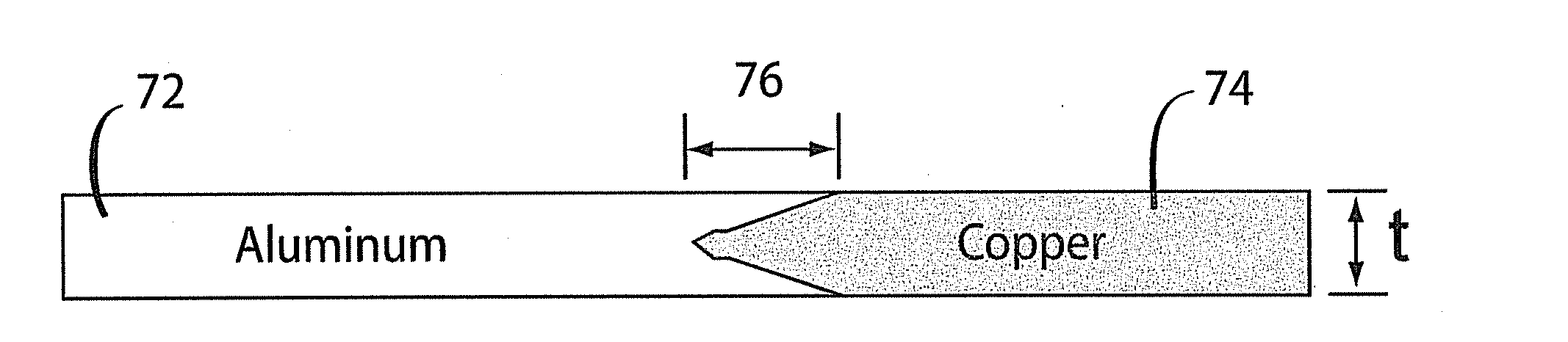

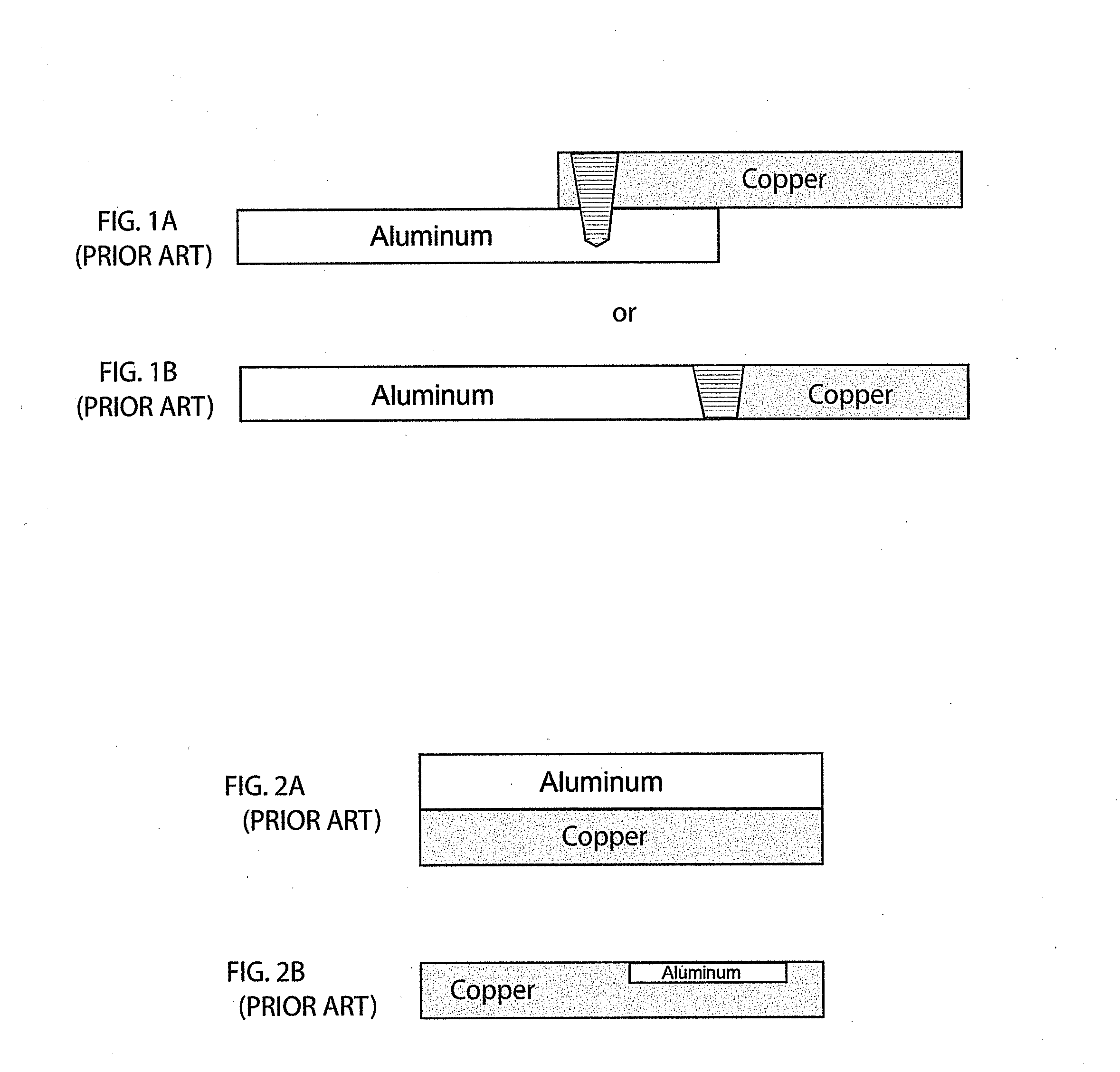

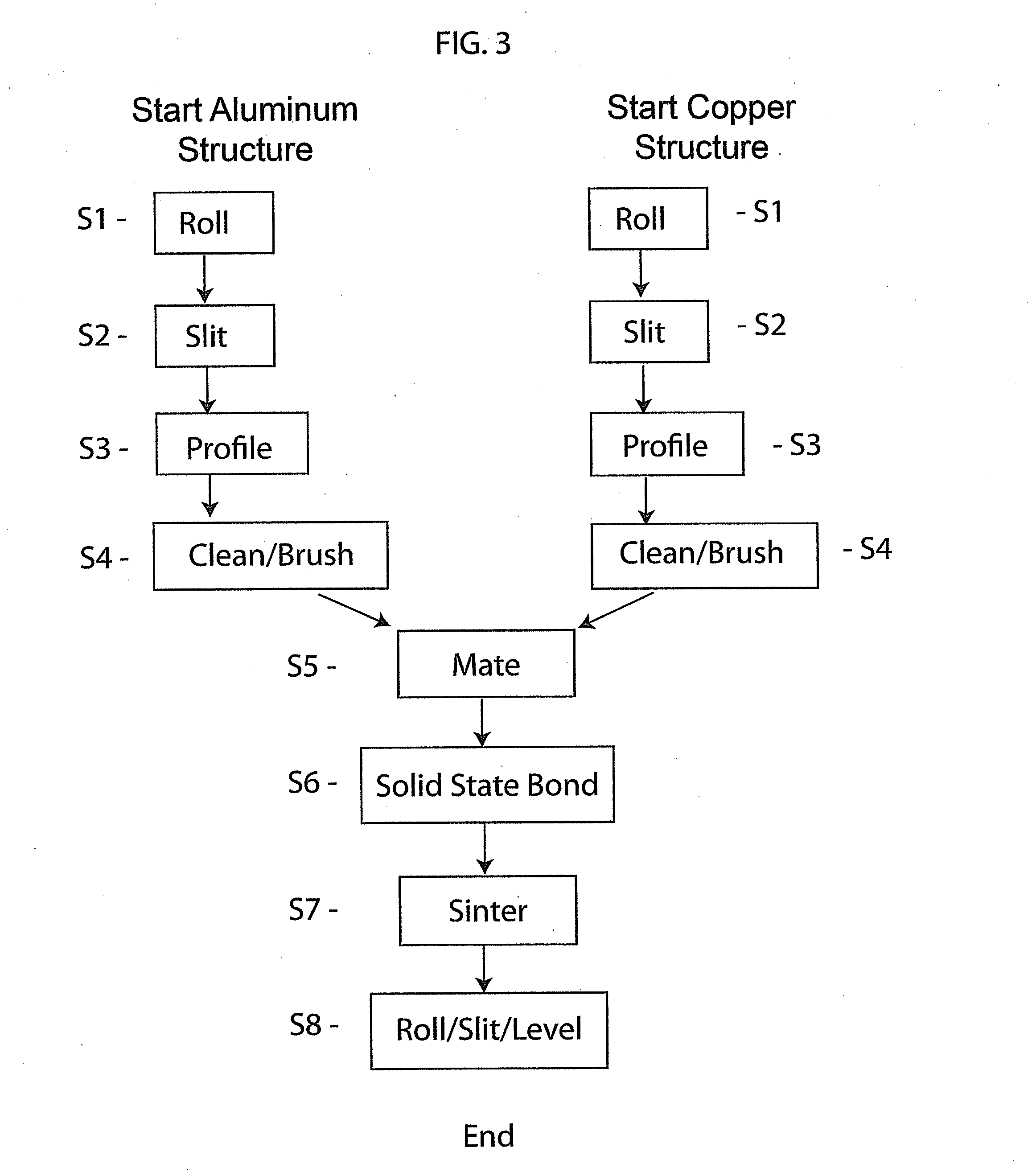

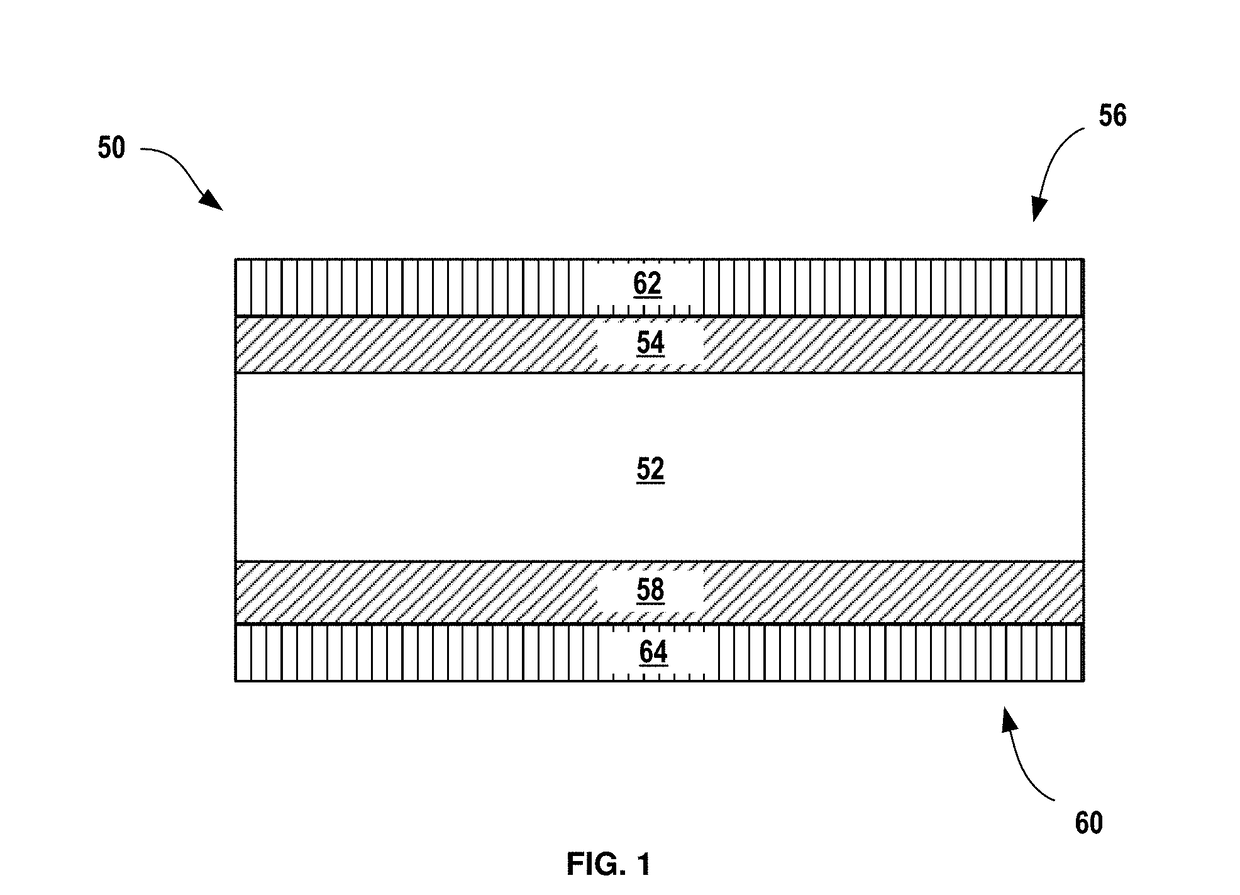

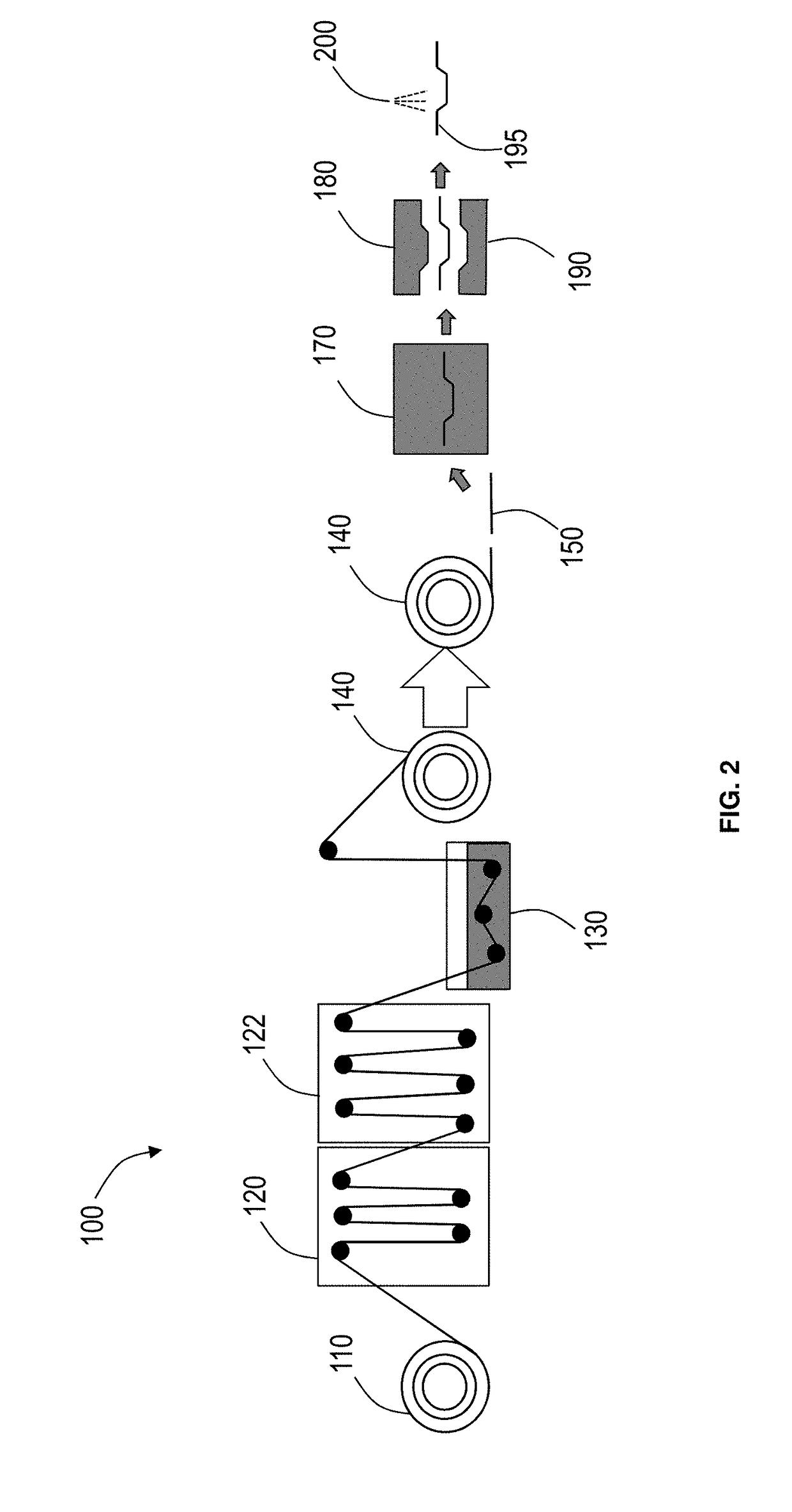

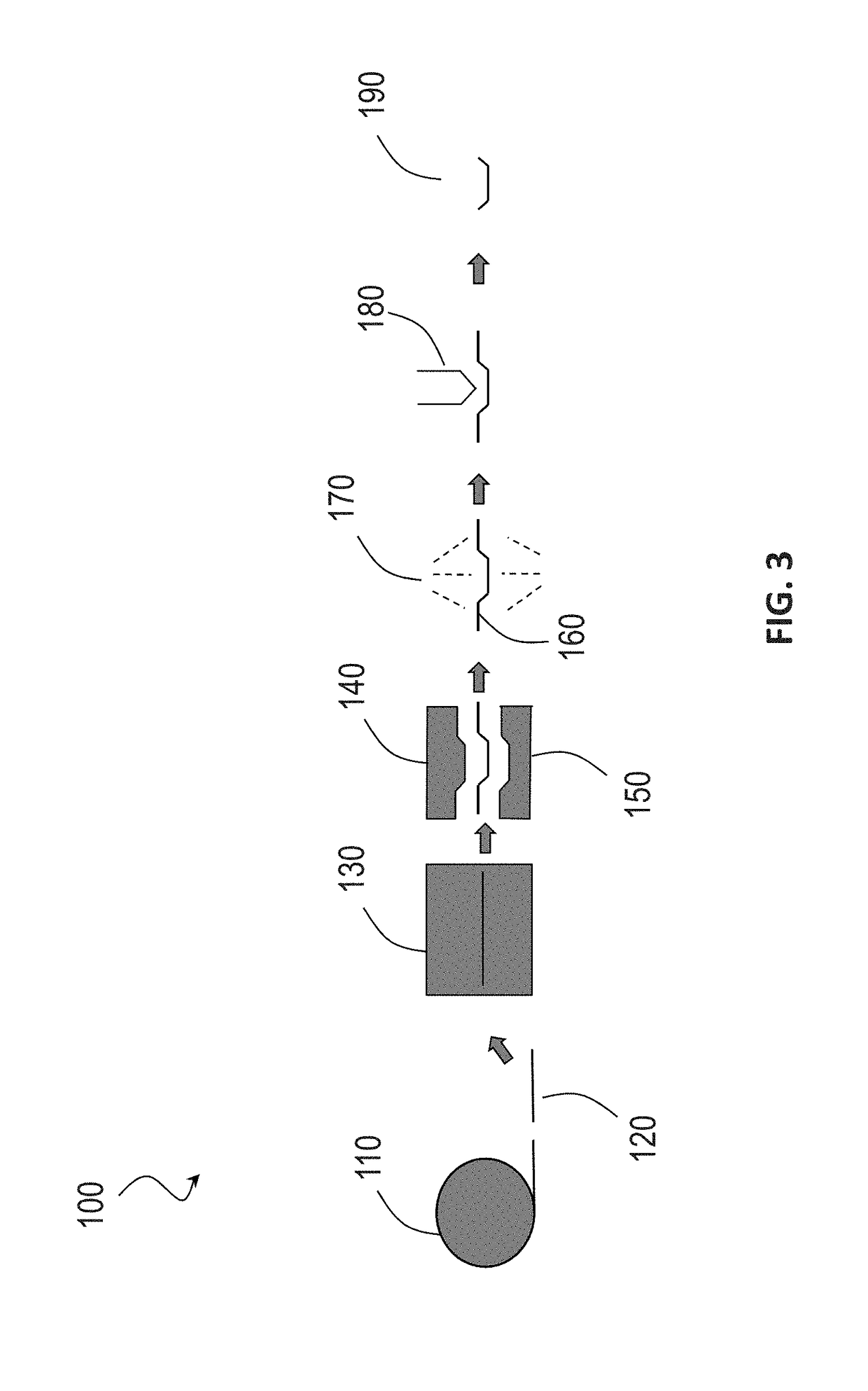

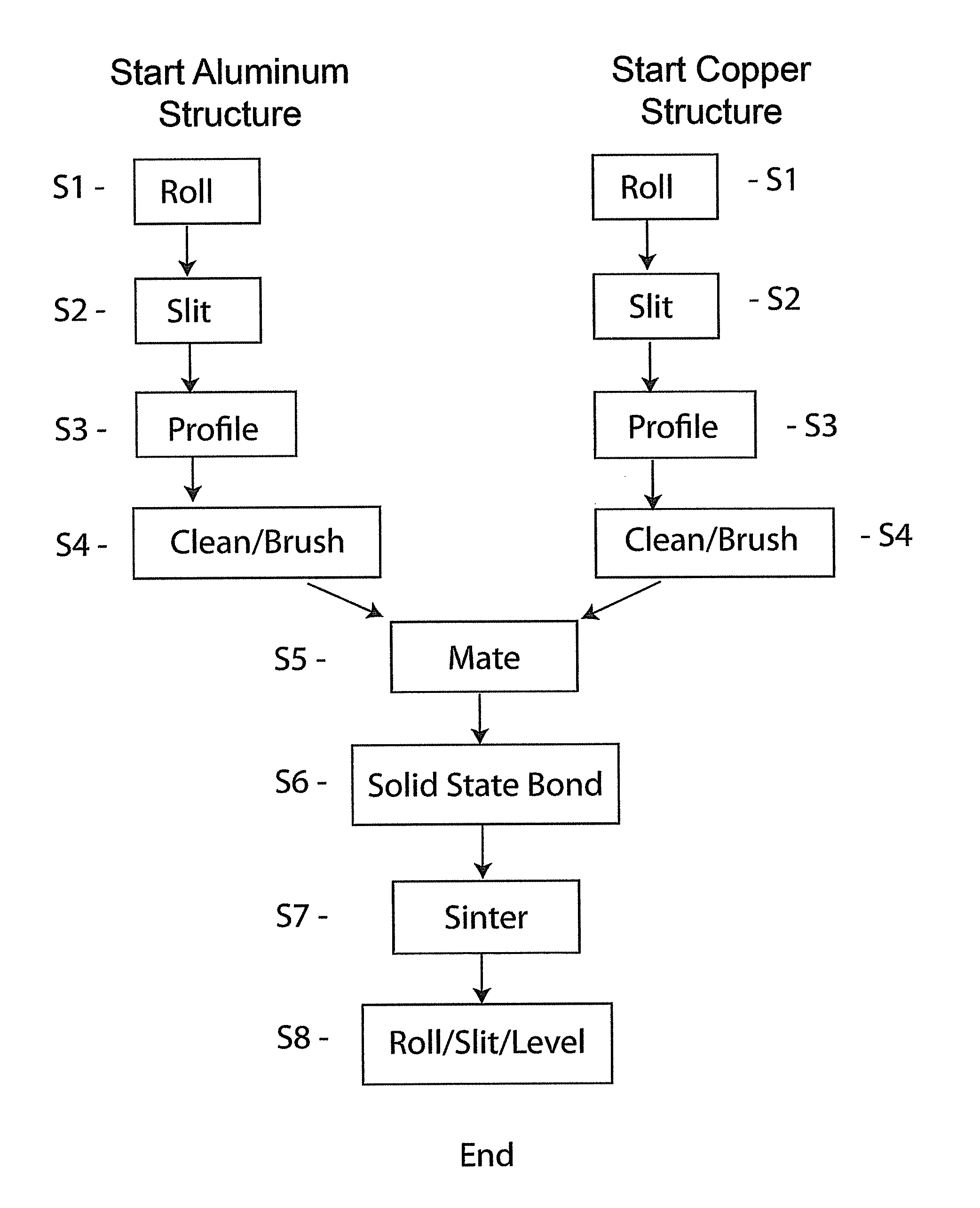

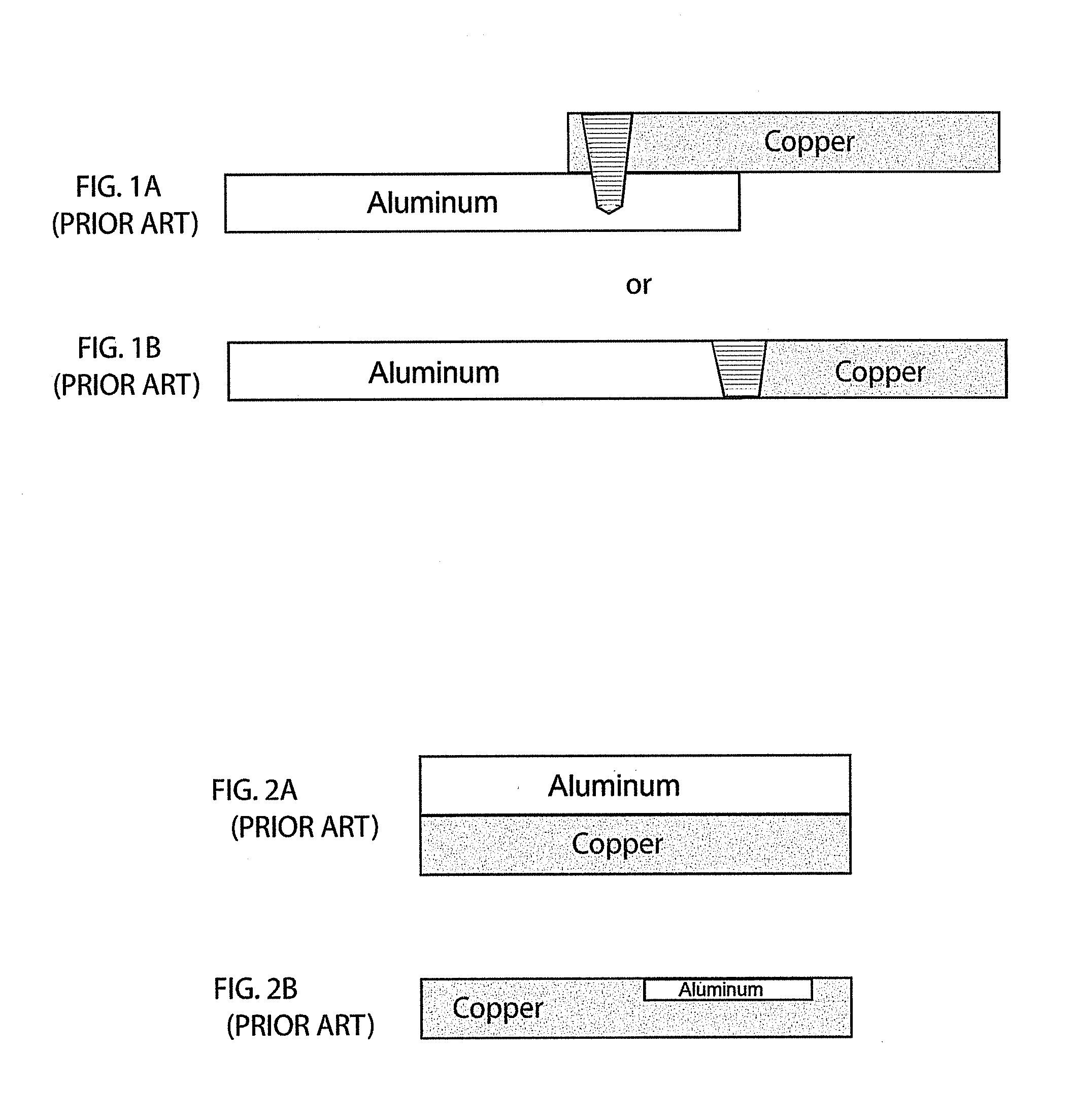

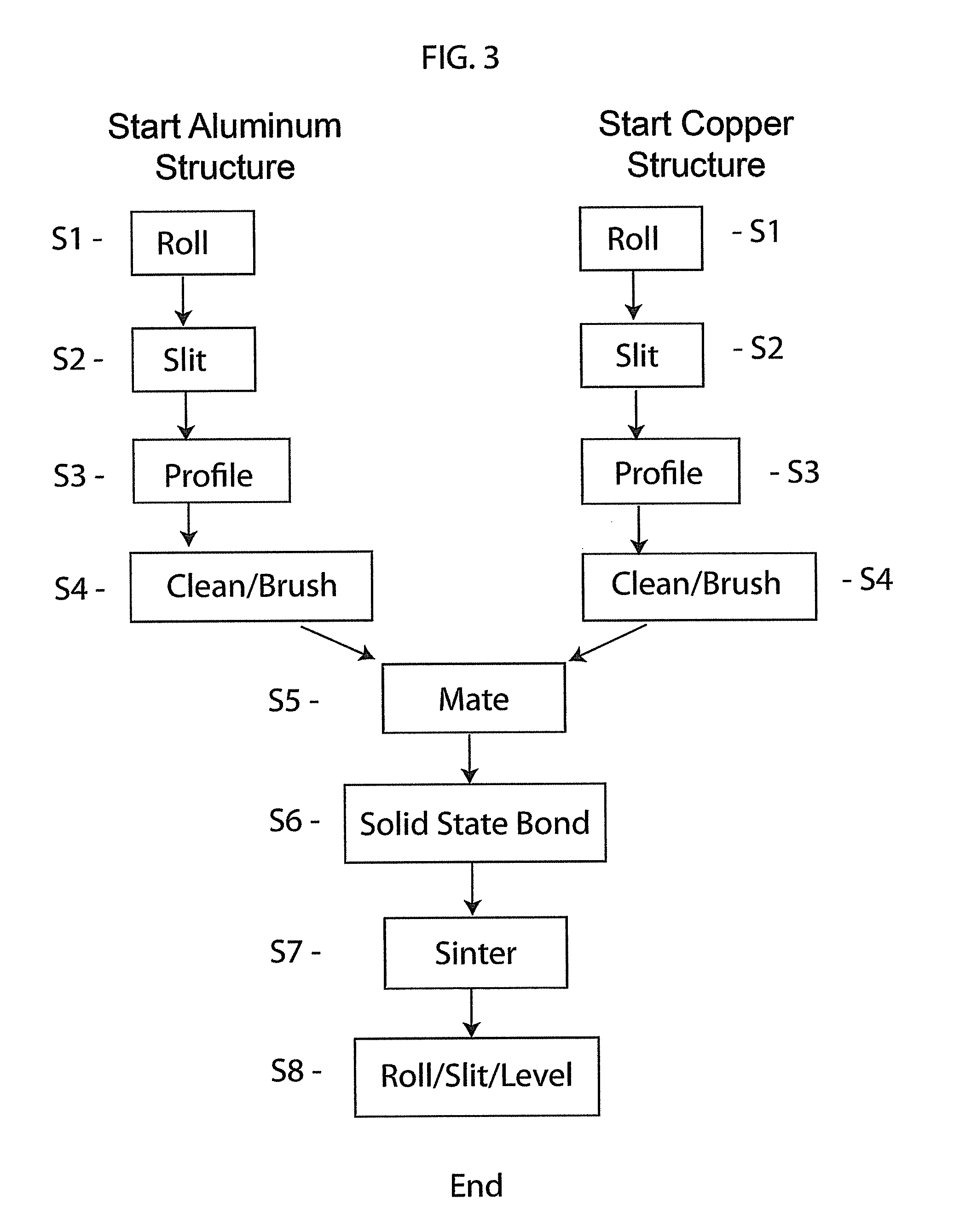

Methods for creating side-by-side metallic bonds between different materials using solid-phase bonding and the products produced thereby

ActiveUS20110206943A1Solve the lack of ductilitySimilar yield strength and ductility and extrusion behaviorCooking-vessel materialsLayered productsElectricityElectrical connection

Methods of producing composite products formed between at least two different metal structures in a side-by-side configuration are provided. The method includes providing at least two structures made of different materials that are not compatible for welding or conventional cladding processes. A geometric profile is provided in at least one of the edges of the first structure, and a corresponding mirror image of the geometric profile is provided in a corresponding edge of the second structure. The two structures are positioned together so that the profiled edge or edges form a complimentary composite structure and are then solid-phase bonded to form a composite product. The process may be repeated with additional structure at either end of the first or second structure to achieve multiple side-by-side products. The methods and corresponding products provided herein yield edge to edge products suitable for various electrical connection type applications.

Owner:MATERION TECHN MATERIALS

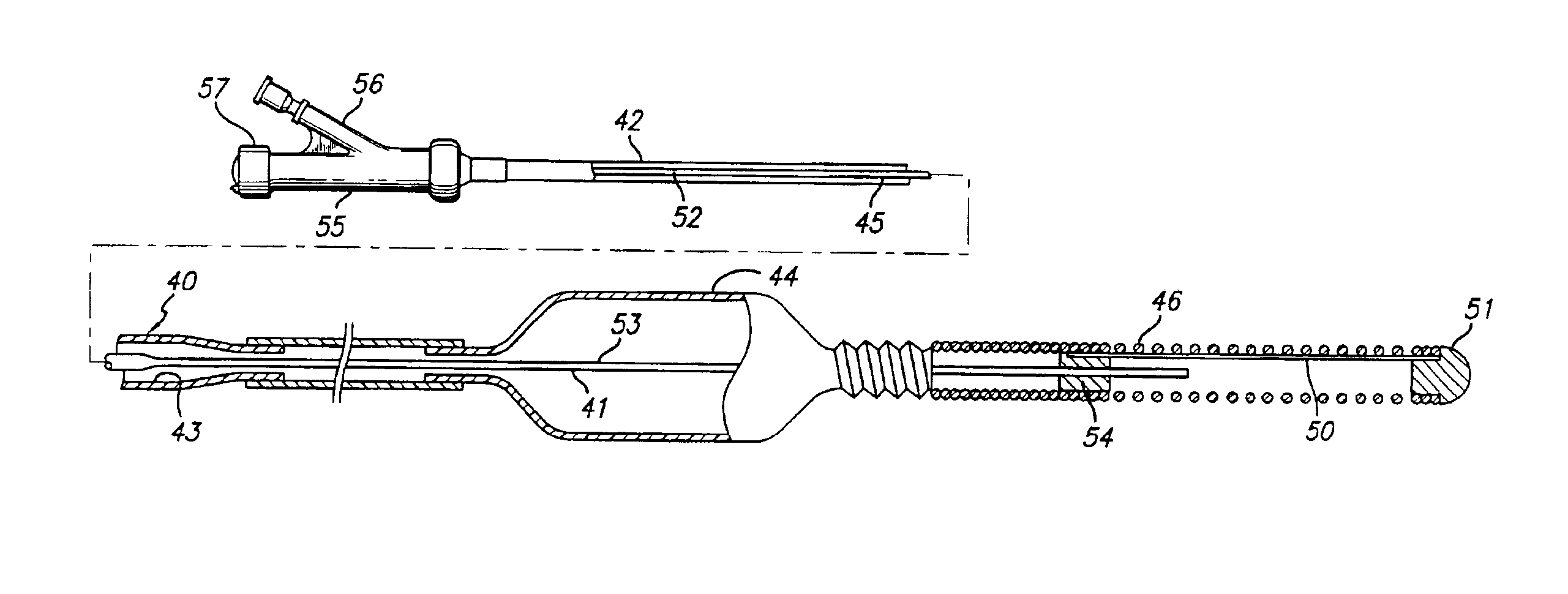

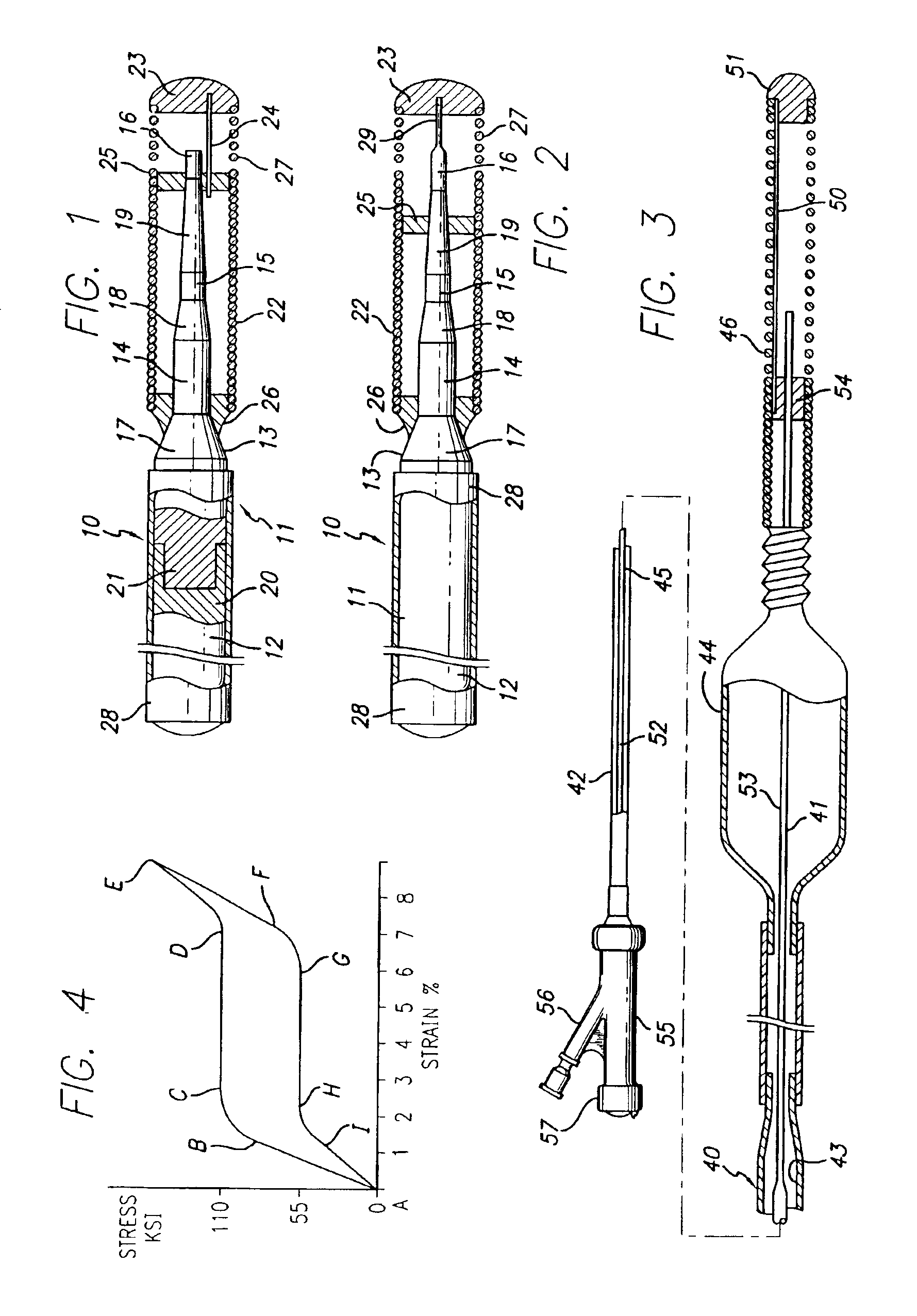

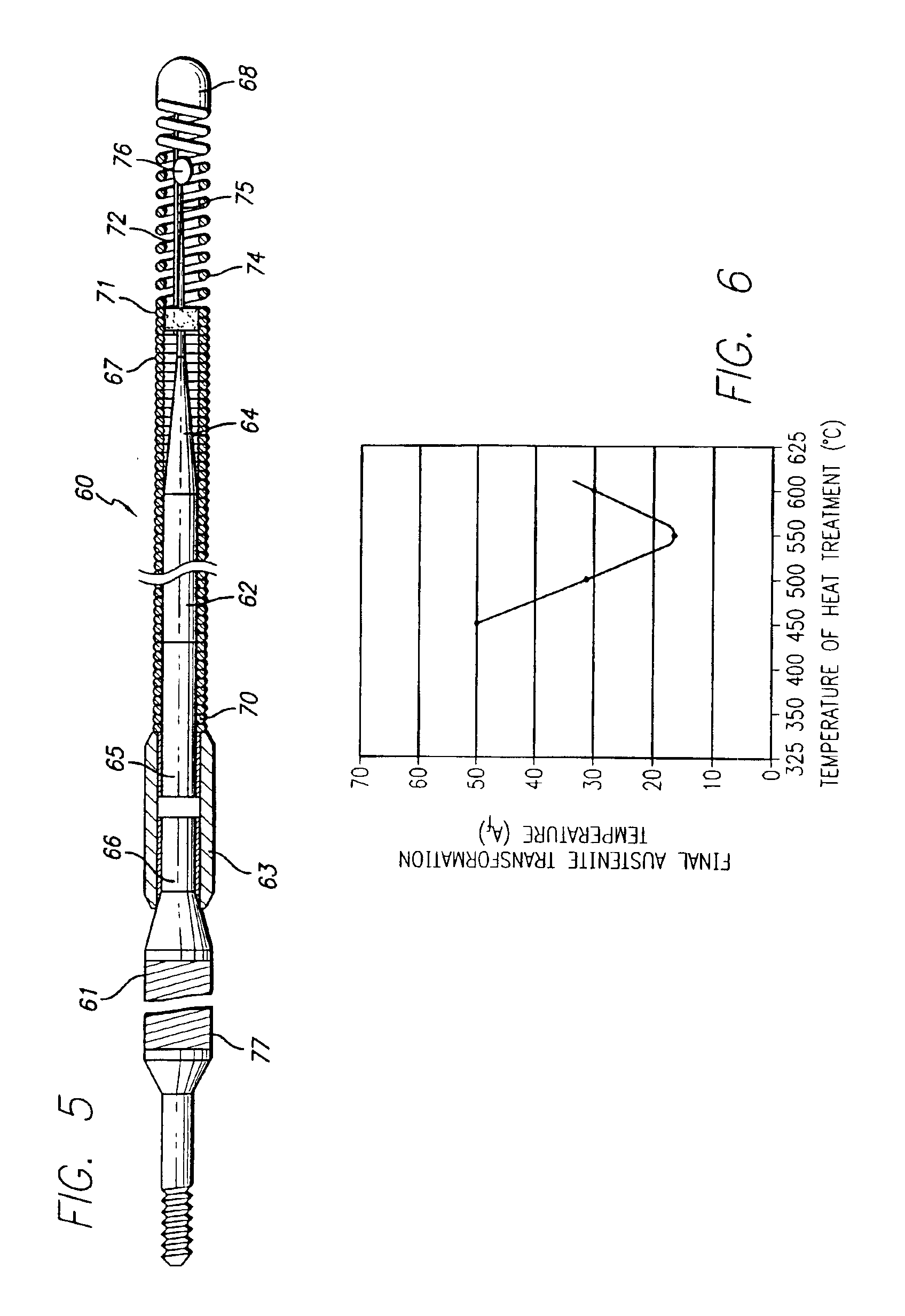

Superelastic guiding member

InactiveUS7244319B2Uniform residual stressImproved torque responseStentsGuide wiresStress inducedNiobium

An improved guiding member for use within a body lumen having a unique combination of superelastic characteristics. The superelastic alloy material has a composition consisting of about 30% to about 52% (atomic) titanium, and about 38% to 52% nickel and may have one or more elements selected from the group consisting of iron, cobalt, platinum, palladium, vanadium, copper, zirconium, hafnium and niobium. The alloy material is subjected to thermomechanical processing which includes a final cold working of about 10 to about 75% and then a heat treatment at a temperature between about 450° and about 600° C. and preferably about 475° to about 550° C. Before the heat treatment the cold worked alloy material is preferably subjected to mechanical straightening. The alloy material is preferably subjected to stresses equal to about 5 to about 50% of the room temperature ultimate yield stress of the material during the thermal treatment. The guiding member using such improved material exhibits a stress-induced austenite-to-martensite phase transformation at an exceptionally high constant yield strength of over 90 ksi for solid members and over 70 ksi for tubular members with a broad recoverable strain of at least about 4% during the phase transformation. An essentially whip free product is obtained.

Owner:ABBOTT CARDIOVASCULAR

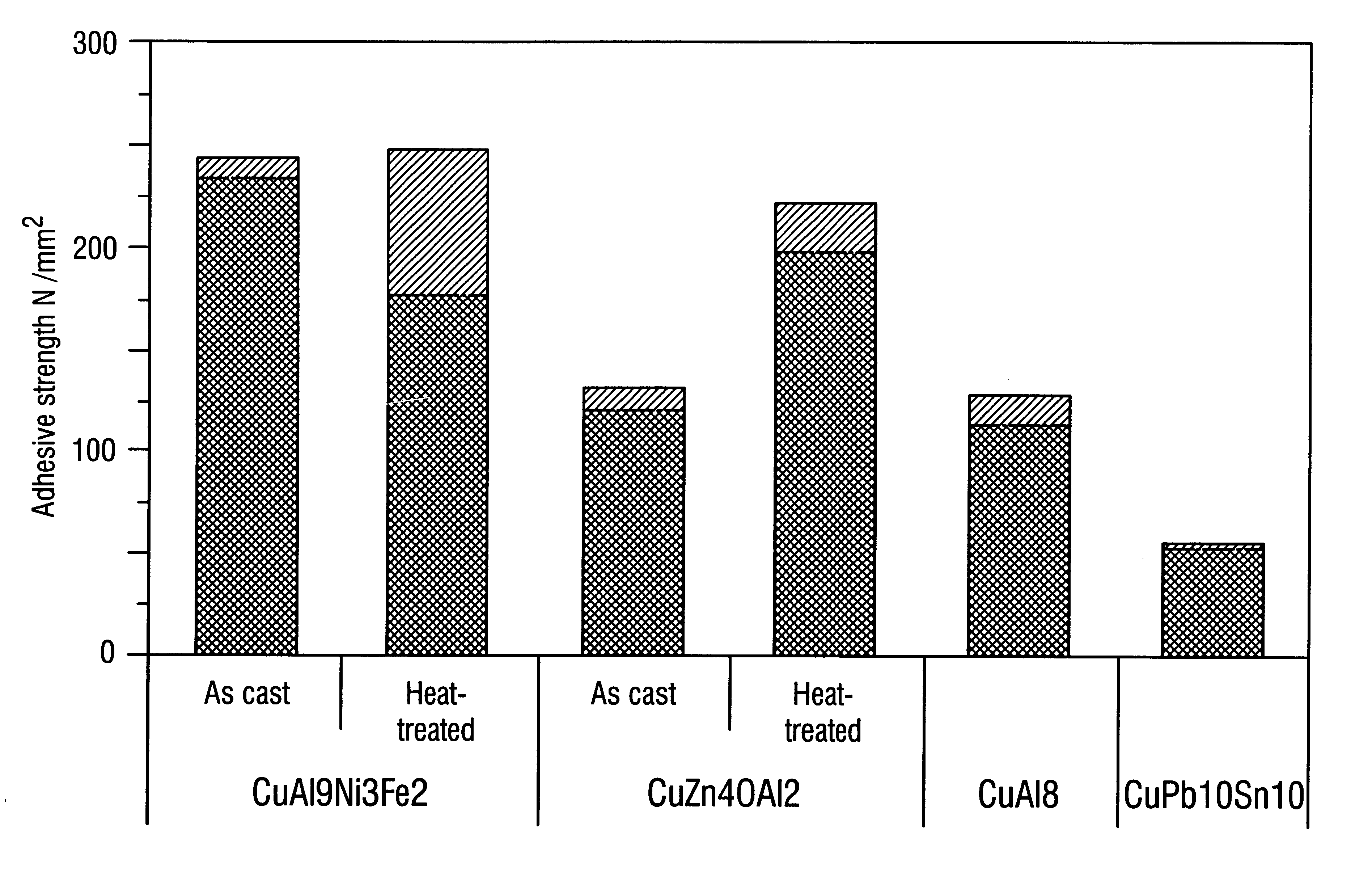

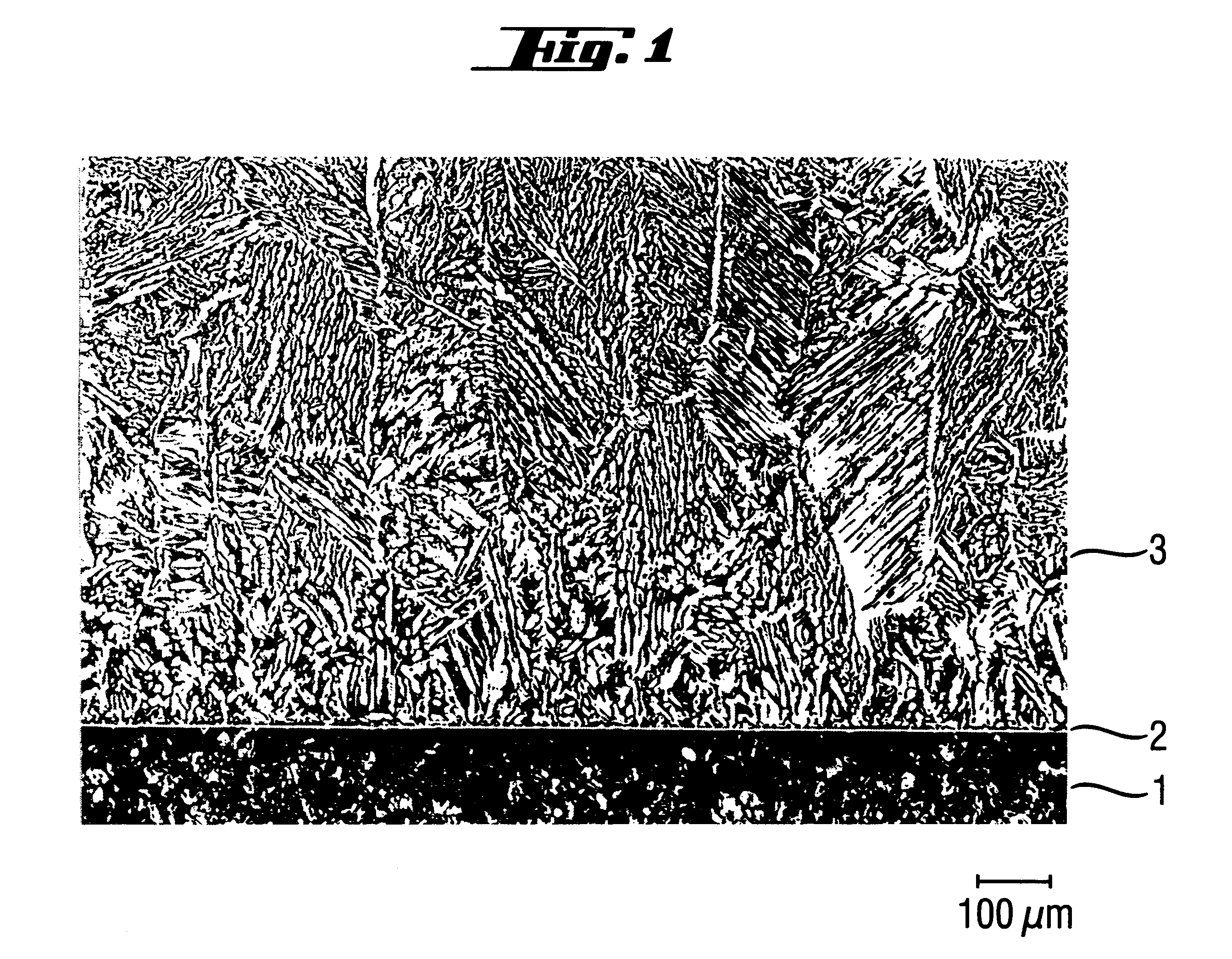

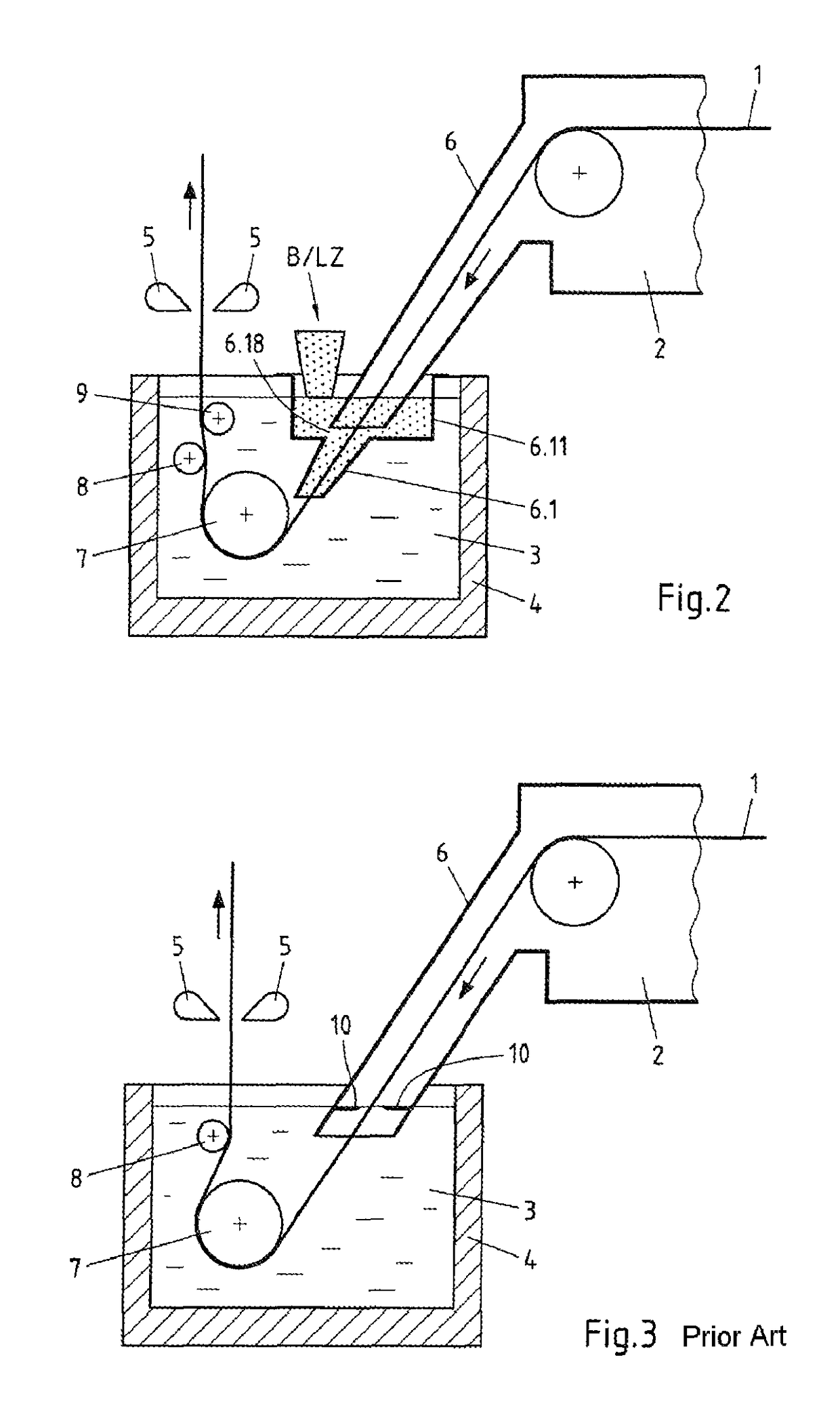

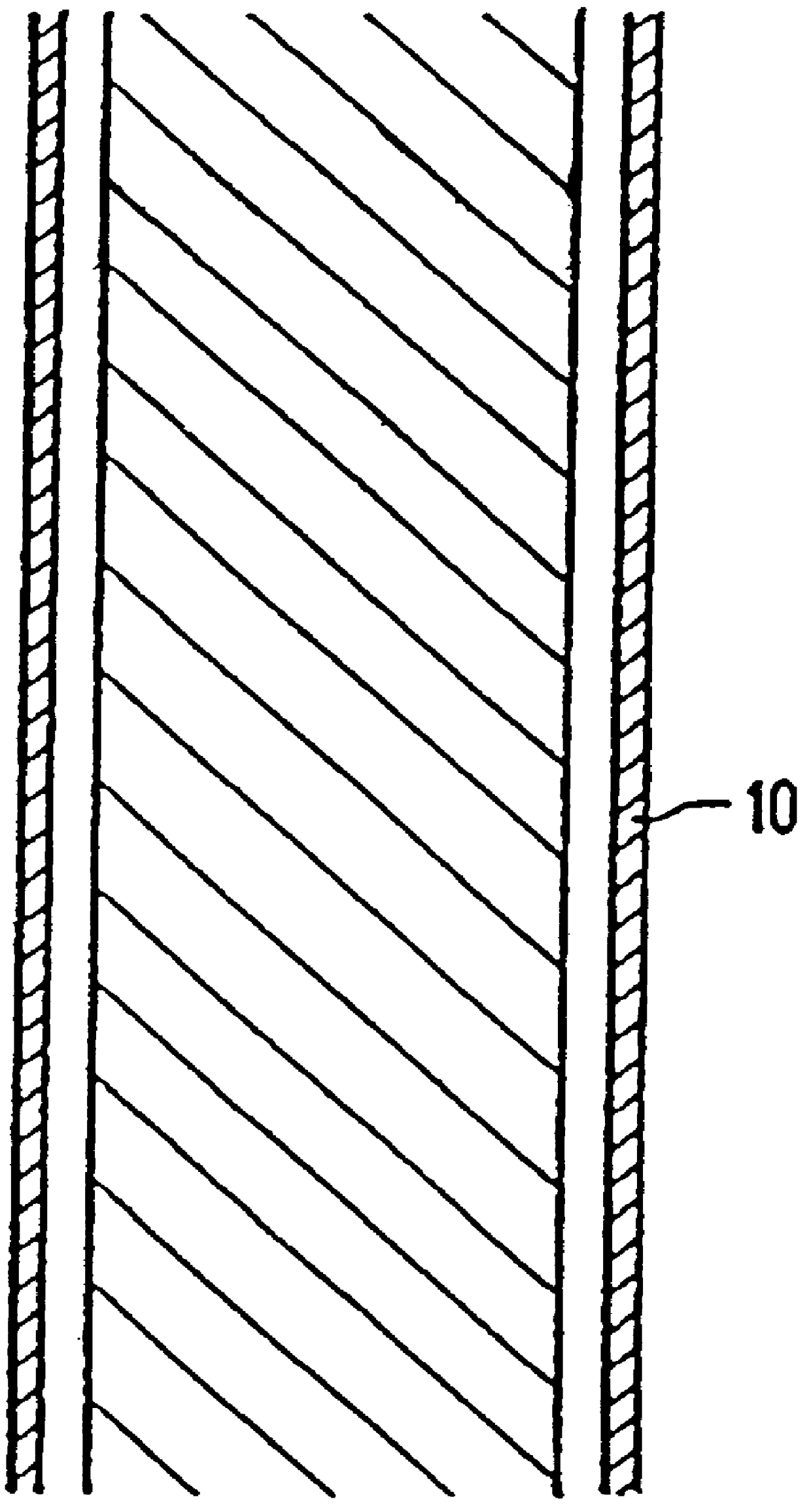

Stratified composite material for sliding elements and method for the production thereof

InactiveUS6273972B1High load carry capacityGood tribological propertyHot-dipping/immersion processesShaftsCorrosion resistantZinc

A composite multilayer material and a method for the production thereof are described which are suitable for bearing points subject to mixed friction, said material being corrosion-resistant and cold-formable and capable of withstanding extremely high loads. According to the method, the backing material is preheated to a temperature of 1000° C. to 1100° C., a heterogeneously developing, lead-free copper-zinc- or copper-aluminum-based bearing alloy at a temperature of from 1000° C. to 1250° C. is cast thereon, and the composite multilayer material is cooled from the casting temperature of the bearing alloy to 100° C. within 2 to 4 minutes. A metallurgical bond zone (2) is present between the bearing alloy (3) and the backing material (1), which metallurgical bond zone (2) comprises 80-95% iron and the usual impurities, the rest being copper, and is crystallised in cubic form.

Owner:FEDERAL MOGUL WIESBADEN

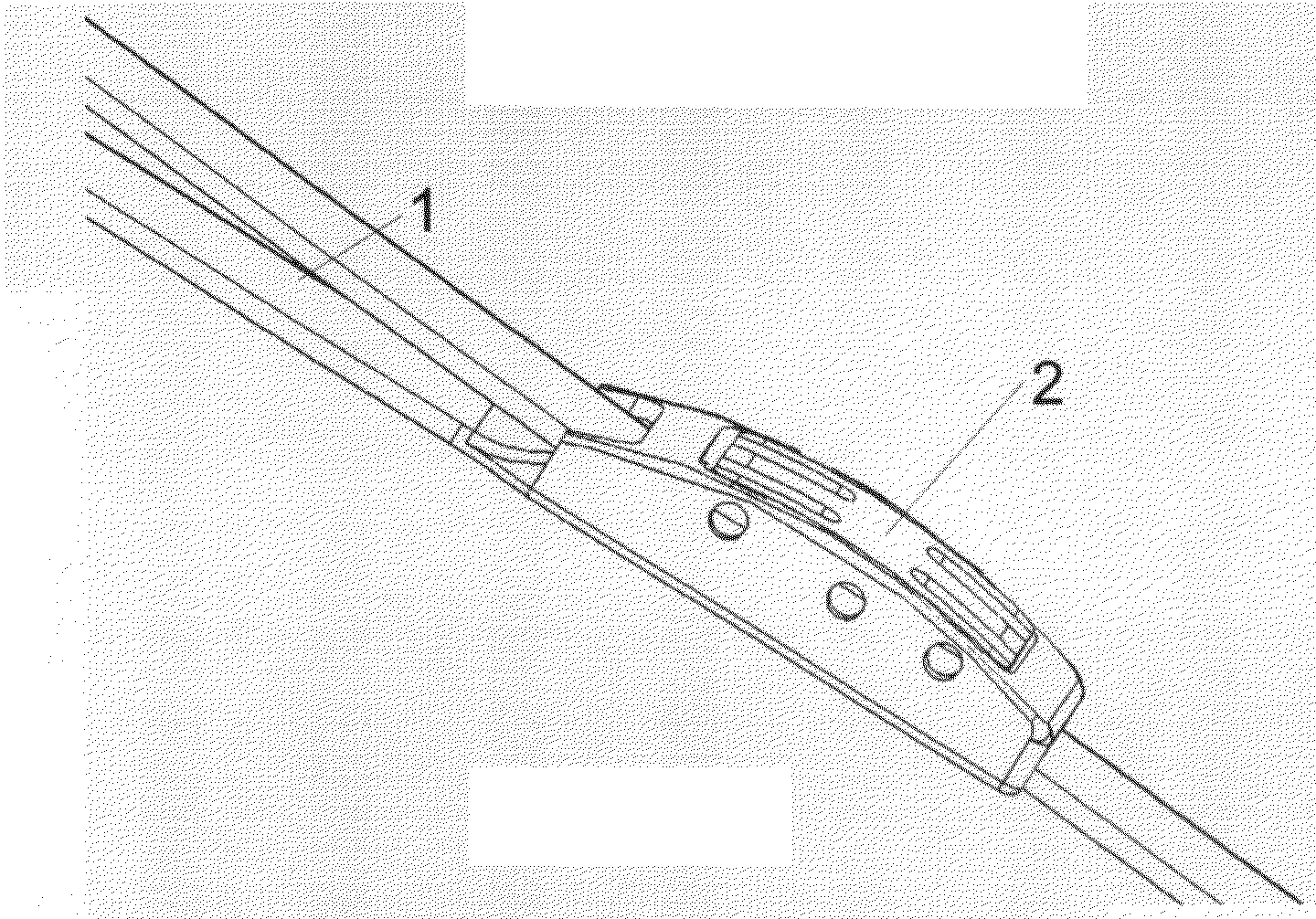

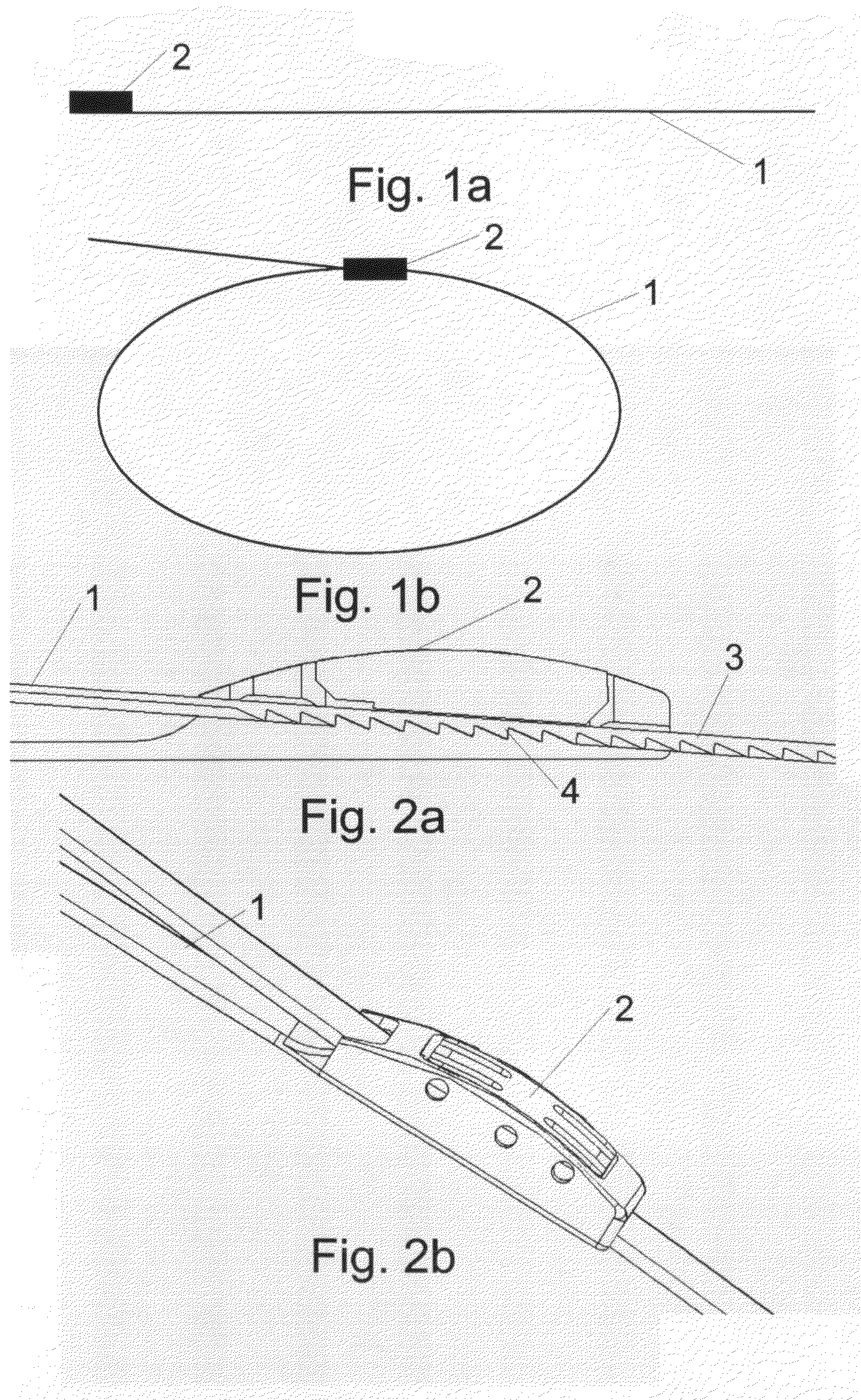

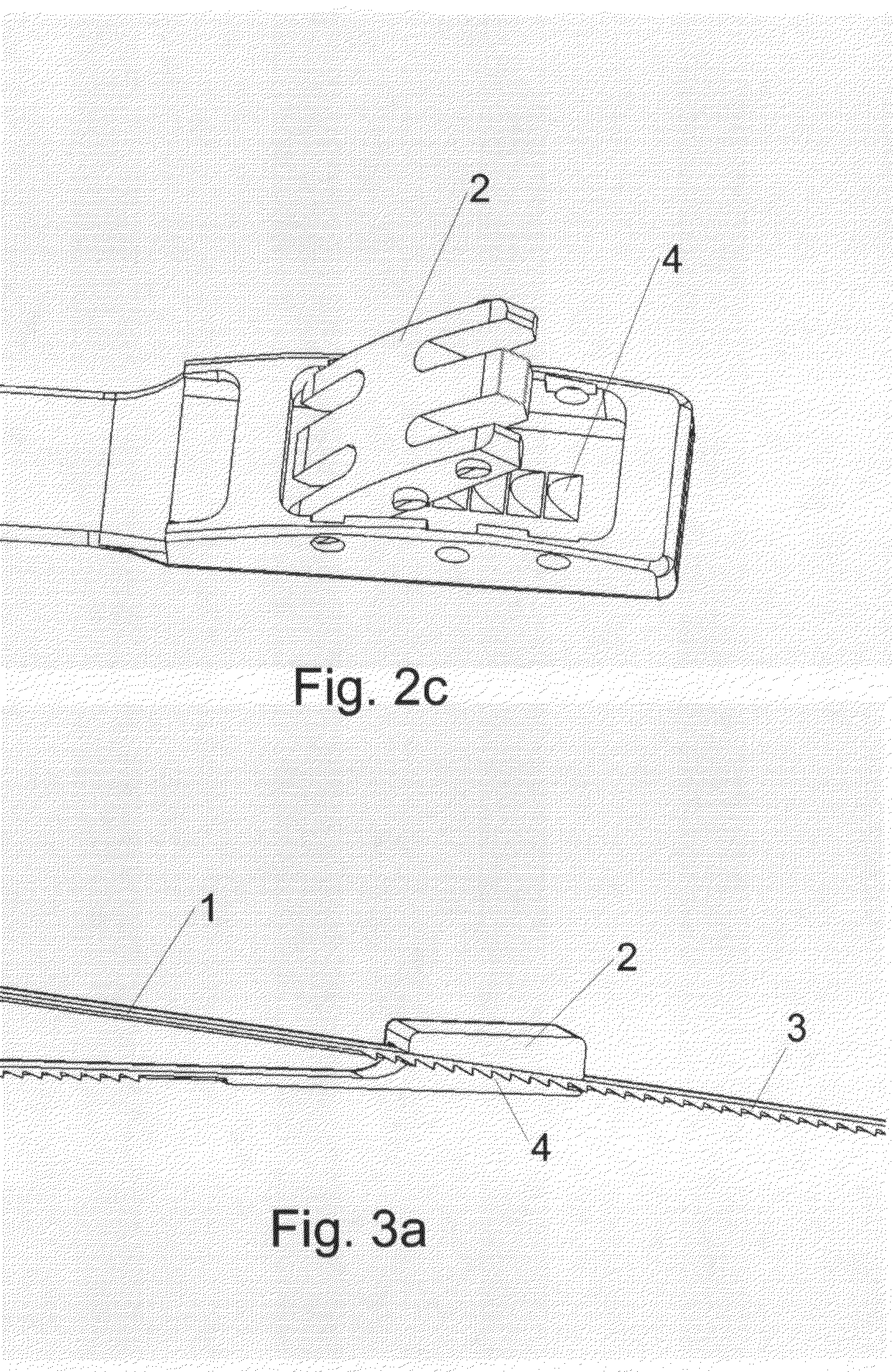

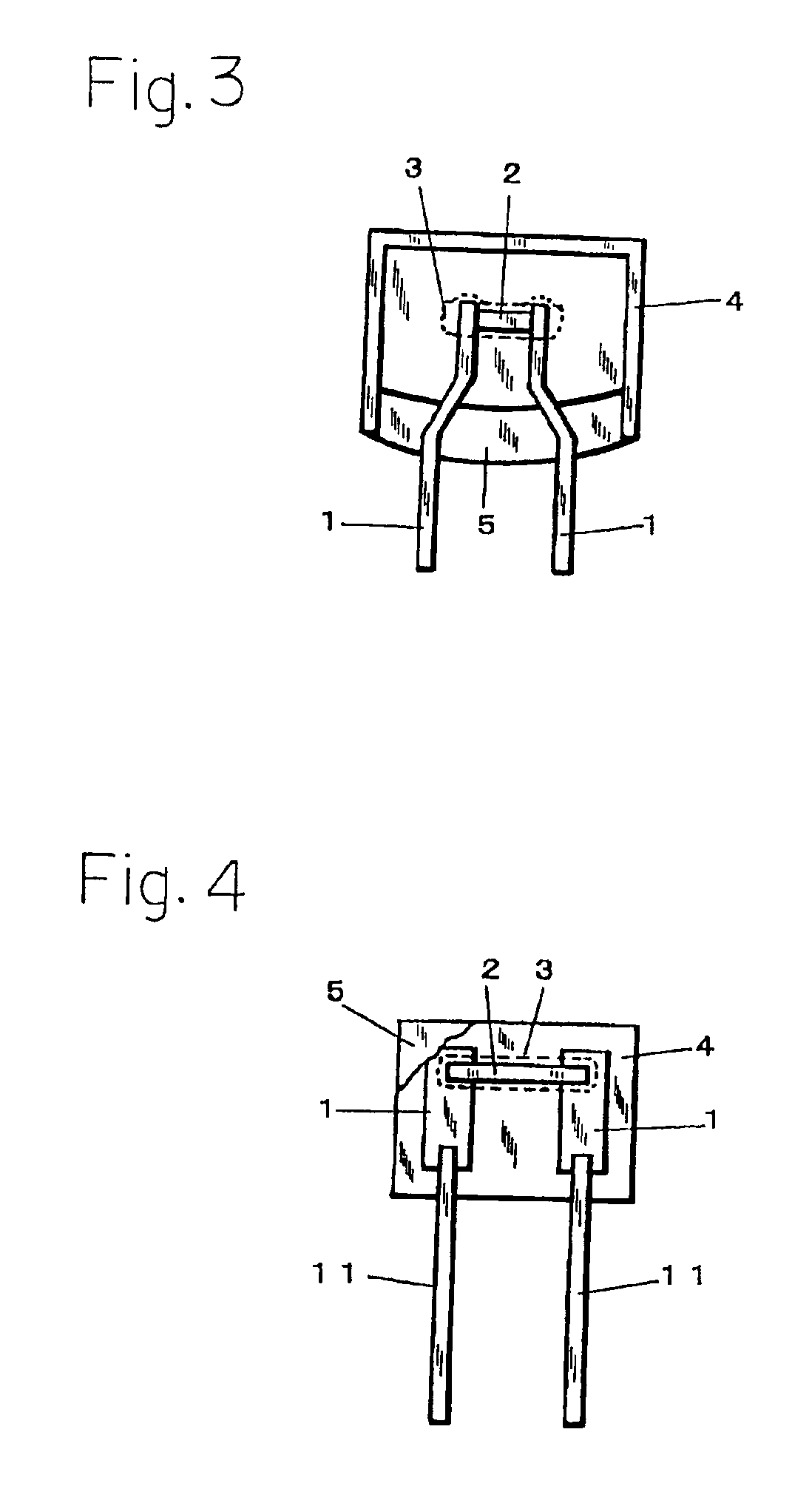

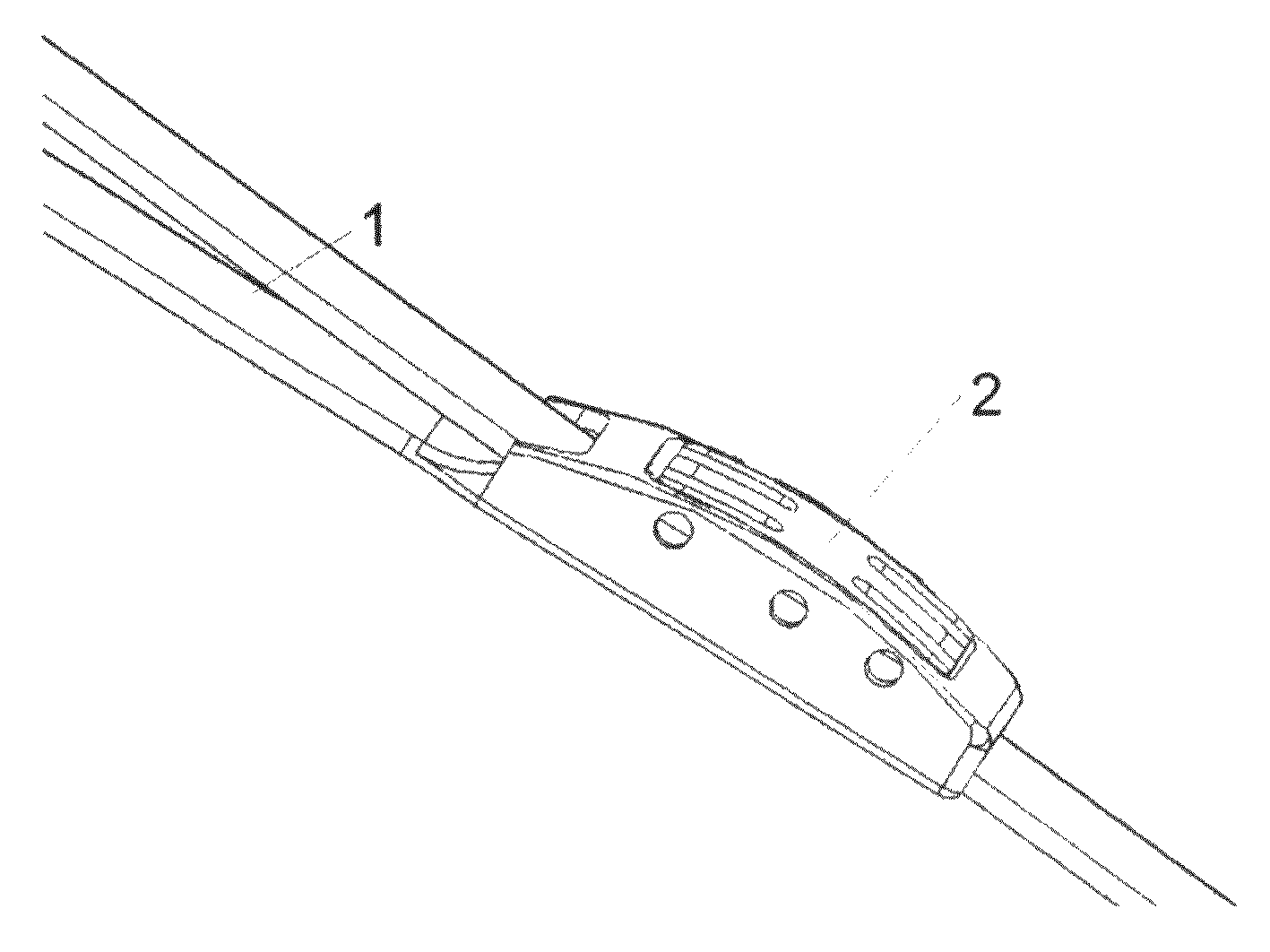

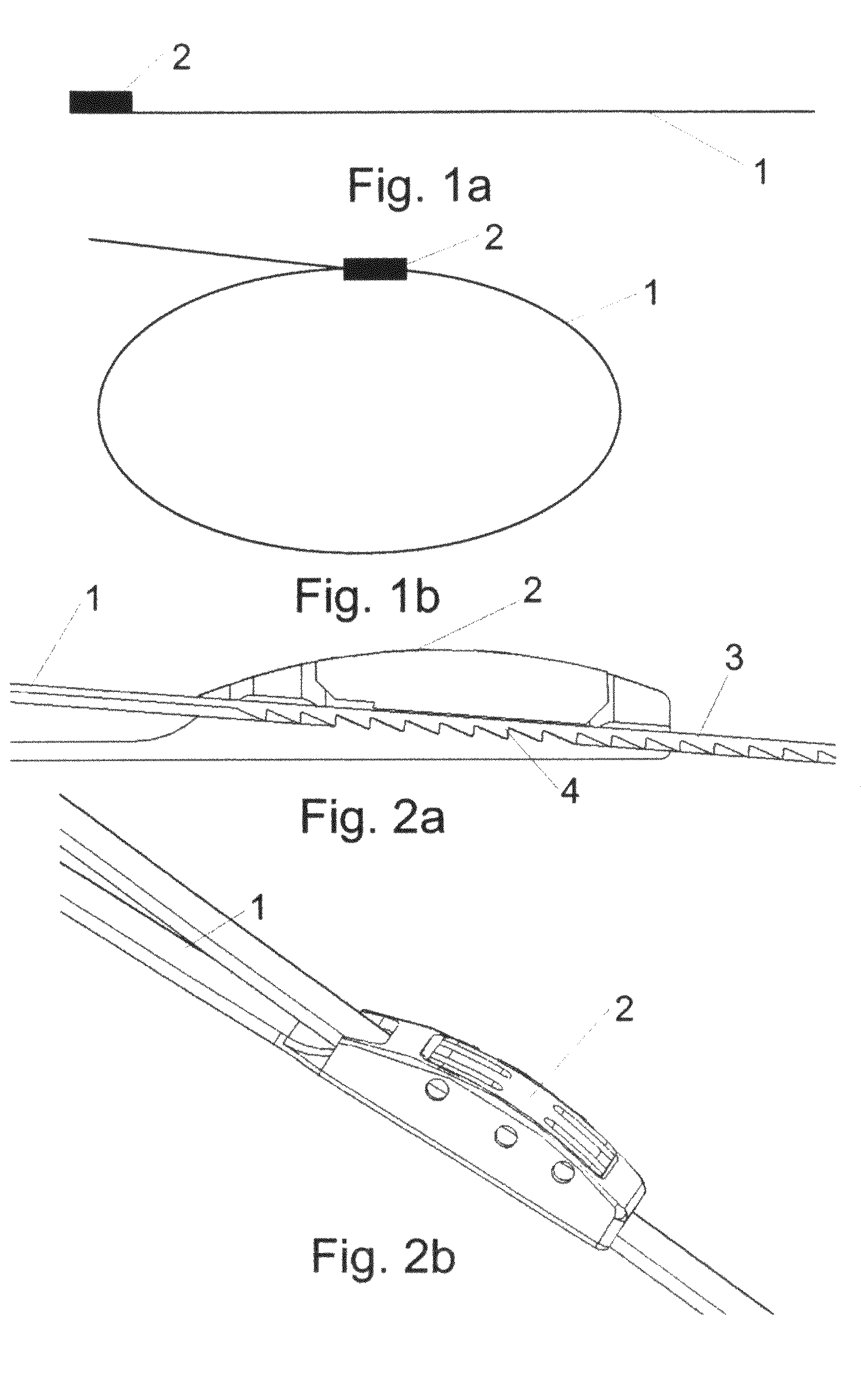

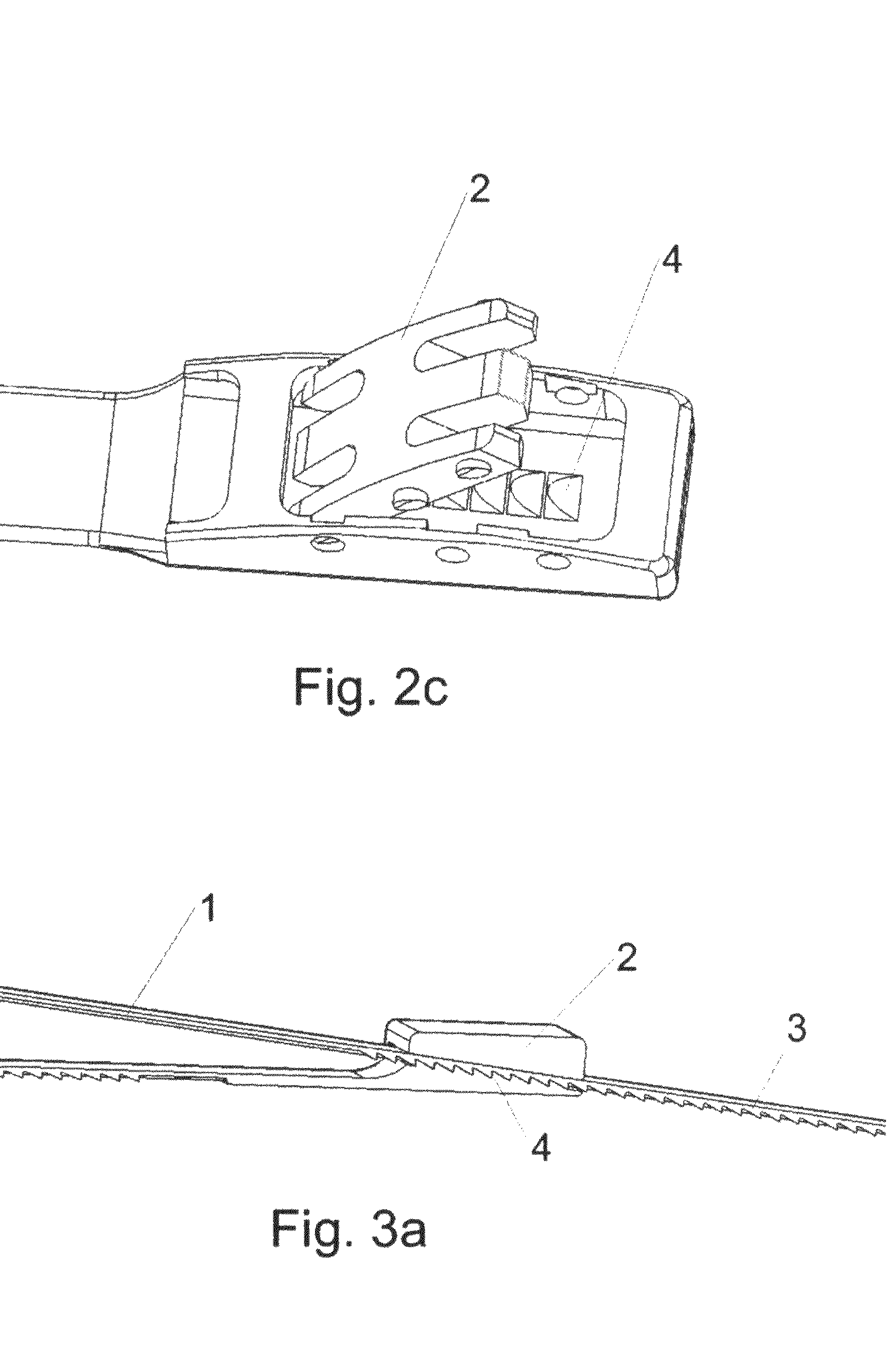

Bioabsorbable band system,a bioabsorbable band, a method for producing a bioabsorbable band, a needle system of a bioabsorbable band and a locking mechanism

ActiveUS20090270923A1Mitigate such drawbackPrecise tensionInternal osteosythesisJoint implantsLocking mechanismOsteotomy

A bioabsorbable band system for securing a bone fracture, or an osteotomy, or a soft tissue on a bone. The bioabsorbable band system includes a needle system and a bioabsorbable band including a bioabsorbable locking member. The bioabsorbable band includes a length having an at least partially oriented structure. The bioabsorbable band further includes a locking mechanism with a locking member. Also a method for producing the bioabsorbable band.

Owner:BIORETEC

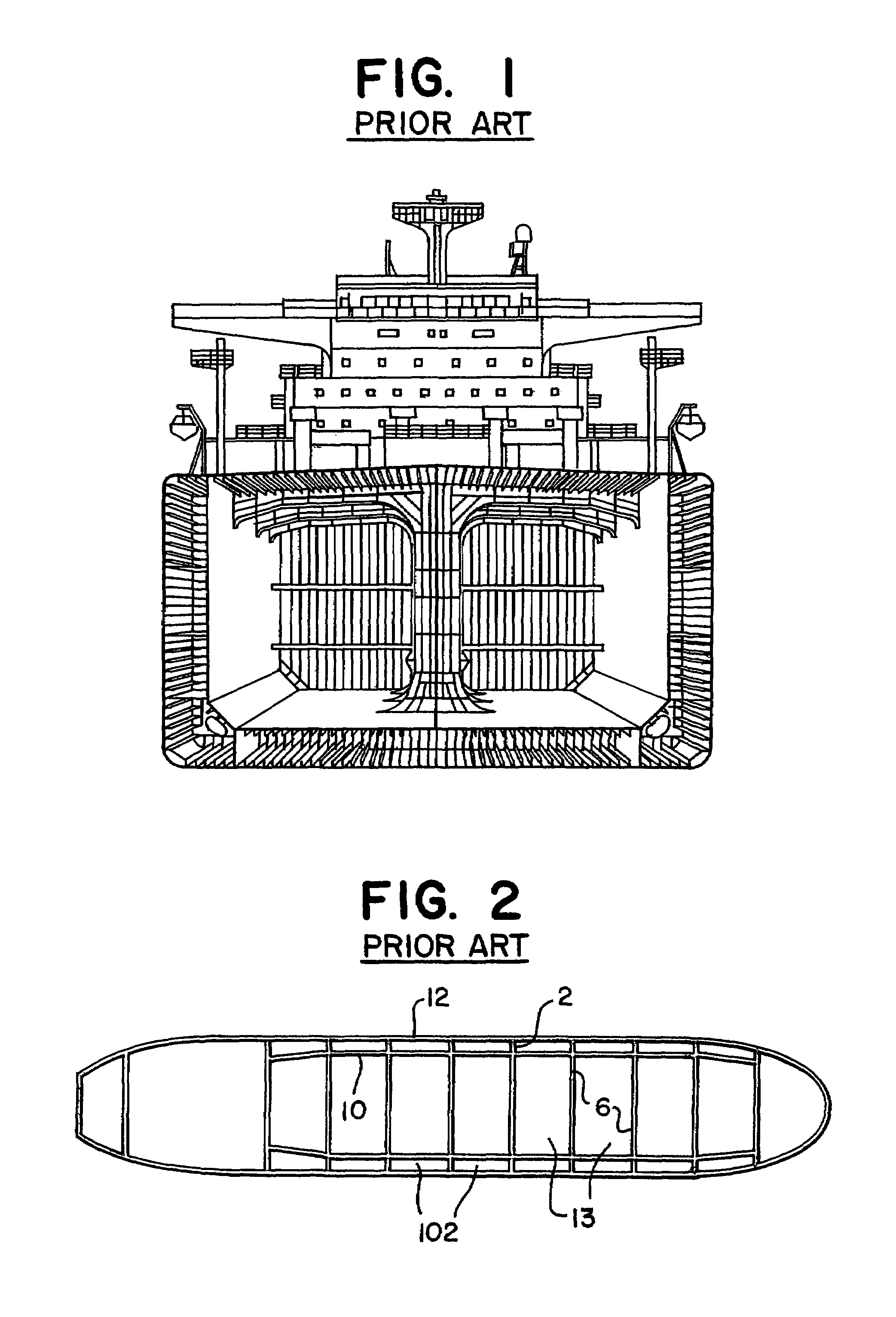

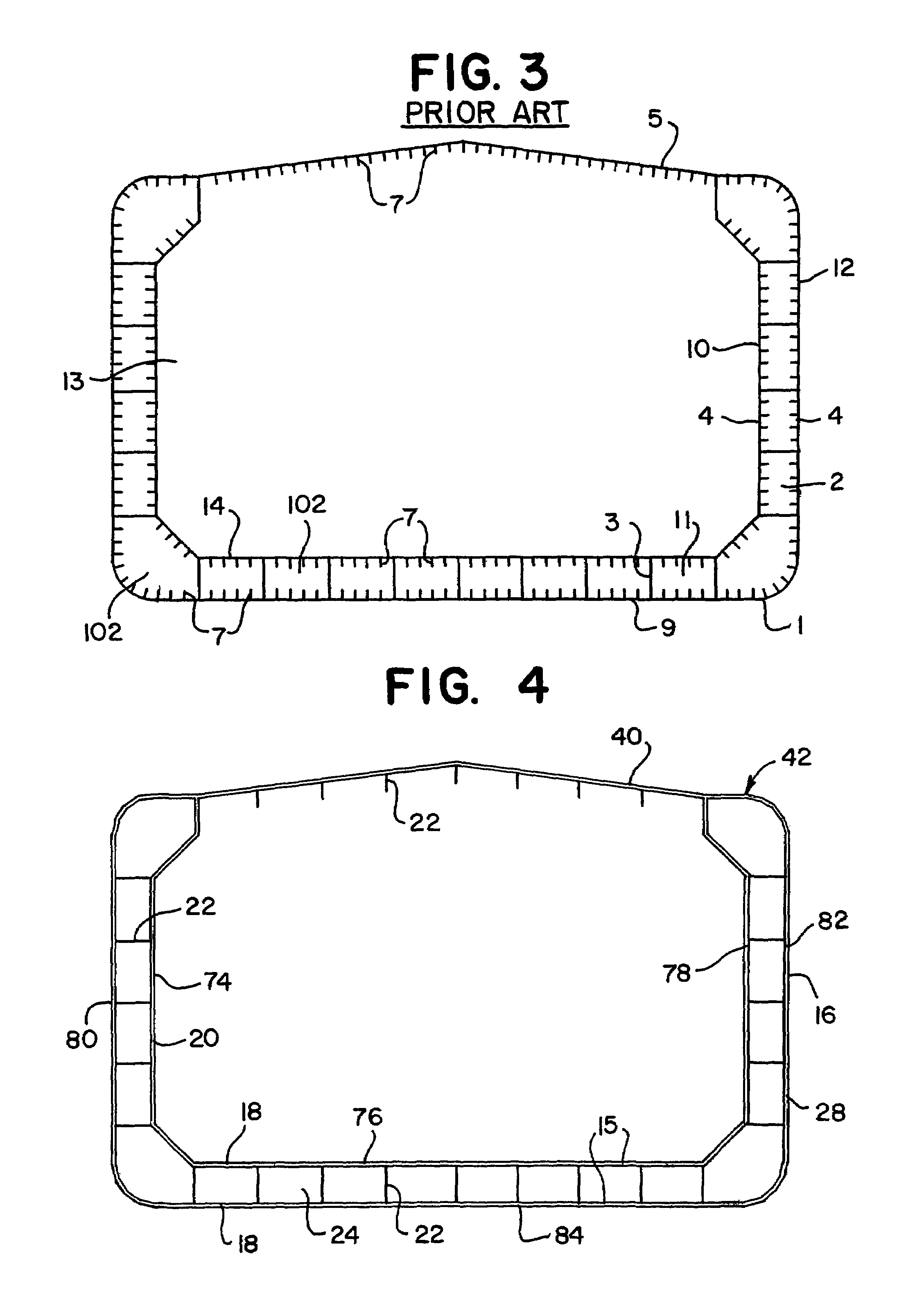

Composite steel structural plastic sandwich plate systems

InactiveUS6984452B2Solve the lack of ductilityReduce in quantityNon-magnetic metal hullsSynthetic resin layered productsStress concentrationComposite construction

Owner:INTELLIGENT ENG BAHAMAS

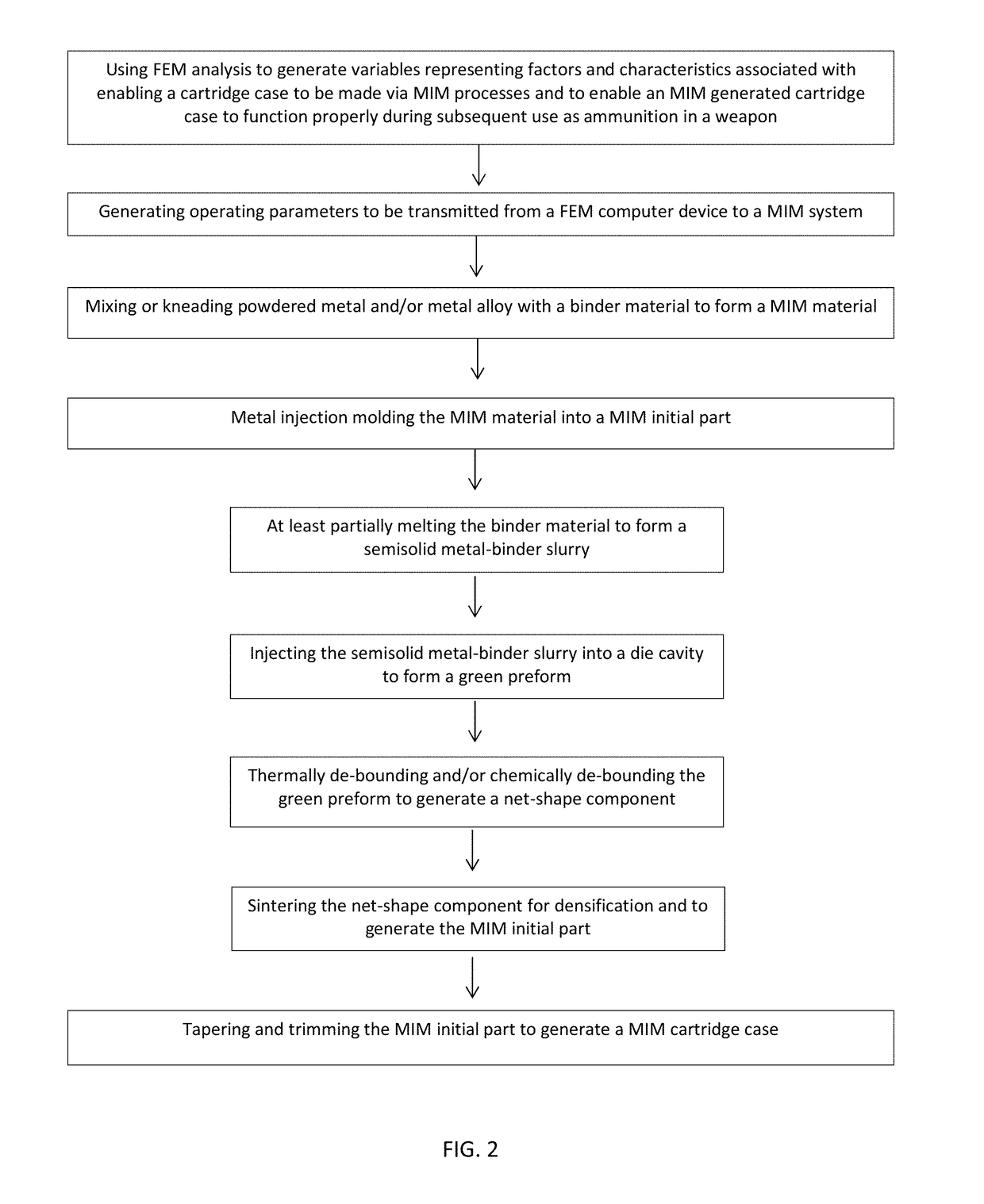

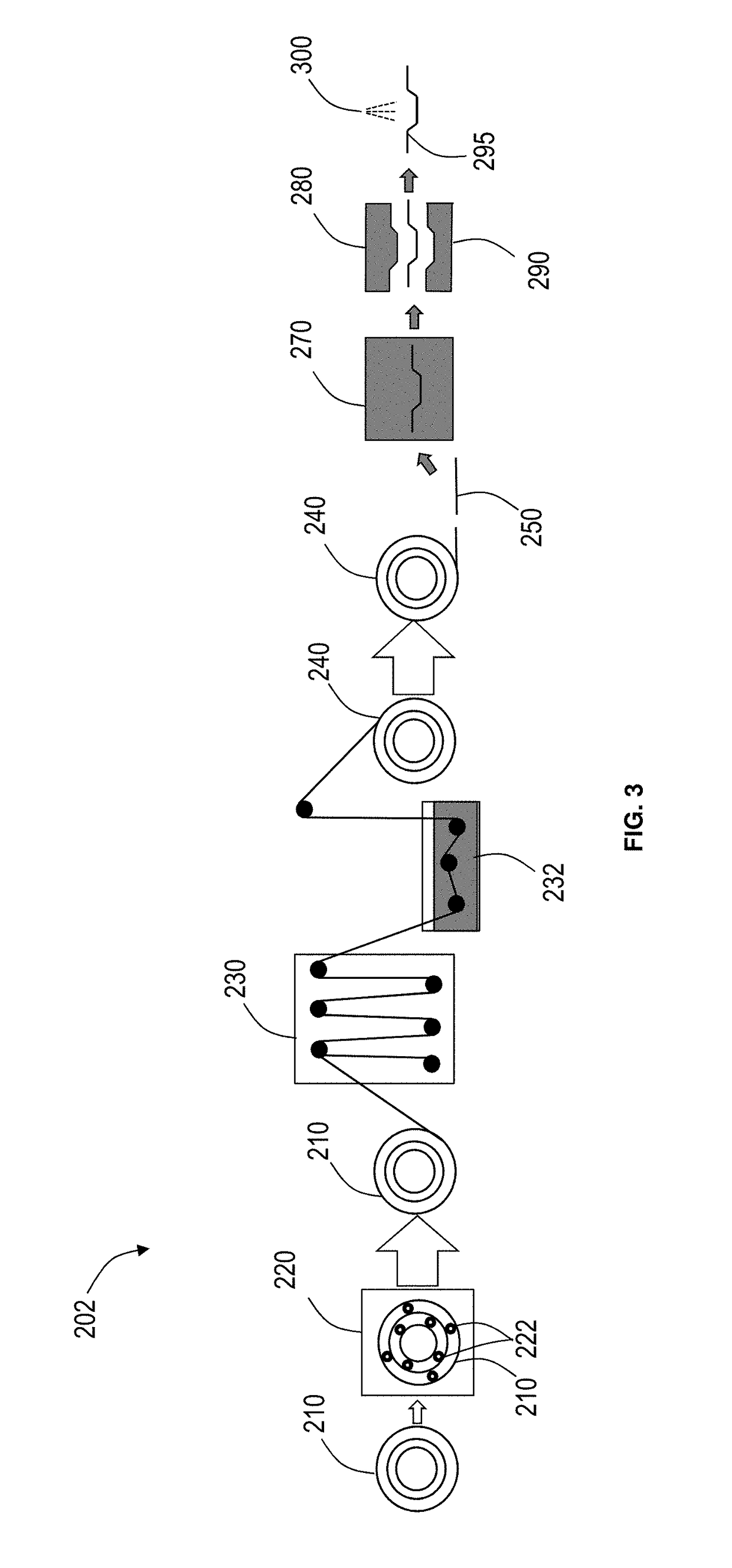

Metal Injection Molded Cased Telescoped Ammunition

ActiveUS20200318937A1Solve the lack of ductilitySufficient to elongationTransportation and packagingMetal-working apparatusMetal alloyInjection moulding

Disclosed is a cartridge case for various caliber ammunition that can consist essentially of a powdered metal and / or powdered metal alloy(s) that is formed into the cartridge case through an injection mold processing. Also disclosed is a method for forming a cartridge case, which may include use of Metal Injection Molding (“MIM”) processes to produce the cartridge case which retains a primer, propellant, and / or a bullet. Also disclosed are embodiments related to a case telescoped cartridge that may include a cap and a body. The body can consist essentially of or consists entirely of a powdered metal and / or powdered metal alloy(s) that has been formed through MIM. The cap can comprise plastic that has been formed through plastic molding or comprise powdered metal and / or powdered metal alloy(s) that has been formed through MIM.

Owner:CONCURRENT TECH

Mitigating liquid metal embrittlement in zinc-coated press hardened steels

InactiveUS20180237877A1High strengthSolve the lack of ductilityHot-dipping/immersion processesFurnace typesSurface layerMicrometer

Methods of reducing liquid metal embrittlement (LME) in zinc-coated high-strength steel alloys are provided. In one variation, the method includes decarburizing an exposed surface of a high-strength steel alloy to form a decarburized surface layer. The decarburized surface layer has a thickness of less than or equal to about 50 micrometers. The decarburized surface layer may have greater than or equal to about 80 volume % ferrite. The method also includes applying a zinc-based coating to the decarburized surface layer. A blank is formed from the high-strength steel alloy. The method also includes heating and press hardening the blank to form a press-hardened component having an ultimate tensile strength of greater than or equal to about 1,100 MPa that is substantially free of liquid metal embrittlement.

Owner:GM GLOBAL TECH OPERATIONS LLC

Weldable, crack-resistant co-based alloy and overlay method

ActiveUS20080193675A1Solve the lack of ductilityImprove corrosion resistancePretreated surfacesArc welding apparatusAlloyWear resistance

A method for imparting wear- and corrosion-resistance to a metal component comprising overlaying the component with a ductile Co-based alloy comprising between about 0.12 wt % and about 0.7 wt % C, between about 20 wt % and about 30 wt % Cr, between about 10 wt % and about 15 wt % Mo, between about 1 wt % and about 4 wt % Ni, and balance of Co, without forming cracks during the alloy's solidification.

Owner:KENNAMETAL INC

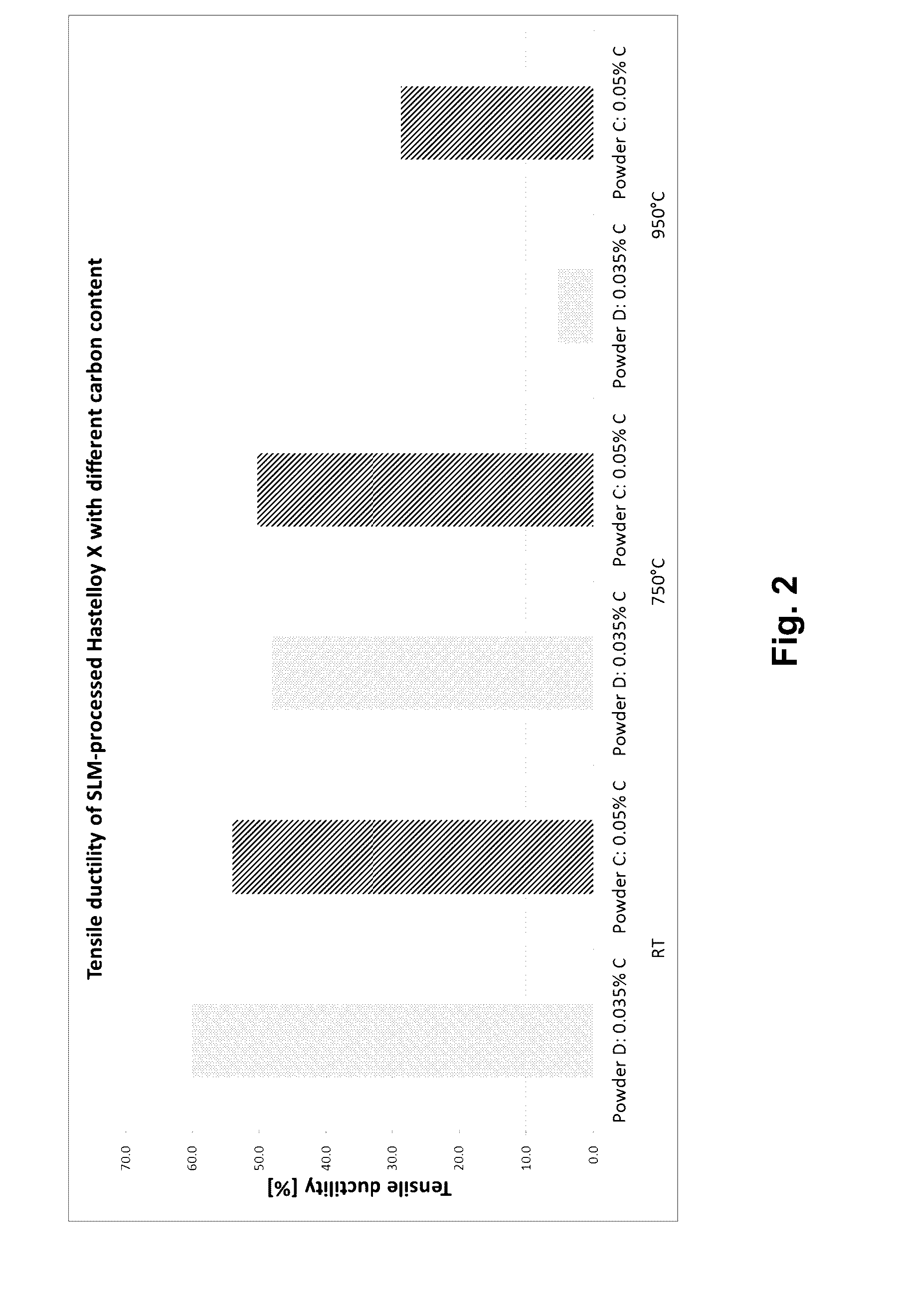

High temperature nickel-base superalloy for use in powder based manufacturing process

InactiveUS20170021415A1Reduce hot cracksAvoid missingAdditive manufacturing apparatusTransportation and packagingSelective laser meltingChemical composition

The application relates to the technology of producing three-dimensional articles by means of powder-based additive manufacturing, such as selective laser melting or electron beam melting. Especially, it refers to a Nickel-base superalloy powder on basis of Hastelloy X consisting of the following chemical composition: 20.5-23.0 Cr, 17.0-20.0 Fe, 8.0-10.0 Mo, 0.50-2.50 Co, 0.20-1.00 W, 0.04-0.10 C, 0-0.5 Si, 0-0.5 Mn, 0-0.008 B, remainder Ni and unavoidable residual elements and wherein the powder has a powder size distribution between 10 and 100 μm and a spherical morphology and the ratio of the content of alloying elements C / B is at least 5 or more.

Owner:ANSALDO ENERGIA IP UK LTD

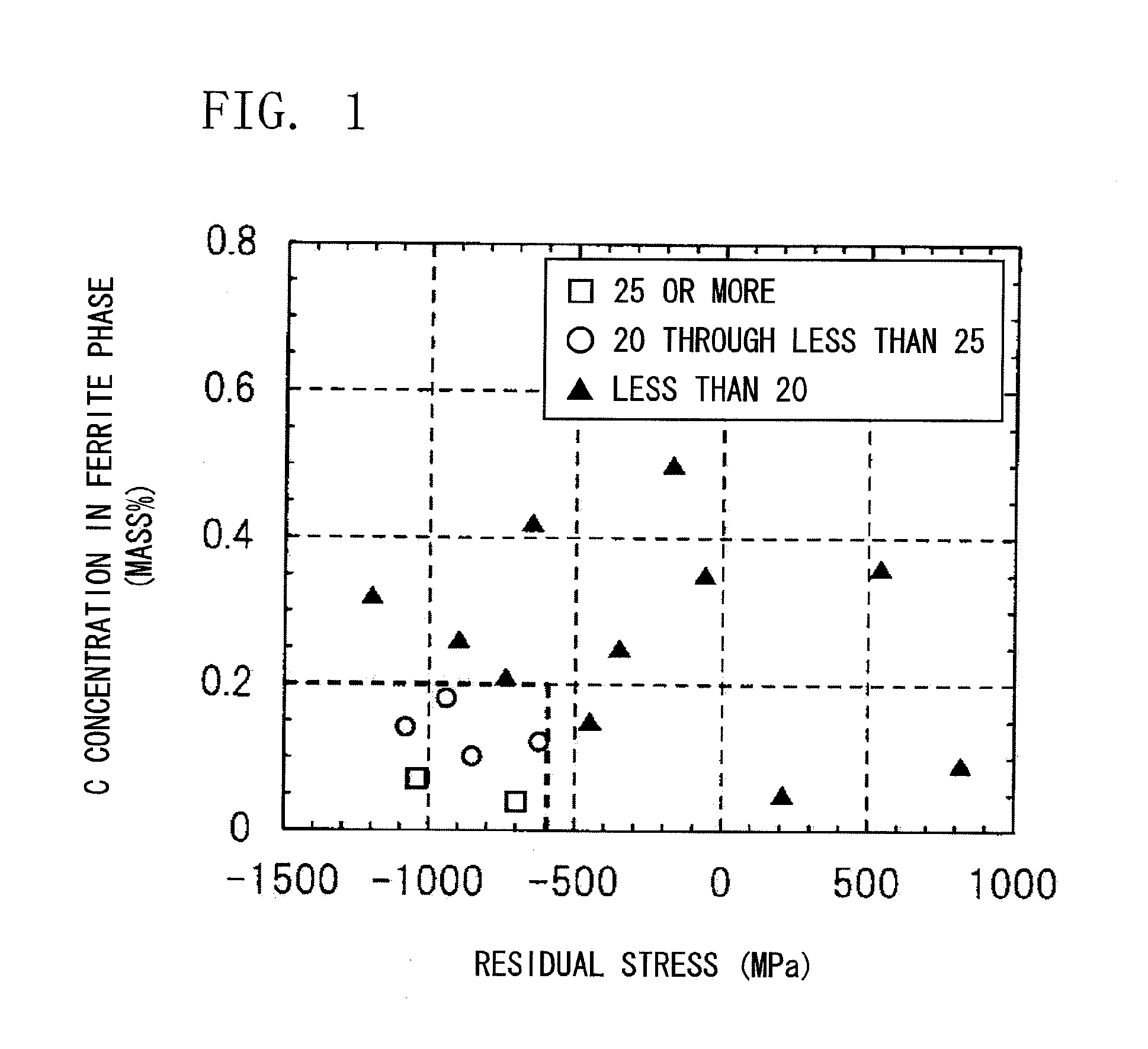

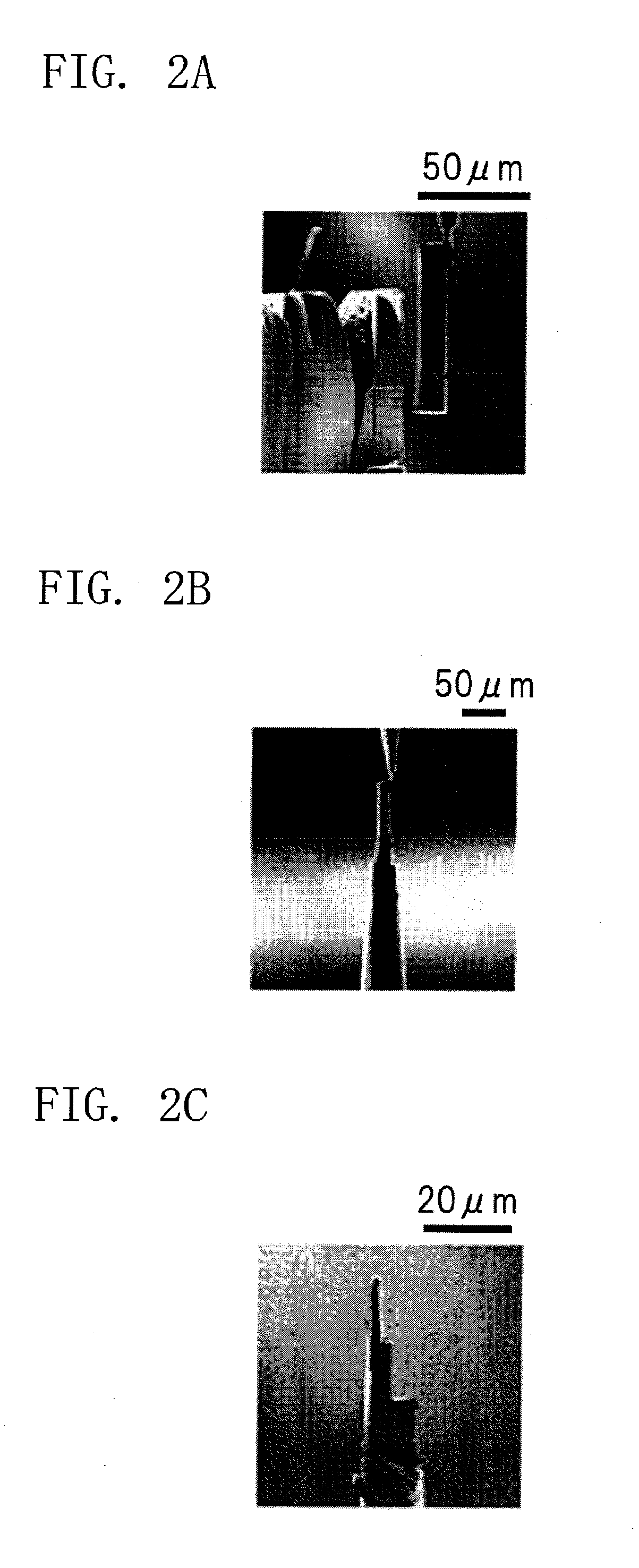

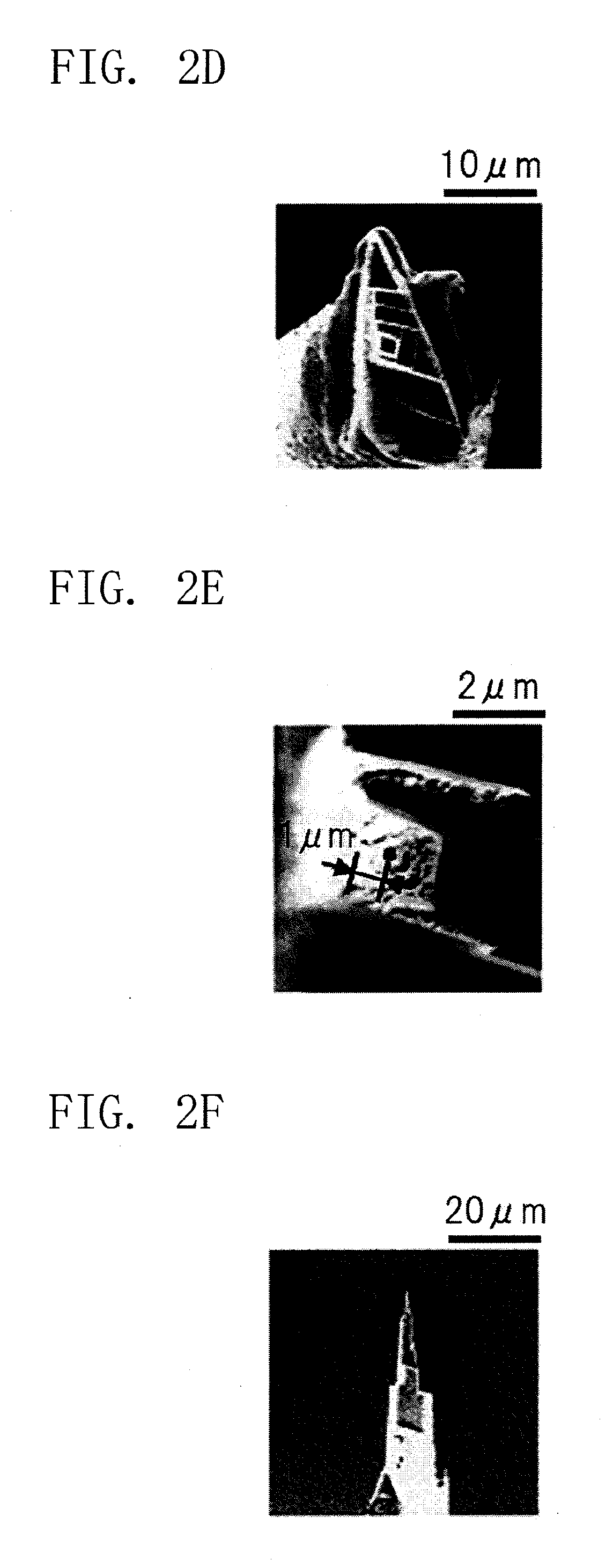

High-strength ultrathin steel wire and method of manufacturing the same

InactiveUS20110168302A1High strengthImprove ductilityFurnace typesHeat treatment furnacesChemical compositionMetallurgy

The present invention provides a steel wire, including chemical components of: C: 0.7-1.2 mass %; Si: 0.05-2.0 mass %; and Mn: 0.2-2.0 mass %, with a balance including Fe and inevitable impurities, in which the steel wire has a pearlite structure, the average C concentration at a center portion of a ferrite phase in an outermost layer of the steel wire is 0.2 mass % or lower, and a residual compressive stress in the longitudinal direction of the steel wire in the outermost layer is 600 MPa or more.

Owner:NIPPON STEEL CORP

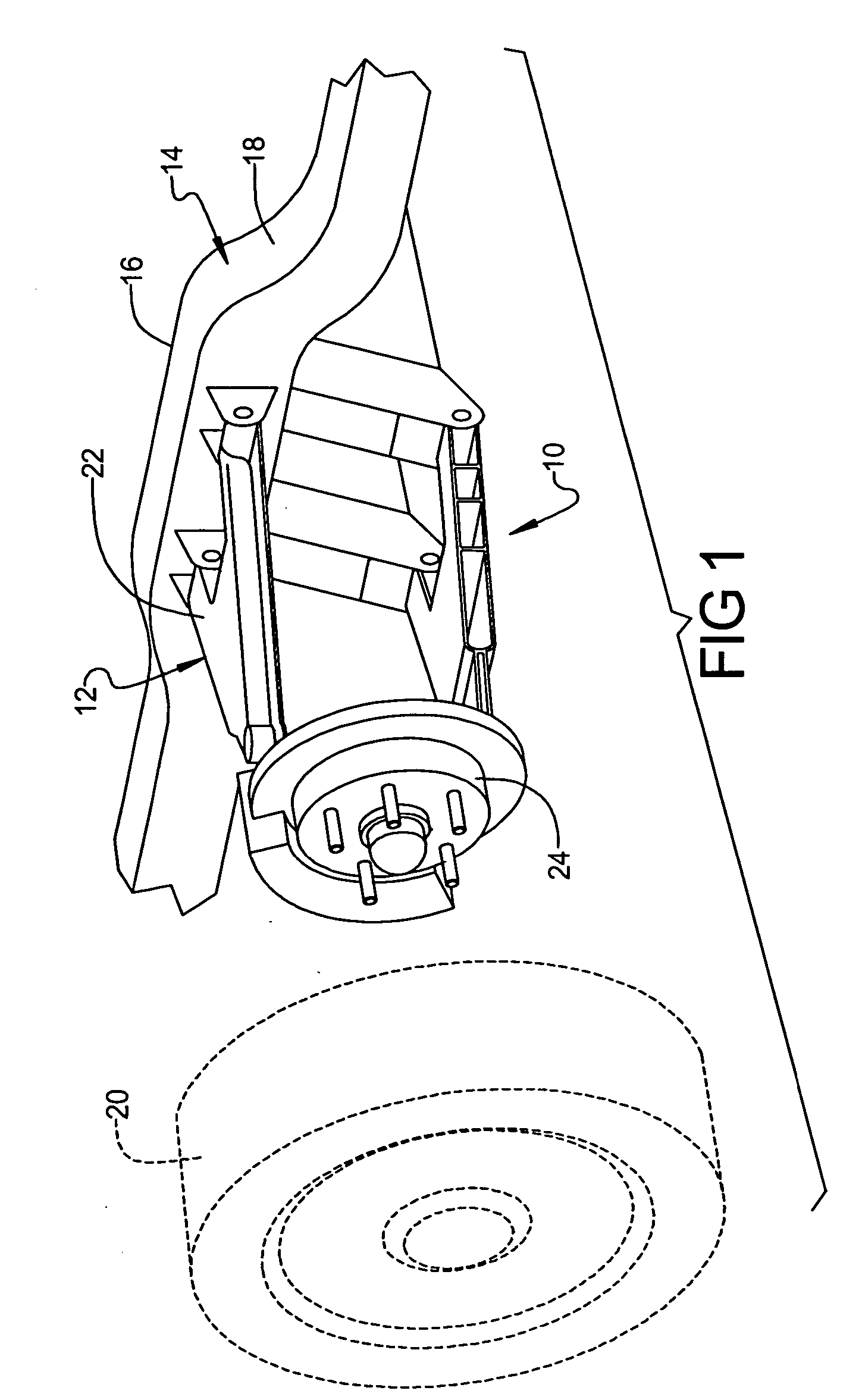

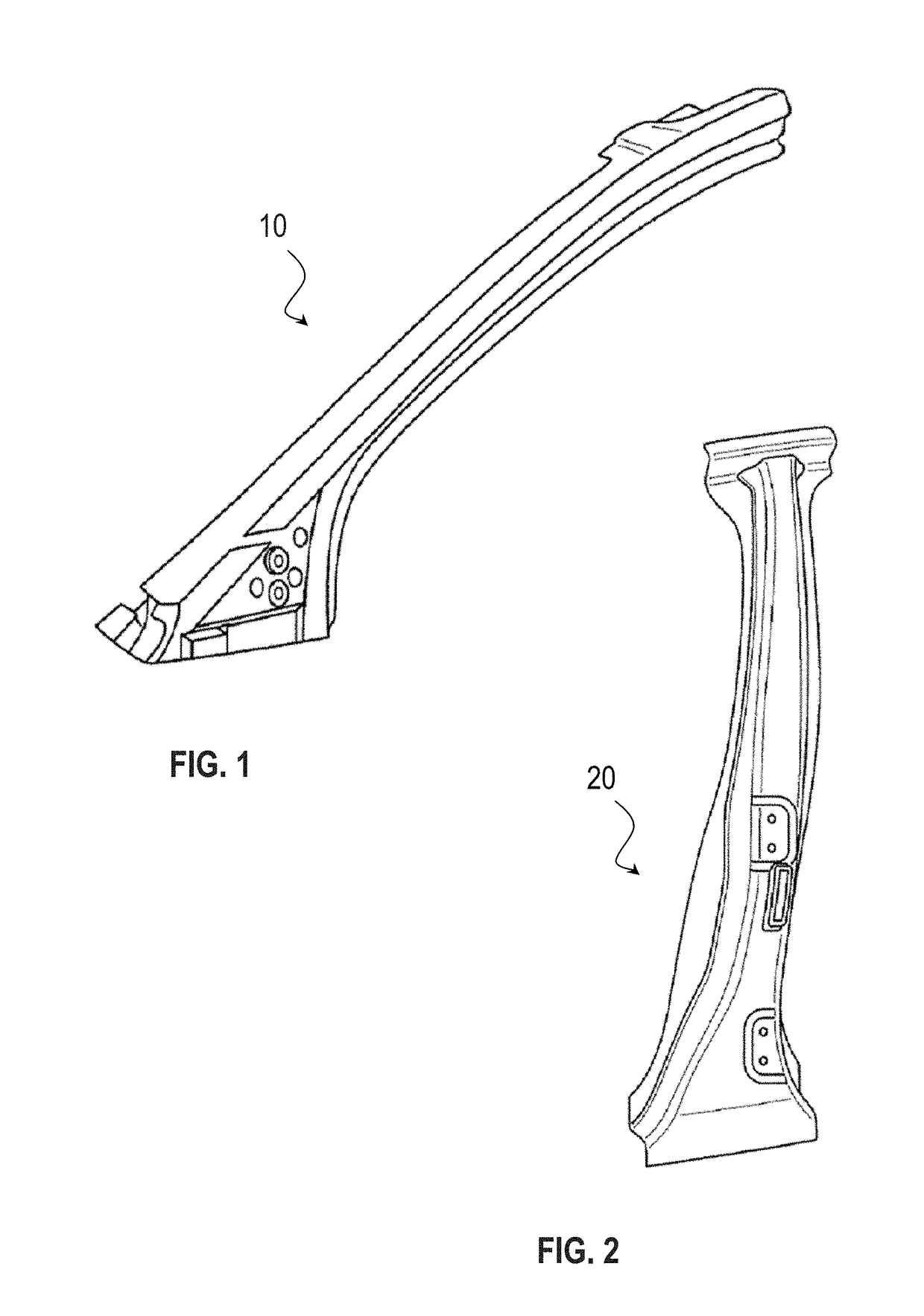

Suspension control arm assembly for vehicles

InactiveUS20060108763A1Avoid excessive massSolve the lack of ductilityResilient suspensionsPivoted suspension armsControl armControl theory

A control arm assembly for a suspension system of a vehicle includes a one-piece extruded control arm for operative connection to a frame of the vehicle. The control arm assembly also includes at least one of a bushing and / or balljoint connected to the control arm and for connection to structure of the vehicle.

Owner:GENERAL MOTORS COMPANY

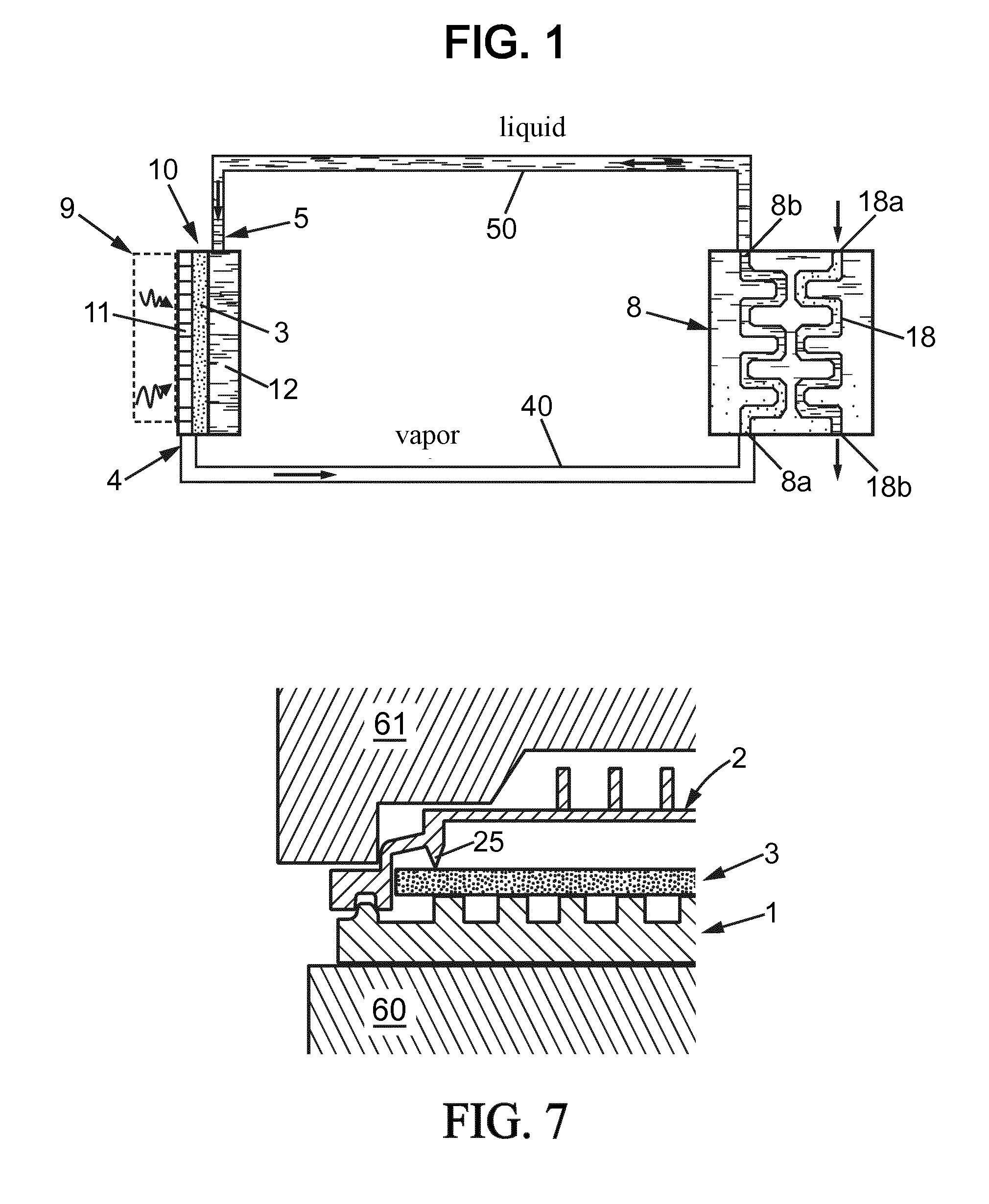

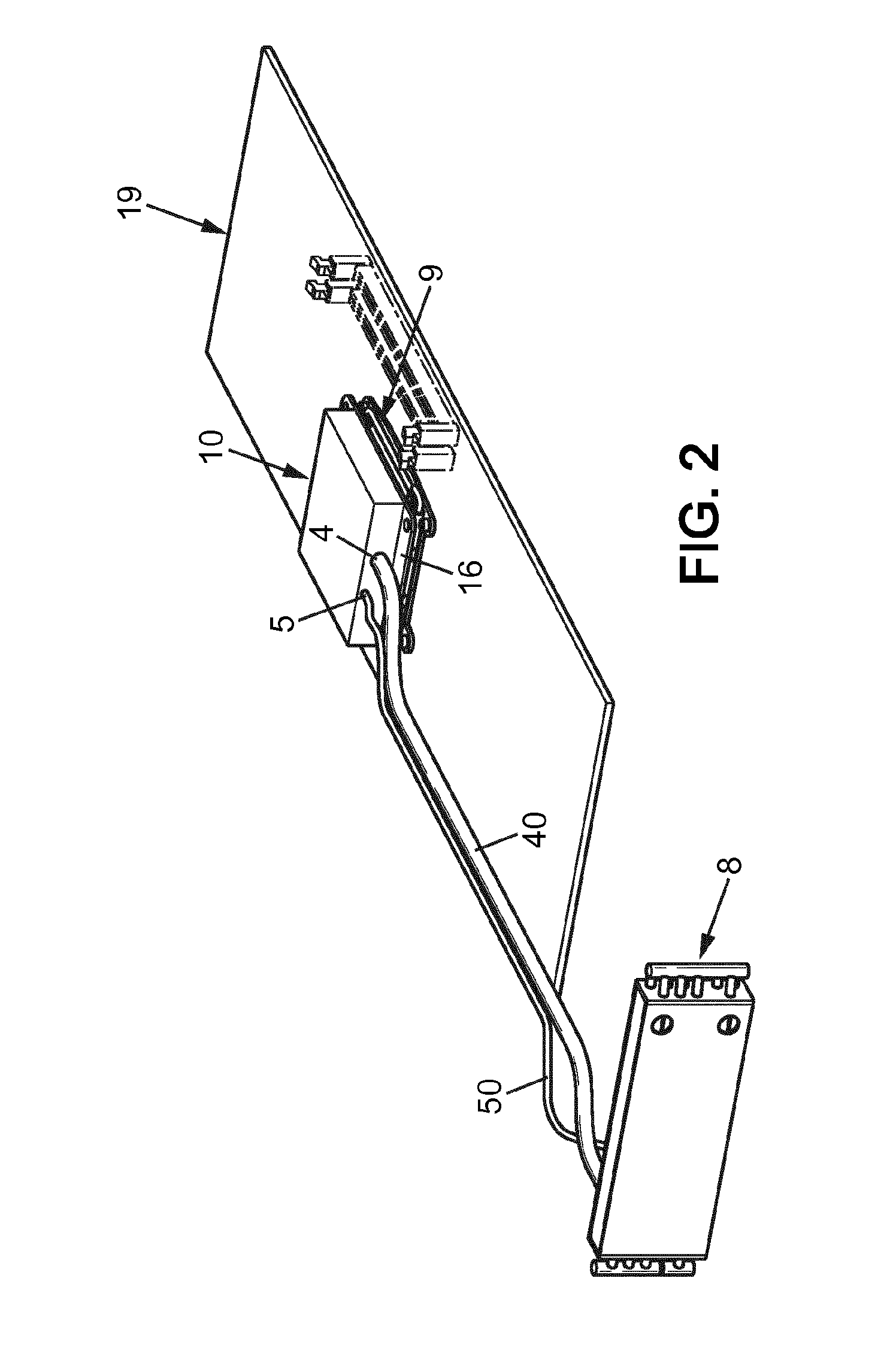

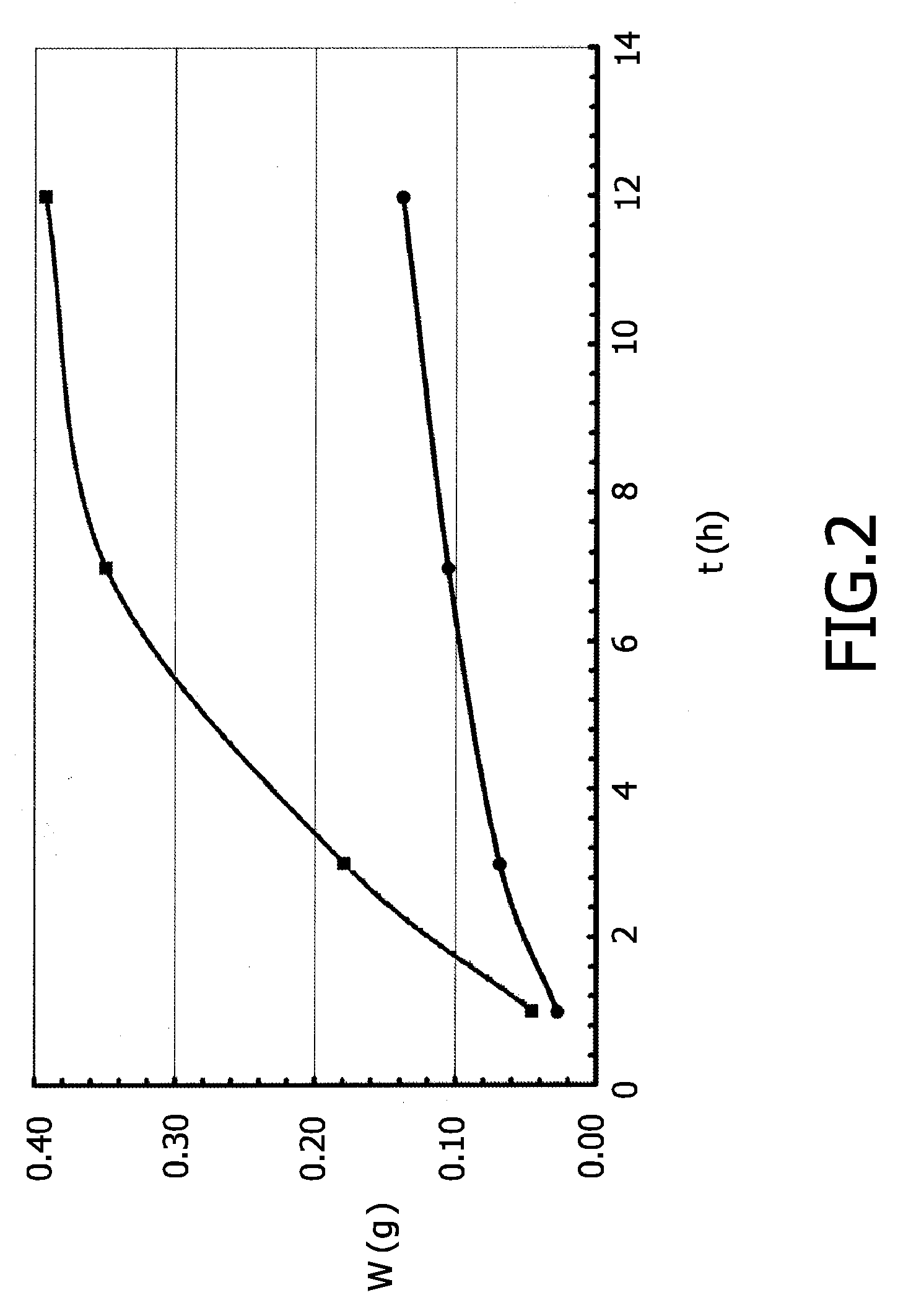

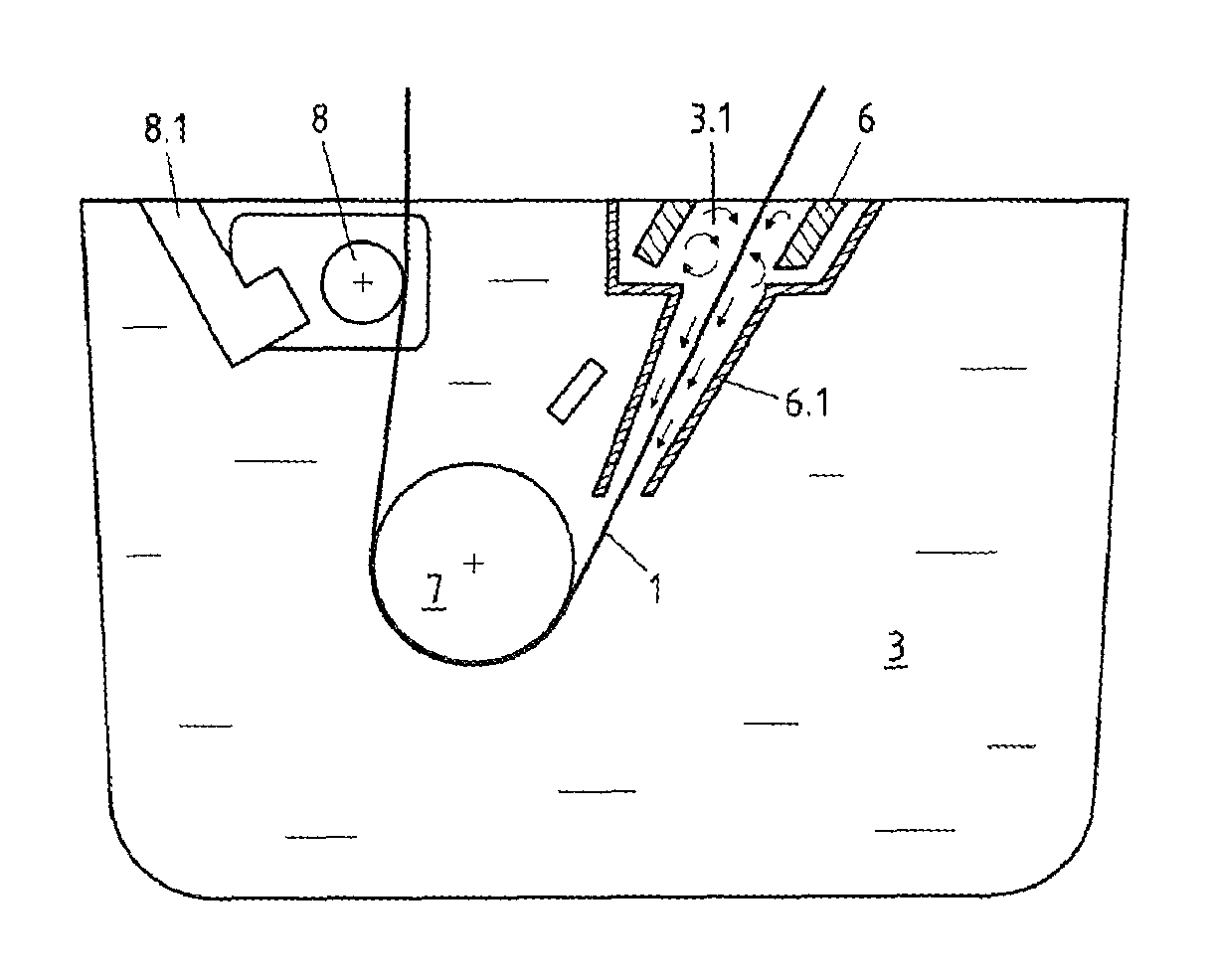

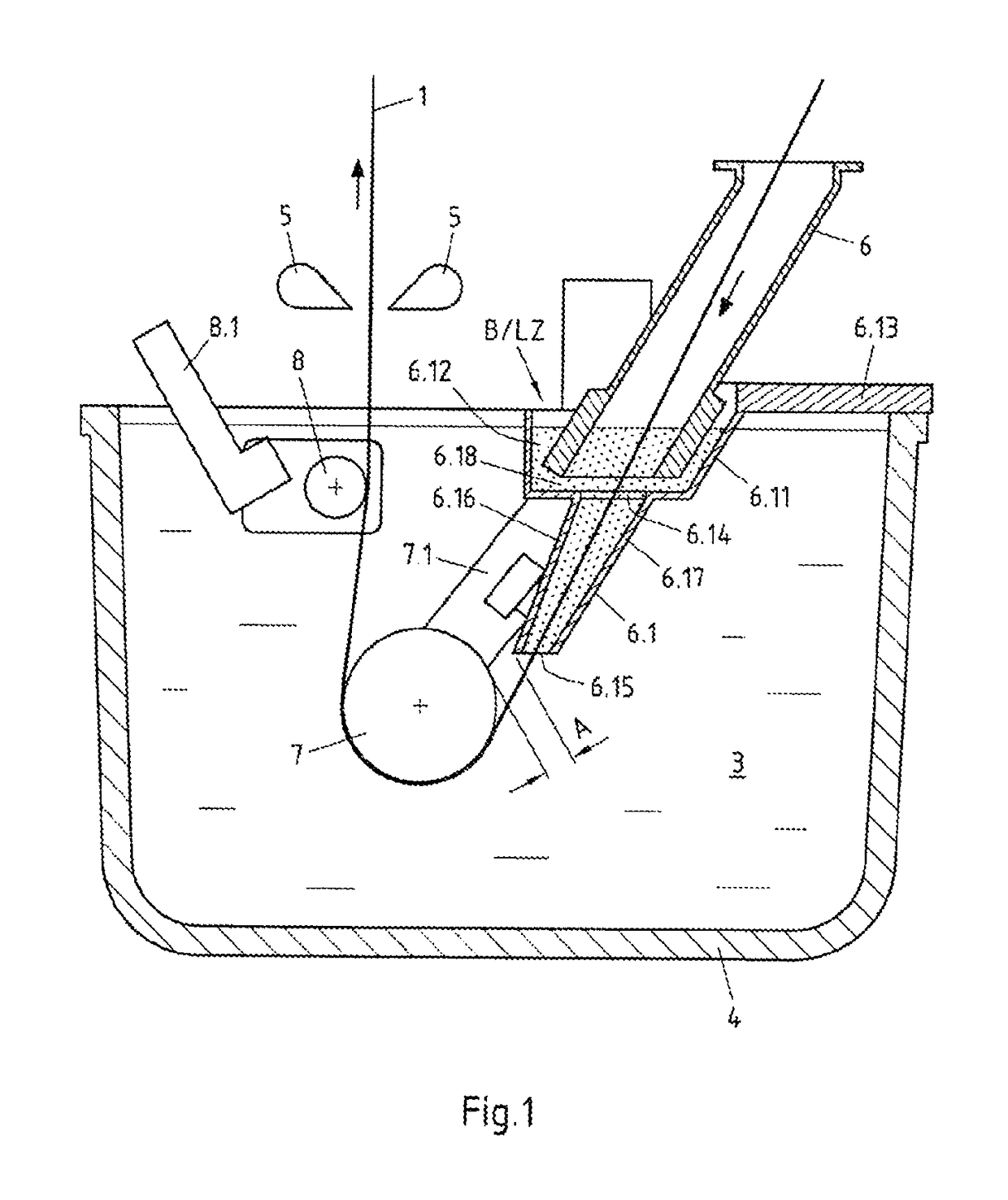

Evaporator with simplified assembly for diphasic loop

ActiveUS20160131438A1Low priceEasy to produceSemiconductor/solid-state device detailsSolid-state devicesEngineeringGas chamber

An evaporator for a diphasic heat transfer system with capillary pumping, includes a base plate with a peripheral edge and an outer face for receiving heat receiving calories from a dissipative element, a body with a bottom, side portions and a border adjacent to the peripheral border of the base plate, a porous mass forming a layer with a capillary structure, interposed between the base plate and the bottom, which defines a first gas chamber and a second liquid chamber, the body being assembled on the base plate by crimping, such that there is no need for a gluing, screwing, riveting or welding operation to obtain a tight assembly of the evaporator.

Owner:CALYOS

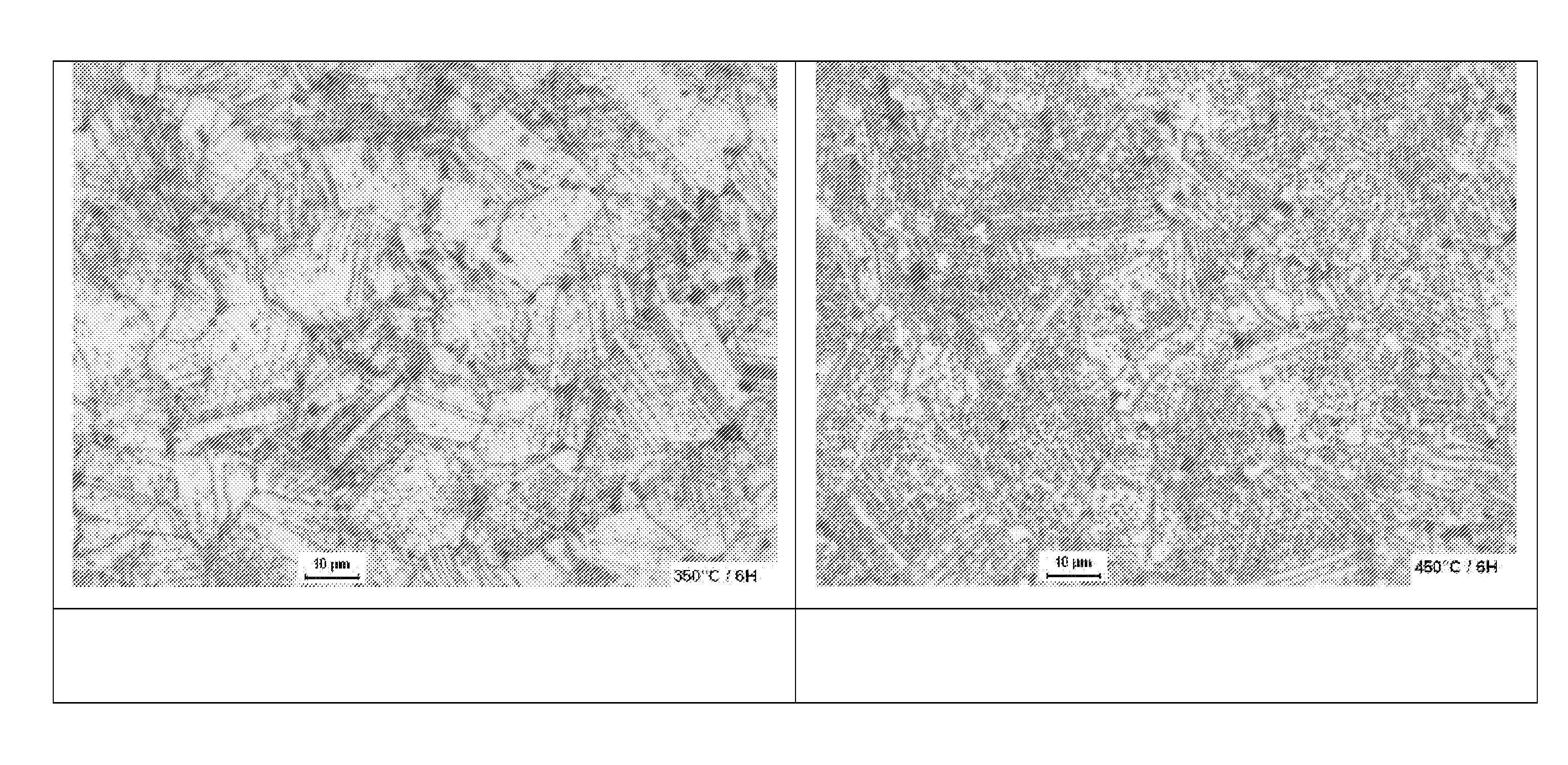

Cu-Ni-Zn-Mn Alloy

Precipitation hardened alloy on the basis of copper, zinc, nickel and manganese exhibiting a high strength and ductility with values similar to those of stainless steels in combination with excellent machinability. The inventive alloy family is characterized by fine fibre-like or globular precipitates that emerge during intermediate temperature annealing treatments, which in case of the unleaded variations significantly improves the machinability. The alloy of invention is particularly suited for free machining applications such as the production of pen tips and reservoirs for writing implements of reduced tip dimensions, where conventional Cu—Ni—Zn—Mn alloys fail due to lack of strength and where the corrosion resistance in gel-based inks is insufficient without restriction to other fields of application.

Owner:BAOSHIDA SWISSMETAL

Two-step hot forming of steels

InactiveUS20180216205A1Shorten the timeSave energyHot-dipping/immersion processesFurnace typesAlloyUltimate tensile strength

Methods for press hardening steel alloys comprised of medium-Mn are provided. The press-hardened steel alloy may have an ultimate tensile strength (UTS) of at least 1,700 MPa and a tensile elongation of at least 8%. The press-hardened steel alloy may be formed in two forming steps above the martensitic finish temperature. The press-hardened steel may have a microstructure comprising martensite at greater than or equal to about 80% to less than or equal to about 98% and retained austenite at less than or equal to about 20% to greater than or equal to about 2%.

Owner:GM GLOBAL TECH OPERATIONS LLC

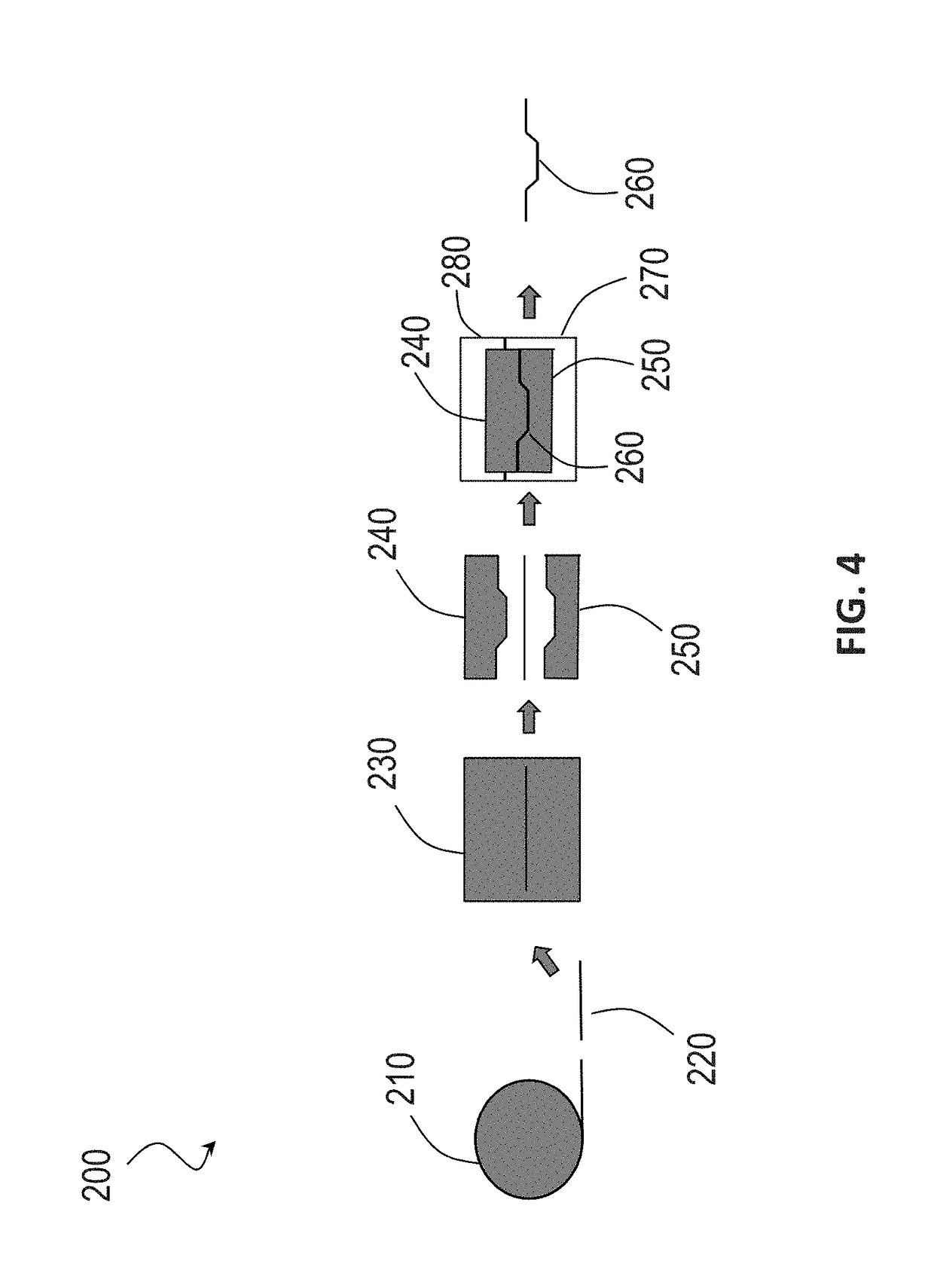

Iron base high temperature alloy and method of making

InactiveUS6841011B2Low densityImprove tensile propertiesPump componentsBlade accessoriesRoom temperatureSolid solution

The present invention is directed to an iron, aluminum, chromium, carbon alloy and a method of producing the same, wherein the alloy has g good room temperature ductility, excellent high temperature oxidation resistance and ductility. The alloy includes about 10 to 70 at. % iron, about 10 to 45 at. % aluminum, about 1 to 70 at. % chromium and about 0.9 to 15 at. % carbon. The invention is also directed to a material comprising a body-centered-cubic solid solution of this alloy, and a method for strengthening this material by the precipitation of body-centered-cubic particles within the solid solution, wherein the particles have substantially the same lattice parameters as the underlying solid solution. The ease of processing and excellent mechanical properties exhibited by the alloy, especially at high temperatures, allows it to be used in high temperature structural applications, such as a turbocharger component.

Owner:LIN HUI

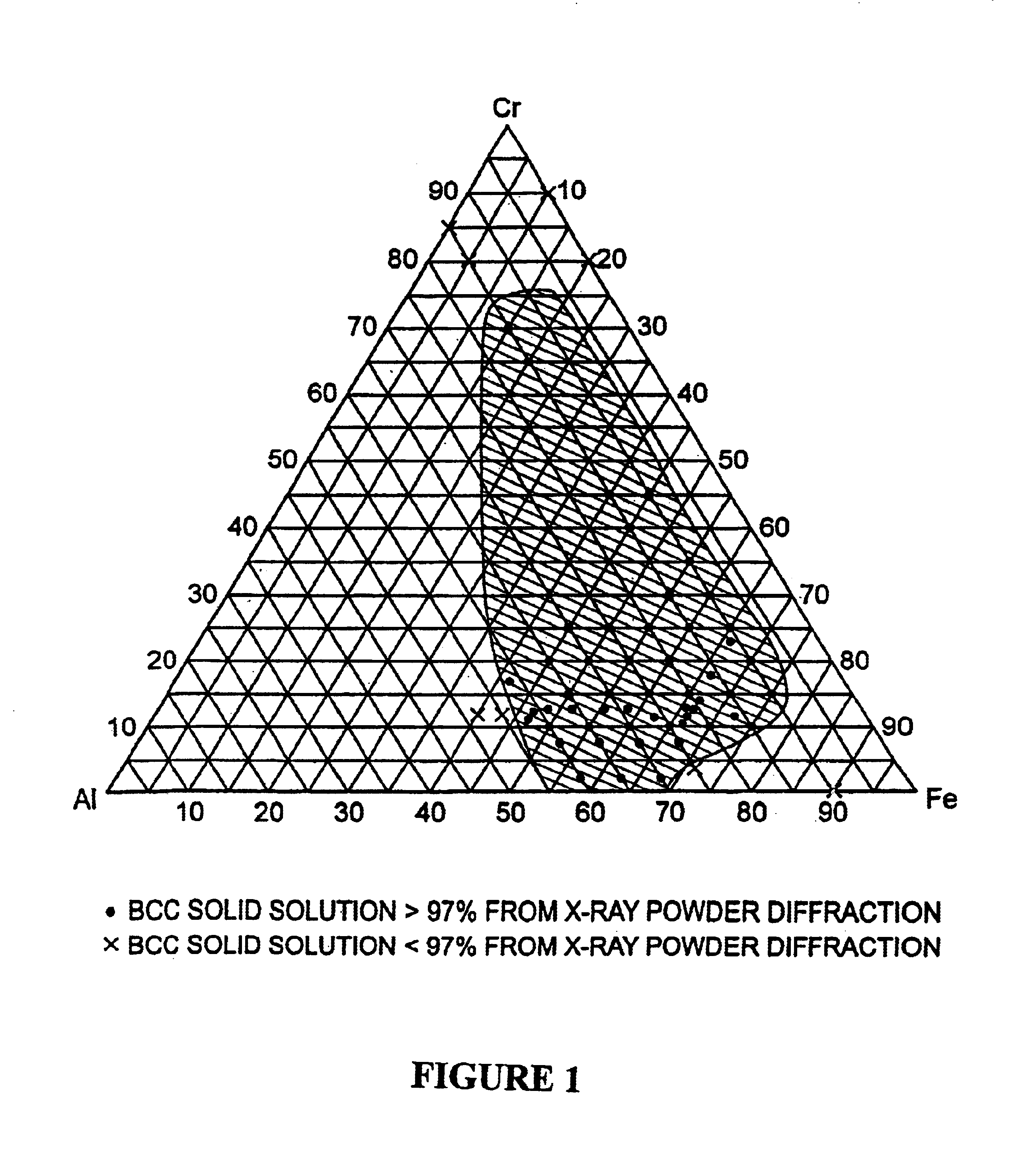

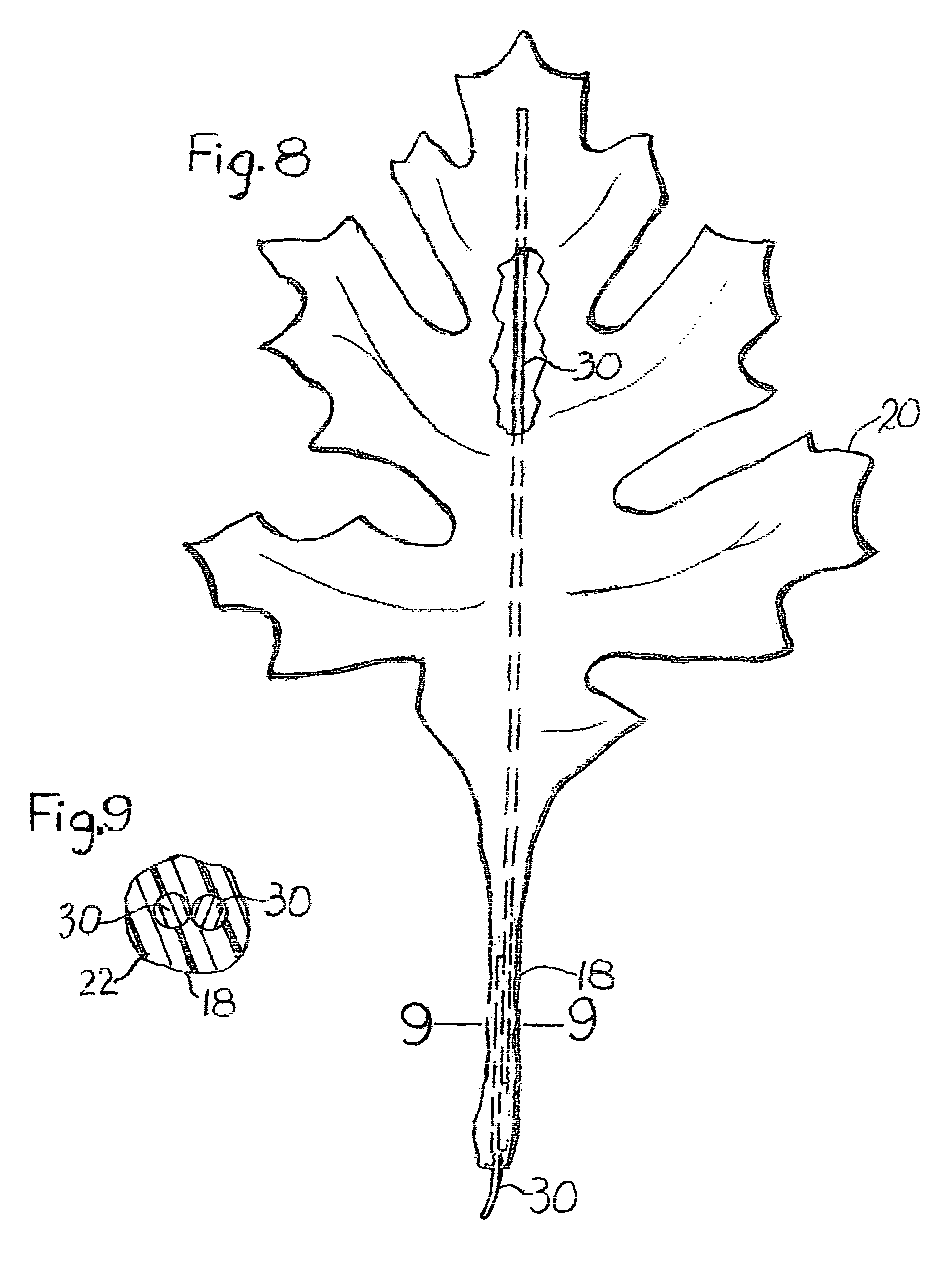

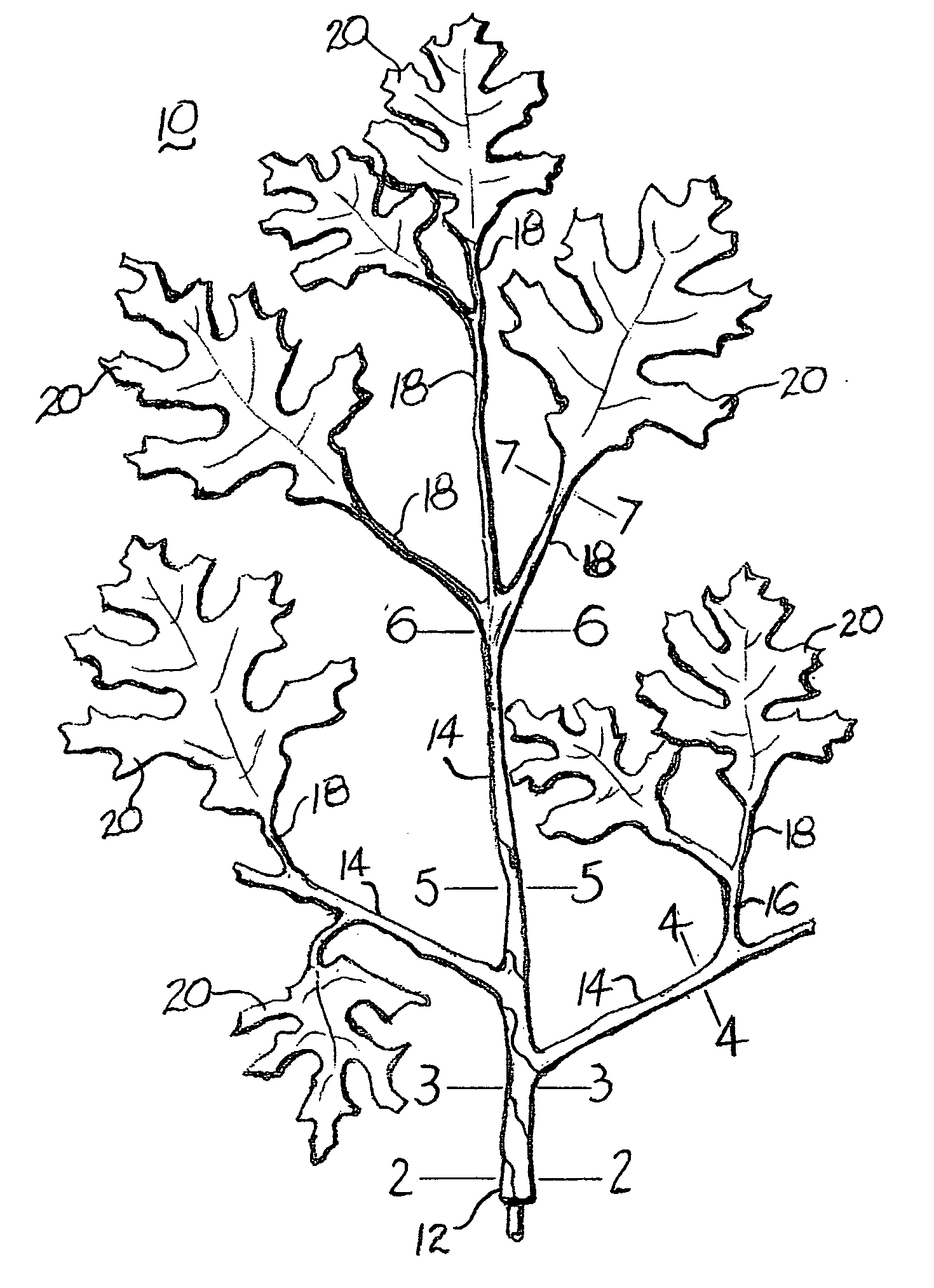

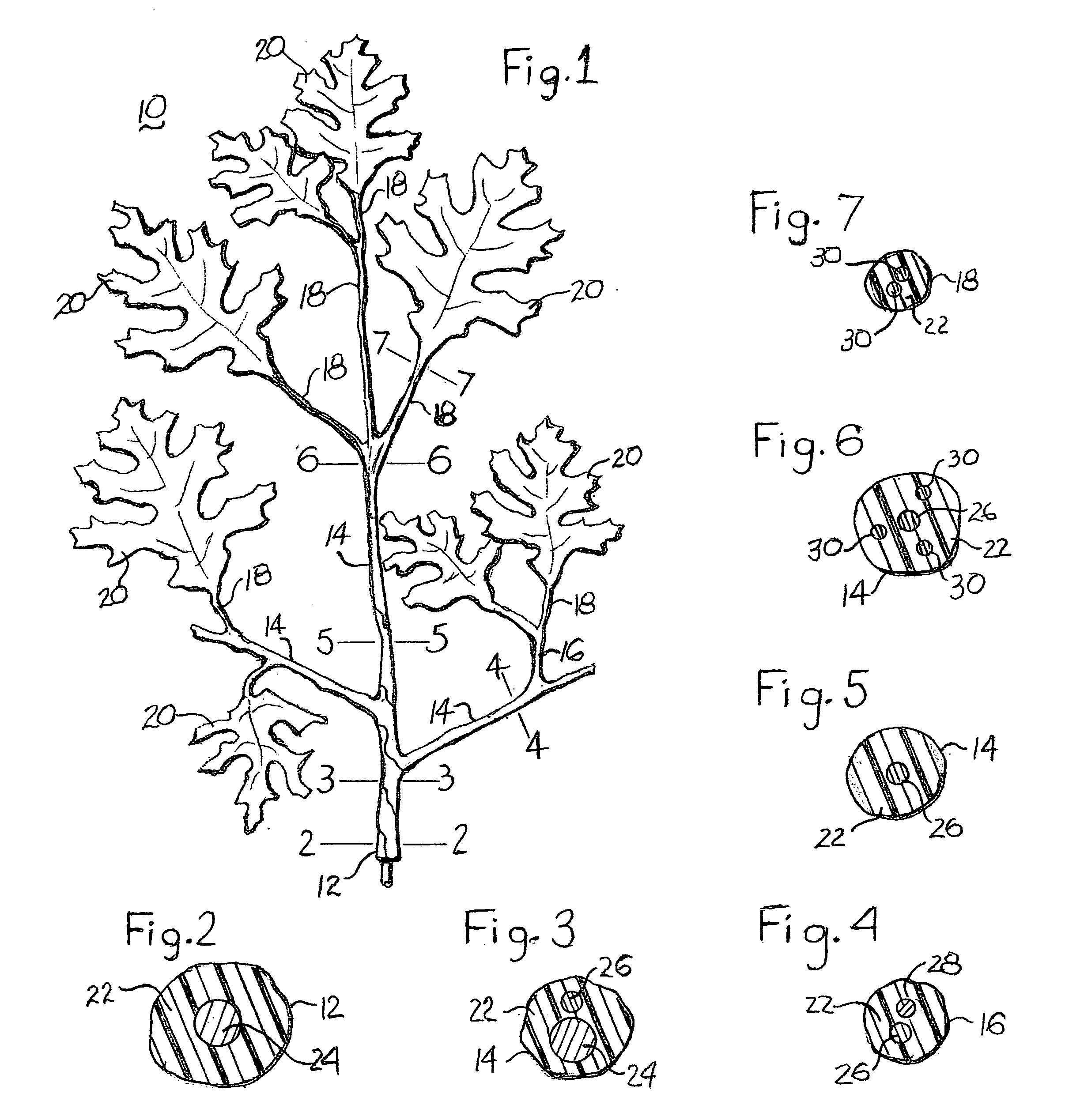

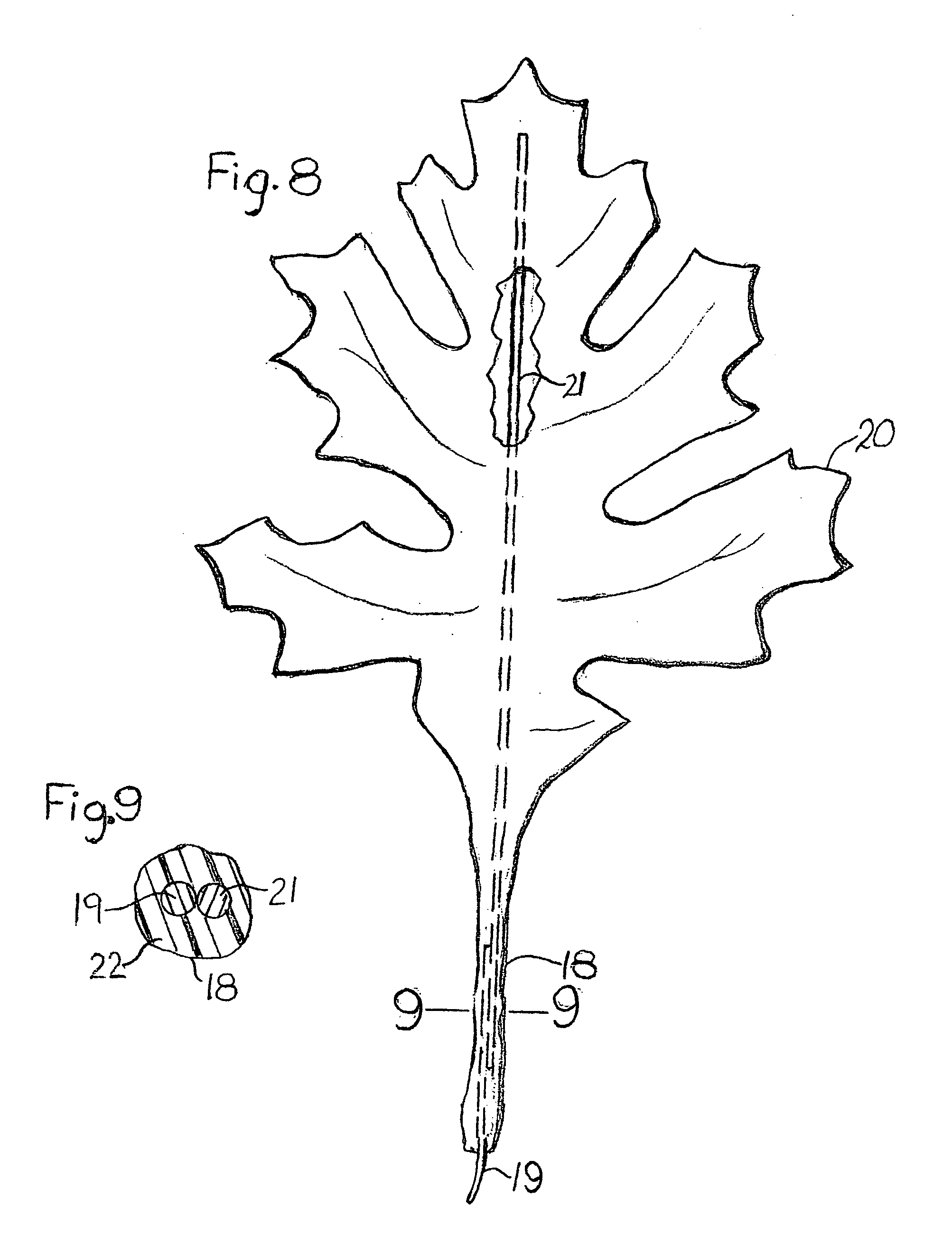

Artificial foliage

ActiveUS7371442B2Sufficient degree of elasticitySolve the lack of ductilityDead plant preservationArtificial flowers and garlandsPiano wireEngineering

An artificial foliage structure with wire cores embedded in its leafy parts causing these parts to “spring back” upon removal of compressive loading acting thereupon. These wire cores may be made of hard, springy steel such as piano wire or small diameter spring wire. Thicker, woody limbs and branches have embedded therein heavier wire cores that are sufficiently soft to be given a set solely by manually applied bending force.

Owner:AMERICAN PRIDE OUTDOORS LLC

Alloy type thermal fuse and wire member for a thermal fuse element

InactiveUS6963264B2Dispersion suppressionSatisfactory operationHeating/cooling contact switchesEmergency protective devicesHot meltOperational stability

The invention relates to an alloy type thermal fuse and a wire member for a thermal fuse element, and provides an alloy type thermal fuse in which a fuse element does not contain a harmful metal, the operating temperature is about 150° C., the dispersion of the operating temperature can be sufficiently suppressed, and the operation stability to a heat cycle can be satisfactorily assured. The thermal fuse has an alloy composition of 30 to 70% Sn, 0.3 to 20% Sb, and a balance Bi.

Owner:UCHIHASHI ESTEC

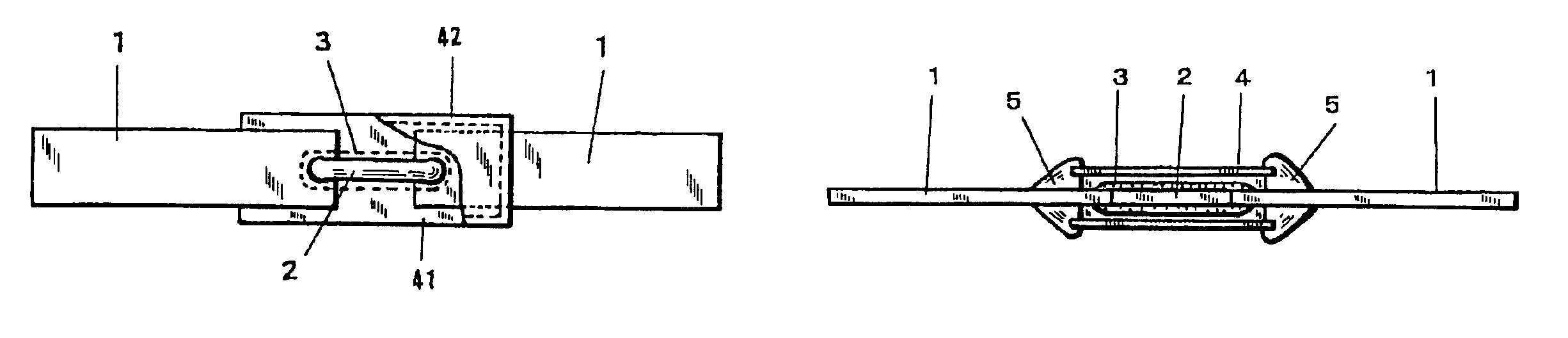

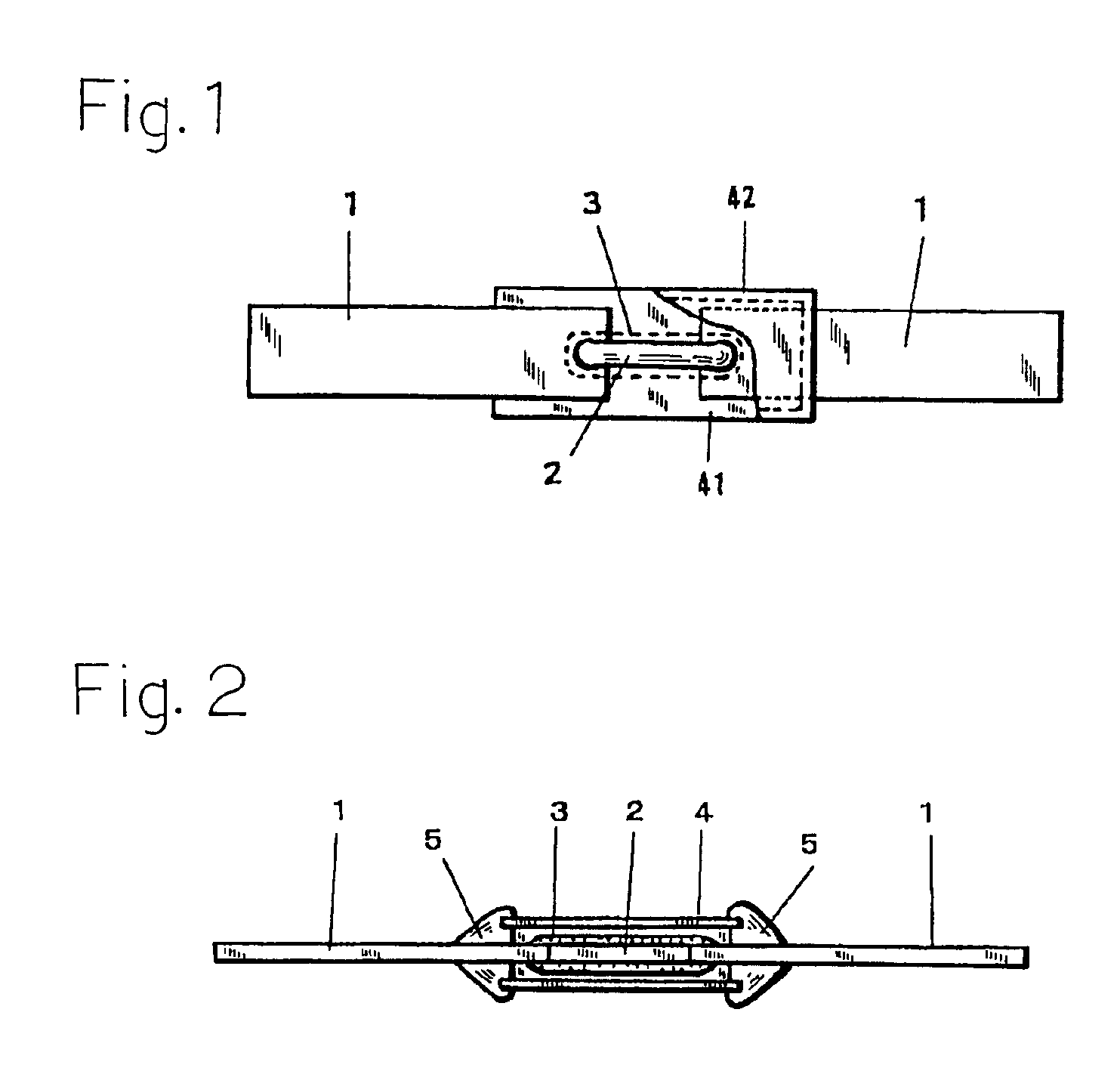

Plain bearing

A plain bearing is described having a bearing metal layer, supported by a support shell, made of an aluminum or copper alloy and having a lead-free running layer, possibly applied to the bearing metal layer over an intermediate layer, made of a zinc matrix having at least one further alloy element. To achieve good tribological properties, it is suggested that the zinc matrix of the running layer contains 1 to 49 wt.-% bismuth as an additional alloy element.

Owner:GLEITLAGER +1

Austenitic alloy

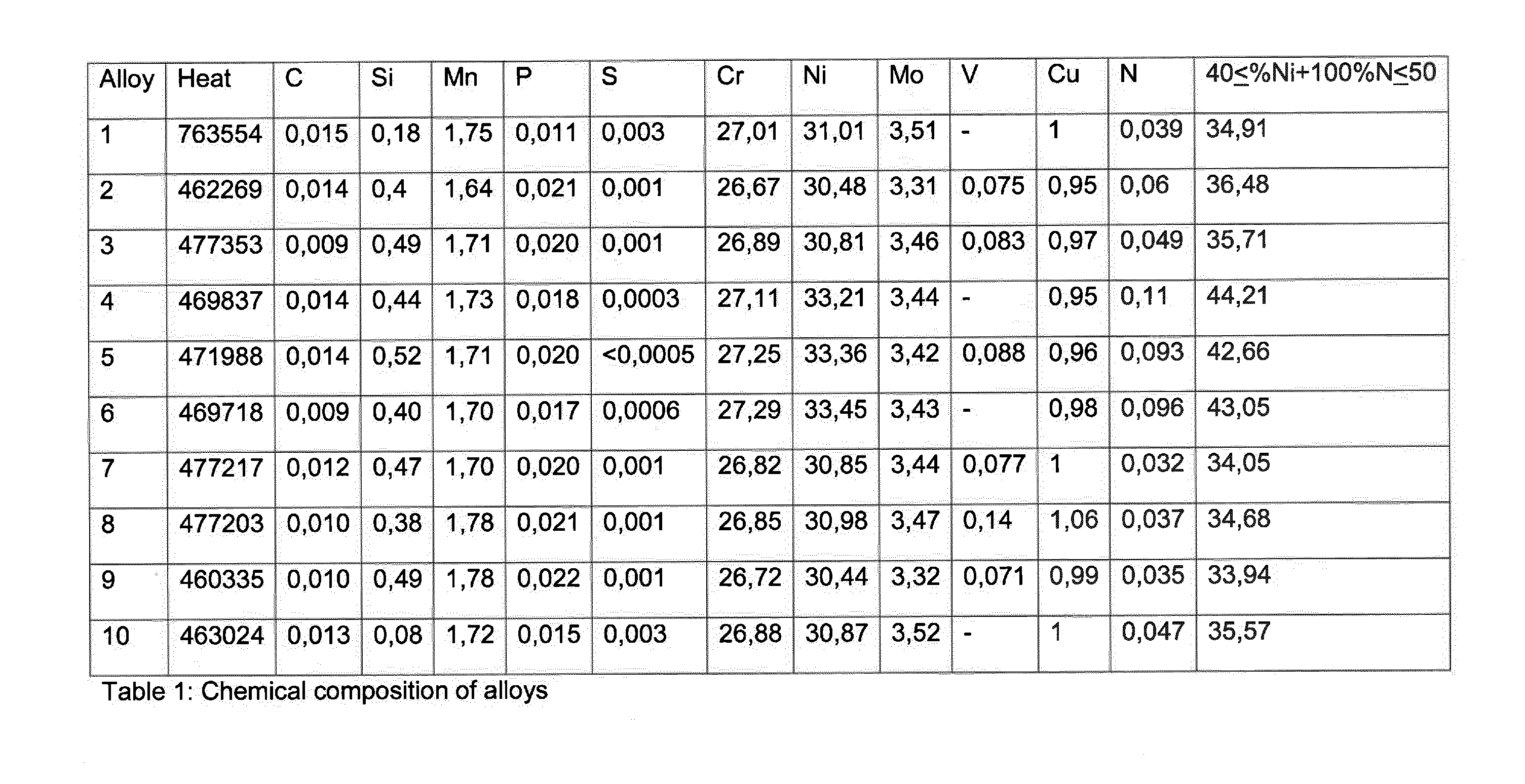

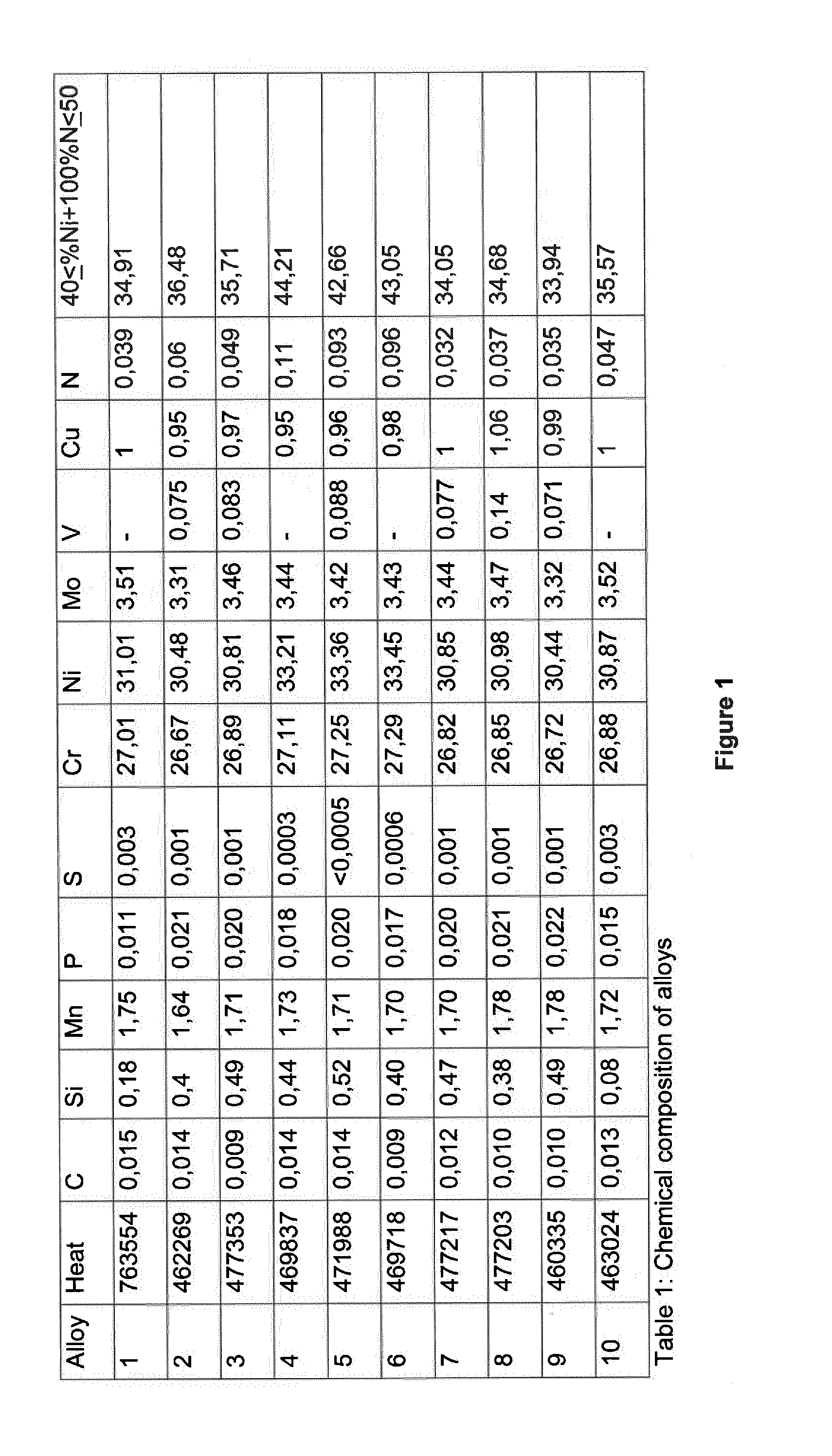

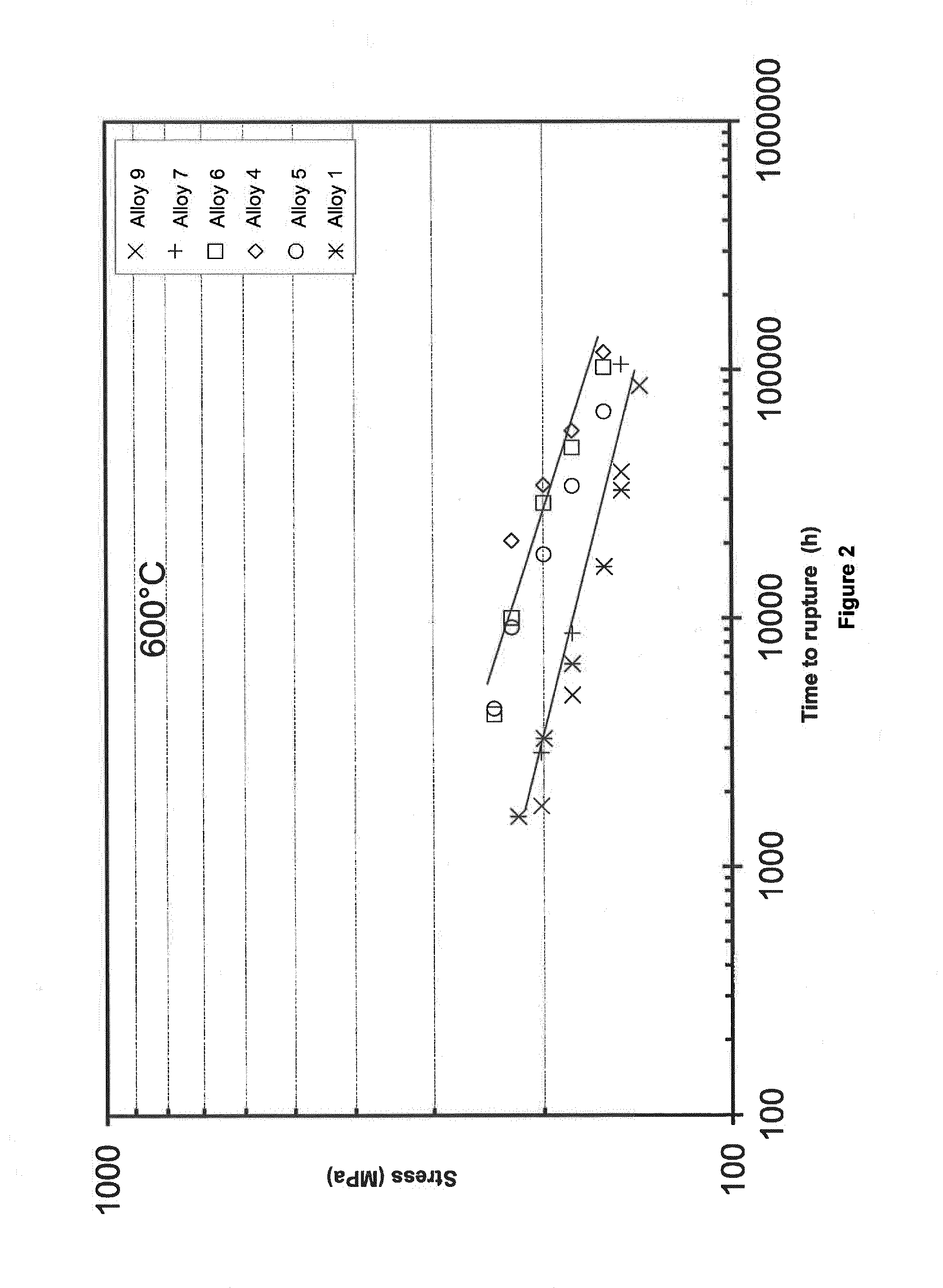

ActiveUS20140348699A1Stable structureImpact of ductility and elongationSteam boilersSteam boilers componentsAlloyImpurity

An austenitic alloy comprising (in weight %):C: 0.01-0.05Si: 0.05-0.80Mn: 1.5-2Cr: 26-34.5Ni: 30-35Mo: 3-4Cu: 0.5-1.5N: 0.05-0.15V: <0.15the balance being Fe and unavoidable impurities, wherein 40<% Ni+100*% N<50.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

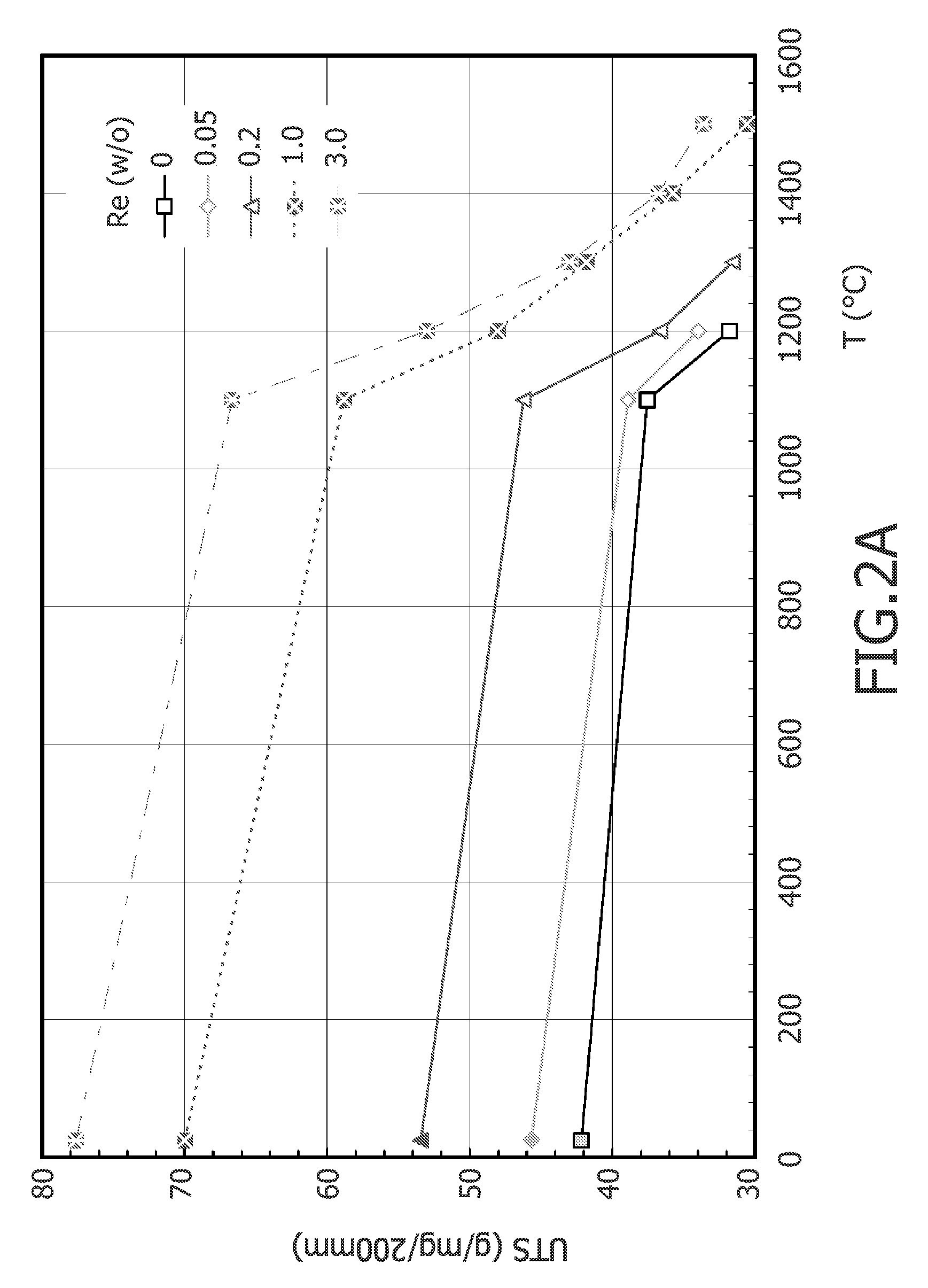

Lamp Having Molybdenum Alloy Lamp Components

InactiveUS20080203920A1Improve oxidation resistanceImprove corrosion resistanceHigh-pressure discharge lampsSolid cathode detailsRheniumIridium

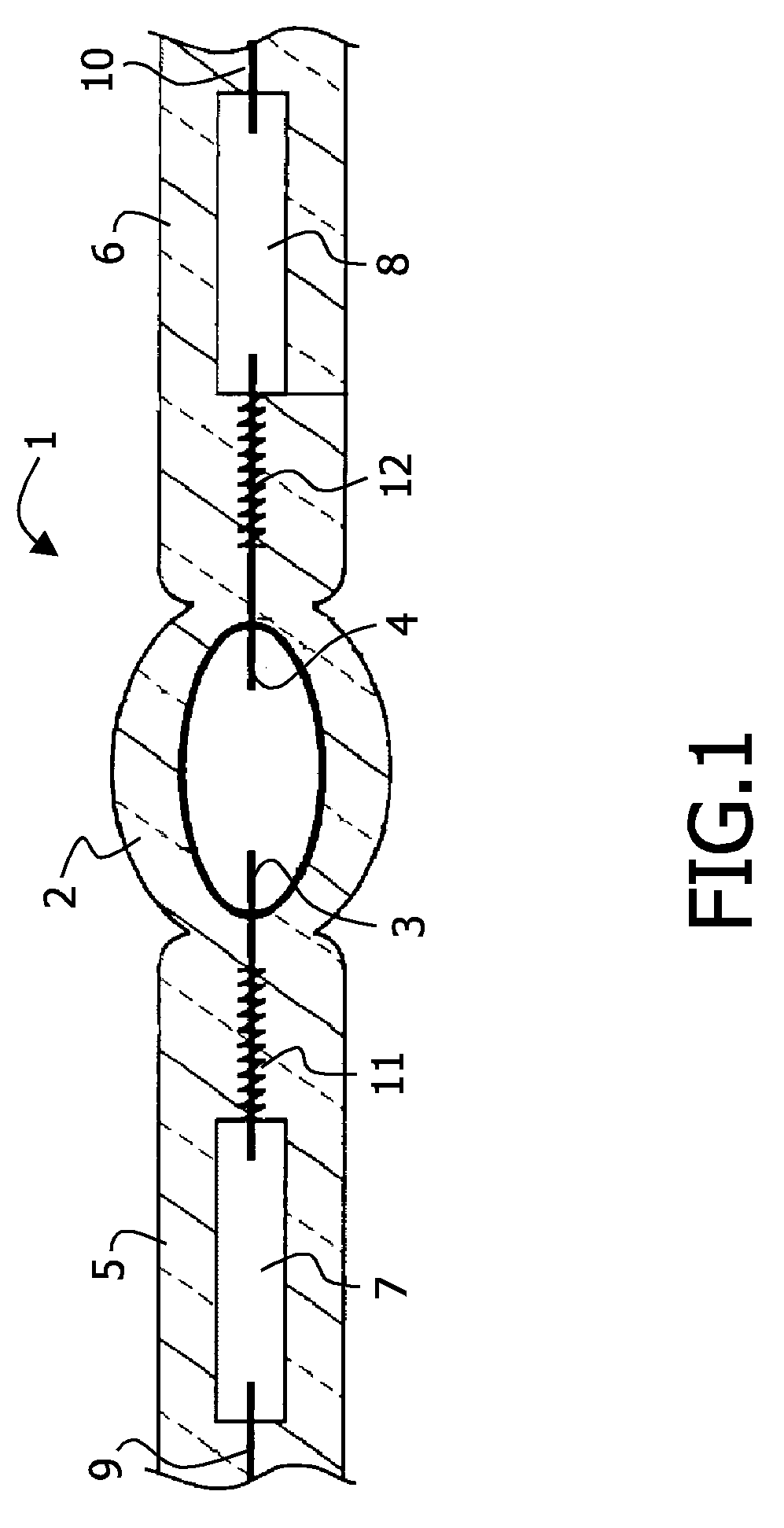

The invention relates to a lamp (1) comprising a gastight vessel (2) embedding one or more feedthrough elements (7,8) electrically interconnecting an outer current conductor (9,10) and an inner current conductor (3,4) for operating said lamp. The feedthrough elements and / or the outer and inner current conductor are molybdenum alloy components containing at least one constituent from the group formed by rhenium and chromium in a quantity between 0.01 and 5% by weight; titanium in a quantity between 0.01 and 0.1% by weight; and aluminum, cobalt, gadolinium, hafnium, iridium, iron and zirconium in a quantity between 0.01 and 1% by weight of said alloy. The invention further relates to a method of manufacturing a lamp and a lamp component.

Owner:KONINKLJIJKE PHILIPS NV

Bioabsorbable band system, a bioabsorbable band, a method for producing a bioabsorbable band, a needle system of a bioabsorbable band and a locking mechanism

ActiveUS8512379B2Mitigate such drawbackPrecise tensionInternal osteosythesisJoint implantsLocking mechanismOsteotomy

A bioabsorbable band system for securing a bone fracture, or an osteotomy, or a soft tissue on a bone. The bioabsorbable band system includes a needle system and a bioabsorbable band including a bioabsorbable locking member. The bioabsorbable band includes a length having an at least partially oriented structure. The bioabsorbable band further includes a locking mechanism with a locking member. Also a method for producing the bioabsorbable band.

Owner:BIORETEC

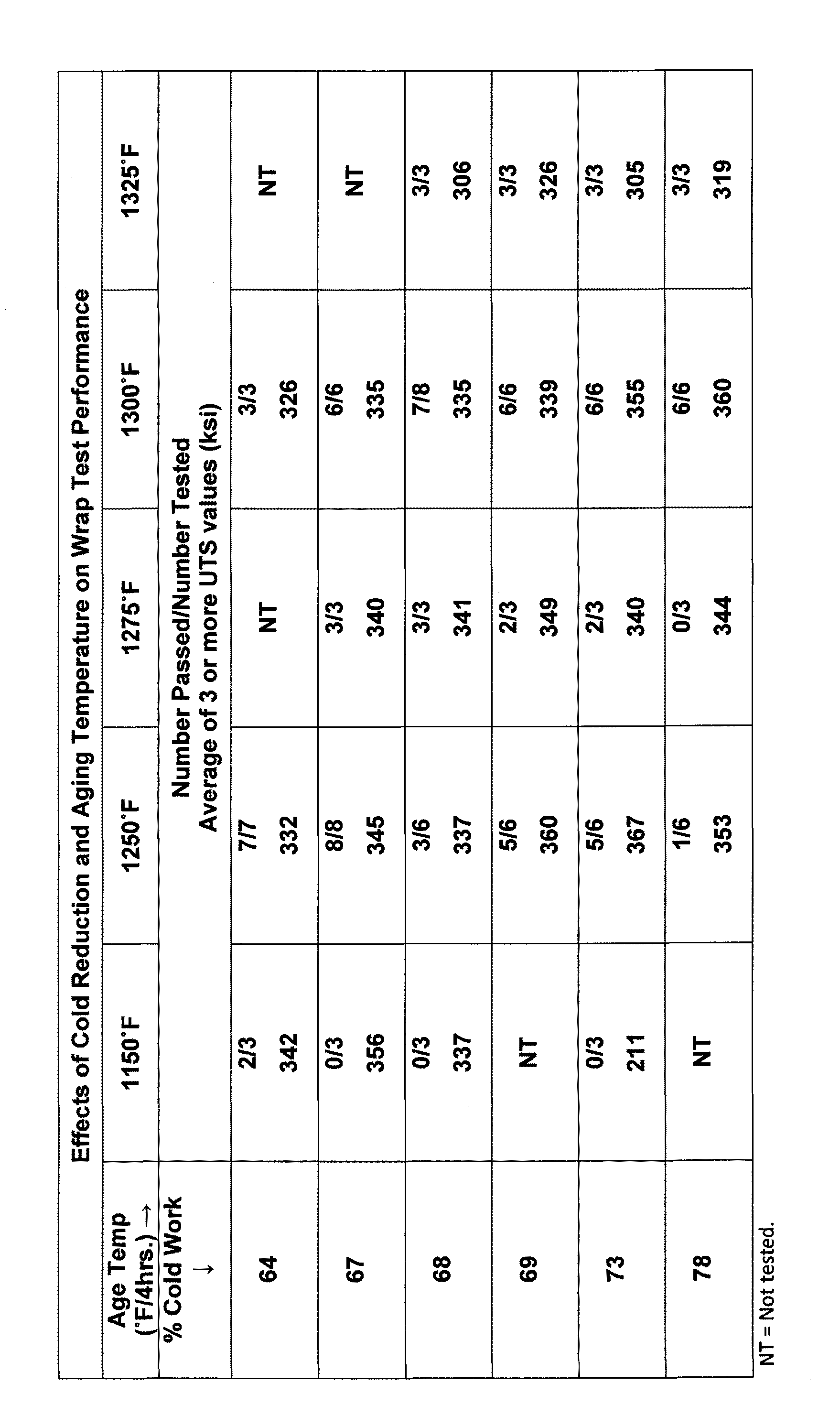

Ultra-High Strength, Corrosion Resistant Wire, a Method of Making Same, and a Method of Using Same

InactiveUS20100230017A1High strengthCorrosion resistanceMagnetic/electric field screeningThin material handlingCarbon fibersManganese

A method of making steel wire is described that includes the step of forming a length of wire from a high strength, corrosion resistant alloy. The alloy preferably has the following composition in weight percent.Carbon0.03max.Manganese0.15max.Silicon0.15max.Phosphorus0.015max.Sulfur0.010max.Chromium19.00-21.00Nickel33.00-37.00Molybdenum 9.00-10.50Titanium1.00max.Boron0.010max.Iron1.00max.The balance of the alloy is cobalt and usual impurities. The wire is annealed at a combination of temperature and time effective to provide a grain size of about ASTM 6 or finer. The annealed wire is then drawn such that the cross-sectional area of the wire is reduced by about 50 to 80%. The as-drawn wire is then heat treated at a second combination of temperature and time effective to provide the wire with high strength and sufficient ductility that when the wire is wrapped to provide a coil having an inside diameter substantially commensurate with the diameter of the wire and then unwrapped it does not crack or break.

Owner:FRANK RICHARD B +1

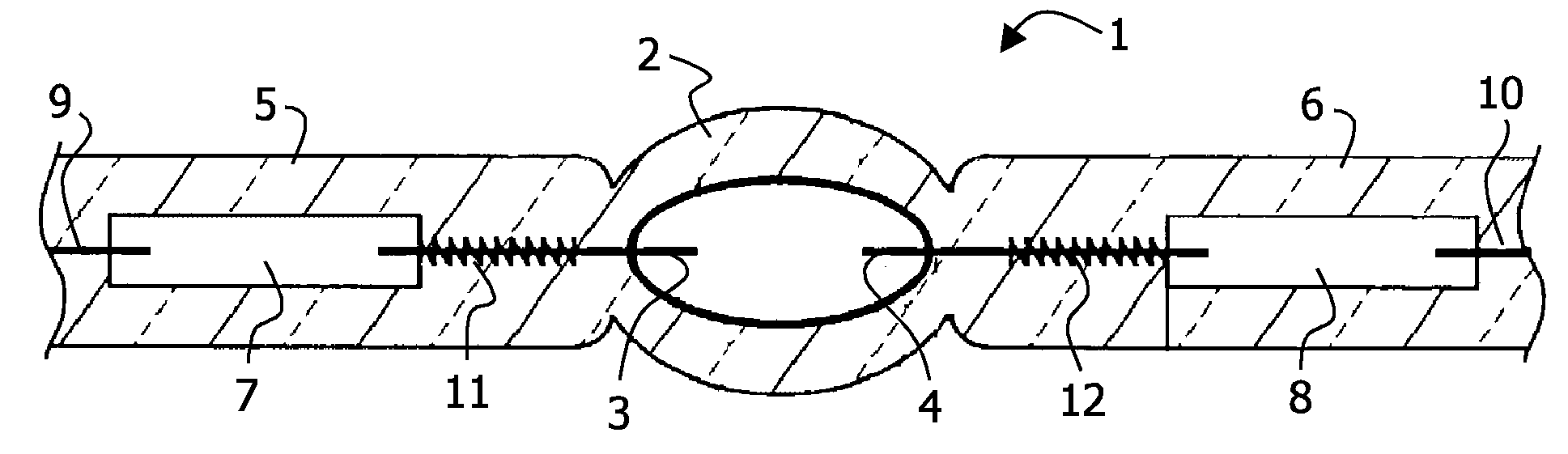

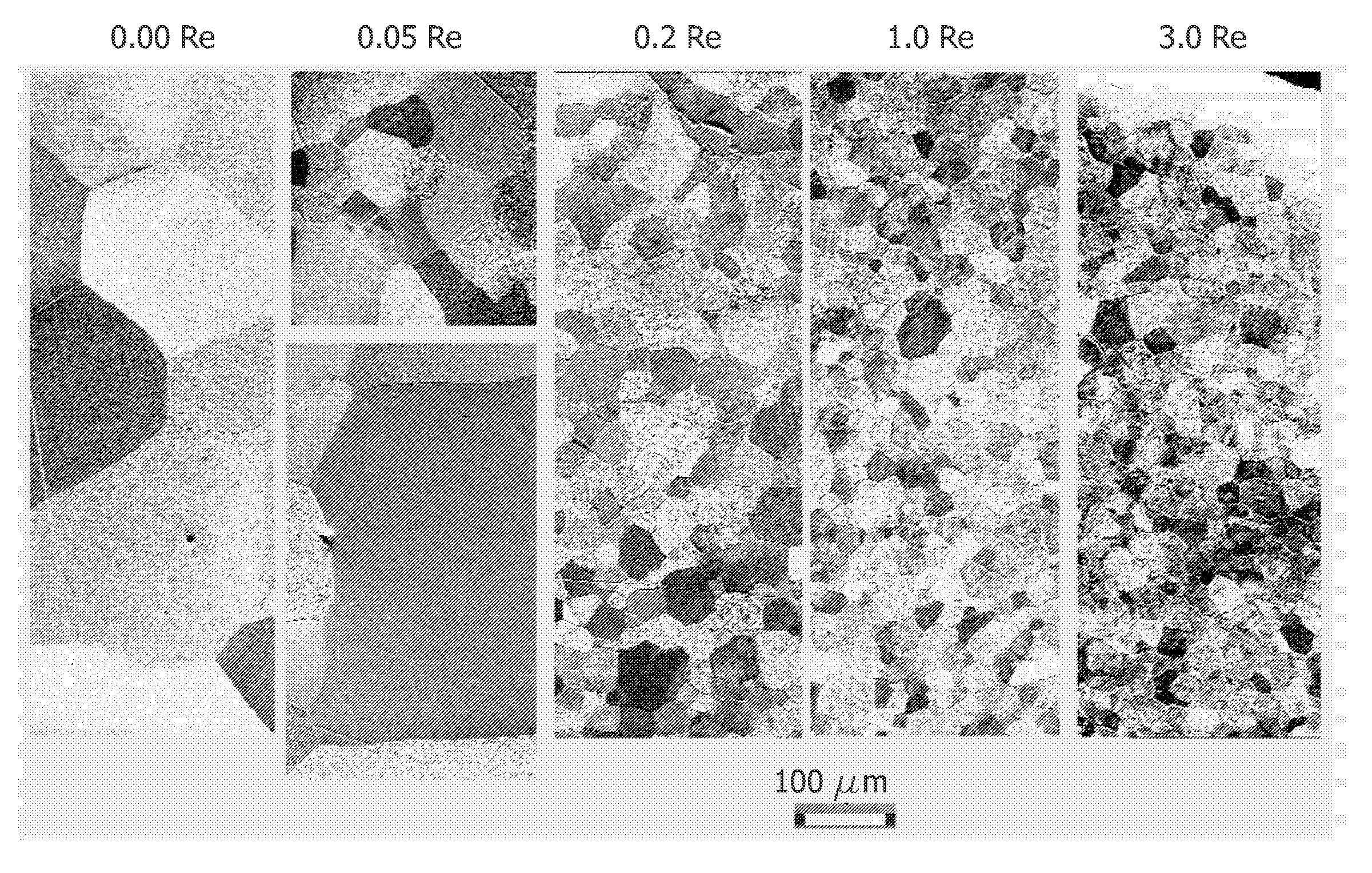

Discharge Lamp with Electrode Made Of Tungsten Alloy Comprising < 3 Wt.% Of Rhenium

InactiveUS20090128039A1Reduced blackening behaviorConsiderable mechanical strengthSolid cathode detailsGas discharge lamp detailsIridiumRhenium

The invention relates to a high-pressure gas discharge lamp (1) comprising a discharge chamber (4) with a gas filling and electrodes (5) disposed in the discharge chamber. At least one of said electrodes is a tungsten alloy electrode, where the alloy is made of (a) ultra-high pure tungsten and (b) at least one of rhenium, osmium, tantalum, hafnium, iridium, and zirconium in a quantity of 0.01 to 3% by weight of the quantity of tungsten. The tungsten alloy of the invention strikes an appropriate balance between a rhenium or osmium content, which is high enough to obtain sufficient ductility allowing wire processing, and low enough to reduce the amount of rhenium evaporation responsible for blackening the interior of the discharge chamber during operation of the lamp. The invention further relates to a method of manufacturing such a lamp.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Methods for creating side-by-side metallic bonds between different materials using solid-phase bonding and the products produced thereby

ActiveUS8999081B2Solve the lack of ductilitySimilar yield strength and ductility and extrusion behaviorWelding/soldering/cutting articlesThin material handlingElectrical connectionEngineering

Methods of producing composite products formed between at least two different metal structures in a side-by-side configuration are provided. The method includes providing at least two structures made of different materials that are not compatible for welding or conventional cladding processes. A geometric profile is provided in at least one of the edges of the first structure, and a corresponding mirror image of the geometric profile is provided in a corresponding edge of the second structure. The two structures are positioned together so that the profiled edge or edges form a complimentary composite structure and are then solid-phase bonded to form a composite product. The process may be repeated with additional structure at either end of the first or second structure to achieve multiple side-by-side products. The methods and corresponding products provided herein yield edge to edge products suitable for various electrical connection type applications.

Owner:MATERION TECHN MATERIALS

Artificial foliage

ActiveUS20060008598A1Sufficient degree of elasticitySolve the lack of ductilityDead plant preservationArtificial flowers and garlandsPiano wireEngineering

An artificial foliage structure with wire cores embedded in its leafy parts causing these parts to “spring back” upon removal of compressive loading acting thereupon. These wire cores may be made of hard, springy steel such as piano wire or small diameter spring wire. Thicker, woody limbs and branches have embedded therein heavier wire cores that are sufficiently soft to be given a set solely by manually applied bending force.

Owner:AMERICAN PRIDE OUTDOORS LLC

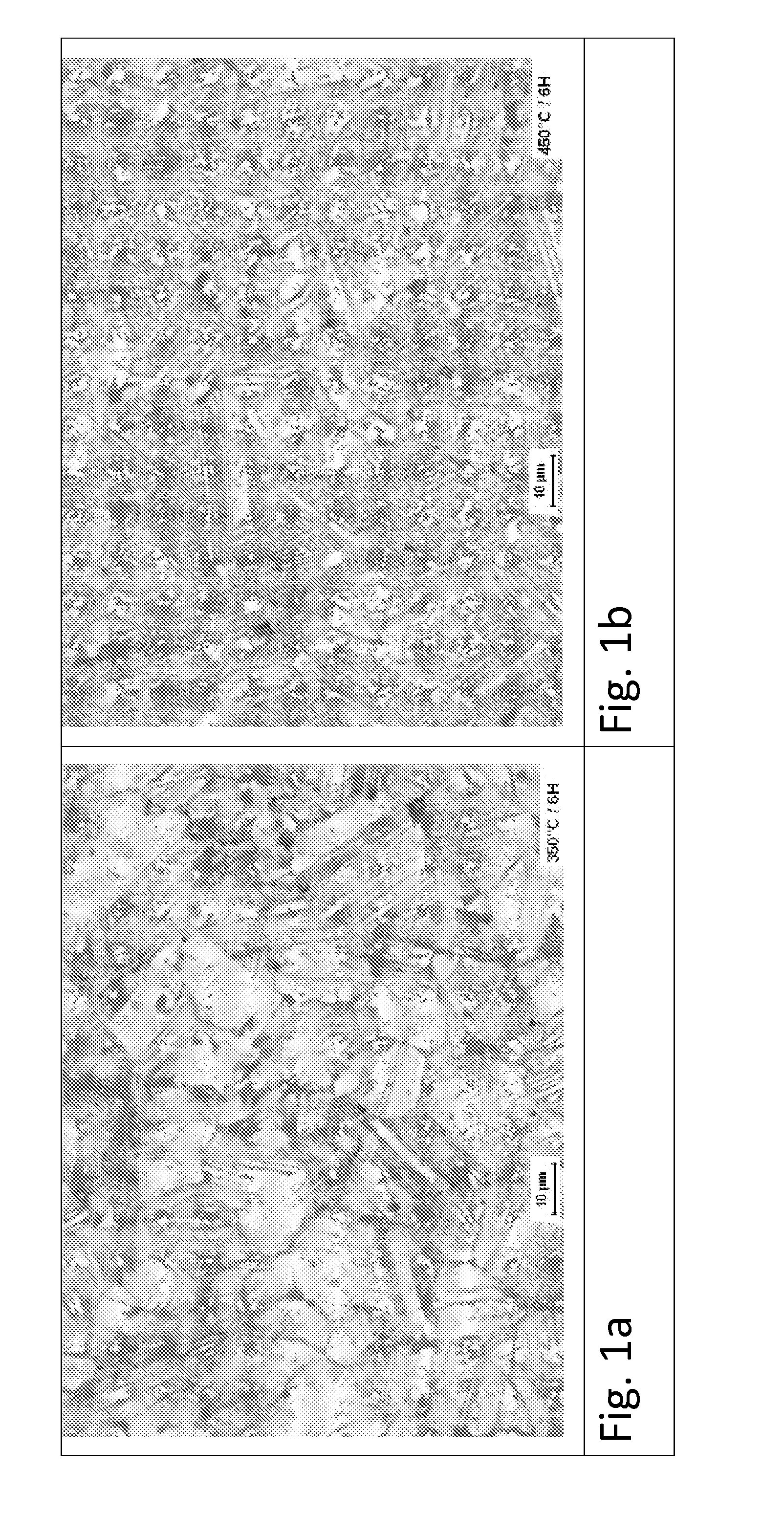

Metallic flat product which is subjected to surface finishing by hot-dip coating and which is preferably composed of steel

InactiveUS10081857B2Convenient coatingGood deformabilityHot-dipping/immersion processesSuperimposed coating processSurface finishSurface layer

A metallic flat product is disclosed which is subjected to surface finishing by hot-dip coating and which is preferably composed of steel. The metallic flat product includes a metallic alloy layer (11) and a metallic surface layer (12′), which metallic alloy layer and metallic surface layer differ from one another in terms of their chemical composition. The two layers (11, 12′) are produced in a one process step and define a continuous transition region (13) in which a mixture of the two different chemical compositions is present. The metallic alloy layer (11) has a thickness of less than 8 μm, preferably less than 6 μm, and the surface layer (12′) is formed from aluminum or zinc. The flat product has an improved coating, by means of which the flat product more effectively satisfies the requirements with regard to good deformability and has good anti-corrosion protection.

Owner:THYSSENKRUPP STEEL EURO AG

Manufacturing of materials and workpieces for components in nuclear plant applications

InactiveUS6132525AExtended durationReduce the temperatureOptical rangefindersFuel elementsNuclear plantNuclear reactor

PCT No. PCT / US92 / 11261 Sec. 371 Date Mar. 7, 1997 Sec. 102(e) Date Mar. 7, 1997 PCT Filed Dec. 18, 1992 PCT Pub. No. WO94 / 14993 PCT Pub. Date Jul. 7, 1994Austenitic steel intended for use in radiation areas of nuclear reactors is largely resistant to irradiation-induced stress corrosion cracking if its silicon, phosphorus and sulfur contents are reduced in relation to standard commercial steel quantities and its grain structure has finely dispersed carbide precipitation, particularly of niobium carbide. The finely dispersed distribution can be induced in that larger niobium precipitation takes place at annealing temperatures between 1100 and 1150 DEG C., and carbide is precipitated through the corresponding annealing at temperatures of approximately 750 DEG C.

Owner:ELECTRIC POWER RES INST INC

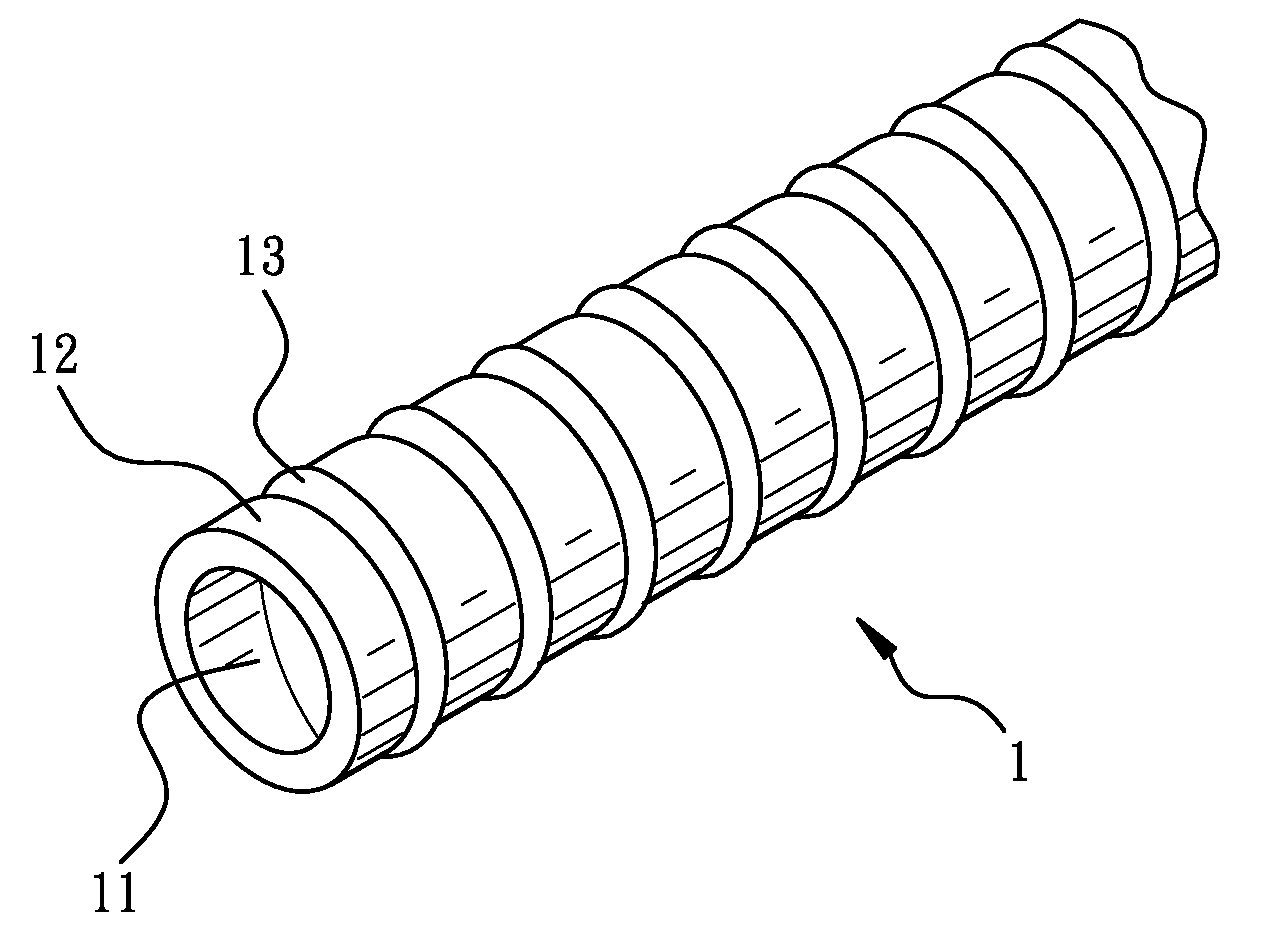

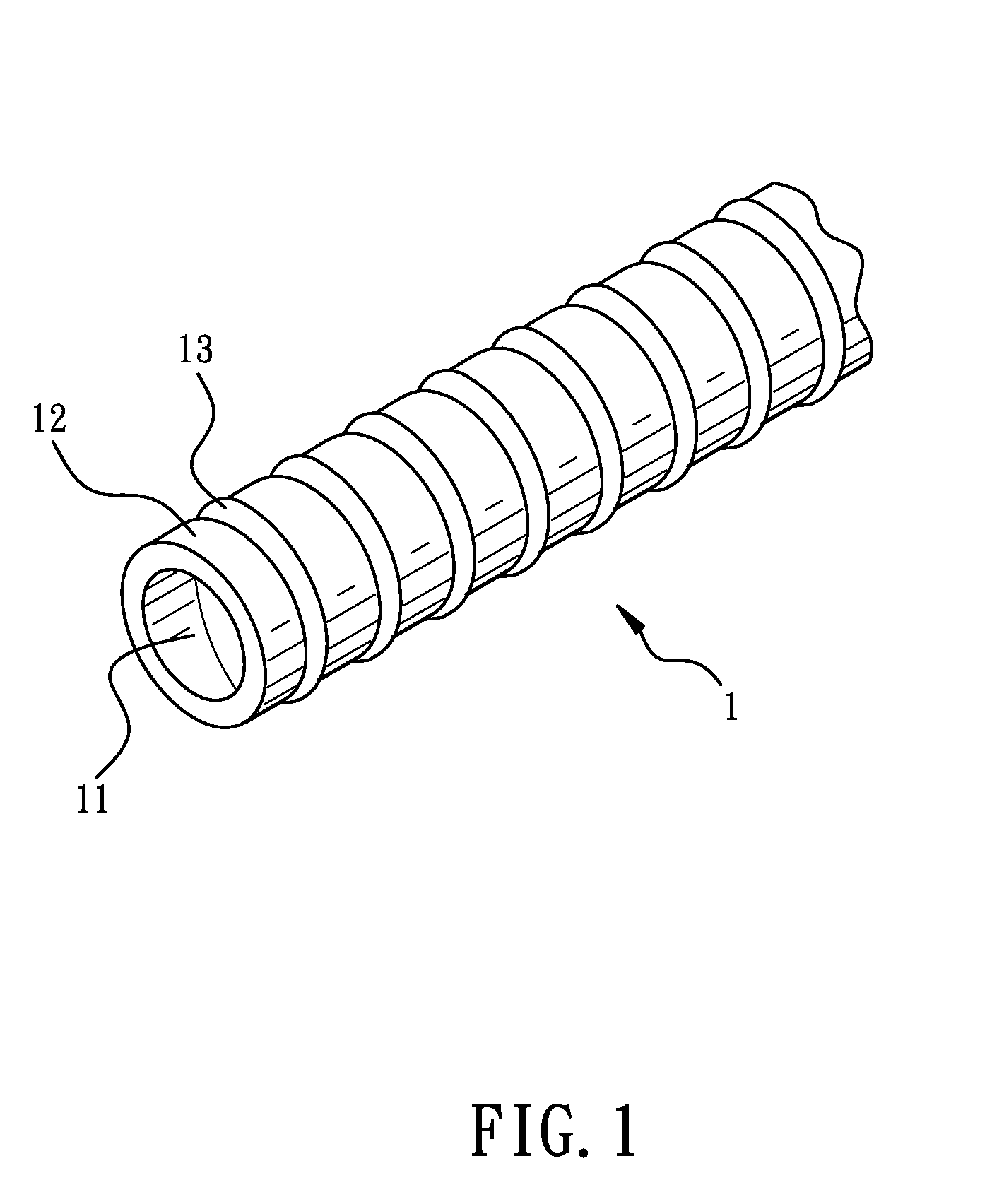

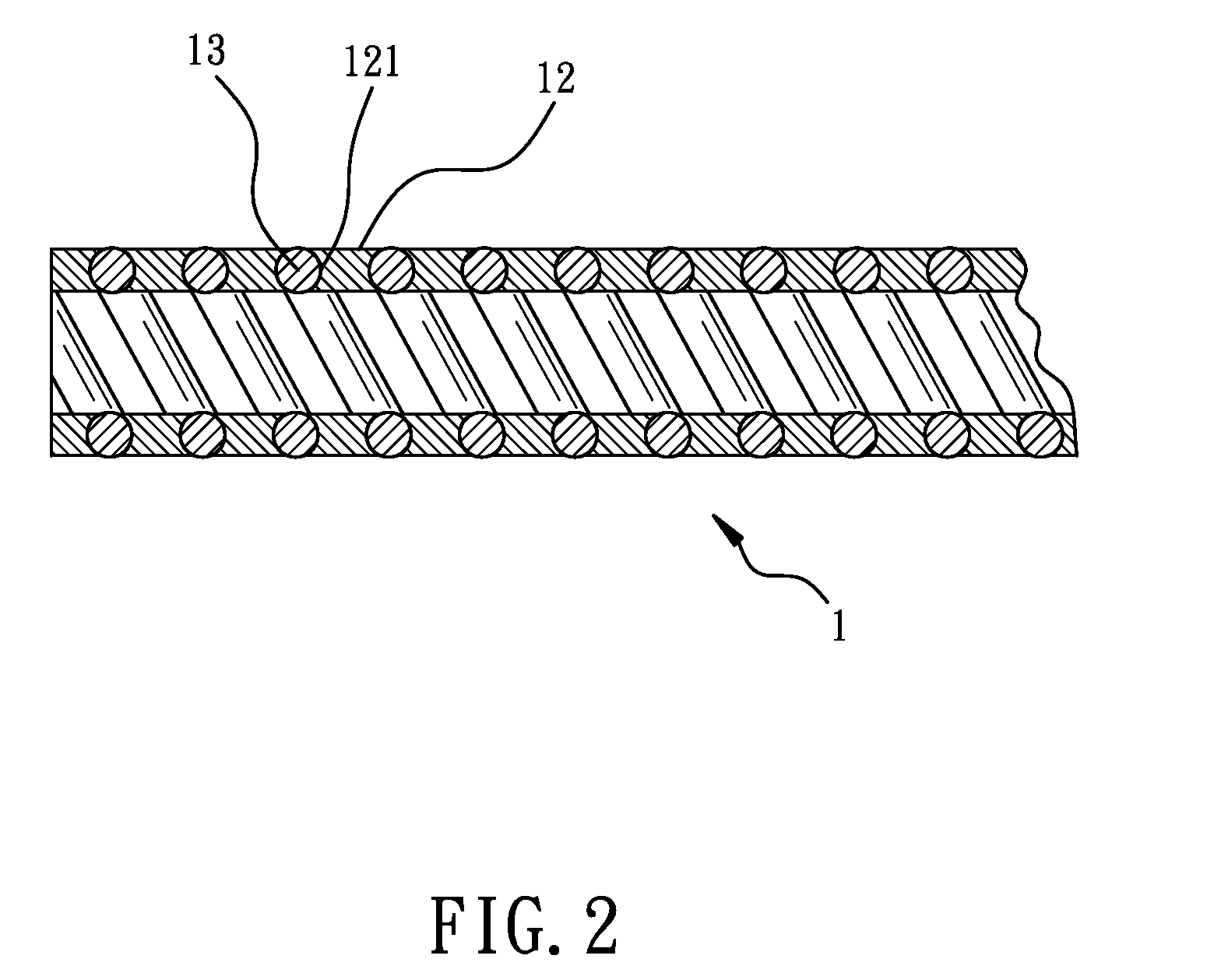

Tube structure for bicycle cable

InactiveUS20120291906A1Improve tube structureImproved tube structureWire articlesMachine supportsDuctilityEngineering

A tube structure for bicycle cable includes a rigid metallic member spirally wound into a tubular body. The tubular body has a channel centrally defined therein and axially extending therethrough for adapting to be passed through by a bicycle brake cable. A flexible metallic member is connected with the rigid metallic member and is spirally disposed along a length of the rigid metallic member. When the tubular body is impacted with an external force, the rigid metallic member provides an enhanced rigidity to the tubular body for preventing a deformation of the tubular body. The flexible metallic member and the rigid metallic member are alternately arranged so as to allow the tubular body to be bendable and have a sufficient ductility.

Owner:ASHIMA LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com