Bearing roller spherical surface superfinishing mechanism

A technology of bearing rollers and sliding mechanism, which is applied to superfinishing machines, grinding workpiece supports, metal processing equipment, etc. , convenient for loading and unloading and the effect of processing workpieces of different shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

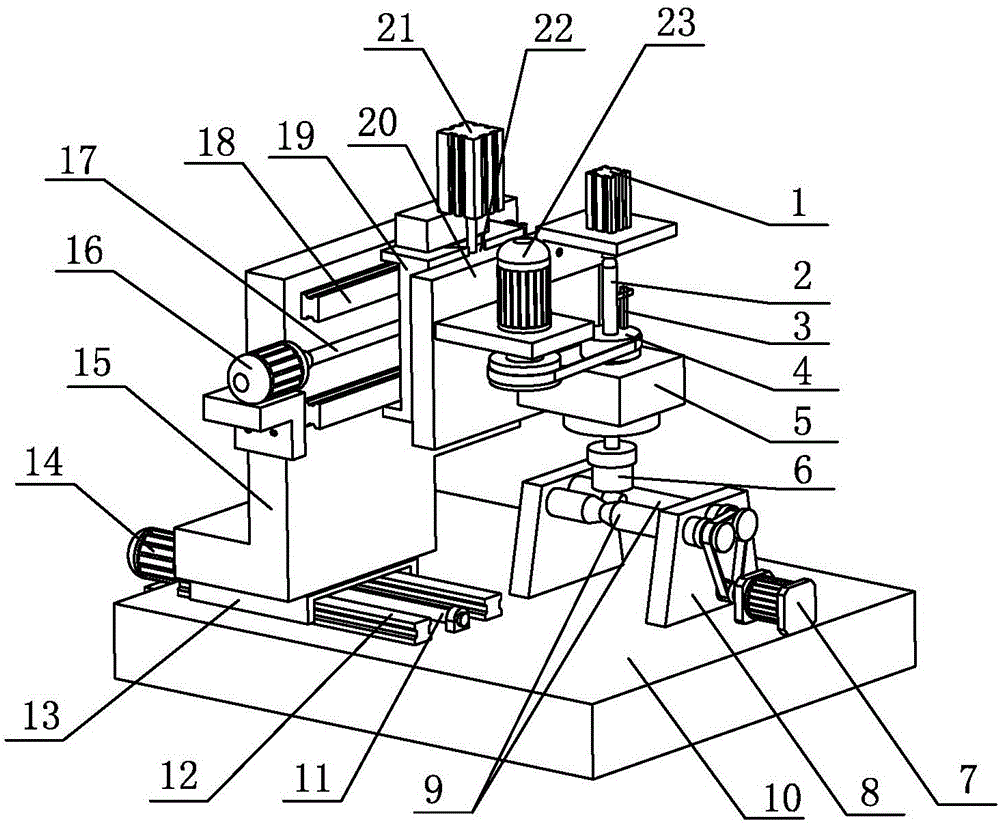

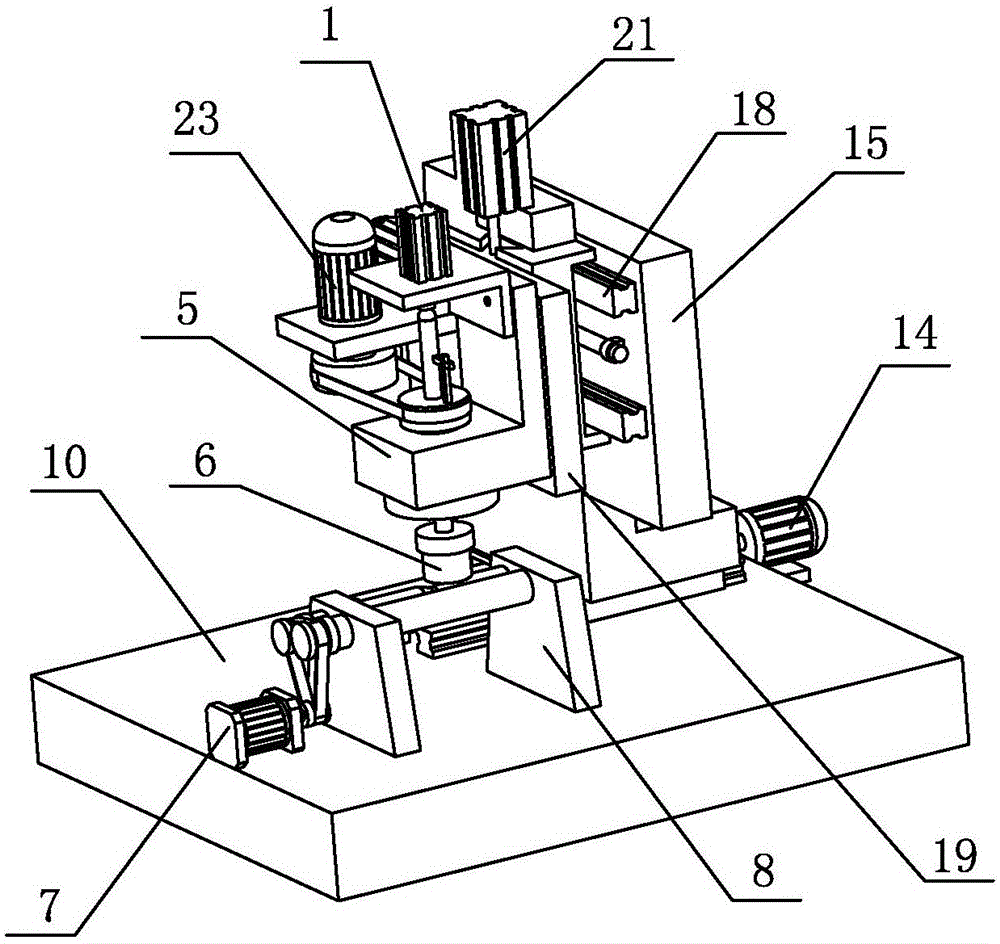

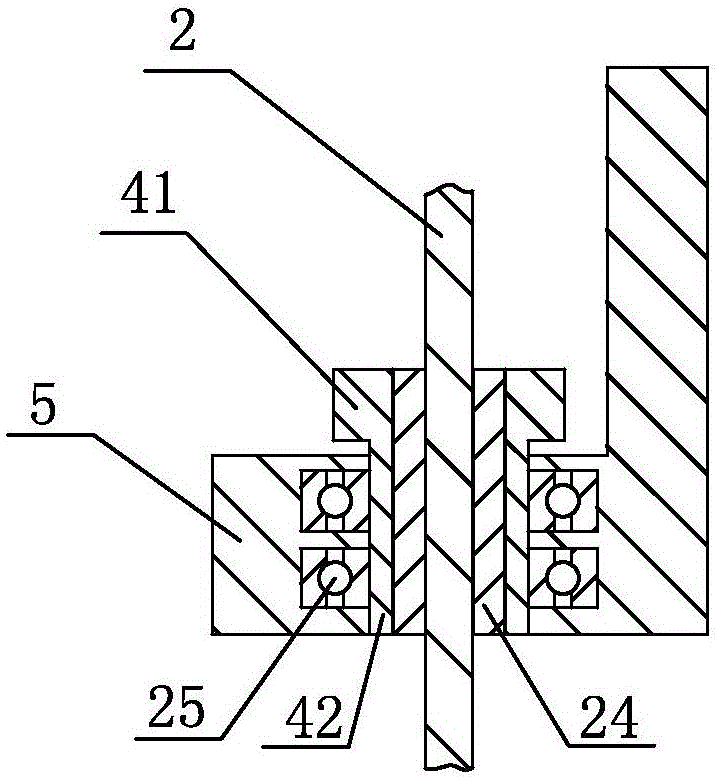

[0025] Such as Figure 1~Figure 3As shown, the present invention includes a bed 10 and a workpiece support mechanism installed on the bed 10, a workpiece drive device, a cutter device, a control system and an automatic loading and unloading mechanism, and the cutter device includes a mounting support 14, a whetstone 6, and a whetstone drive mechanism , X-axis sliding mechanism, Y-axis sliding mechanism and Z-axis feed mechanism, the X-axis sliding mechanism includes an X-axis sliding plate 13, an X-axis sliding guide mechanism, an X-axis screw pair and an X-axis sliding drive The motor 14, the X-axis sliding guide mechanism is an X-axis guide rail pair distributed along the X-axis direction, the guide rail 12 of the X-axis guide rail pair is fixedly installed on the top surface of the bed 10 along the X-axis direction, and the X-axis sliding plate 13 is fixedly installed on the On the slider of the X-axis guide rail pair, the mounting support 14 is fixedly installed on the X-a...

Embodiment approach 2

[0028] As another embodiment, when the outer circular surfaces of the two supporting rollers 9 are cylindrical surfaces, the two supporting rollers 9 are separated by a certain distance, but the distance between the two supporting rollers 9 is not greater than that of the spherical roller workpiece to be processed. The outer diameter of the workpiece support is formed between the two support rollers 9, and the workpiece backer is arranged between the two support rollers 9. The workpiece backer is provided with two abutting parts at a certain distance in the axial direction of the support roller 9. When the workpiece is to be processed When the spherical roller workpiece is placed on the workpiece supporting part, the two ends of the workpiece respectively abut against the two abutting parts so as to position the workpiece. Through the sliding adjustment of the X-axis sliding mechanism, when When the workpiece curvature center plane is located in the center line of the workpiece...

Embodiment approach 3

[0030] As another embodiment, two workpiece support parts can also be arranged in the axial direction between the two support rollers. The support rollers on both sides corresponding to one workpiece support part are cylindrical surfaces, and the other workpiece support part The support roller on the corresponding side is provided with a V-shaped annular groove, and the support roller on the other side is a cylindrical surface. In this way, spherical rollers of different shapes can be ground on the same grinding mechanism, which improves the processing efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com