Controlled perforation plasma-arc welding system and process on basis of back small-hole visual inspection

A visual inspection and plasma arc technology, applied in plasma welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of limited information on small holes, and the inability to give the shape and size of small holes, etc., to ensure complete penetration and avoid melting Pool collapse and burn-through, to ensure the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

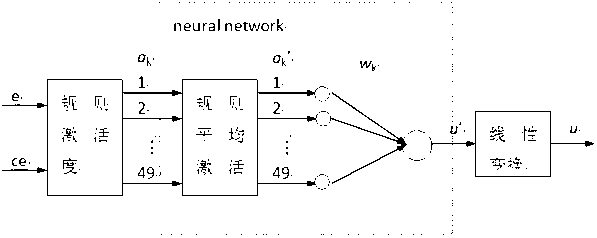

Method used

Image

Examples

Embodiment

[0081] Embodiment A controlled perforation plasma arc welding process based on visual detection of small holes on the back

[0082] Proceed as follows:

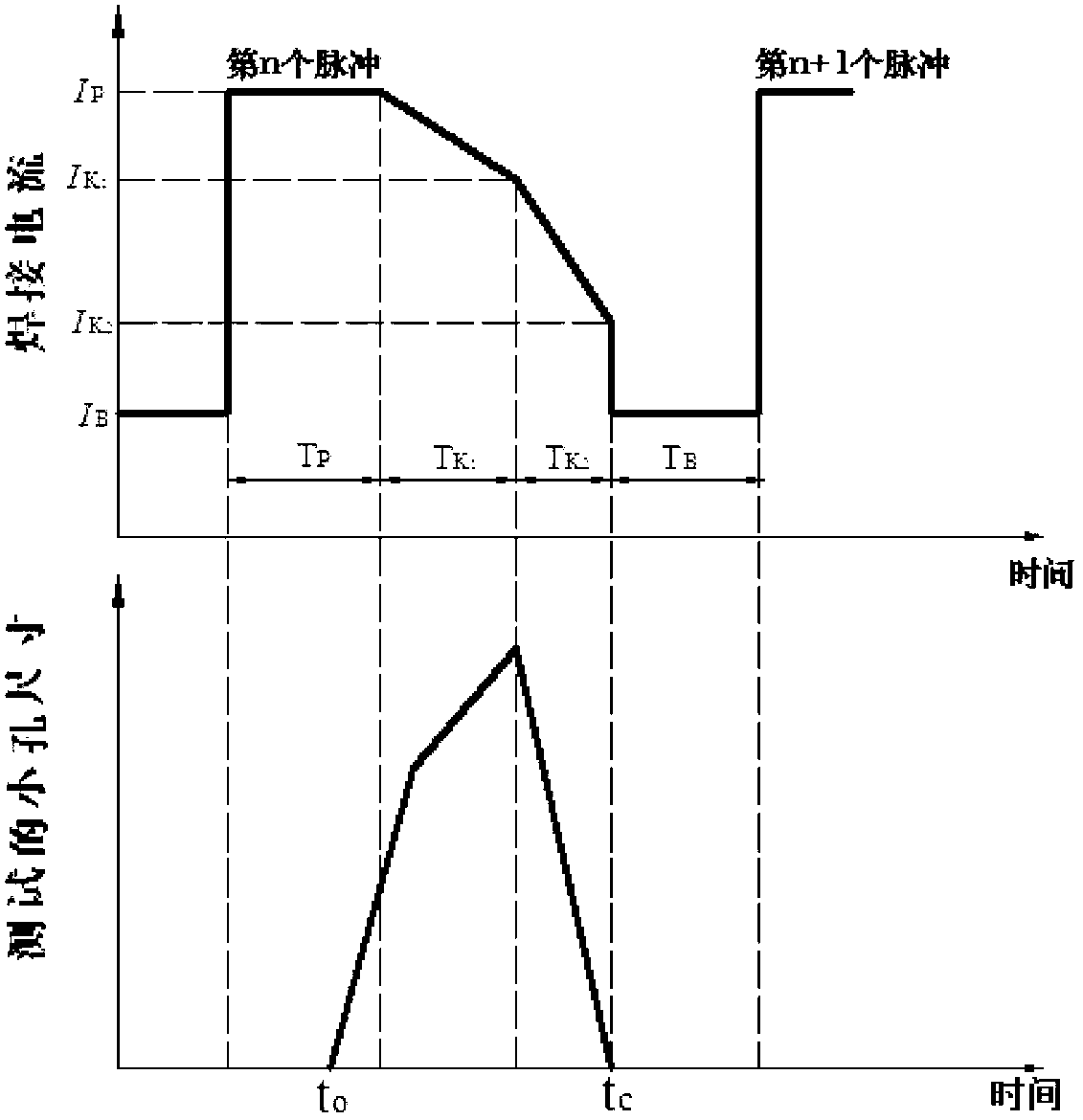

[0083] (1) Start: Select the appropriate current waveform parameters according to the material and thickness of the material to be perforated, including the base current I B and its action time T B , peak current I P and its action time T P , the falling slope K of the pulse trailing edge 1 、K 2 and its transition time T K1 , T K2 ;

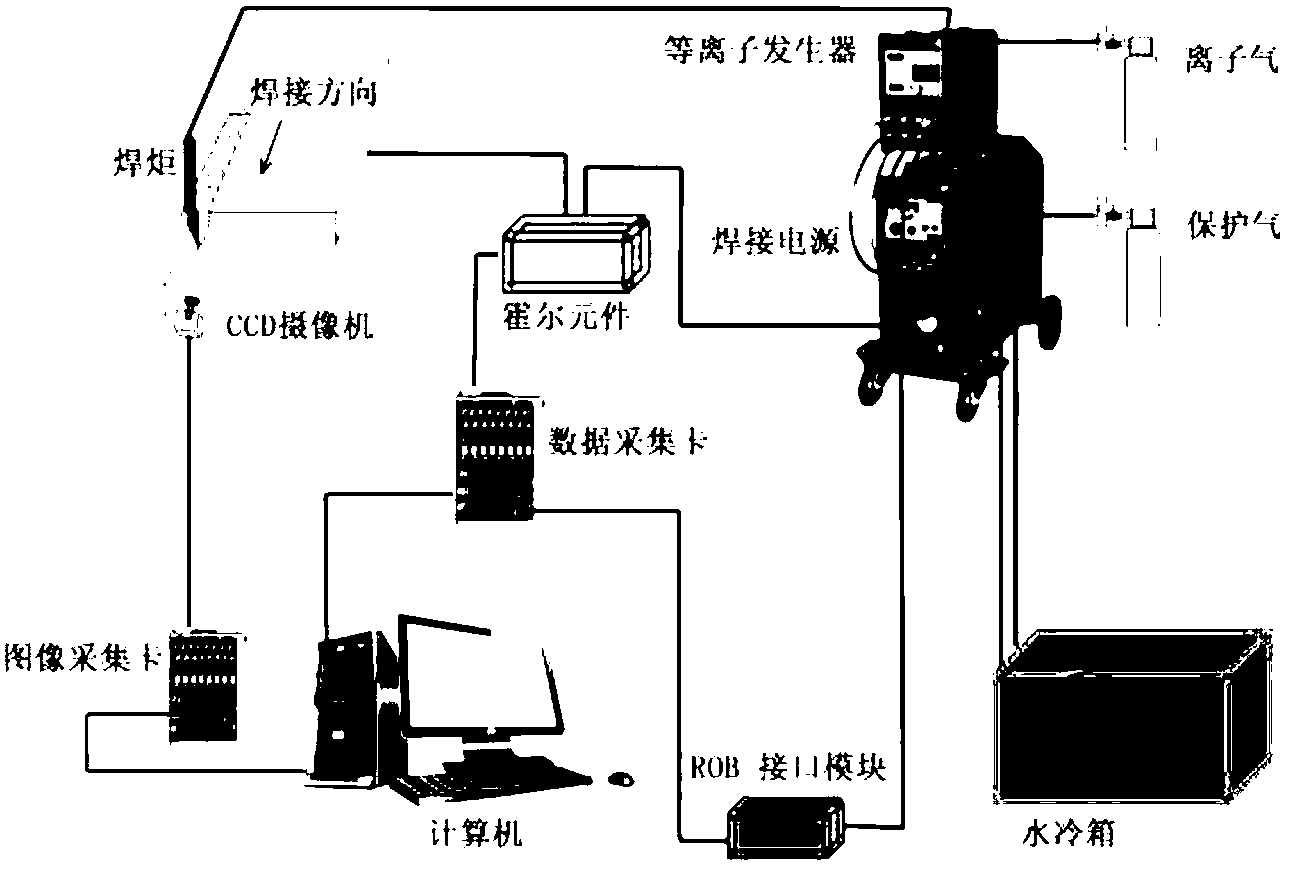

[0084] (2) After selecting and setting the parameters, start welding. The CCD camera, composite filter device and Hall element collect the current waveform and the small hole image on the back in real time, and then transmit the information to the computer to calculate the size of the small hole and calculate the Deviation of the set value: ① If the deviation is less than the given value (the given value is the expected value of the small hole size on the back, which is preset according ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com