E309L stainless steel lengthened welding electrode capable of being used for large-current welding

A technology of E309L and stainless steel, applied in the field of E309L stainless steel elongated electrodes, can solve the problems of electrode cracking, electrode waste, red coating, etc., and achieve the effect of stable arc, convenient operation and good welding seam formation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

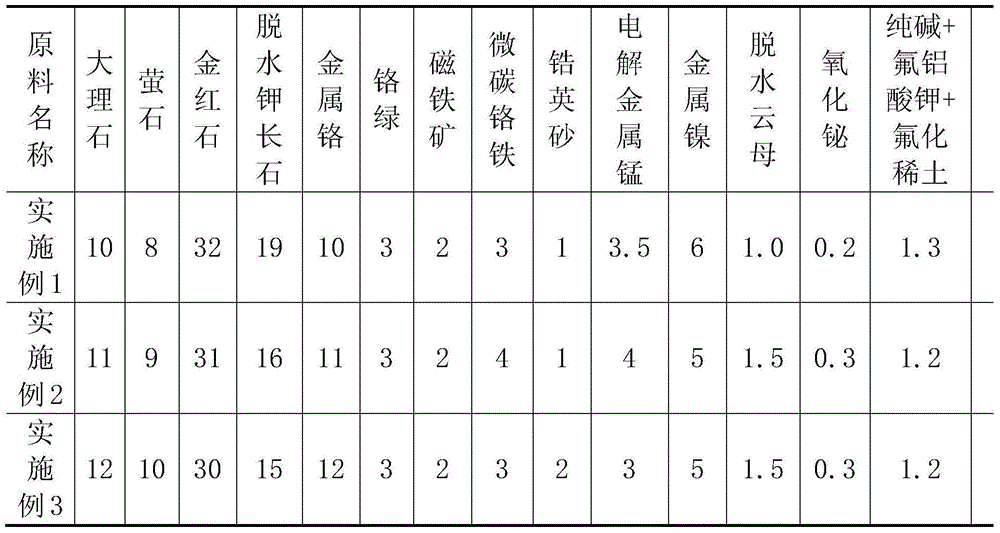

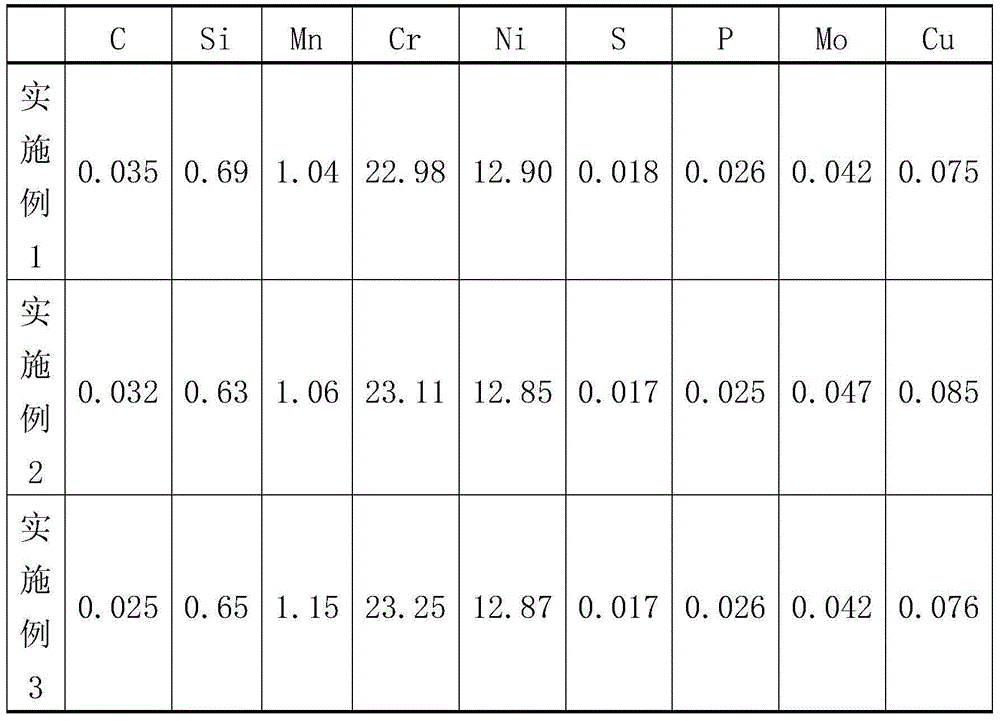

[0034] The stainless steel elongated electrode of the present invention belongs to the acid electrode, wherein marble, fluorite, zircon sand, dehydrated potassium feldspar, rutile, etc. are slagging agents, and chrome green and magnetite can enhance the oxidation of the electrode and reduce the hydrogen partial pressure and Improve welding porosity tendency, potassium fluoroaluminate K 3 AlF 6 And rare earth fluoride can dehydrogenate and eliminate hydrogen pores, metal chromium powder can transfer chromium element to deposited metal, metal nickel powder can transfer nickel element to deposited metal, electrolytic metal manganese can not only deoxidize and desulfurize, but also can The transition of manganese to the deposited metal, micro-carbon ferrochrome and electrolytic manganese as deoxidizers can ensure the purity of the weld deposited metal.

[0035] As the main slagging agent, rutile can simultaneously improve the slag removal and forming quality of the weld metal, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com