Poly-isocyanurate polyurethane coating curing agent and preparation method thereof

A technology of polyisocyanurate and isocyanurate, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problem of no pure MDI trimer products, achieve excellent adhesion, and reduce production costs , The effect of low cost of paint matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

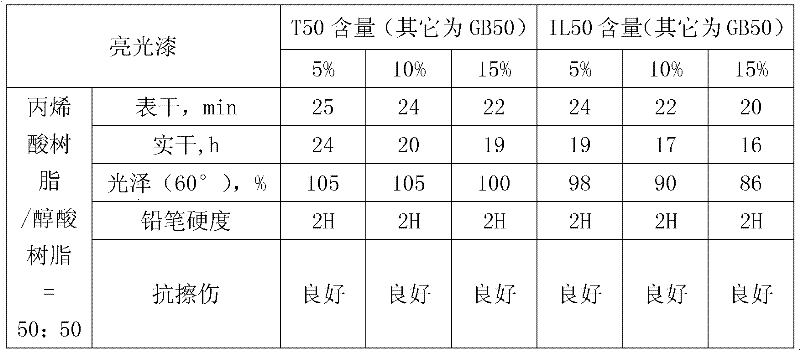

Examples

Embodiment 1

[0020] Add 108.3g of toluene diisocyanate (TDI) and 55g of ethyl acetate into a four-neck flask equipped with a condenser and nitrogen protection, start heating and stirring, and raise the temperature to 40°C to 45°C within 10min. Add 100g of isocyanurate-based polyether polyol in batches, and add the material every 20 minutes. After the feeding is completed and the temperature is stable, slowly raise the temperature to 65°C-70°C within 30 minutes, keep the temperature for 2 hours, and then raise the temperature to 80°C within 20 minutes. Insulate at ~85°C for 1 hour, take samples to detect -NCO content, stop the reaction when the -NCO content is between 10.15% and 10.25%, add 0.02g of phosphoric acid, stir for 20 minutes, cool down to 50°C, discharge, and store in a nitrogen seal.

Embodiment 2

[0022] Add 138.4g of isophorone diisocyanate (IPDI) and 104g of ethyl acetate into a four-necked flask with a condenser and nitrogen protection, start heating and stirring, and raise the temperature to 50°C to 55°C within 10min. Add 100g of isocyanurate-based polyether polyol in 3 batches, and add the material every 20 minutes. After the feeding is completed and the temperature is stable, slowly raise the temperature to 75 ° C ~ 80 ° C within 30 minutes, keep the temperature for 3 hours, and then raise the temperature within 20 minutes Heat the reaction at 85°C to 90°C for 2 hours, take a sample to detect the -NCO content, stop the reaction when the -NCO content is between 7.50% and 8.00%, add 0.02g of phosphoric acid, stir for 20min, cool down to 50°C and discharge, nitrogen seal save.

Embodiment 3

[0024] 63.7g of toluene diisocyanate (TDI), 42.5g of hexamethylene diisocyanate (HDI) and 140g of ethyl acetate were added to a four-necked flask with a condenser and nitrogen protection, started heating and stirring, and heated up to 45℃~50℃, at this temperature, add 100g of isocyanurate-based polyether polyol in 4 batches, add the material every 20 minutes, after the feeding is completed and the temperature is stable, slowly increase the temperature to 70℃~75℃ within 30min , heat preservation reaction for 2 hours, then heat up to 80 ℃ ~ 85 ℃ heat preservation reaction for 2 hours within 20 minutes, take a sample to detect the -NCO content, when the -NCO content is between 7.40% and 7.80%, stop the reaction, add 0.02g of phosphoric acid, stir for 20 minutes, Cool down to 50°C and discharge, and store in a sealed nitrogen atmosphere.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com