Cr3 series hot work die steel and heat treatment method thereof

A technology of hot work die steel and heat treatment method, which is applied in the alloy field of forging die, can solve the problems of easy cracking, poor thermal strength and wear resistance of 5CrNiMo die steel, and achieve the effect of improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0102]The preparation method of Cr3 series hot working die steel is characterized in that it comprises steps: electric furnace smelting, LF furnace refining (LADLE FURNACE, ladle refining furnace), vacuum degassing (VD), mold casting, annealing, electroslag remelting (ESR ), slow cooling, annealing, forging, normalizing, spheroidizing annealing, hydrogen expansion, roughing, inspection, finishing, quenching and tempering, finishing, inspection, and production (to obtain modules or molds). Marked as YD3 die steel.

[0103] By controlling the composition of molten steel, the prepared die steel contains C0.40%, Si0.23%, Mn0.70%, P0.003%, S0.001%, Cr3.23%, Ni1. 41%, Mo 1.84%, V 0.16%, Al 0.020%, Nb 0.03%, and the balance Fe. and inevitable inclusions.

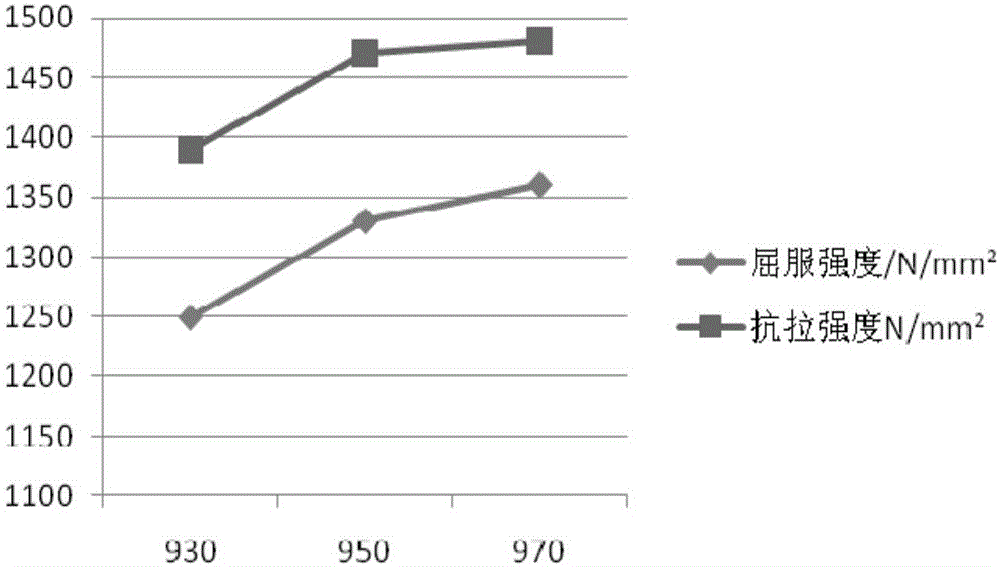

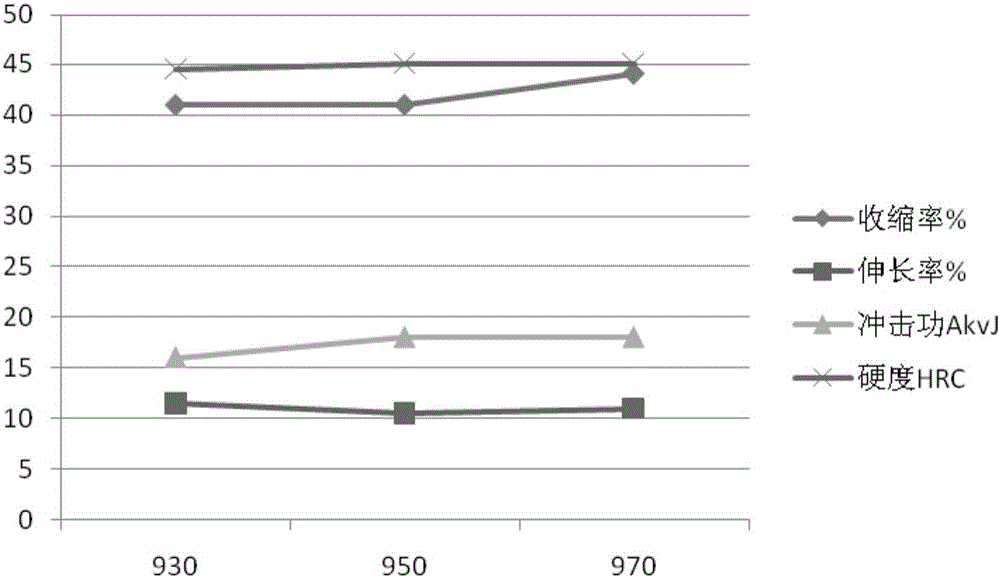

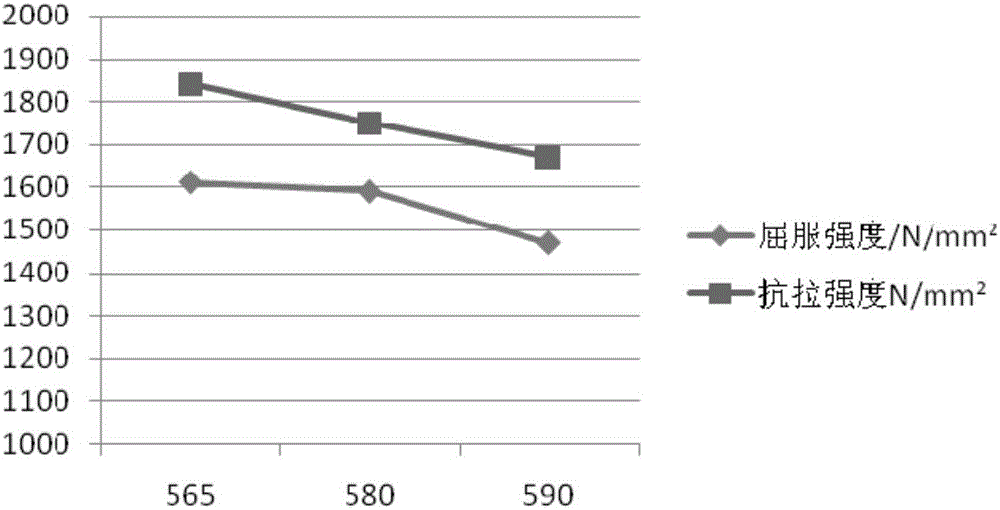

[0104] Figure 8 It is a YD3 die steel specimen, spheroidized annealed after forging, corroded by 4% nitric acid alcohol solution, and the observed structure is AS7 grade.

Embodiment 2

[0106] The method of smelting is with embodiment 1. By controlling the composition of molten steel, the prepared mold steel contains C 0.45%, Si 0.40%, Mn 0.50%, P 0.007%, S 0.002%, Cr 2.80%, Ni 1.60%, Mo2.20 in weight % %, V0.30%, Al 0.060%, Nb 0.10%, the balance of Fe and unavoidable inclusions.

Embodiment 3

[0108] The method of smelting is with embodiment 1. By controlling the composition of molten steel, the prepared mold steel contains C 0.46%, Si 0.40%, Mn 0.70%, P 0.007%, S 0.002%, Cr 3.00%, Ni 1.80%, Mo2.00 in weight % %, V 0.20%, Al 0.080%, Nb 0.15%, the balance of Fe and unavoidable inclusions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com