A kind of preparation method of steel hot-rolled round wire rod for 10.9 high-strength bolts

A technology of high-strength bolts and discs, applied in the field of iron and steel metallurgy and ferrous metal pressure processing, can solve the problems of suboptimal microstructure and proportion, low plastic toughness and section shrinkage rate, and limited processing deformation capacity. , to achieve the effect of reducing processing procedures and energy consumption, improving the deformation capacity of upsetting and high cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of the 10.9-grade high-strength bolt steel hot-rolled round wire rod of the present invention, described preparation method comprises the following steps:

[0020] A. Hot metal pretreatment desulfurization: transport the blast furnace hot metal to the KR method hot metal pretreatment device for desulfurization, the insertion depth of the stirring head is controlled at 1800~2000mm, and the amount of steel is 10.0~12.0 kg / t, and CaO desulfurizer is added for desulfurization For processing, the stirring time is controlled to 5 minutes; after the stirring is completed, the slag removal operation is carried out to ensure that the molten iron surface in the ladle is exposed ≥ 3 / 4, and the desulfurization slag is removed to obtain the pretreated molten iron;

[0021] B. Molten steel smelting: Put the molten iron and high-quality steel scrap pretreated in step A into the LD converter, and carry out conventional top-bottom composite blowing. Adding amount ...

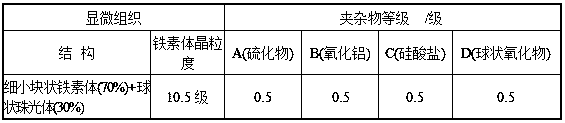

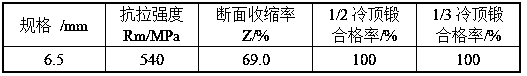

Embodiment 1

[0043] A, hot metal pretreatment desulfurization: blast furnace hot metal (chemical composition C 4.0wt%, Si 0.25wt%, Mn 0.60wt%, P0.105wt%, S 0.030wt%, the rest is Fe and unavoidable impurities) transport Go to the KR method molten iron pretreatment device for desulfurization treatment. The insertion depth of the stirring head is controlled at 1800mm. According to the amount of 10.0 kg / t steel, add conventional CaO desulfurization agent for desulfurization treatment. The stirring time is controlled at 5 minutes; After the slag operation, ensure that the molten iron surface in the ladle is exposed ≥ 3 / 4, and remove the desulfurization slag; the composition of the molten iron after pretreatment is controlled as follows: C 4.0wt%, Si 0.25wt%, Mn 0.60wt%, P 0.105wt%, S 0.005 wt%, the rest is Fe and unavoidable impurities.

[0044] B, molten steel smelting: the molten iron after the pretreatment of step A (chemical composition C 4.0wt%, Si 0.25wt%, Mn0.60wt%, P 0.105wt%, S 0.030wt...

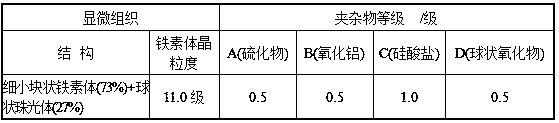

Embodiment 2

[0056] A. Hot metal pretreatment desulfurization: blast furnace hot metal (chemical composition C 4.2wt%, Si 0.35wt%, Mn 0.75wt%, P0.095wt%, S 0.024wt%, the rest is Fe and unavoidable impurities) transport To the KR method molten iron pretreatment device for desulfurization treatment, the insertion depth of the stirring head is controlled at 1900mm, according to 11.0 kg / t 钢 Add the conventional CaO-based desulfurizer for desulfurization treatment, and control the stirring time to 5 minutes; after the stirring, carry out the slag removal operation to ensure that the molten iron surface in the ladle is exposed ≥ 3 / 4, and remove the desulfurization slag; the molten iron composition after pretreatment The control is: C 4.2wt%, Si 0.35wt%, Mn 0.75wt%, P 0.095wt%, S 0.004wt%, the rest is Fe and unavoidable impurities.

[0057] B, molten steel smelting: the molten iron after the pretreatment of step A (chemical composition C 4.2wt%, Si 0.35wt%, Mn0.75wt%, P 0.095wt%, S 0.004wt%, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com