Method for manufacturing pipeline assembly from shape memory alloy

A technology of memory alloy and pipeline, which is applied in the field of pipeline components made of shape memory alloy, can solve the problems that cannot meet the high performance index of memory alloy pipe joints, achieve high hardenability and resistance, increase strength and recovery rate, The effect of improving the strength of the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

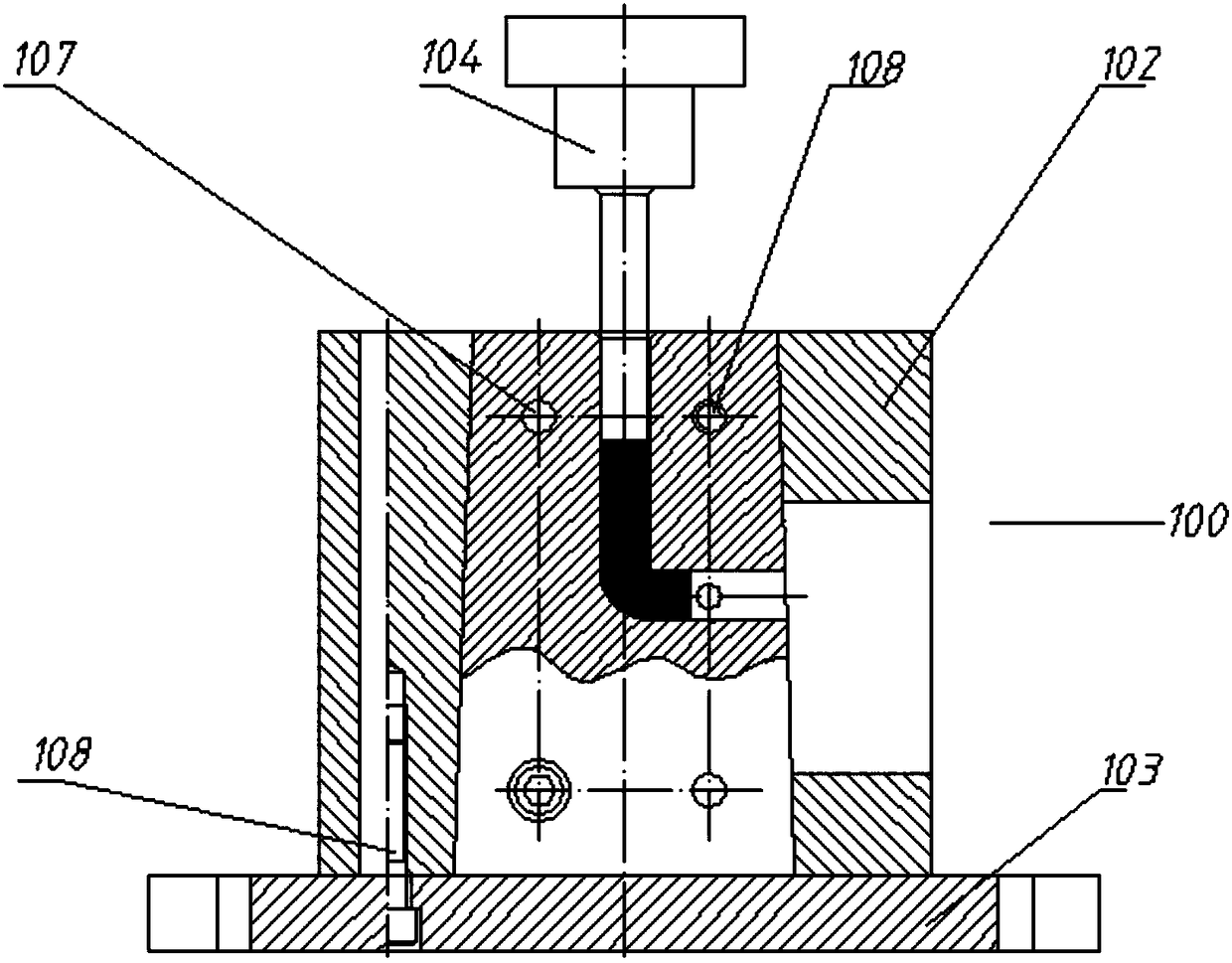

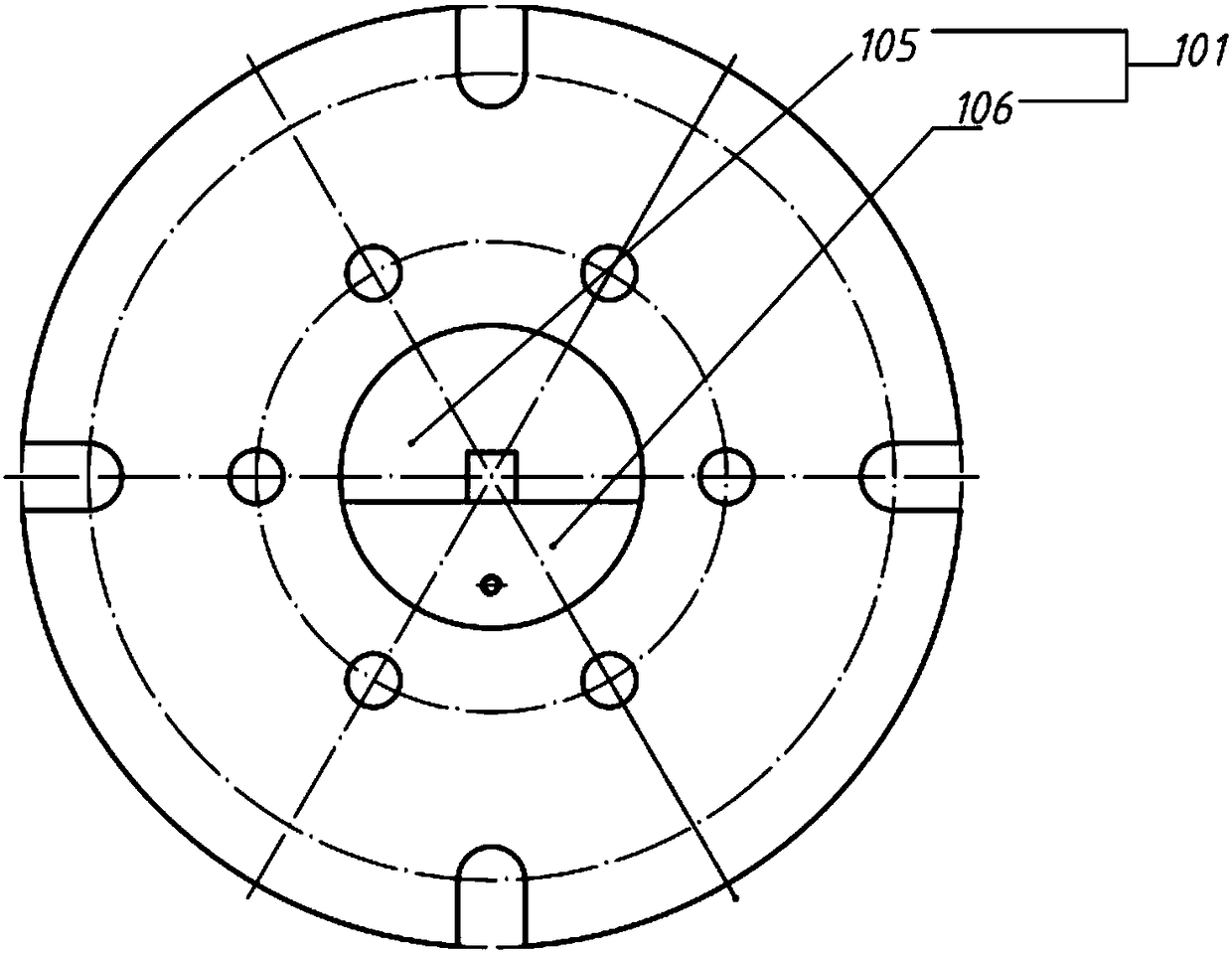

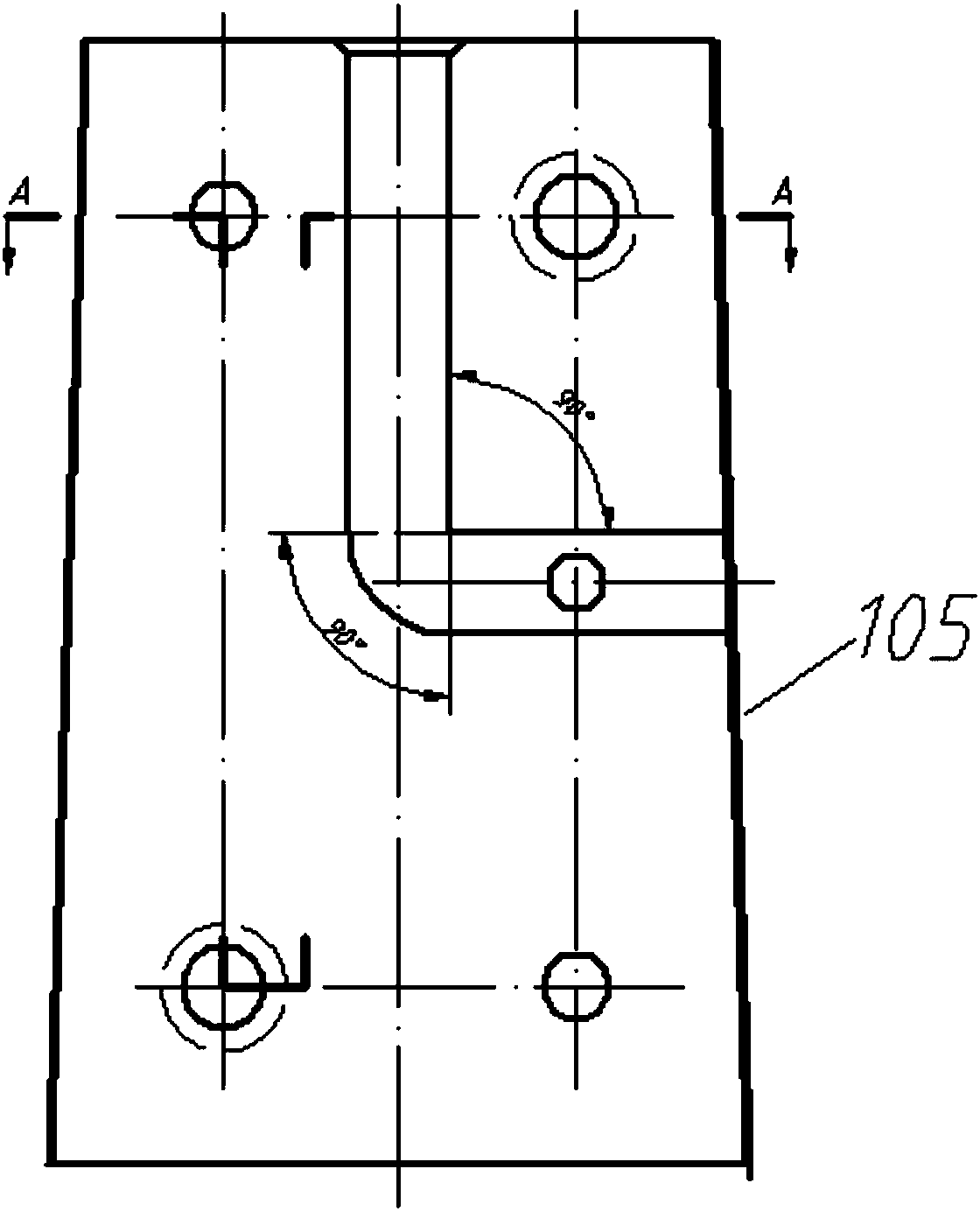

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0022] The present invention is a method for manufacturing a pipeline assembly using a shape memory alloy, which comprises the following steps:

[0023] 1) Preheat the shape memory alloy sample. The preheating temperature is 400°C for 30 minutes, and 860°C for 20 minutes;

[0024] Among them, the shape memory alloy sample adopts 99.96% sponge titanium, 99.96% pure nickel and 99.96% pure niobium, according to the ratio of Ni47-Ti44-Nb9 (this composition ratio is known, and the alloy formed by other ratios has no Shape memory performance, so it is impossible to make shape memory pipeline components, so this method is limited to Ni47-Ti44-Nb9) configuration.

[0025] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com