High-hardenability and high-strength ultra-thick marine steel plate and production method thereof

A high-hardenability, steel plate technology is applied in the field of high-hardenability, high-strength, toughness, and extra-thick marine steel plates and its preparation. It can solve problems such as uneven structure and performance, low yield ratio, etc., and achieve improved thickness direction structure, The effect of low yield ratio and high yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

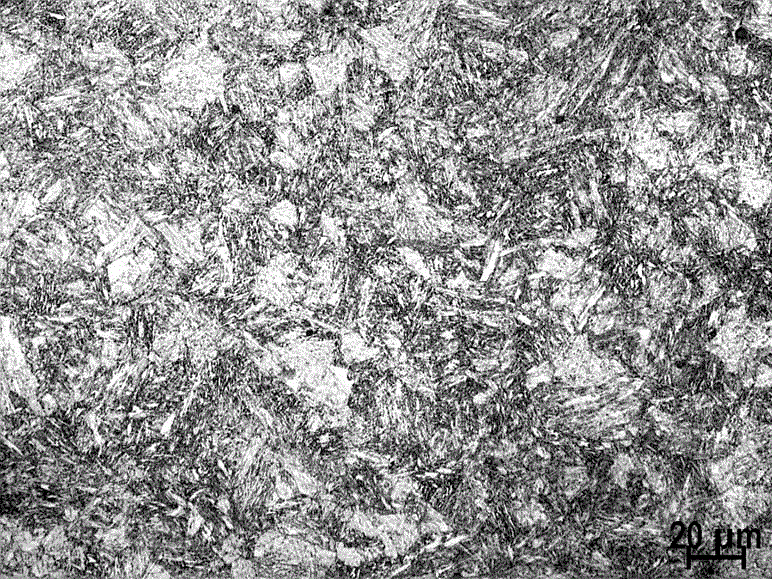

Embodiment 1

[0037]This example is a high-hardenability, high-strength and toughness extra-thick marine steel plate with a thickness of 150mm. The chemical composition and its mass fraction are 0.06%C, 7.1%Mn, 0.22%Si, 0.02%Als, 0.36%Mo, 0.045% %Nb, 0.004%S, 0.007%P, and the balance of Fe and impurity elements, the metallographic structure is a complex phase structure of tempered martensite + reverse transformed austenite, the yield strength at 1 / 4 of the thickness is 725MPa, the yield strength Ratio 0.82, elongation 32%, -80°C Charpy impact test longitudinal impact absorption energy is 136J, 147J, 145J; yield strength at 1 / 2 thickness is 713MPa, yield ratio 0.84, elongation 30%, -80°C Charpy Impact test longitudinal impact absorbed energy is 128J, 143J, 131J.

[0038] The preparation process of the above-mentioned high-hardenability, high-strength and toughness extra-thick marine steel plate is carried out according to the following steps:

[0039] Put a 320mm thick blank into a heating ...

Embodiment 2

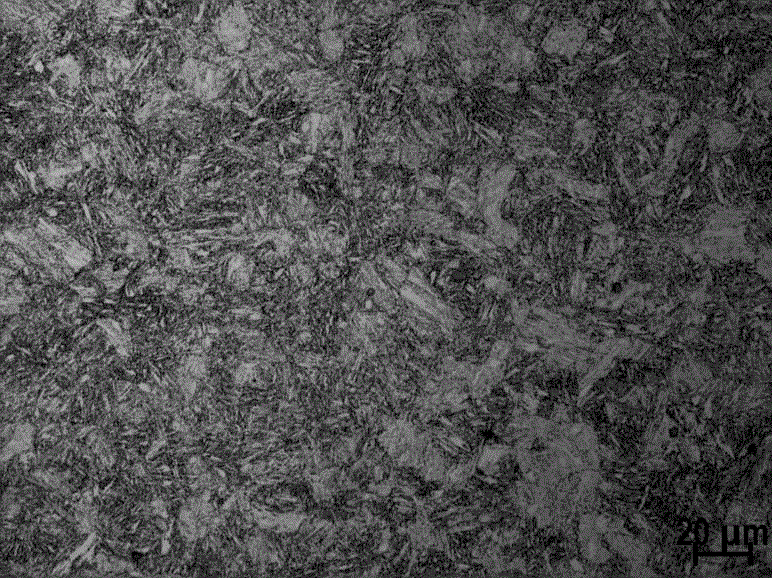

[0043] This example is a high-hardenability, high-strength and toughness extra-thick marine steel plate with a thickness of 80mm. %Nb, 0.004%S, 0.007%P, and the balance of Fe and impurity elements, the metallographic structure is a multiphase structure of tempered martensite + reverse transformed austenite, the yield strength at 1 / 4 of the thickness is 730MPa, the yield strength Ratio 0.82, elongation 34%, -80°C Charpy impact test longitudinal impact absorption energy is 142J, 148J, 154J; thickness 1 / 2 yield strength 722MPa, yield ratio 0.84, elongation 32%, -80°C Charpy Impact test longitudinal impact absorbed energy is 126J, 138J, 136J.

[0044] The preparation process of the above-mentioned high-hardenability, high-strength and toughness extra-thick marine steel plate is carried out according to the following steps:

[0045] Put a 320mm thick blank into a heating furnace and heat it to 1030°C and keep it warm for 120min. The chemical composition of the blank is the above c...

Embodiment 3

[0049] This example is a high-hardenability, high-strength and toughness extra-thick marine steel plate with a thickness of 60mm. %Nb, 0.004%S, 0.006%P, and the balance of Fe and impurity elements, the metallographic structure is a complex phase structure of tempered martensite + reverse transformed austenite, the yield strength at 1 / 4 of the thickness is 735MPa, the yield strength Ratio 0.80, elongation 33%, -80°C Charpy impact test longitudinal impact absorption energy is 146J, 149J, 155J; thickness 1 / 2 yield strength 726MPa, yield ratio 0.82, elongation 32%, -80°C Charpy Impact test longitudinal impact absorbed energy is 133J, 137J, 145J.

[0050] The preparation process of the above-mentioned high-hardenability, high-strength and toughness extra-thick marine steel plate is carried out according to the following steps:

[0051] Put a 260mm thick billet into a heating furnace and heat it to 1020°C and keep it warm for 100min. The chemical composition of the billet is the ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com