High-manganese ultralow temperature steel welding wire and welding process thereof

A welding process and ultra-low temperature technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problem of high welding material cost, achieve the effect of reducing Ni content, reducing cost and expense, and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A high manganese ultra-low temperature steel welding wire, its chemical composition and mass percentage content are as follows: C is 0.33%, Mn is 24.4%, Si is 0.05%, S is 0.002%, P is 0.013%, Ni is 1.6%, Cr is 3.1% %, Cu is 0.2%, N is 0.035%, and the balance is Fe and the residual elements usually present in steelmaking.

[0023] Use this welding wire to weld high-manganese ultra-low temperature steel, adopt tungsten argon arc welding, the groove type is "V", the heat input is 4KJ, and the shielding gas is high-purity argon.

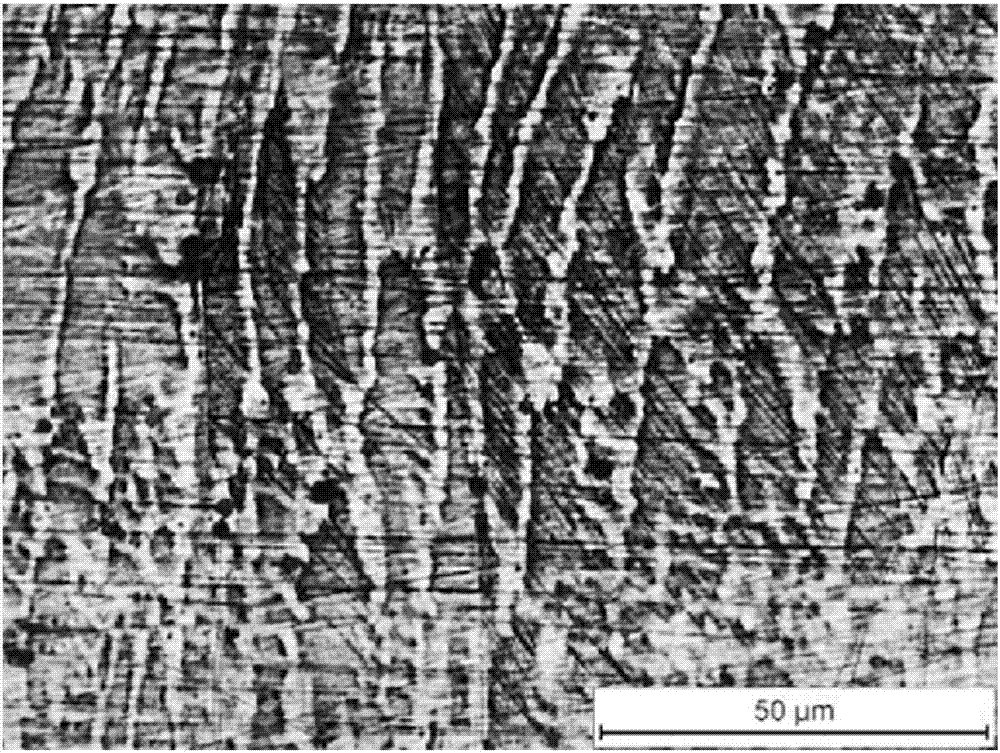

[0024] as attached figure 1 Shown is a photograph of the metallographic structure of the weld metal, the microstructure type is austenitic. Measured specified non-proportional elongation strength R of the weld metal p0.2 =551MPa, tensile strength R m =813MPa, elongation A=44%, impact test impact absorption energy KV at -196°C 2 =50J.

Embodiment 2

[0026] A high manganese ultra-low temperature steel welding wire, its chemical composition and mass percentage content are as follows: C is 0.2%, Mn is 27.0%, Si is 0.15%, S is 0.001%, P is 0.02%, Ni is 1.0%, Cr is 4.5% %, Cu is 0.33%, N is 0.06%, and the balance is Fe and the residual elements usually present in steelmaking.

[0027] Use this welding wire to weld high-manganese ultra-low temperature steel, adopt tungsten argon arc welding, the groove type is "V", the heat input is 15KJ, and the shielding gas is high-purity argon.

[0028] The microstructure type of the weld metal is austenitic, and the specified non-proportional elongation strength R p0.2 =420MPa, tensile strength R m =680MPa, elongation A=51%, impact test impact absorption energy KV at -196°C 2 =92J.

Embodiment 3

[0030] A high manganese ultra-low temperature steel welding wire, its chemical composition and mass percentage content are as follows: C is 0.4%, Mn is 18.0%, Si is 0.07%, S is 0.001%, P is 0.007%, Ni is 3.0%, Cr is 2.0% %, Cu is 0.5%, N is 0.01%, and the balance is Fe and the residual elements usually present in steelmaking.

[0031] Use this welding wire to weld high-manganese ultra-low temperature steel, adopt argon tungsten arc welding, the groove type is "V", the heat input is 21KJ, and the shielding gas is high-purity argon.

[0032] The microstructure type of the weld metal is austenitic, and the specified non-proportional elongation strength R p0.2 =486MPa, tensile strength R m =741MPa, elongation A=40%, impact test impact absorption energy KV at -196°C 2 =64J.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com