Large-section high-performance hot work die steel for die casting and preparation technology thereof

A technology of hot work die steel and preparation process, applied in the field of alloy steel, can solve the problems of lower product yield and manufacturing capacity, low high temperature strength, low impact toughness of materials, etc., to improve high temperature performance and thermal stability performance, increase the carbon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] In this example, the components and mass percentages of the high-performance hot-work die steel for large-section die-casting are as follows:

[0056] C 0.65%, Si 1.00%, Mn 1.00%, Cr 5.50%,

[0057] Mo 3.00%, V 0.80%, P 0.015%, S 0.007%,

[0058] Ni 2.00%, Nb 0.20%, Fe balance.

[0059] The technical process and steps of producing hot work die steel with the material in this embodiment are as follows:

[0060] A Electric furnace smelting: melting in an electric arc furnace according to the ratio of alloy elements in the above examples, the melting temperature is higher than 1500°C, casting into electrode rods of φ400mm~φ450mm and cooling in air.

[0061] B Electroslag remelting: The poured steel ingot is placed in the electroslag remelting device as a consumable electrode for electroslag remelting. The slag melting voltage is 56-62V, the current is 3000-5000A, and the voltage of the electricity system is 57 ~59V, current 11000~12000A, capping voltage 57~5...

Embodiment 2

[0085] In this example, the components and mass percentages of the high-performance hot-work die steel for large-section die-casting are as follows:

[0086] C 0.47%, Si 0.30%, Mn 0.40%, Cr 4.80%,

[0087] Mo 2.40%, V 0.50%, P 0.007%, S 0.003%,

[0088] Ni 1.50%, Nb 0.18%, Fe balance.

[0089] The process and steps of producing hot work die steel using the materials in this embodiment are the same as in Embodiment 1, and will not be repeated here.

[0090] After the above-mentioned smelting, thermal processing and heat treatment of the hot work die steel in this embodiment, the final finished product specification is 500mm*800mm*4000mm module, and samples are taken for performance testing. The analysis results are as follows:

[0091] A phase transition point:

[0092] Ac1, Ac3, and Ms point test results were 831°C, 957°C, and 307°C, respectively.

[0093] B tempering characteristics:

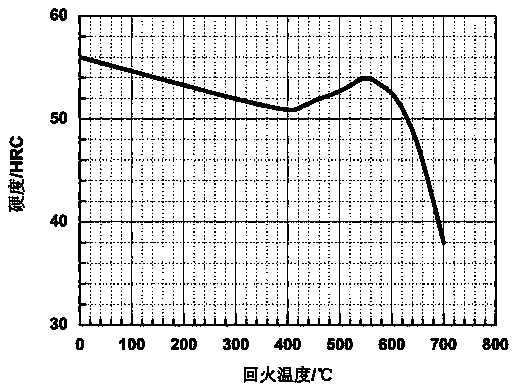

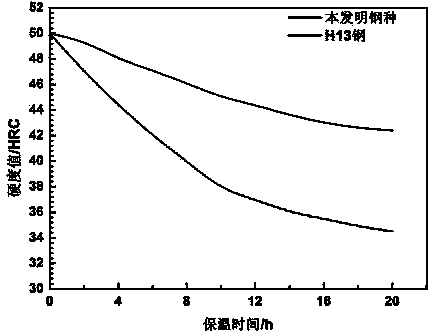

[0094] The characteristic curve of tempering hardness changing with tempering tempera...

Embodiment 3

[0107] In this example, the components and mass percentages of the high-performance hot-work die steel for large-section die-casting are as follows:

[0108] C 0.45%, Si 0.50%, Mn 0.70%, Cr 3.50%,

[0109] Mo 2.00%, V 0.60%, P 0.001%, S 0.005%,

[0110] Ni 1.00%, Nb 0.17%, Fe balance.

[0111] The process and steps of using the materials in this embodiment to produce hot work die steel are the same as those in Embodiment 1, and will not be repeated here.

[0112] After the hot work die steel of the present invention is through the above-mentioned smelting, thermal processing and heat treatment, the final finished product specification is 500mm*800mm*4000mm module, sampling is carried out performance test, and analysis result is:

[0113] A phase transition point:

[0114] Ac1, Ac3, and Ms point test results were 831°C, 962°C, and 306°C, respectively.

[0115] B tempering characteristics:

[0116] The characteristic curve of tempering hardness changing with temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Quenching hardness | aaaaa | aaaaa |

| Tempering hardness | aaaaa | aaaaa |

| Quenching hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com