Method for preparing biomass carbon by utilizing agricultural and forestry waste

A technology of agricultural and forestry waste and biochar, which is applied in the field of carbon material preparation and biomass resource utilization, can solve the problems of high cost, complex process, unsustainable source, etc., achieve high carbon content and calorific value, and simple preparation method , Conducive to the effect of industrialization promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Preparation of biochar by using agricultural waste corn stalks.

[0027] (1) Cut the collected agricultural waste corn stalks into small pieces, dry them in an oven at 60°C for 16 hours, pulverize them with a pulverizer and collect 40-60 mesh components;

[0028] (2) Fully mix the powdery raw materials and deionized water at a mass ratio of 1:10, and let stand for 4 hours. Then the mixture was transferred to a high-pressure reactor, under the protection of nitrogen, the temperature was raised to 250°C at a rate of 4°C per minute, and the reaction was carried out for 4 hours. The pressure of the reactor was 4.0MPa, and the rotation speed of the reactor was 150 rpm;

[0029] (3) After the reaction, the autoclave was cooled to room temperature. Then the obtained solid residue was vacuum filtered, washed with hot water, and dried in an oven at 60° C. for 16 hours to obtain biochar.

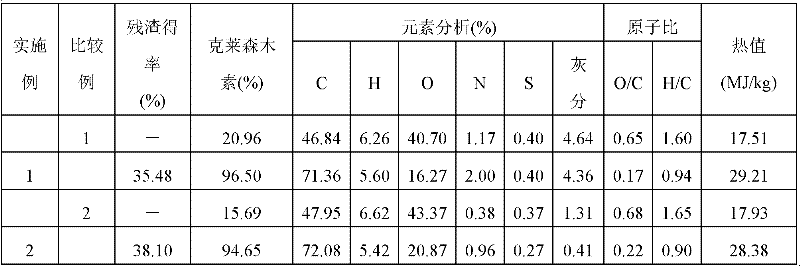

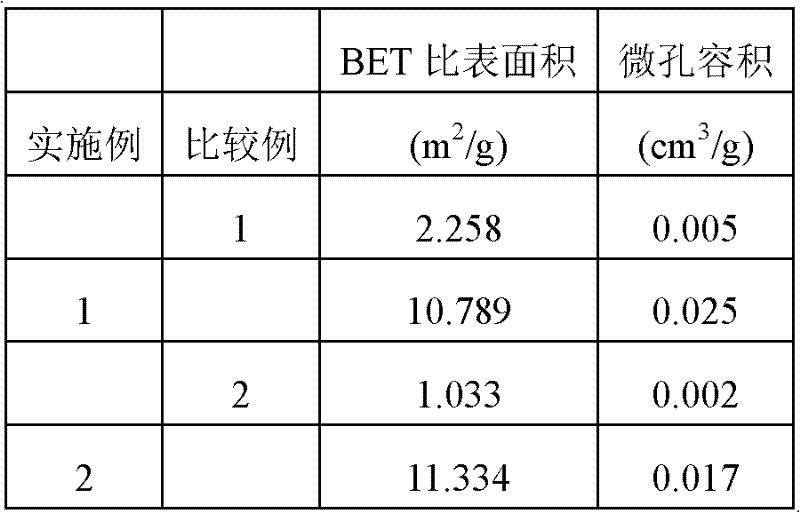

[0030] In the biochar prepared in this example, the yield of biochar is 35.48%...

Embodiment 2

[0031] Example 2: Preparation of biochar by utilizing forestry waste shrub tamarisk.

[0032] (1) The collected forestry waste shrub red willow was cut into small pieces, dried in an oven at 60° C. for 16 hours, pulverized with a pulverizer and collected 40-60 mesh components.

[0033] (2) Fully mix wood flour and deionized water in a mass ratio of 1:10, and let stand for 4 hours. Then the mixture was transferred to a high-pressure reactor, and under the protection of nitrogen, the temperature was raised to 250° C. at a rate of 4° C. per minute, and the reaction was carried out for 4 hours. The pressure of the reactor was 4.0 MPa, and the rotation speed of the reactor was 150 rpm.

[0034] (3) After the reaction, the autoclave was cooled to room temperature. Then the obtained solid residue was vacuum filtered, washed with hot water, and dried in an oven at 60° C. for 16 hours to obtain biochar.

[0035] In the biochar prepared in this example, the biochar yield rate is 38.1%, ...

Embodiment 3

[0036] Example 3: Preparation of biochar by using forestry waste eucalyptus, a broad-leaved wood.

[0037] (1) The collected forestry waste eucalyptus broad-leaved wood raw material was cut into small pieces, dried in an oven at 60° C. for 16 hours, pulverized with a pulverizer and collected 40-60 mesh components.

[0038] (2) Fully mix wood powder and deionized water in a mass ratio of 1:16, and let stand for 5 hours. Then the mixture was transferred to a high-pressure reactor, and under the protection of nitrogen, the temperature was raised to 250° C. at a rate of 4° C. per minute, and the reaction was carried out for 2 hours. The pressure of the reactor was 4.0 MPa, and the rotation speed of the reactor was 150 rpm.

[0039] (3) After the reaction, the autoclave was cooled to room temperature. Then the obtained solid residue was vacuum filtered, washed with hot water, and dried in an oven at 60° C. for 16 hours to obtain biochar.

[0040] In the biochar prepared in this e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com