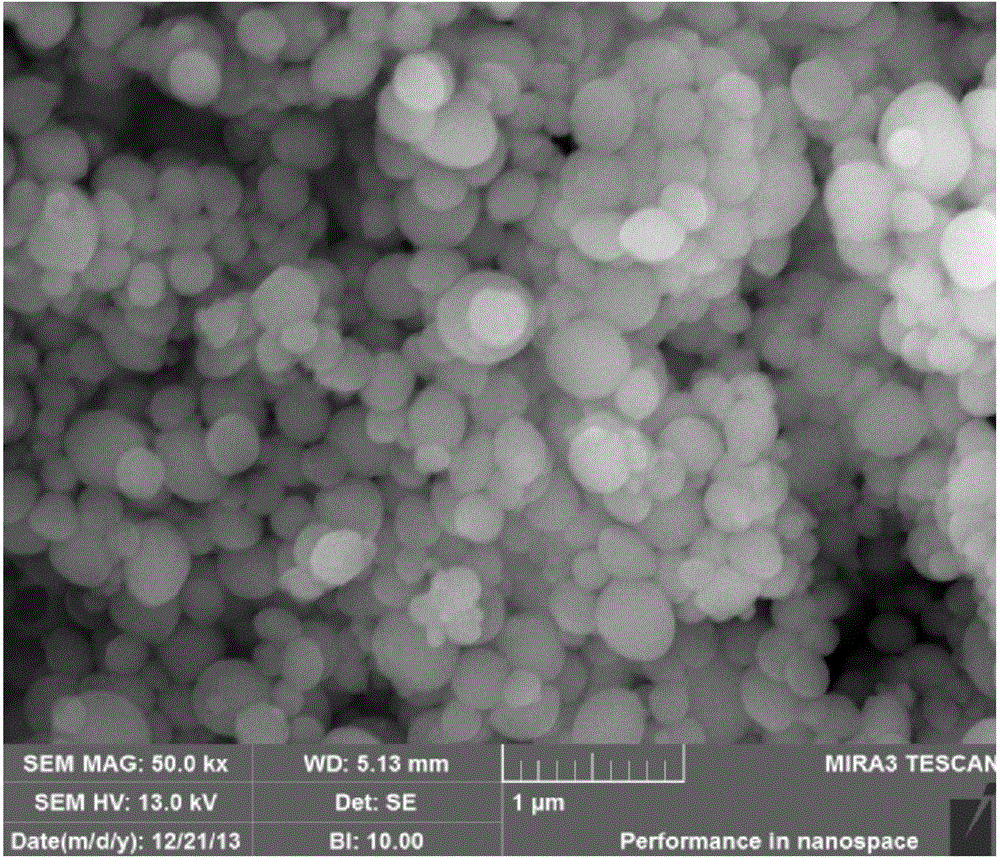

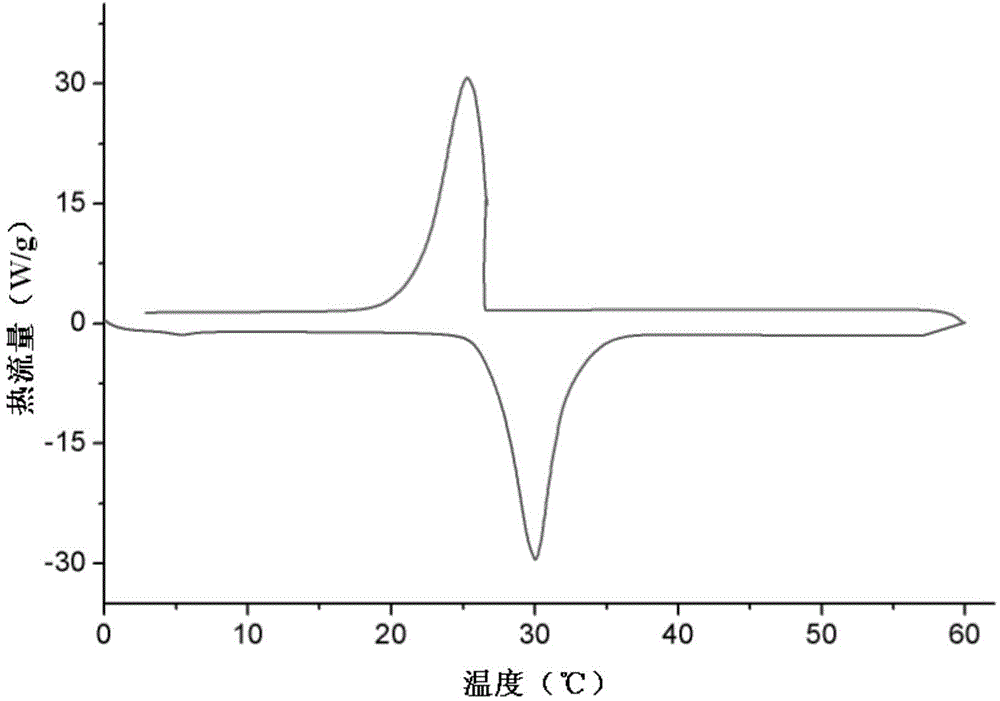

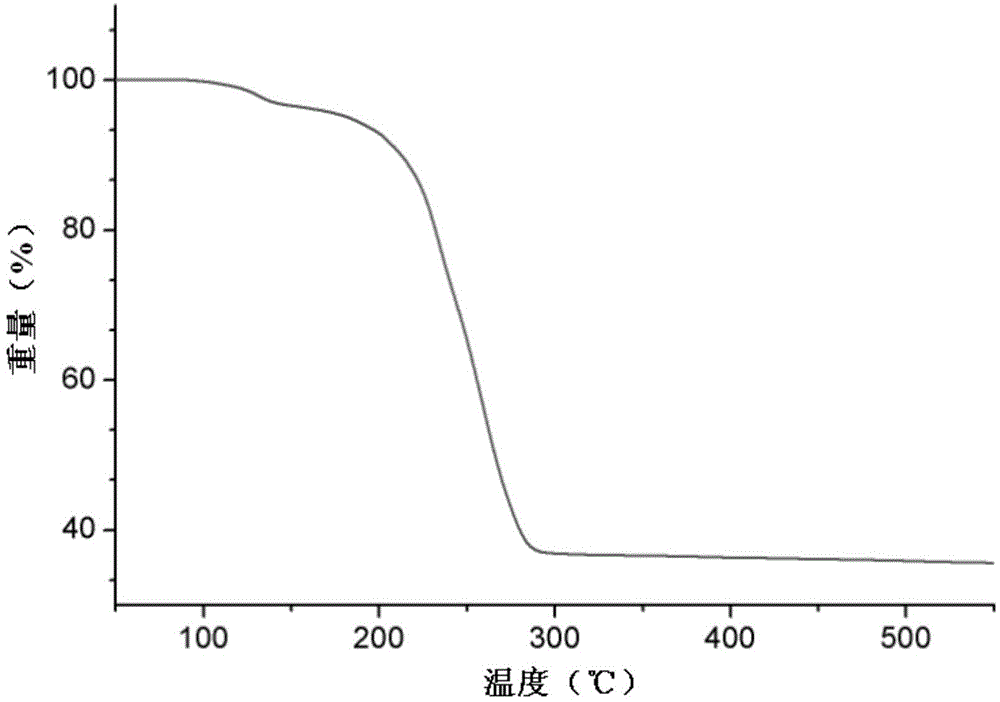

Low-temperature phase-change thermal storage microcapsule as well as preparation method and application thereof

A low-temperature phase change and microcapsule technology, applied in the field of materials, can solve the problems of few nanocapsules, complex equipment, high operation requirements, etc., and achieve the effect of good encapsulation, good coating and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) Add 100g (100mL) deionized water in a beaker, add dropwise hydrochloric acid to adjust its pH value to 2.18, then add 0.2g (4% of n-octadecane mass) sodium dodecylbenzenesulfonate, stir to make After dissolving it, add 5.0 g of n-octadecane (the mass ratio of water to water is 1:20), stir and mix evenly to obtain an oil-in-water mixed liquid.

[0036]2) Place the beaker in a water bath at 80°C, emulsify with a high-speed emulsifying dispersing homogenizer, the emulsifying speed is 12000rpm / min, slowly add 5mL of n-amyl alcohol (5% of the water volume in step 1) during the emulsification process, and emulsify After 20 minutes, the emulsion was obtained.

[0037] 3) Pour the emulsion into a three-necked flask and change it to magnetic stirring at a speed of 400rpm / min. After stabilization, add 3g of phenyltrimethoxysilane (the mass ratio to n-octadecane is 0.6:1) dropwise for hydrolysis. 10 minutes after the dropwise addition, the hydrolysis was completed. At this tim...

Embodiment 2

[0043] 1) Add 100g (100mL) deionized water in a beaker, add dropwise hydrochloric acid to adjust its pH value to 2.18, then add 0.1g (2% of n-octadecane mass) sodium dodecylbenzenesulfonate, stir to make After dissolving it, add 5.0 g of n-octadecane (the mass ratio of water to water is 1:20), stir and mix evenly to obtain an oil-in-water mixed liquid.

[0044] 2) Place the beaker in a water bath at 80° C., emulsify with a high-speed emulsifying and dispersing homogenizer, and the emulsifying speed is 3000 rpm / min. Slowly add 5 mL of n-amyl alcohol (5% of the water volume in step 1) during the emulsifying process to emulsify After 20 minutes, the emulsion was obtained.

[0045] 3) Pour the emulsion into a three-necked flask and change it to magnetic stirring at a speed of 400rpm / min. After stabilization, add 3g of phenyltrimethoxysilane (the mass ratio to n-octadecane is 0.6:1) dropwise for hydrolysis. 10 minutes after the dropwise addition, the hydrolysis was completed. At t...

Embodiment 3

[0049] 1) Add 100g (100mL) deionized water in a beaker, add dropwise hydrochloric acid to adjust its pH value to 2.18, then add 0.1g (2% of n-octadecane mass) sodium dodecylbenzenesulfonate, stir to make After dissolving it, add 5.0 g of n-octadecane (the mass ratio of water to water is 1:20), stir and mix evenly to obtain an oil-in-water mixed liquid.

[0050] 2) Place the beaker in a water bath at 80° C., emulsify with a high-speed emulsifying and dispersing homogenizer, and the emulsifying speed is 3000 rpm / min. Slowly add 5 mL of n-amyl alcohol (5% of the water volume in step 1) during the emulsifying process to emulsify After 20 minutes, the emulsion was obtained.

[0051] 3) Pour the emulsion into a three-necked flask and change it to magnetic stirring at a speed of 400rpm / min. After stabilization, add 3g of phenyltrimethoxysilane (the mass ratio to n-octadecane is 0.6:1) dropwise for hydrolysis. 10 minutes after the dropwise addition, the hydrolysis was completed. At t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| heat storage density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com