Ultrathin flexible flat-plate heat pipe

A flat heat pipe, ultra-thin and flexible technology, applied in the field of heat transfer, can solve the problems of complex manufacturing process, poor heat pipe flexibility, poor surface adaptability, etc., and achieve the effect of uniform temperature distribution, reduced temperature gradient, and good contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further explained below in conjunction with the accompanying drawings.

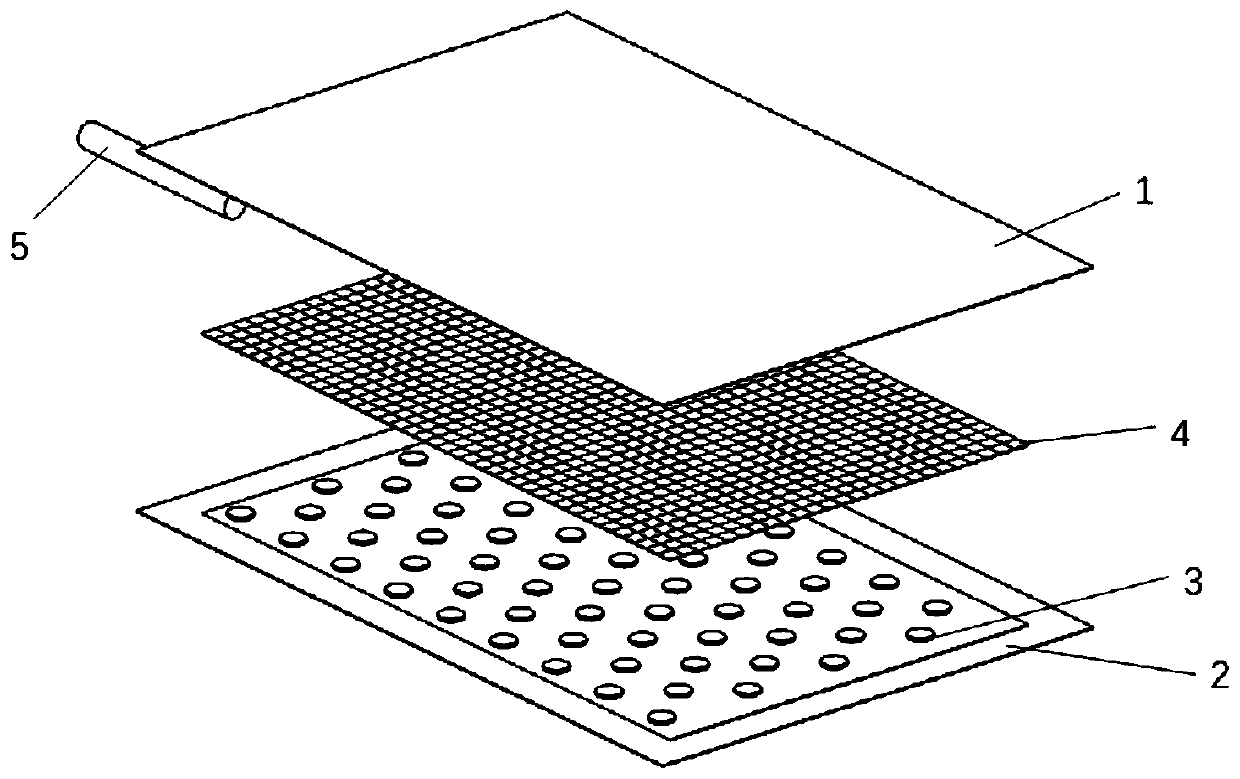

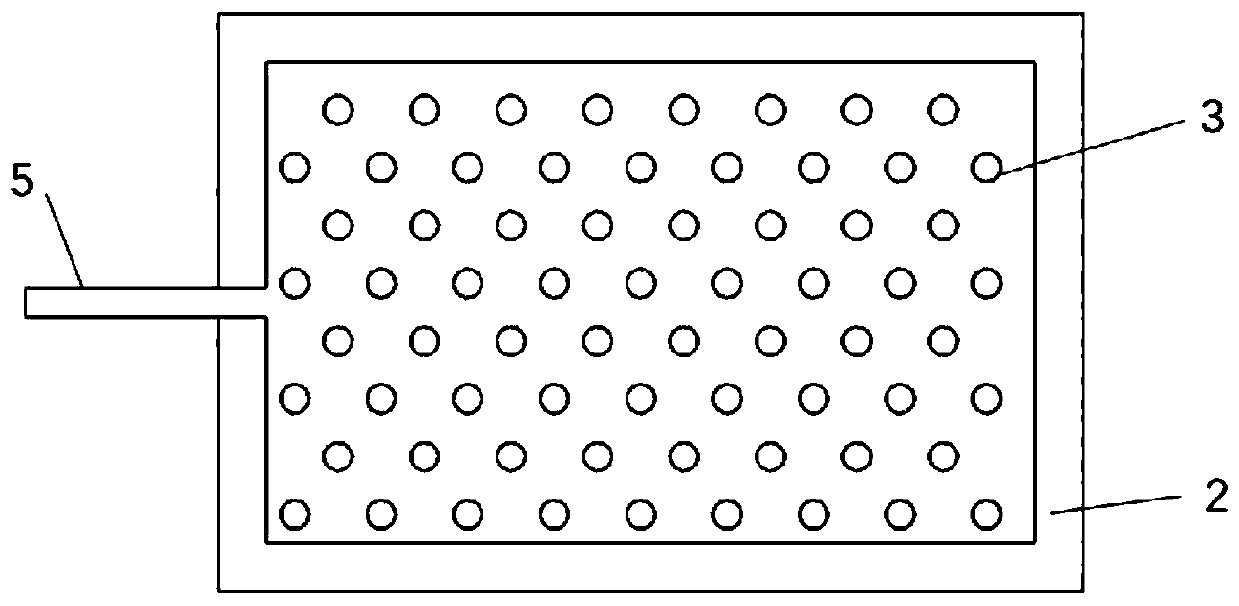

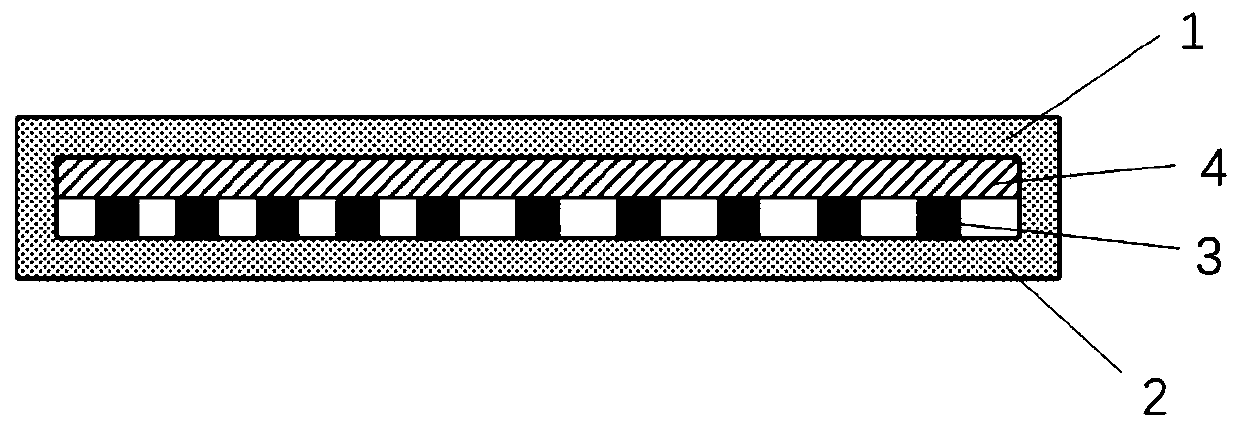

[0025] An ultra-thin flexible flat heat pipe comprises an upper flexible cover plate 1 and a lower flexible cover plate 2 . The micro-columns 3 are evenly spaced in the lower flexible cover plate 2. The micro-columns 3 are formed by electrodeposition, 3D printing or high-temperature mold extrusion. The cross-section of the micro-columns is circular and the diameter is 1mm. , the distance between the centers of adjacent microcolumns is 3 mm. The microcolumn 3 forms a guide column and a supporting column of the steam chamber inside the heat pipe.

[0026] A flexible red copper wire mesh 4 is formed on the inside of the upper flexible cover plate 1 by thermal sintering and pressing. The flexible red copper wire mesh 4 is a 200-mesh red copper wire mesh. The area and position of the flexible red copper wire mesh correspond to the area and position of the micro-pillars. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com