Low-temperature composite phase change cold storage agent and preparation method thereof

A composite phase change and cold storage agent technology, applied in the direction of chemical instruments and methods, heat exchange materials, etc., can solve the problems that it is difficult to meet the requirements of cold storage and the performance requirements of cold storage agent, and achieve large phase change latent heat, The preparation process is simple and feasible, and the effect of the preparation process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

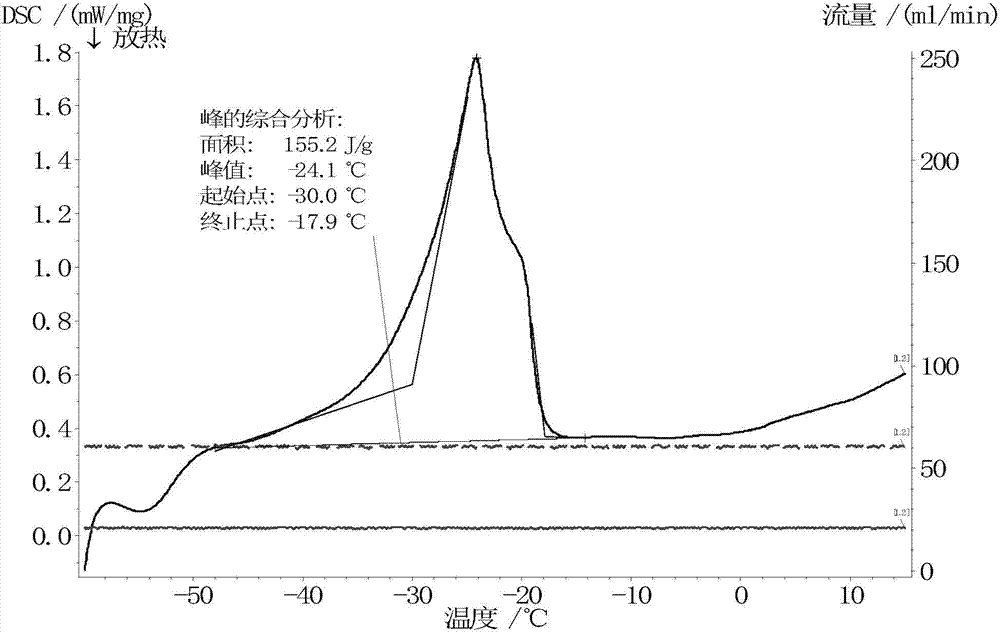

Embodiment 1

[0025] In this embodiment, a low-temperature composite phase-change cool storage agent is composed of the following component ratios according to the mass percentage:

[0027] Glycerol 12.5%,

[0028] Water 72.5%.

[0029] Wherein, the above-mentioned water can be selected pure water or distilled water.

[0030] The preparation method of the low-temperature composite phase change cold storage agent comprises the following steps:

[0031] S1. prepare 20% sodium chloride solution according to the mass percentage: pour pure water or distilled water into the stirring container, add sodium chloride, fully stir to make sodium chloride dissolve, and obtain 20% sodium chloride solution;

[0032] S2. Prepare a 50% glycerol solution according to the mass percentage: pour pure water or distilled water into the stirring container, add glycerol, and stir to obtain a 50% glycerol solution;

[0033] S3. Pour the sodium chloride solution and glycerol solution...

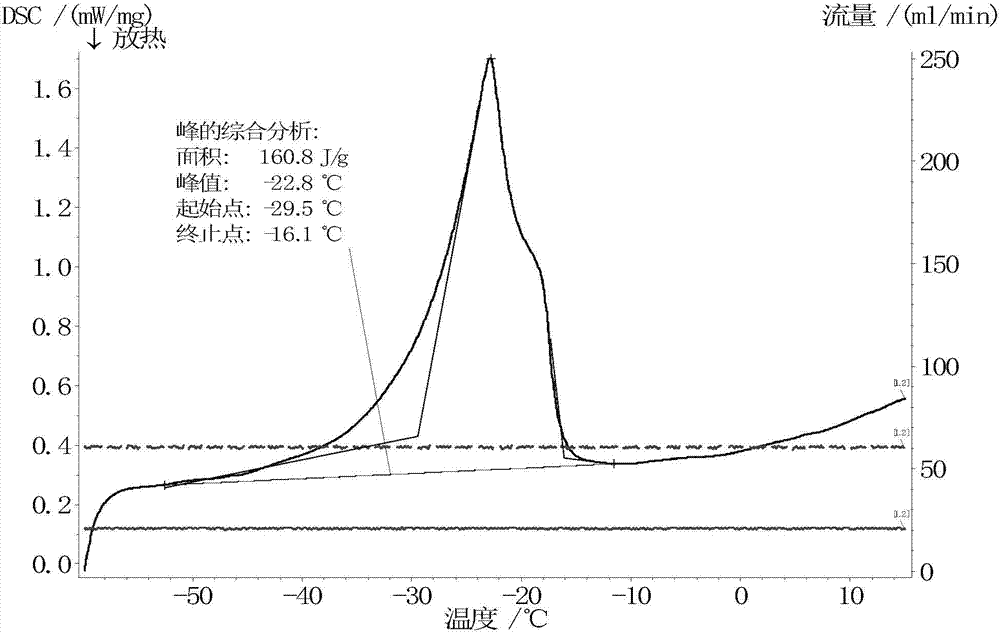

Embodiment 2

[0036] In this embodiment, a low-temperature composite phase-change cool storage agent is composed of the following component ratios according to the mass percentage:

[0037] Sodium Chloride 15.75%,

[0038] Glycerol 12.5%,

[0039] Water 71.75%.

[0040] Wherein, the above-mentioned water can be selected pure water or distilled water.

[0041] The preparation method of the low-temperature composite phase change cold storage agent comprises the following steps:

[0042] S1. prepare 21% sodium chloride solution according to the mass percentage: pour pure water or distilled water into the stirring container, add sodium chloride, fully stir to make sodium chloride dissolve, and obtain 21% sodium chloride solution;

[0043] S2. Prepare a 50% glycerol solution according to the mass percentage: pour pure water or distilled water into the stirring container, add glycerol, and stir to obtain a 50% glycerol solution;

[0044] S3. Pour the sodium chloride solution and glycerol solu...

Embodiment 3

[0047] In this embodiment, a low-temperature composite phase-change cool storage agent is composed of the following component ratios according to the mass percentage:

[0049] Glycerol 12.5%,

[0050] Water 71%.

[0051] Wherein, the above-mentioned water can be selected pure water or distilled water.

[0052] The preparation method of the low-temperature composite phase change cold storage agent comprises the following steps:

[0053] S1. prepare 22% sodium chloride solution according to the mass percentage: pour pure water or distilled water into the stirring container, add sodium chloride, fully stir to make sodium chloride dissolve, and obtain 22% sodium chloride solution;

[0054] S2. Prepare a 50% glycerol solution according to the mass percentage: pour pure water or distilled water into the stirring container, add glycerol, and stir to obtain a 50% glycerol solution;

[0055] S3. Pour the sodium chloride solution and glycerol solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com