3D additive-manufacturing bilateral laser welding method for T-shaped structure

A technology of laser welding and welding methods, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as difficult to ensure welding wire, difficult welding seam structure alloy control, etc., to achieve high density, uniform alloy control, forming uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

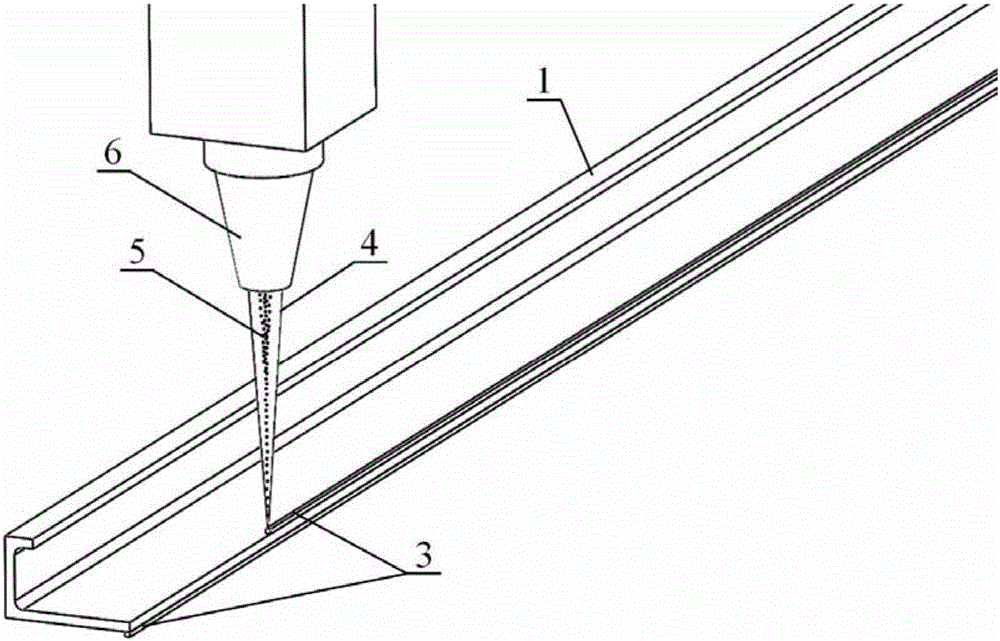

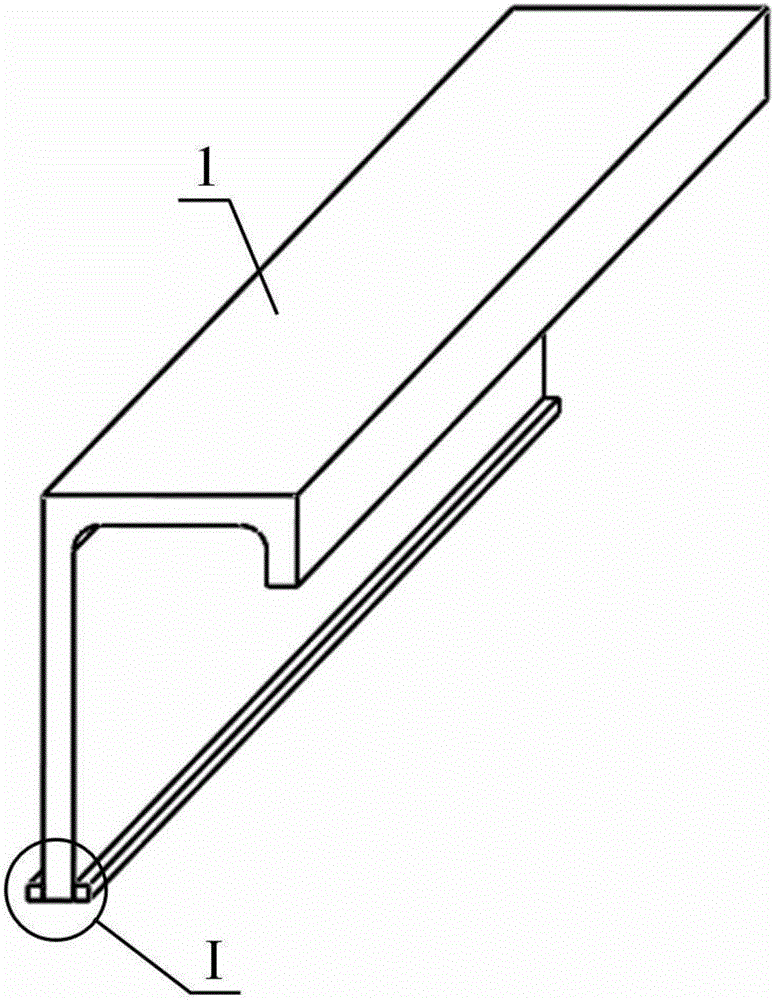

[0019] Specific implementation mode one: combine Figure 1 to Figure 4 Illustrate this embodiment, the welding method of this embodiment is to the welding of T-shaped structure of aircraft wall plate, this T-shaped structure is welded by vertical long stringer 1 and horizontally placed skin 2, and concrete welding method is through This is achieved by the following steps:

[0020] Step 1, chemically cleaning the surface of the stringer 1 to remove the oxide film and oil stains;

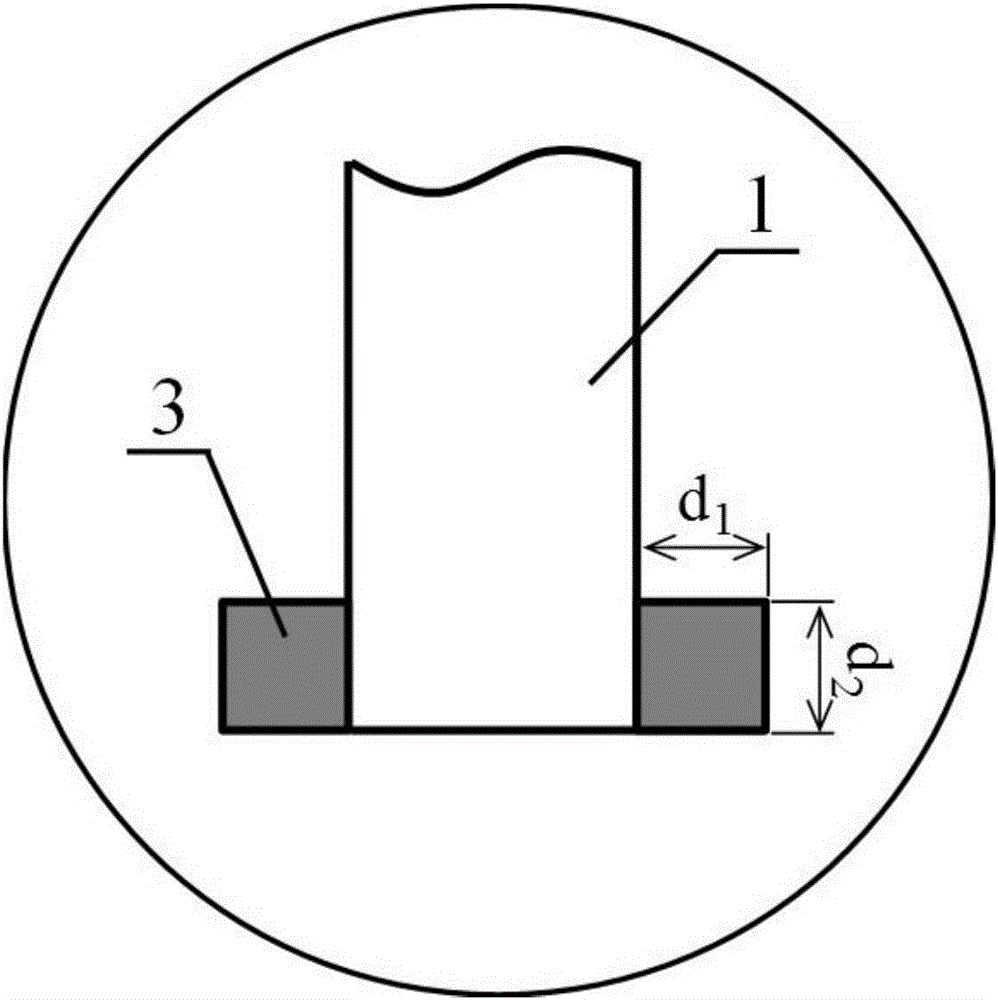

[0021] Step 2, designing the deposition layer 3: designing the deposition layer 3 on the area to be welded on the surface of the girder 1, the cross section of the deposition layer 3 is square or rectangular;

[0022] Step 3: Place the laser cladding head 6 vertically directly above the area to be welded on the surface of the stringer 1, and use the coaxial feeding method of the laser beam 4 and the alloy powder 5 to perform laser 3D on the area to be welded on both sides of the stringer 1 Add mater...

specific Embodiment approach 2

[0024] Specific implementation mode two: combination image 3 Describe this embodiment mode, this embodiment mode is that the cross-section of deposition layer 3 in step 2 is a square, namely d 1 = d 2 , d 1 and d 2 The following relation is satisfied: d 1 d 2 = π·r 2 · v / V, where d 1 is the deposition layer width, d 2 is the height of the deposited layer, r is the radius of the welding wire used in conventional double-sided laser wire-filling welding, v is the wire feeding speed, and V is the welding speed. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0025] Specific implementation mode three: combination image 3 Describe this embodiment mode, this embodiment mode is that the cross-section of deposition layer 3 in step 2 is rectangular, namely d 1 ≠ d 2 , d 1 and d 2 The following relation is satisfied: d 1 d 2 = π·r 2 ·v / V, where r is the radius of the welding wire used in conventional double-sided laser wire-filling welding, v is the wire feeding speed, and V is the welding speed. Other steps are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com