Welding method of laser brazing of X 80 pipeline steel

A welding method and pipeline steel technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., to achieve uniform preheating effect and avoid the effect of multiple processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

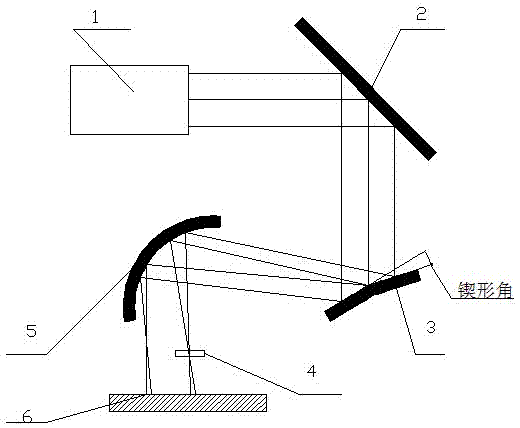

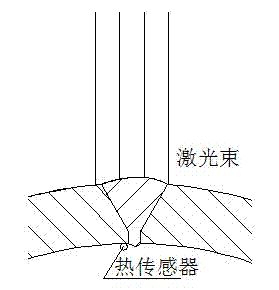

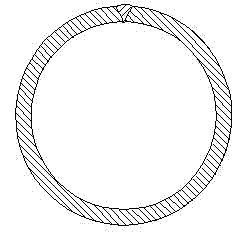

[0012] (1) Welding design: the cross-section of the pipeline steel weldment is as follows: image 3 As shown, according to the thickness of X80 pipeline steel and welding requirements, the V-shaped weld is used to fill the brazing filler metal. In order to ensure the welding, hard brazing filler metal is used. The material is silver-based brazing filler metal. The brazing flux is KBF4 type brazing flux. , the maximum power used is 10kW; in order to determine the specific process parameters, a test welding is carried out, and the schematic diagram of the test welding is as follows figure 2 As shown, firstly, the pre-welding treatment of the test welding sample is carried out, the wedge angle is adjusted to zero, the laser power output value is adjusted, and the speed of 1m / min is preheated, and the temperature of the inner wall of the test welding sample is measured by the thermal sensor at the inner wall of the pipeline steel. , so that the temperature of the inner wall reach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power | aaaaa | aaaaa |

| Spot diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com