Fiber-reinforced light thermoplastic interface-free layered felt material for passenger car interior and exterior decoration, device and preparation method

A fiber-reinforced and thermoplastic technology, applied in the field of composite felt materials for interior and exterior trim of passenger cars, can solve problems such as high equipment cost, achieve the effects of increasing output, being multi-functional and flexible, and avoiding the decline of material mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical scheme of the present invention will be further described below by specific examples:

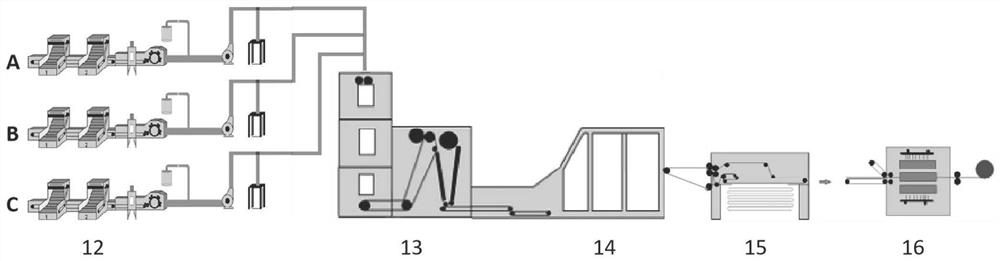

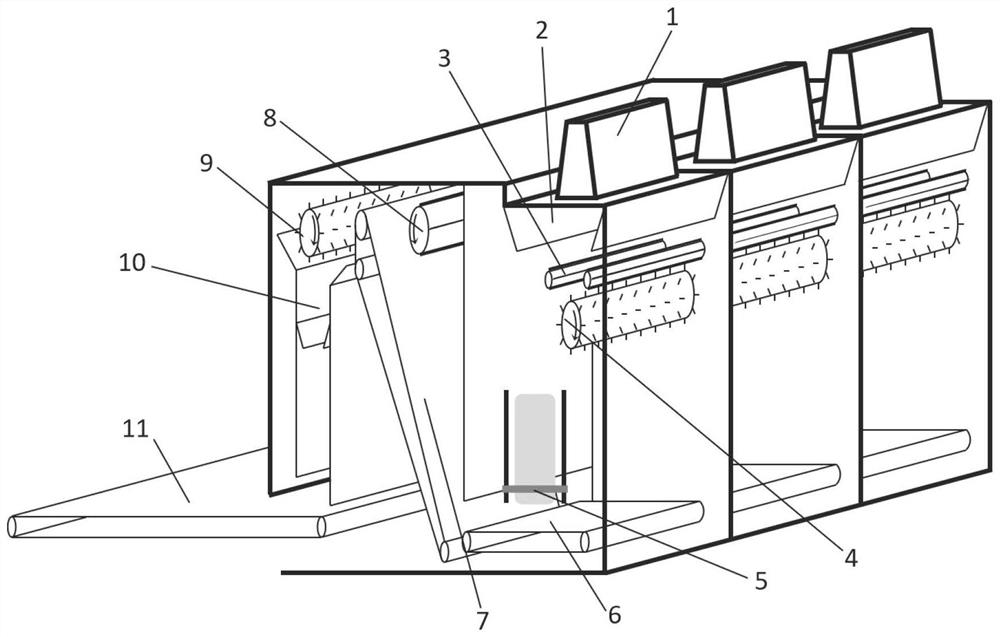

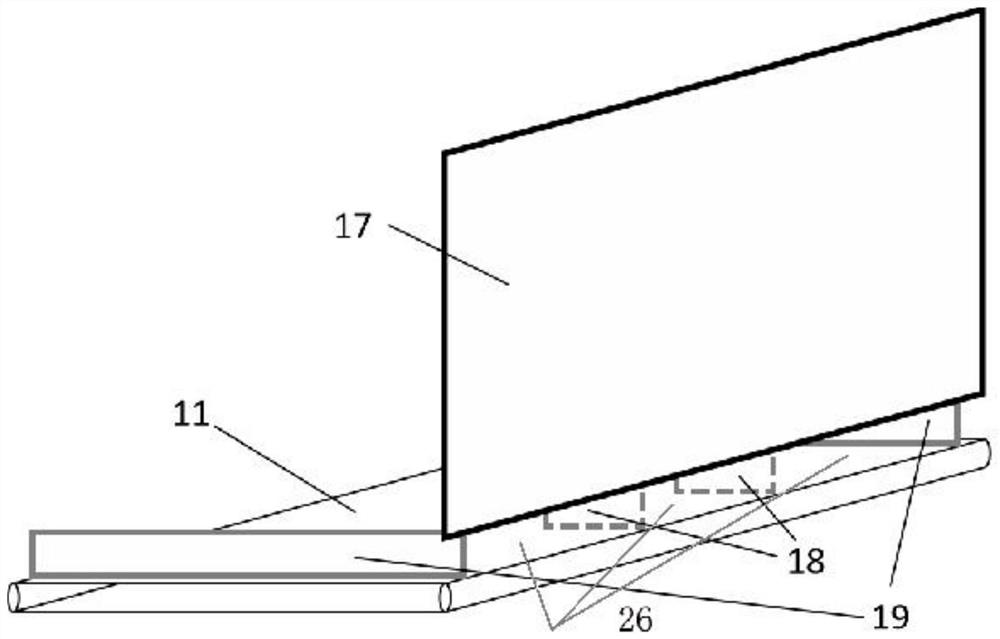

[0039] The invention discloses a cotton feeding box 13 for preparing fiber-reinforced lightweight thermoplastic layered felt for interior and exterior decoration of passenger cars. figure 1It is a flow chart of the dry felting line device adopted in the present invention, and the device includes three bale unpacking machines 12, an all-in-one cotton feeding box 13 connected with the bale opening machine 12, a carding machine 14 connected with the cotton feeding box 13, and a combing machine The net lapper 15 connected with the net lapper 14, and the acupuncture machine 16 connected with the net lapper 15. The three kinds of fibers enter the unpacking and loosening system (A, B, C) and then enter the self-reformed three-in-one cotton feeding box 13, Synchronously sent to the carding machine 14 for carding, then cross-laid by the web lapper 15, and finally needled and con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com