Full-automatic shaftless magnetic mop washer

A fully automatic, washing machine technology, applied in the direction of cleaning machinery, cleaning carpets, cleaning floors, etc., can solve the problems of rotating wheel shaft leakage, burning motors, etc., to achieve the effect of prolonging service life, saving time, and benefiting personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

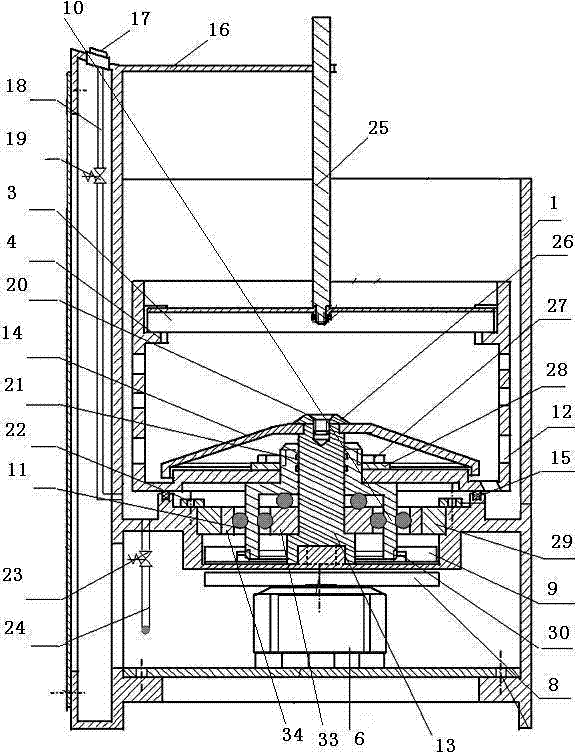

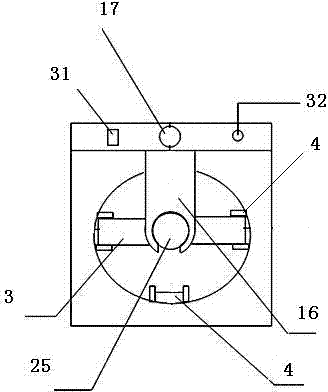

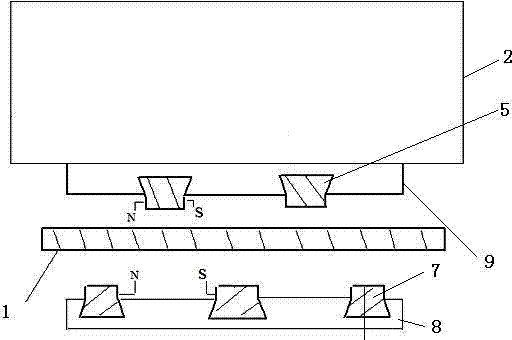

[0014] see figure 1 , 2 , The fully automatic shaftless magnetic mop washing machine includes a cylinder body 1, and the cylinder body 1 contains water. There is a rotating cylinder 2 inside the cylinder body 1, and there are a plurality of water holes 12 on the side wall of the rotating cylinder 2. On the rotary drum 2 there is a rack 4 for placing the cloth 3, and the cloth 3 is a circular mop head and a rectangular mop head. There is a fixed pillar 13 in the middle of the bottom of the cylinder body 1, and there is a fixed dust removal wheel 14 on it. The fixed pillar 13 is covered with a turret 10 (square holes can be used to prevent rotation and easy to install), and the rotating cylinder 2 is set on the turret 10. , 10 turntables stand on the driven turntable 9. Rotary cylinder 2 and turntable 10 cooperate facade to adopt octagonal form, prevents rotary cylinder 2 from rotating. The rotating frame 10 is inserted and sleeved on the bearing 11 in the middle, so it can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com