Novel handle connecting seat and small agricultural machine

A technology for connecting seats and handles, which is applied in pivotal connections, mechanical equipment, sliding contact bearings, etc., can solve problems such as radial swing of mechanical parts, and achieve the effects of avoiding friction, saving processing costs, and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

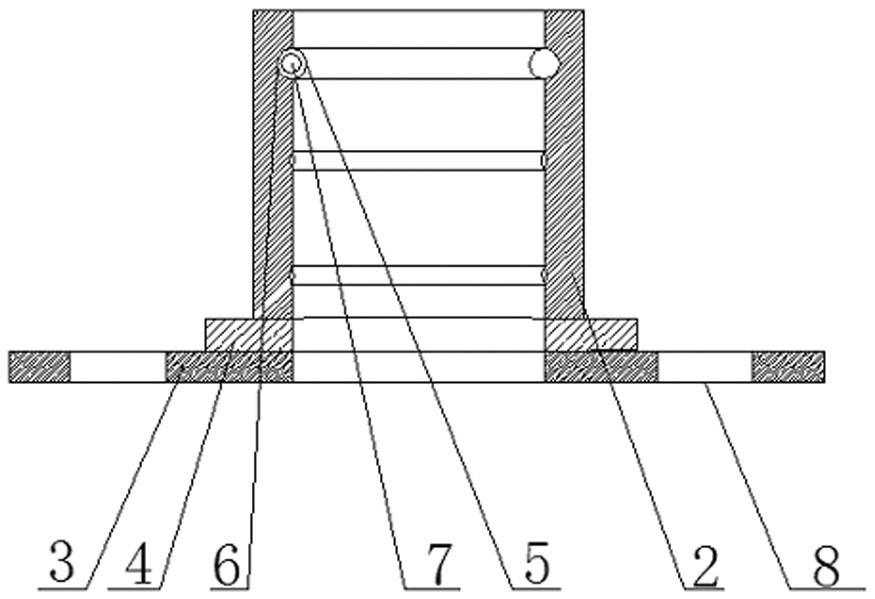

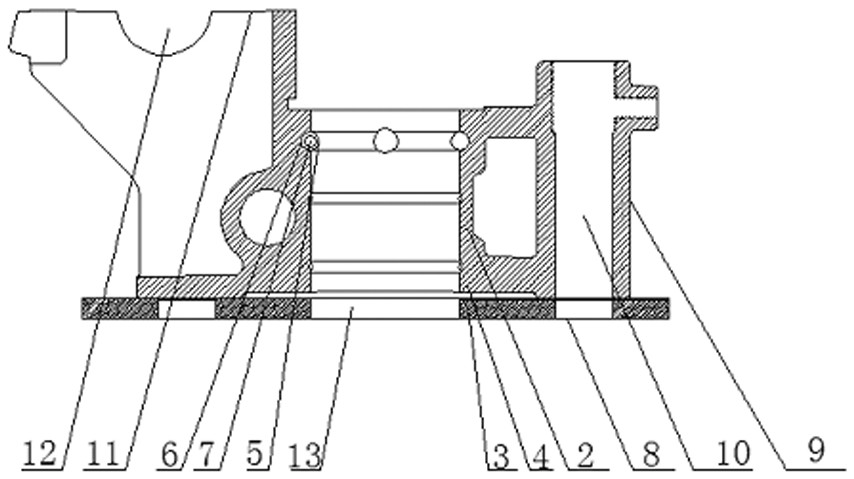

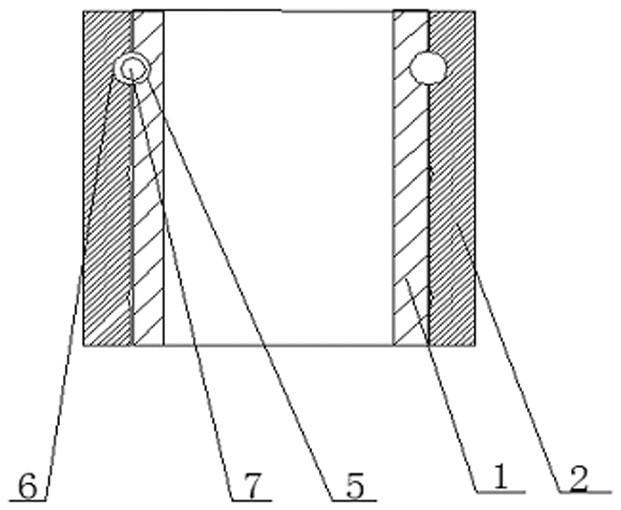

[0052] This embodiment provides a new type of handle connecting seat, which includes a lower base 3, the lower base 3 is connected with the first sleeve 1, and the lower base 3 is provided with a first through hole communicating with the first sleeve 1;

[0053] Also includes an upper base 4, the upper base 4 is connected with the second sleeve 2, the upper base 4 is provided with a second through hole 13 communicating with the second sleeve 2; the second sleeve 2 is sleeved on Outside the first sleeve 1; the second sleeve 2 is rotationally connected with the first sleeve 1, that is, the first sleeve 1 and the first sleeve 2 form a rotating shaft, and the middle of the rotating shaft is a hollow structure; the upper base 4 Mechanical parts can be connected with the lower base 3;

[0054] Also includes a limiting device, the limiting device is located between the first sleeve 1 and the second sleeve 2, not connected with the first sleeve 1 and the second sleeve 2, and the limit...

Embodiment 2

[0066] The same place of this embodiment and embodiment 1 will not be repeated;

[0067] The second limiting device includes a fixing part, the fixing part is a threaded fixing part 17, the threaded fixing part 17 is connected with the first sleeve 1, and the distance between the threaded fixing part 17 and the lower base 3 is no greater than Less than the sum of the lengths of the second sleeve 2 and the upper base 3; the threaded fixing member 17 is sleeved on the first sleeve 1 and is threadedly connected with the first sleeve 1 .

[0068] The hemispherical mounting groove 12 has a diameter of 32cm.

Embodiment 3

[0070] The same place of this embodiment and embodiment 1 will not be repeated;

[0071] The second limiting device includes a fixing member, the fixing member is an annular buckle fixing member 15, and the ring-shaped buckle fixing member 15 is sleeved on the first sleeve 1; the outer wall of the first sleeve 1 is provided with There is an annular protrusion 16 ; the annular buckle fixing part 15 is located between the end of the second sleeve 2 away from the lower base 3 and the annular protrusion 16 .

[0072] The hemispherical mounting groove 12 has a diameter of 36cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com