Automobile window aluminum guide rail stamping equipment

A technology for stamping equipment and car windows, which is applied to push out equipment, metal processing equipment, forming tools, etc., can solve the problems of complex structure of car window guide rails, increased production costs, low production efficiency, etc., to avoid multi-process multi-equipment, reduce Production cost and effect of improving molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, describe the specific embodiment of the present invention in detail:

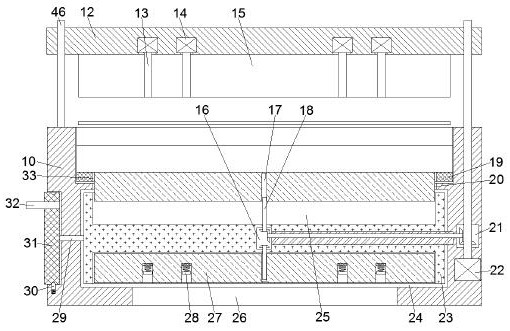

[0022] refer to Figure 1-Figure 6 , according to an embodiment of the present invention, an aluminum guide rail stamping equipment for automobile windows includes a main box body 10, a conversion mechanism for stamping die conversion is arranged inside the main box body 10, and the upper side of the main box body 10 is set There is an upper mold base 12, the lower end surface of the upper mold base 12 is fixed with an upper mold 15, four hydraulic pumps 14 are fixed in the main box body 10, and the lower end surfaces of the four hydraulic pumps 14 are fixed with the Punching die 13 with sliding fit of upper die 15;

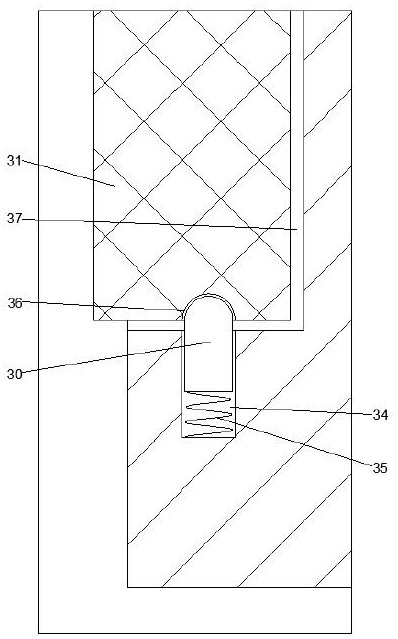

[0023] The conversion mechanism includes a runner 23 arranged in the main box body 10, and the runner 23 is provided with two top block cavities 25 which are up and down symmetrical and open outwards, and inside the two top block cavities...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com