Quality control method for high-frequency resistance welded pipe welding area

A quality control method, high-frequency resistance welding technology, applied in the direction of resistance welding equipment, welding power supply, welding equipment, etc., can solve the micro-loss of key alloy elements and microstructure differences, high stress corrosion cracking sensitivity of welds, no Issues such as heat treatment process are given to achieve the effect of reducing the sensitivity coefficient of trench corrosion, reducing the sensitivity of trench corrosion, and facilitating promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

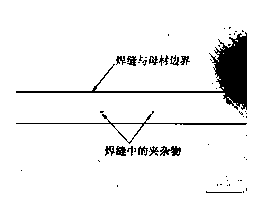

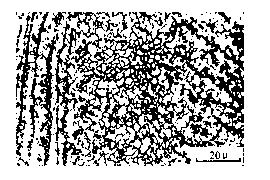

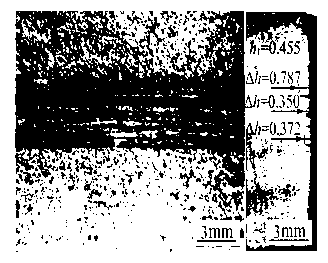

Image

Examples

Embodiment 1

[0036] Quality control is carried out on the welded area of the J55 steel grade Ф139×7.72mm oil well casing. The steel plate has a low S content and the main composition is Fe-0.18%C-1.31%Mn.

[0037] A method for quality control of a welding zone of a high-frequency resistance welded pipe, comprising the following steps:

[0038] First, set the control temperature of high-frequency resistance welding to 1518°C, and the heating time to 7s;

[0039] Second, set an inert gas nozzle on the surface to be welded on both sides of the welded pipe, that is, the gas nozzle uses two nozzles to spray inert gas on the surface to be welded at the same time, and the angle between the two inert gas nozzles is 24° , the angle between the inert gas nozzle and the weld seam is 3°, and the gas flow rate is 7L / min;

[0040]Third, during welding, the inert gas nozzles on both sides of the weld spray carbon dioxide gas to the surface to be welded at the same time when the distance from the weldi...

Embodiment 2

[0054] Quality control is carried out on the welded area of the J55 steel grade Ф339×10.0mm oil well casing. The steel plate is low in S content, and the main composition is Fe-0.11%C-1.17%Mn.

[0055] A method for quality control of a welding zone of a high-frequency resistance welded pipe, comprising the following steps:

[0056] First, set the control temperature of high-frequency resistance welding to 1526°C, and the heating time to 8s;

[0057] Second, install an inert gas nozzle on the surface to be welded on both sides of the welded pipe, that is, the gas nozzle uses two nozzles to spray inert gas on the surface to be welded at the same time, and the angle between the two inert gas nozzles is 26° The angle between the inert gas nozzle and the weld is 4°, and the gas flow rate is 9L / min;

[0058] Third, during welding, the inert gas nozzles on both sides of the weld spray nitrogen to the surface to be welded at a distance of 270mm from the weld extrusion fusion point,...

Embodiment 3

[0073] The quality control is carried out on the CT80 steel grade Ф33×3.18mm coiled tubing welding area. The steel plate is a controlled rolling steel plate, and the main composition is Fe-0.10%C-1.25%Mn.

[0074] A method for quality control of a welding zone of a high-frequency resistance welded pipe, comprising the following steps:

[0075] First, set the control temperature of high-frequency resistance welding to 1527°C, and the heating time to 6s;

[0076] Second, set an inert gas nozzle on the surface to be welded on both sides of the welded pipe, that is, the gas nozzle uses two nozzles to spray inert gas on the surface to be welded at the same time, and the angle between the two inert gas nozzles is 22° The angle between the double nozzles and the welding seam is 2°, and the gas flow rate is 6L / min;

[0077] Third, during welding, the inert gas nozzles on both sides of the weld spray argon to the surface to be welded at a distance of 220 mm from the extrusion fusion p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com