Active agent used for aluminum alloy MIG (metal-inert gas) welding and application method of active agent

A technology of active agent and aluminum alloy, applied in welding medium, welding equipment, welding equipment, etc., can solve the problems of insignificant improvement of mechanical properties and microstructure of welded joints, complicated operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

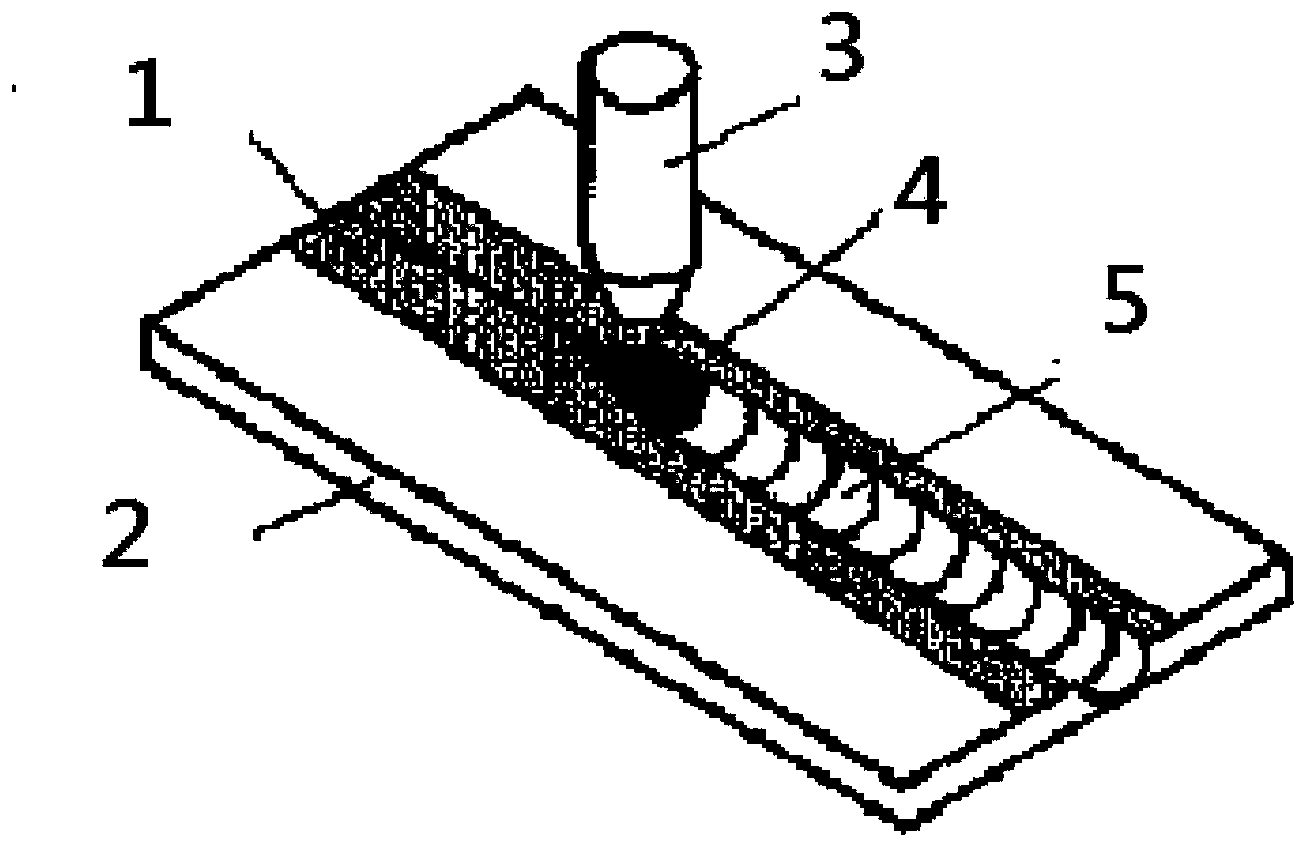

Method used

Image

Examples

Embodiment 1

[0058] Respectively by following activator in the weight ratio in table two:

[0059] Table II

[0060]

[0061] According to the above weight ratio, the active agent ingredients are mixed thoroughly and evenly mixed with the organic solution. The organic solution is acetone or 1% hydroxyethyl cellulose solution, and stirred into a paste; the four groups of base materials are carefully brushed with a stainless steel wire brush. Grind until the bright metal is exposed, wipe the surface of the workpiece with acetone to remove surface oil; apply the prepared paste on a part of the surface of the welding workpiece, and weld the other part without coating the active agent. The original metallic luster is suitable; use a hair dryer to blow to the surface of the workpiece, and perform normal MIG welding on the four groups of workpieces after the organic solution evaporates.

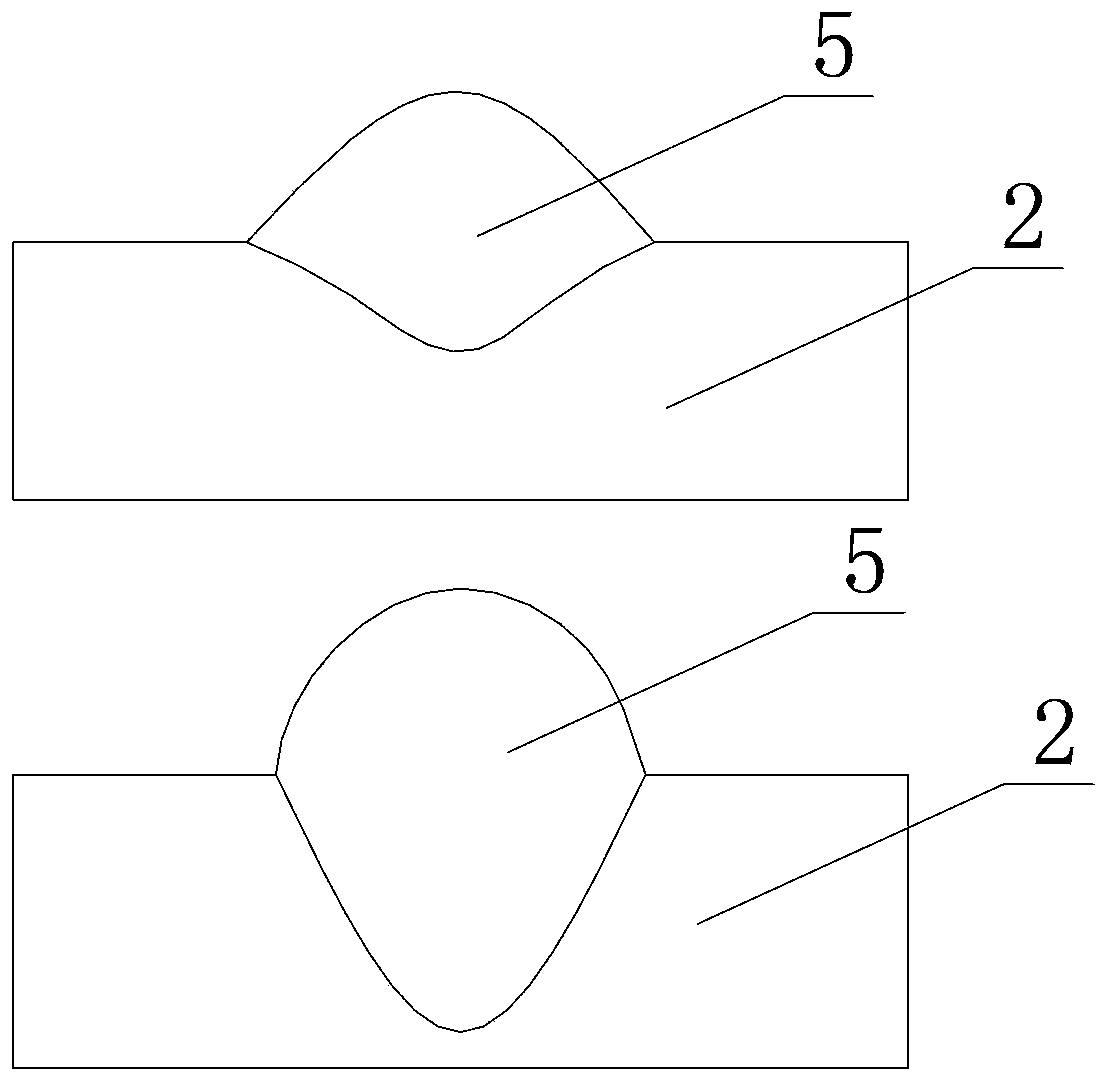

[0062] In terms of the macroscopic appearance of the weld: the front of the weld without activator is we...

Embodiment 2

[0071] active agent B 2 o 3 , NaF, SiO 2 and MgCO 3 The powder particle composition is distributed by weight percentage, respectively B 2 o 3 : 40%, NaF: 40%, SiO 2 : 15%, MgCO 3 : 5%.

[0072] According to the above weight ratio, the active agent ingredients are mixed well and then mixed with the organic solution. The organic solution is selected from acetone or 1% hydroxyethyl cellulose solution and stirred into a paste; the base material is carefully polished with a stainless steel wire brush, Until the bright metal is exposed, wipe the surface of the workpiece with acetone to remove the surface oil; apply the prepared paste on the surface of the welding workpiece, and it is advisable to cover the original metal luster when coating; use a hair dryer to blow on the surface of the workpiece , After the organic solution volatilizes, the workpiece is subjected to normal MIG welding.

[0073] The shape of the formed weld is close to the shape when the H4 activator is use...

Embodiment 3

[0079] active agent B 2 o 3 , NaF, SiO 2 and MgCO 3 The powder particle composition is distributed by weight percentage, respectively B 2 o 3 : 55%, NaF: 25%, SiO 2 : 15%, MgCO 3 : 5%.

[0080] According to the above weight ratio, the active agent ingredients are mixed well and then mixed with the organic solution. The organic solution is selected from acetone or 1% hydroxyethyl cellulose solution and stirred into a paste; the base material is carefully polished with a stainless steel wire brush, Until the bright metal is exposed, wipe the surface of the workpiece with acetone to remove the surface oil; apply the prepared paste on the surface of the welding workpiece, and it is advisable to cover the original metal luster when coating; use a hair dryer to blow on the surface of the workpiece , After the organic solution volatilizes, the workpiece is subjected to normal MIG welding.

[0081] The shape of the formed weld is close to the shape when the H4 activator is use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com