Low-carbon high-nickel content 785 MPa grade gas shielded welding wire

A gas protection, high nickel technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of lowering the phase transition point, poor crack resistance of high-strength steel weld metal, etc., to reduce welding thermal stress , Excellent mechanical properties, excellent crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

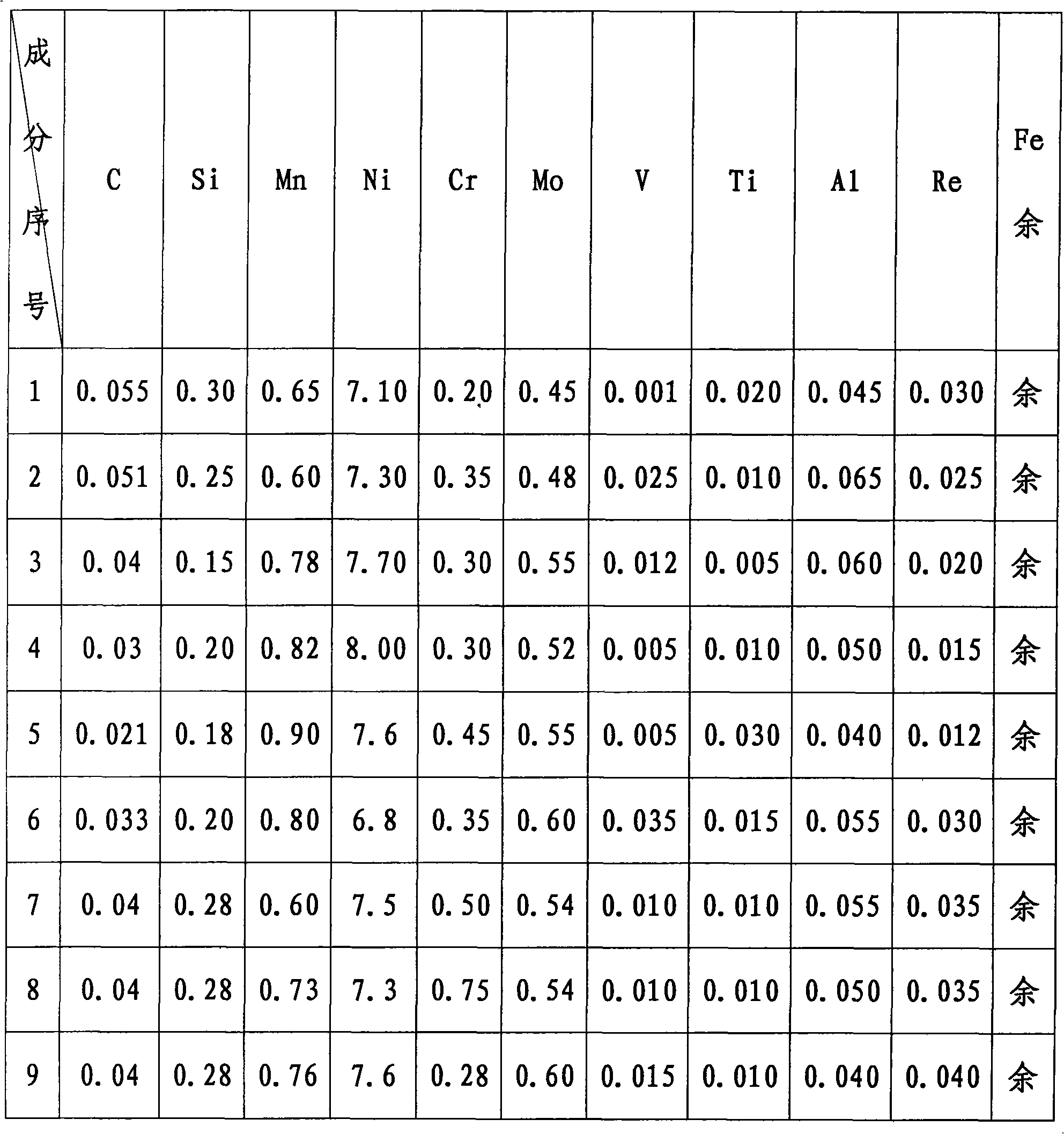

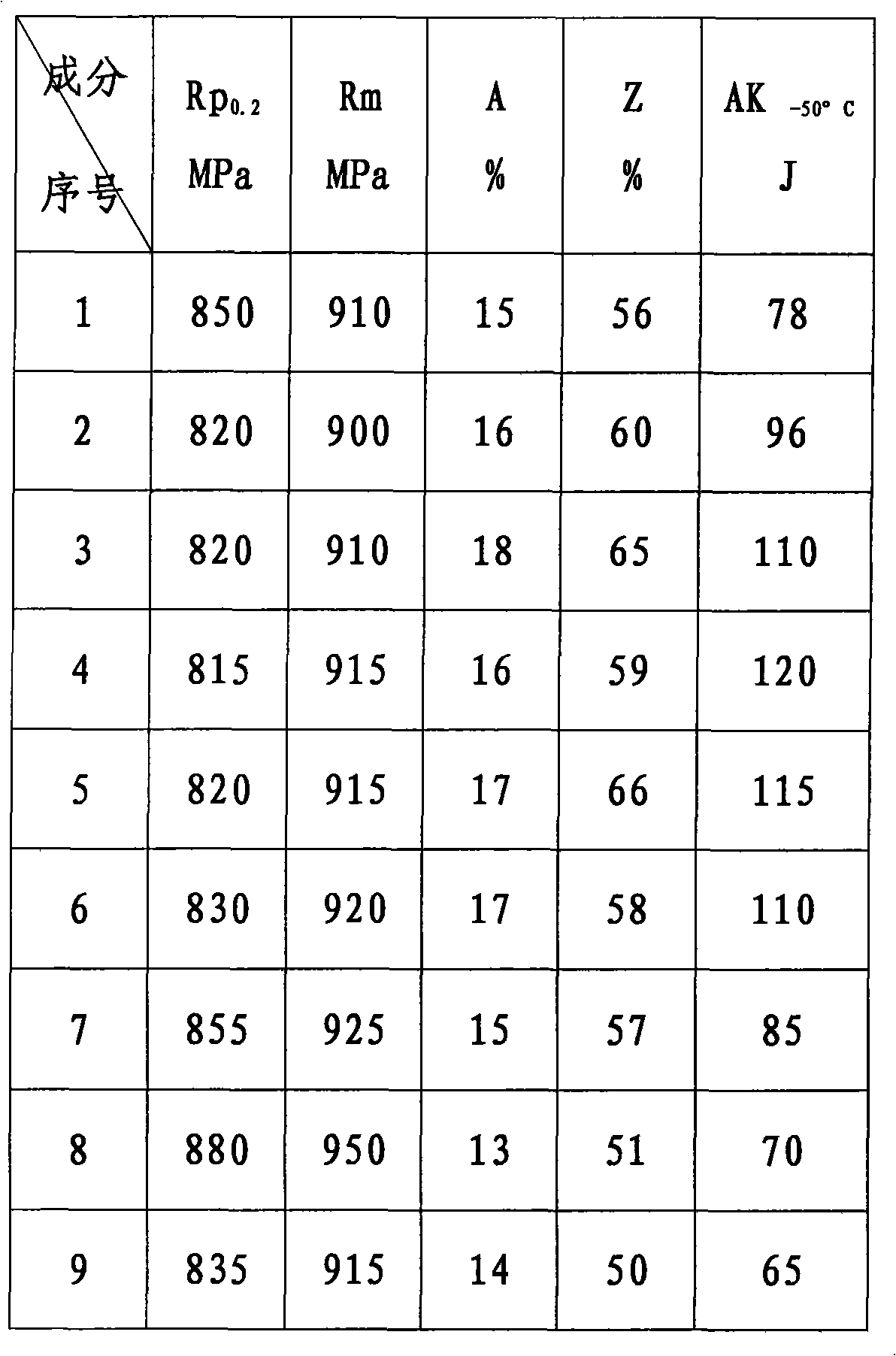

[0014] Within the composition range of the low-carbon, high-nickel, and high-strength gas shielded welding wire of the present invention, 9 batches of welding wires were smelted, constituting 9 groups of embodiments. The composition of the welding wire is shown in Table 1, and the performance of the welding wire with MIG welding deposited metal is shown in Table 2. The low-carbon, high-nickel, and high-strength gas shielded welding wire of the present invention is smelted in a vacuum smelting furnace to improve the purity of the welding wire.

[0015] Table 1 Chemical composition (wt%) of the welding wire material of the embodiment of the present invention

[0016]

[0017] Table 2 Mechanical properties (wt%) of deposited metal for MIG welding with welding wire in the embodiment of the present invention

[0018]

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com