Short-circuit transient welding method and system

A technology of short-circuit transition welding and main circuit, which is applied in the field of welding system and gas metal shielded welding, and can solve the problems of arc improvement in the absence of arc burning stage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The specific implementation manner of the present invention will be described below through application examples.

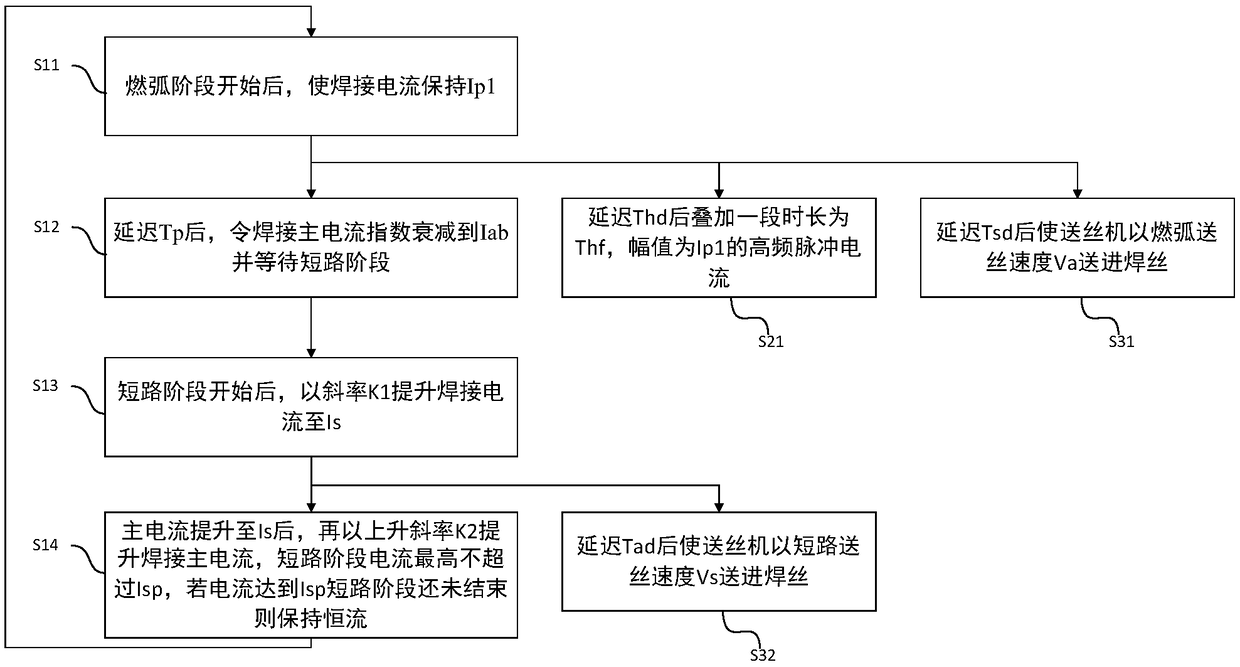

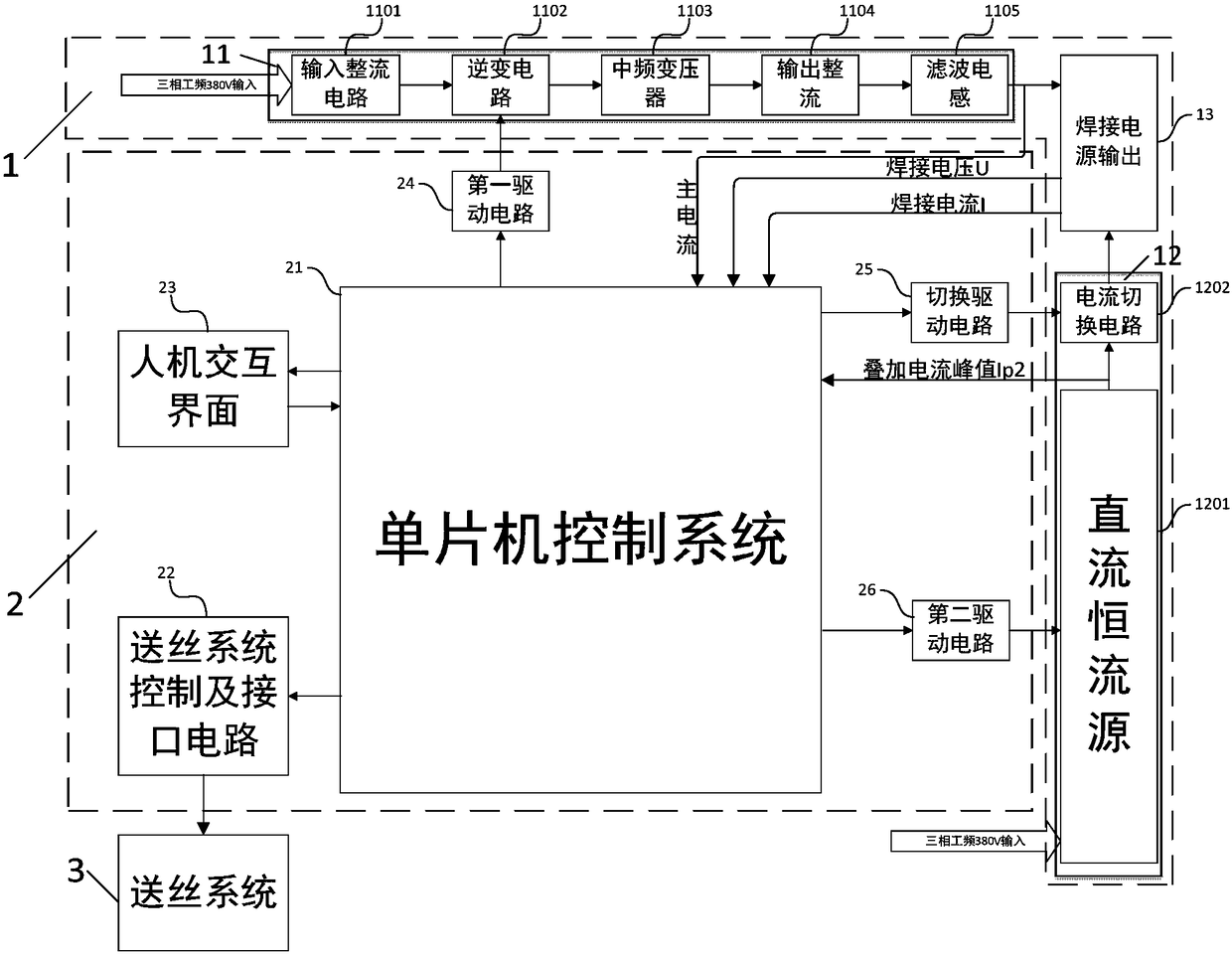

[0045] A specific application example of the present invention is as image 3 with Figure 4 The short-circuit transition welding system is shown and the short-circuit transition welding waveform is shown.

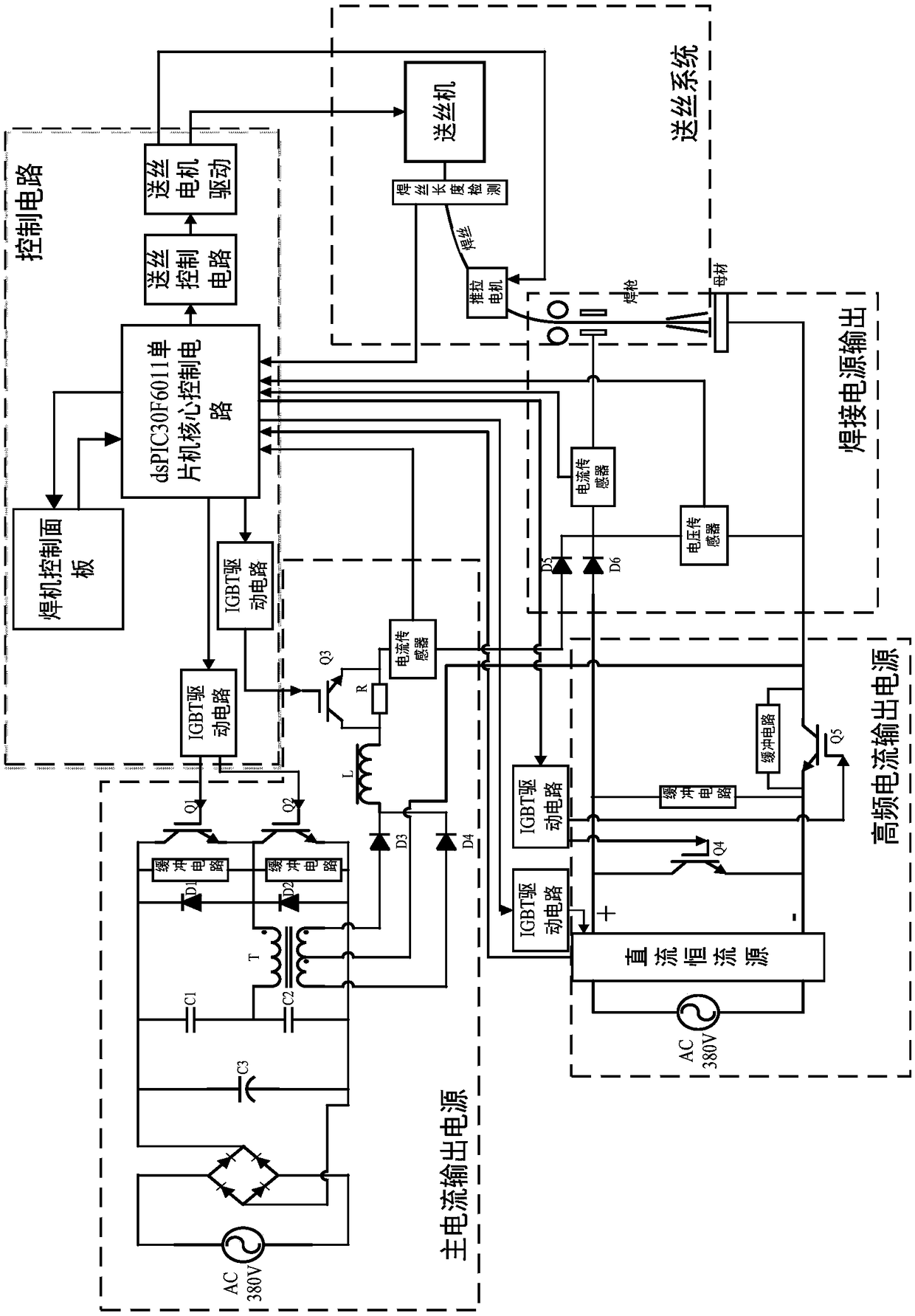

[0046] The welding system used in this example includes five parts: main current output power supply, high-frequency pulse current output power supply, welding power supply output, control circuit and wire feeding system. The output of the main current output power supply and high-frequency pulse current output power supply passes through the welding power supply The output is connected together to form the main circuit of the welding system and is responsible for the power output.

[0047] The rectification circuit of the main current output power supply is composed of four diodes and filter capacitors. The four diodes can be replaced by an integrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com