Magnetic control TIG (Tungsten Inert Gas) welding process for narrow gap of thick plate titanium alloy

A welding process, titanium alloy technology, applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve the problems of TIG welding application, large residual stress and deformation, low welding efficiency and other problems that limit the application range of thick plate titanium alloy, and achieve excellent The effect of mechanical properties, large welding current and stable welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

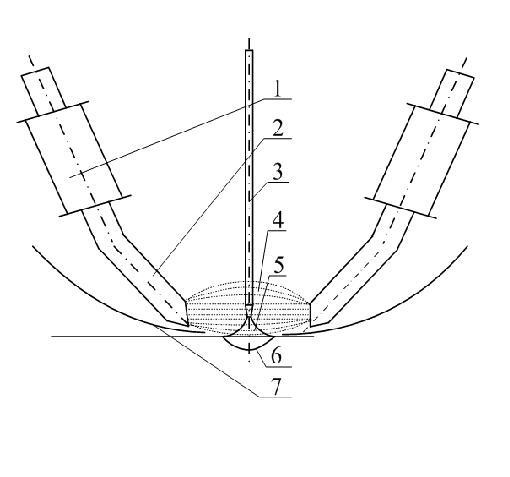

[0034] Example 1: Perform butt welding of a pair of TC4 plates with a thickness of 60mm, a length of 325mm and a width of 130mm. See the groove form Image 6 Because of the mesh strengthening effect of the titanium alloy itself, TA2, which is far inferior to the base material, is used as the welding wire, and the diameter of the welding wire is 3.5mm.

[0035] In the groove design, in order to ensure that the bottom welding can be penetrated without penetration, the assembly gap is 1mm, and the thickness of the blunt edge is 2mm. In accordance with the continuous occurrence of welding deformation during the welding process, the opening angle of the welding groove is 20° to ensure that the welding gun can extend into the lower end of the groove during the welding process. Single-pass multi-layer welding is realized in the welding process.

[0036] The welding parameters used in the welding process are as follows:

[0037] position Current Voltage Wire feeding speed Welding speed...

Embodiment 2

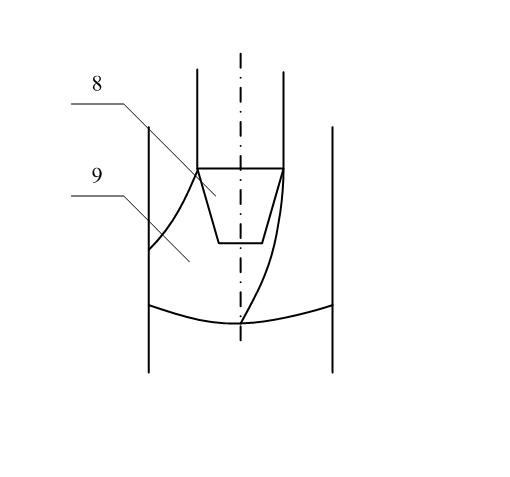

[0041] Example 2: Perform butt welding of a pair of TA15 plates with a thickness of 60mm, a length of 325mm and a width of 130mm. See the groove form Figure 7 Because of the mesh strengthening effect of the titanium alloy itself, TA2, which is slightly worse than the base material, is used as the welding wire, and the diameter of the welding wire is 3.5mm.

[0042] With I-shaped groove, the backing plate and the bottom must be welded before welding. In accordance with the continuous occurrence of welding deformation during the welding process, the opening angle of the welding groove is 10° to ensure that the welding gun can extend into the lower end of the groove during the welding process. Single-pass multi-layer welding is realized in the welding process.

[0043] The welding parameters used in the welding process are as follows:

[0044] position Current Voltage Wire feeding speed Welding speed Magnetic field frequency Magnetic field strength Bottom welding90-4509.5-15.54...

Embodiment 3

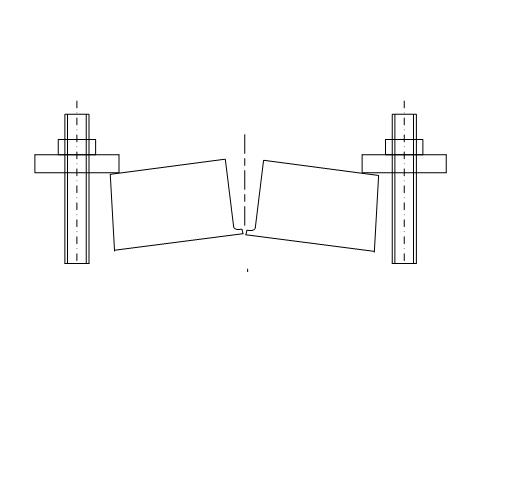

[0048] Example 3: Perform butt welding of a pair of TA4 plates with a thickness of 60mm, a length of 325mm and a width of 130mm. See the groove form Figure 8 Because of the mesh strengthening effect of the titanium alloy itself, TA2, which is far inferior to the base material, is used as the welding wire, and the diameter of the welding wire is 3.5mm.

[0049] In the groove design, in order to ensure the penetration of the bottom welding without welding penetration, the assembly gap is 2mm and the thickness of the blunt edge is 2.5mm. In accordance with the continuous occurrence of welding deformation during the welding process, the opening angle of the welding groove is 10° to ensure that the welding gun can extend into the lower end of the groove during the welding process. Single-pass multi-layer welding is realized in the welding process.

[0050] The welding parameters used in the welding process are as follows:

[0051] position Current Voltage Wire feeding speed Welding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Surface width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com