Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Reduce material stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

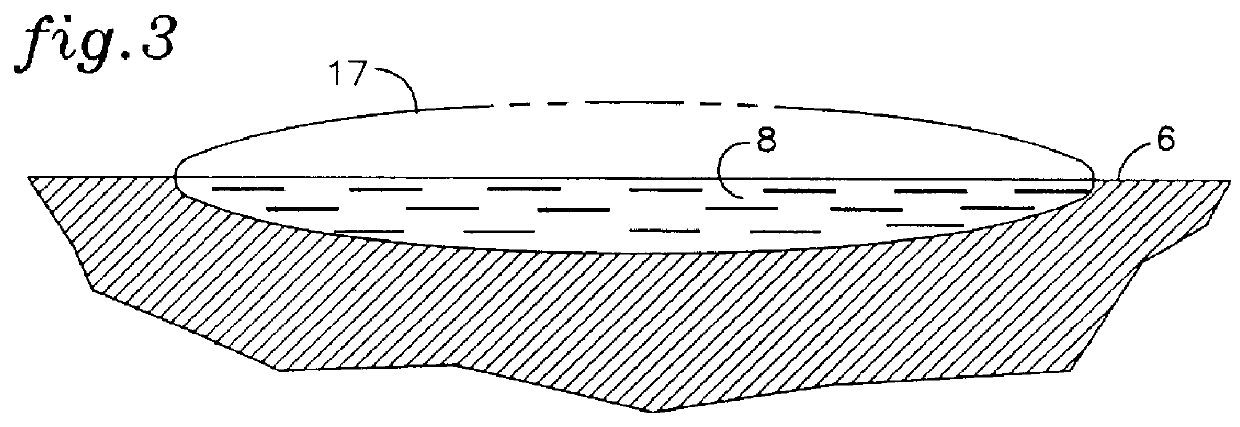

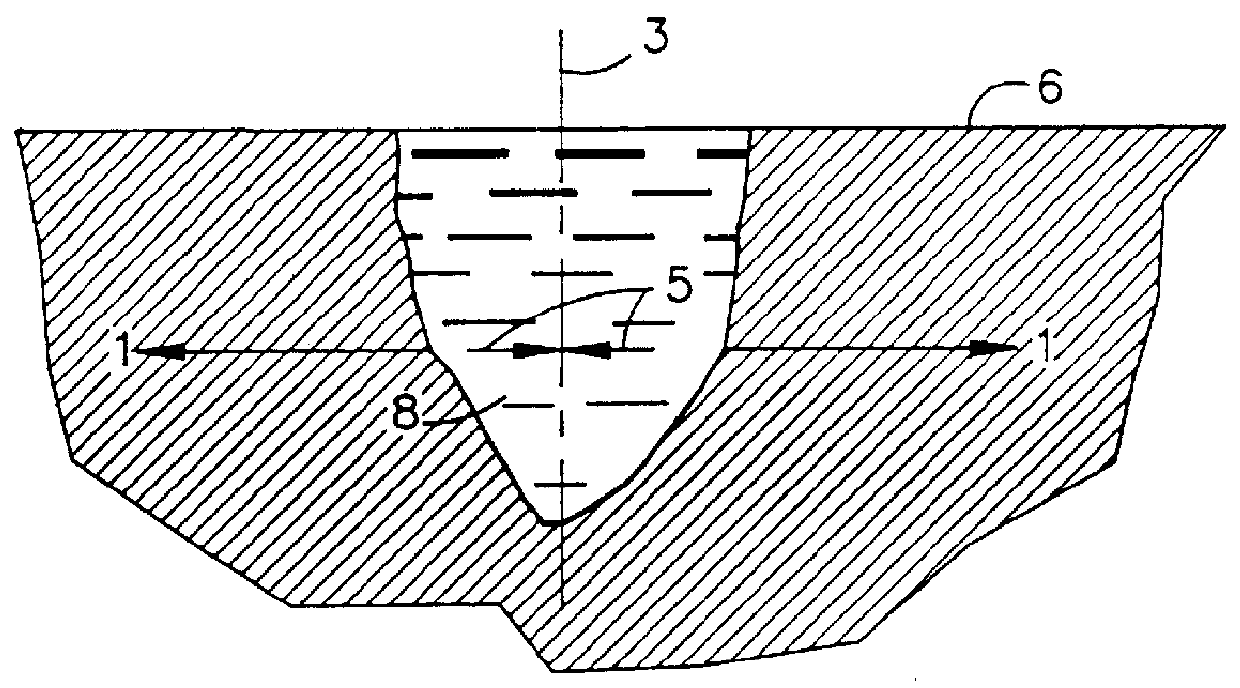

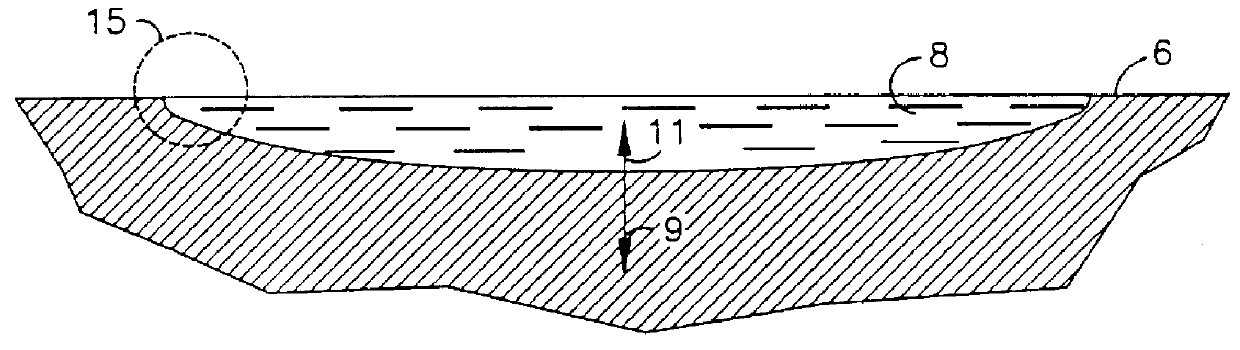

Crack free metallic articles

InactiveUS6103402AReduce material stressReduce solidificationTurbinesBy zone-melting liquidsCrazingClosed loop

A containerless method of producing a crack free metallic article of near-net shape includes melting a filler material into a metallic substrate or seed under conditions chosen to preclude cracking. In a preferred embodiment of the invention, a laser beam is operated at a relatively low power density and at a relatively large beam diameter at the substrate surface for an extended length of time to produce a molten pool with a low aspect ratio. Near-net shape is achieved by applying the process in a closed-loop, multi-axis material deposition system.

Owner:UNITED TECH CORP

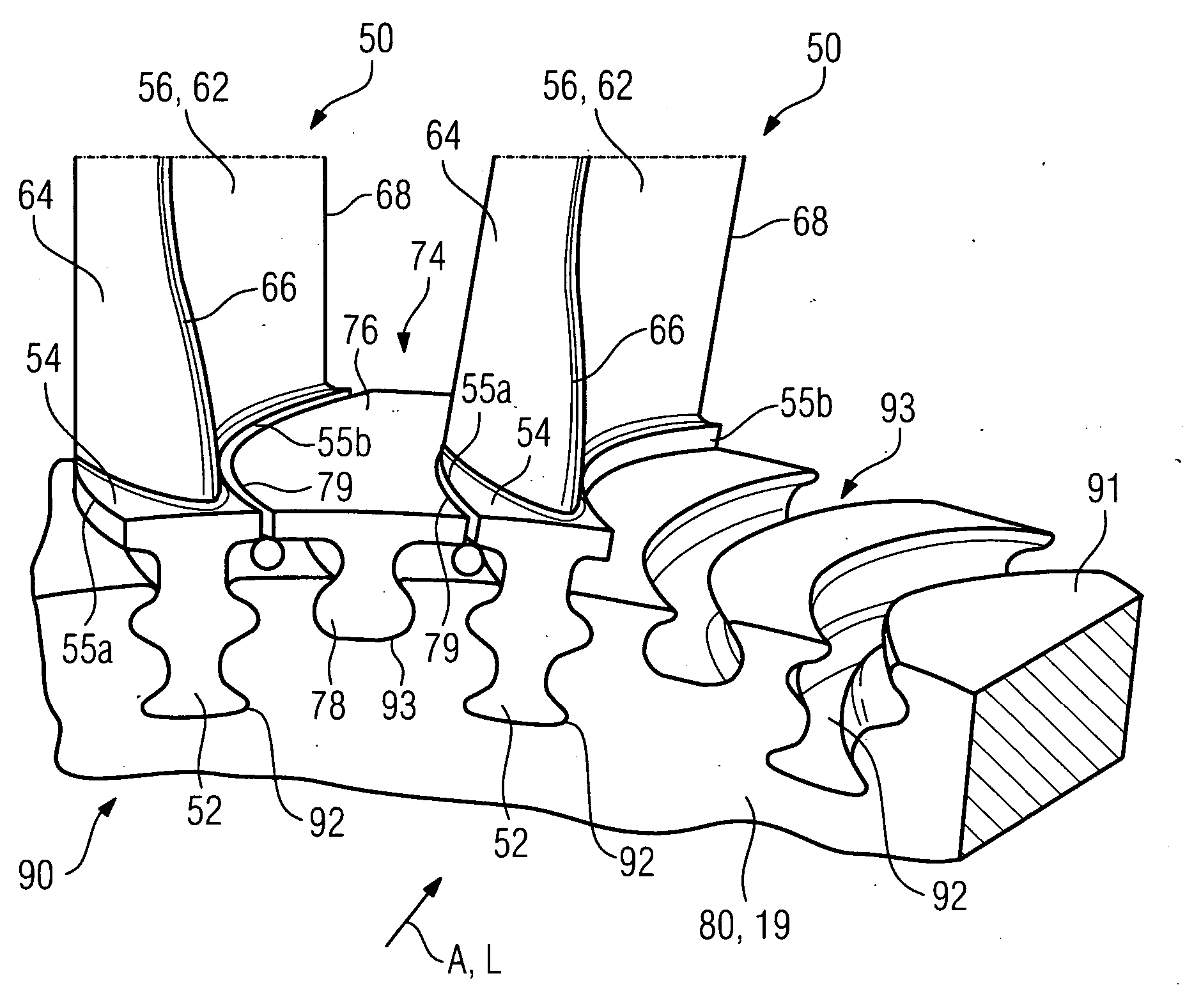

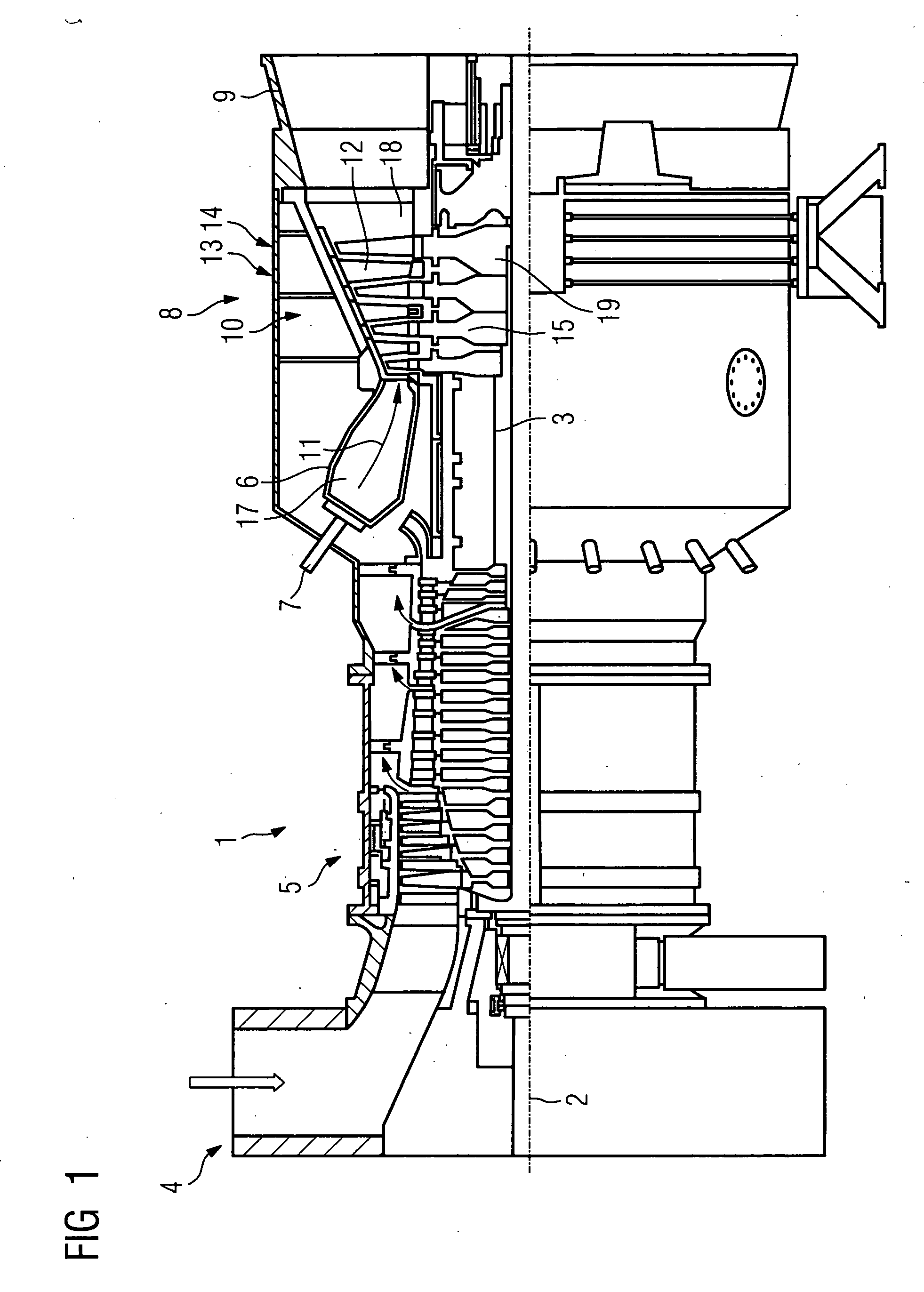

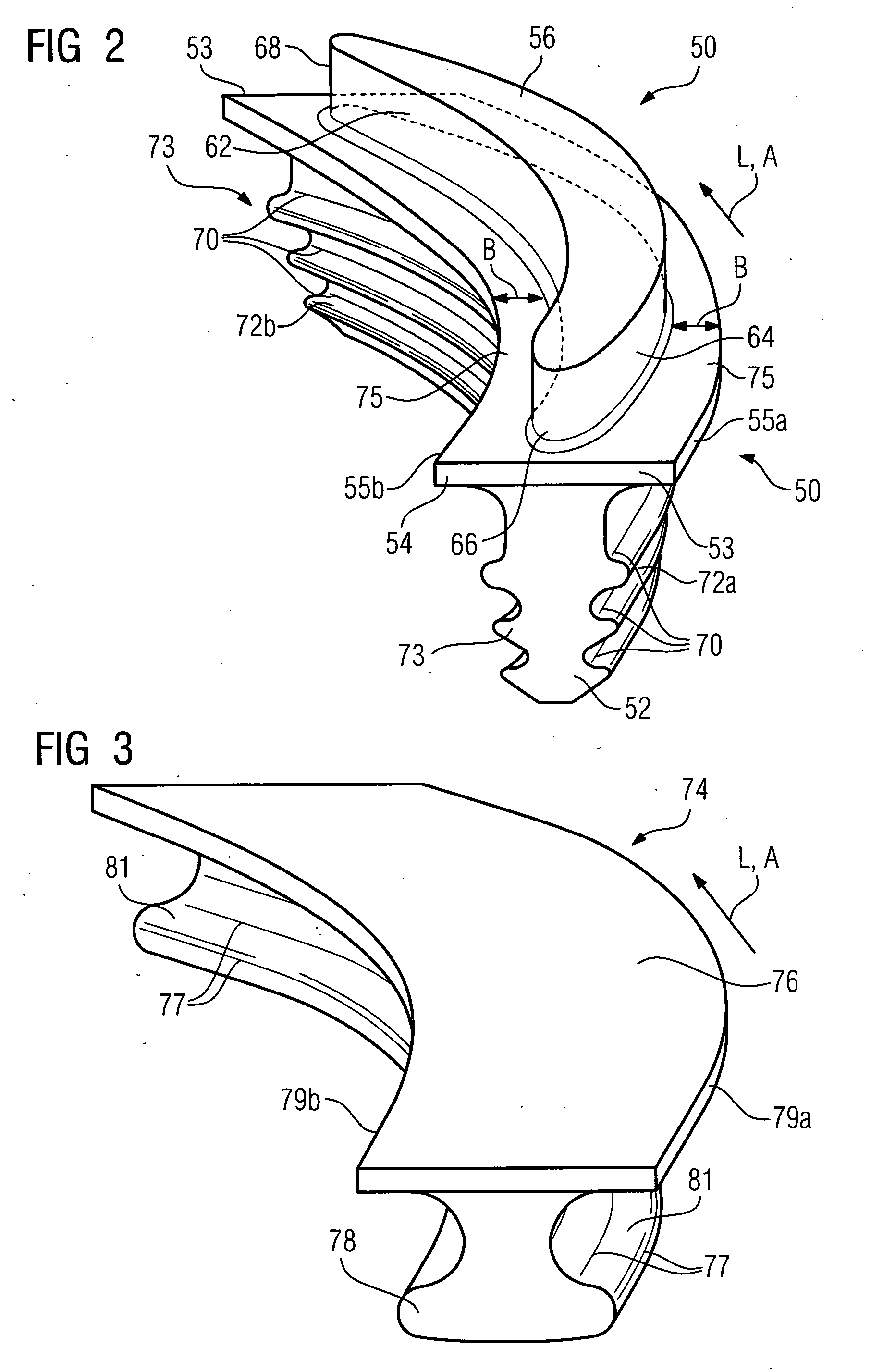

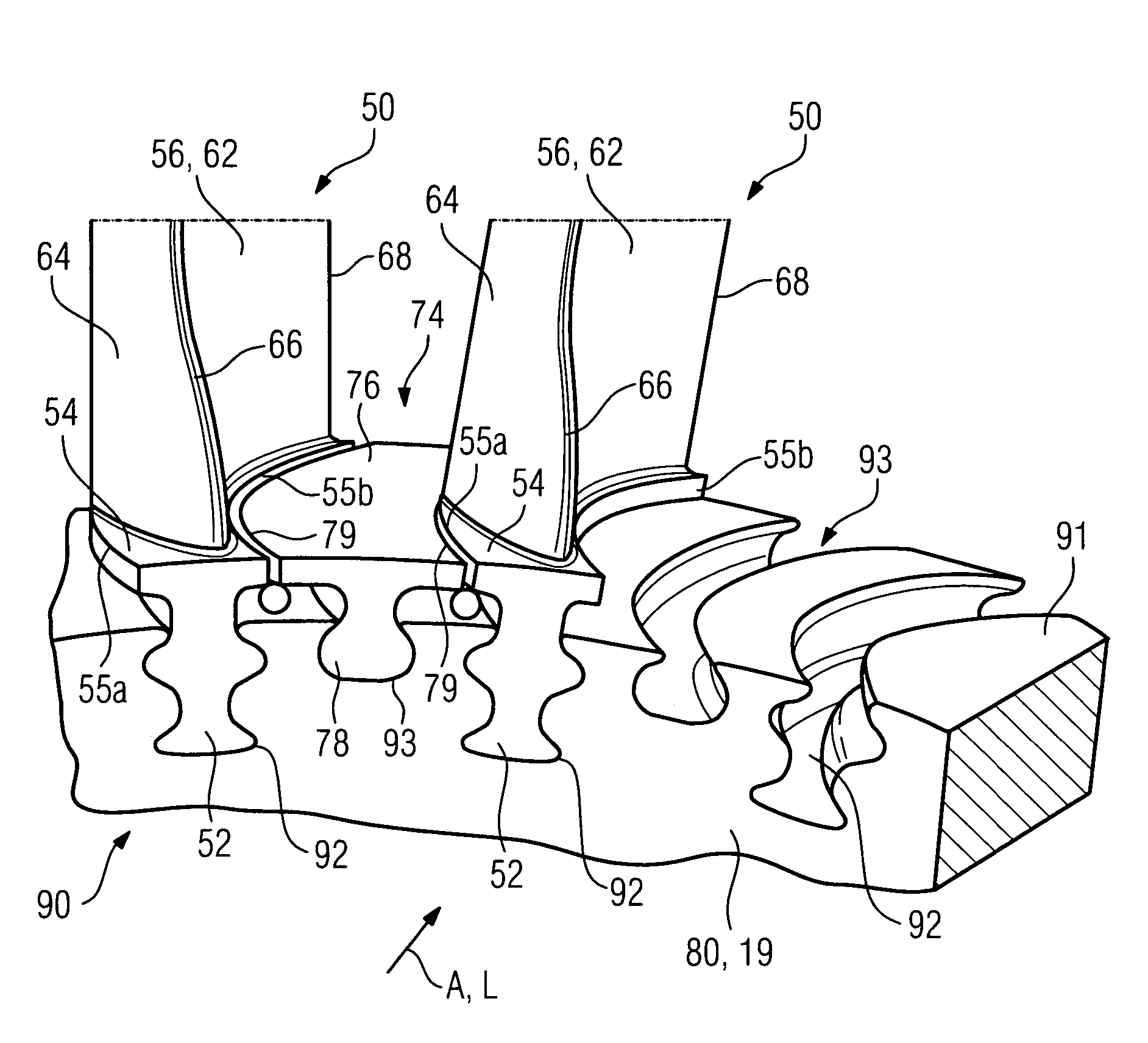

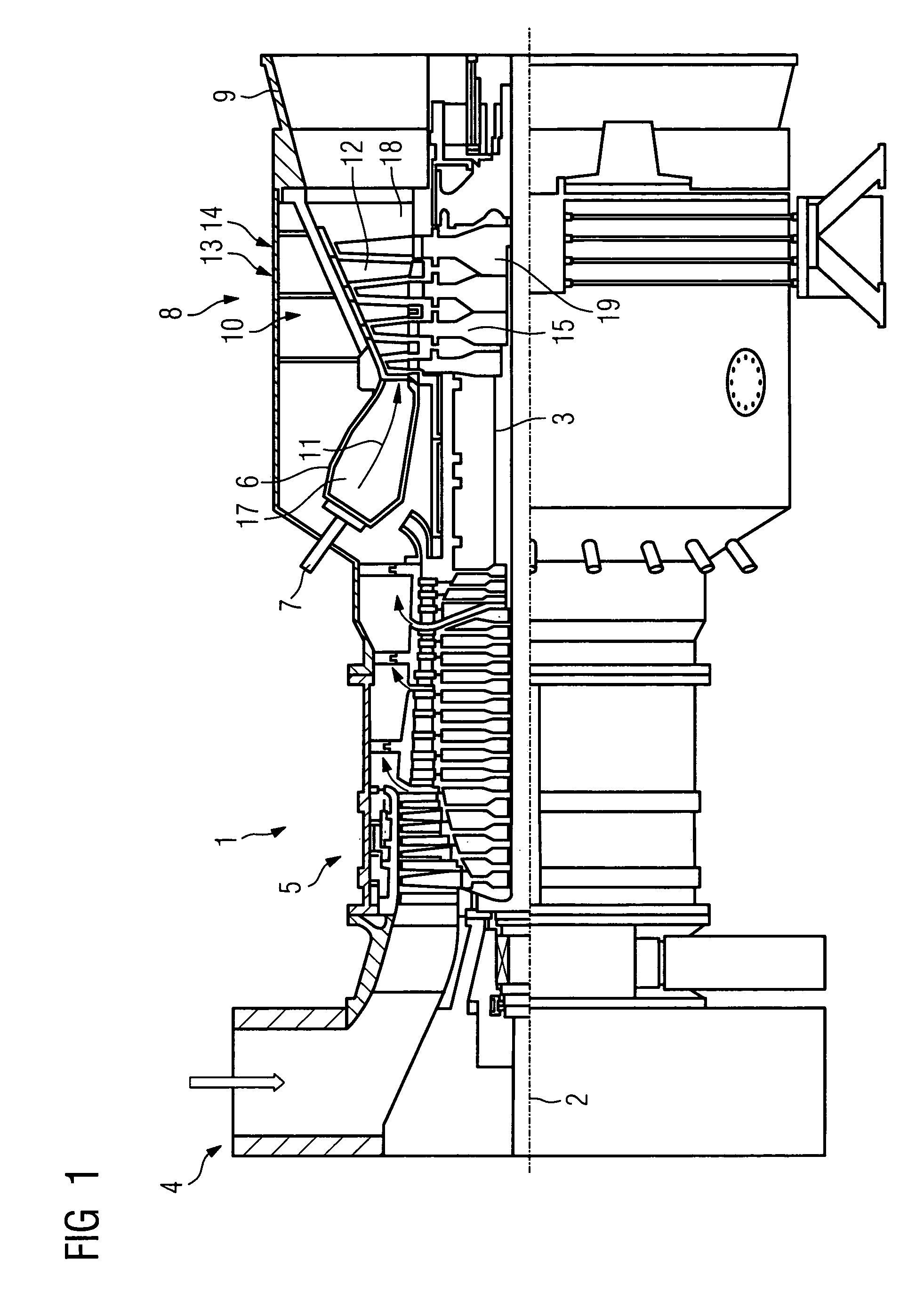

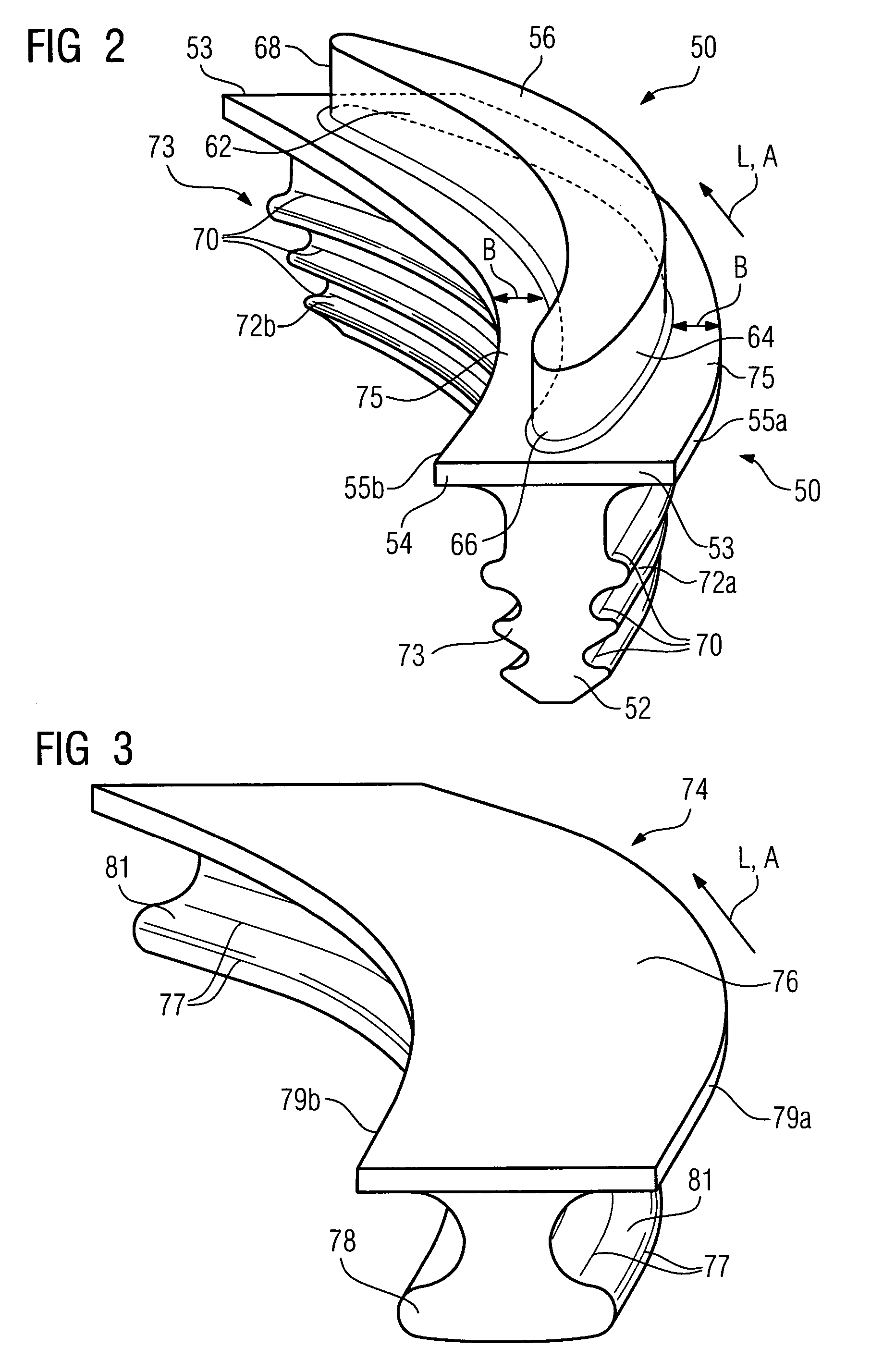

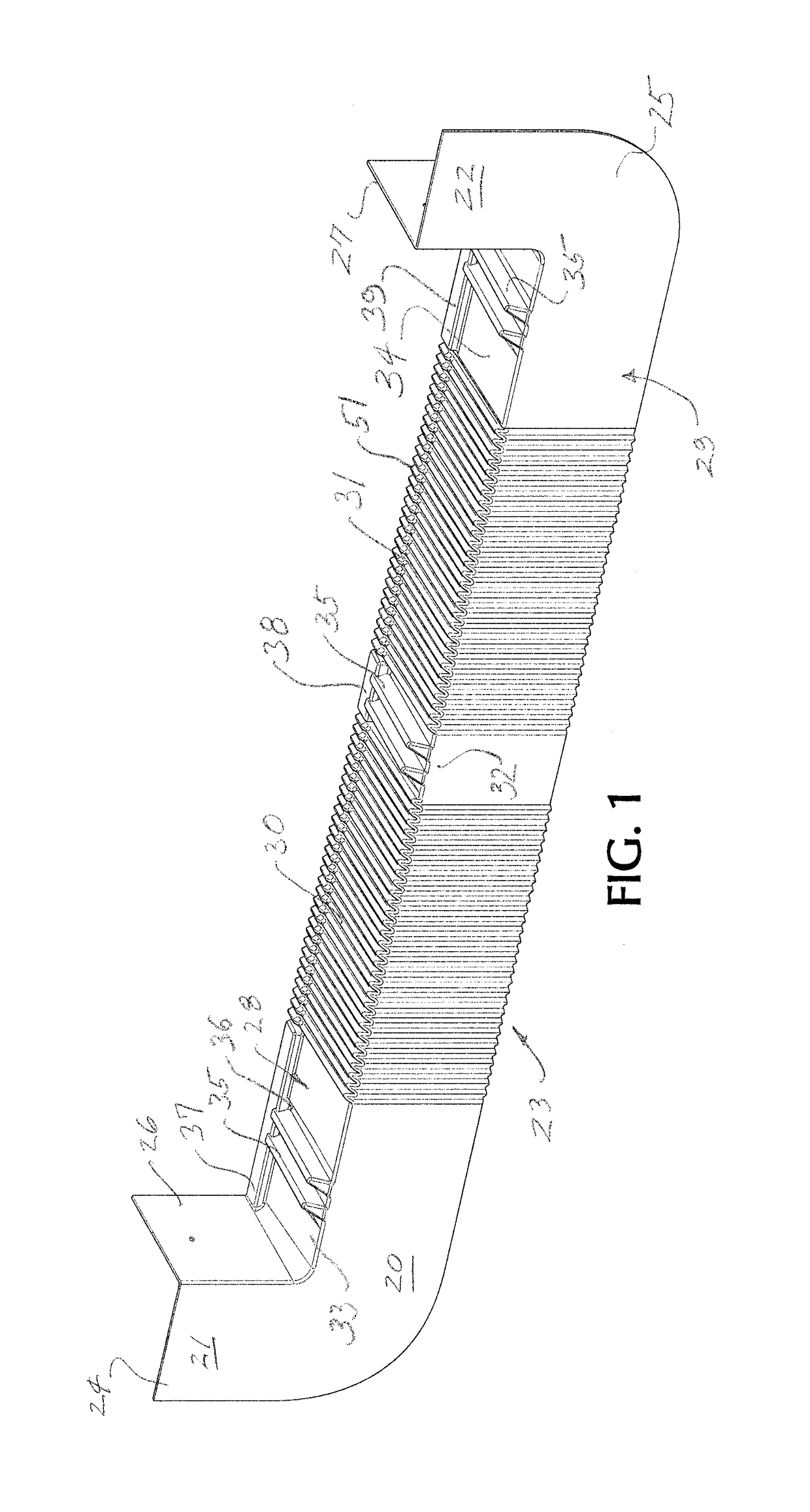

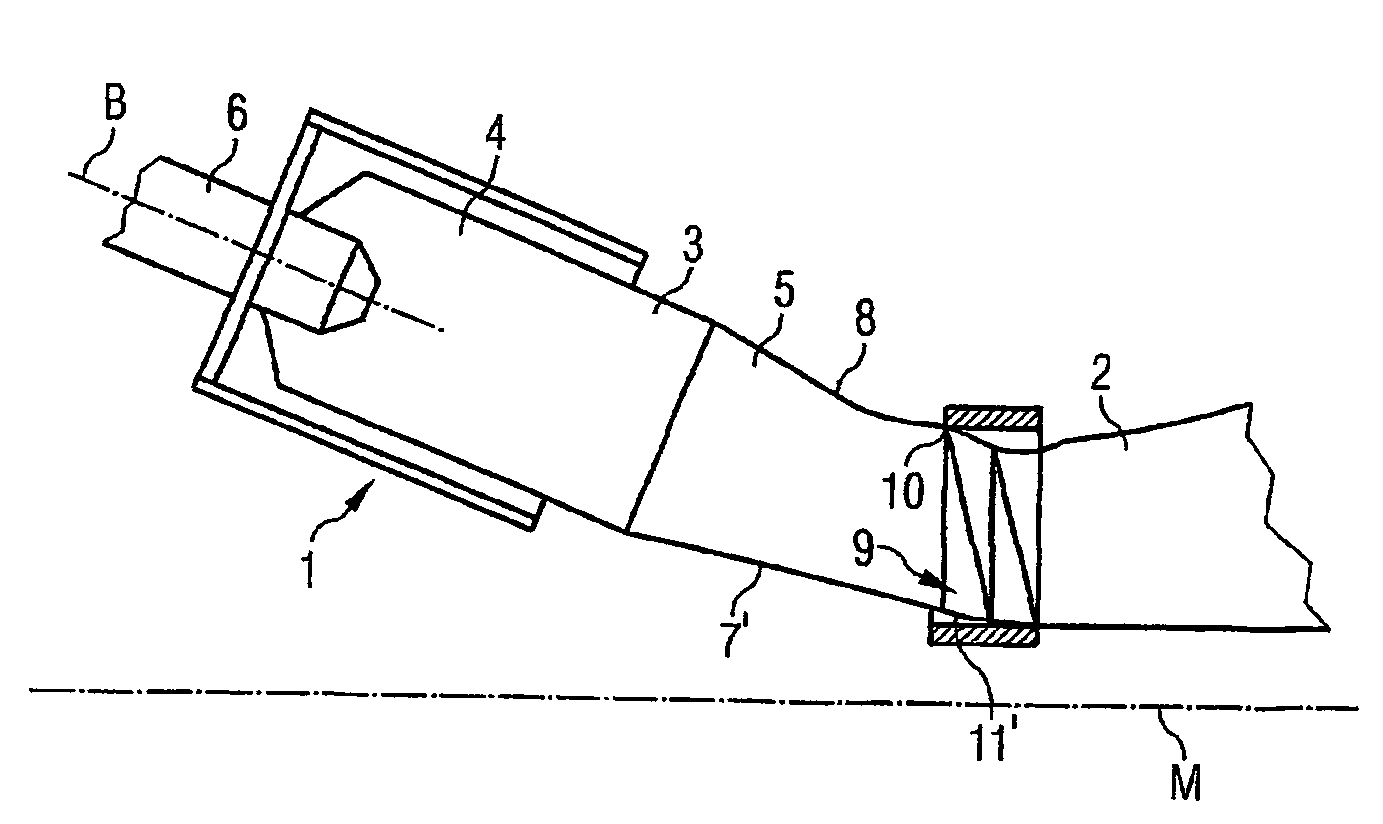

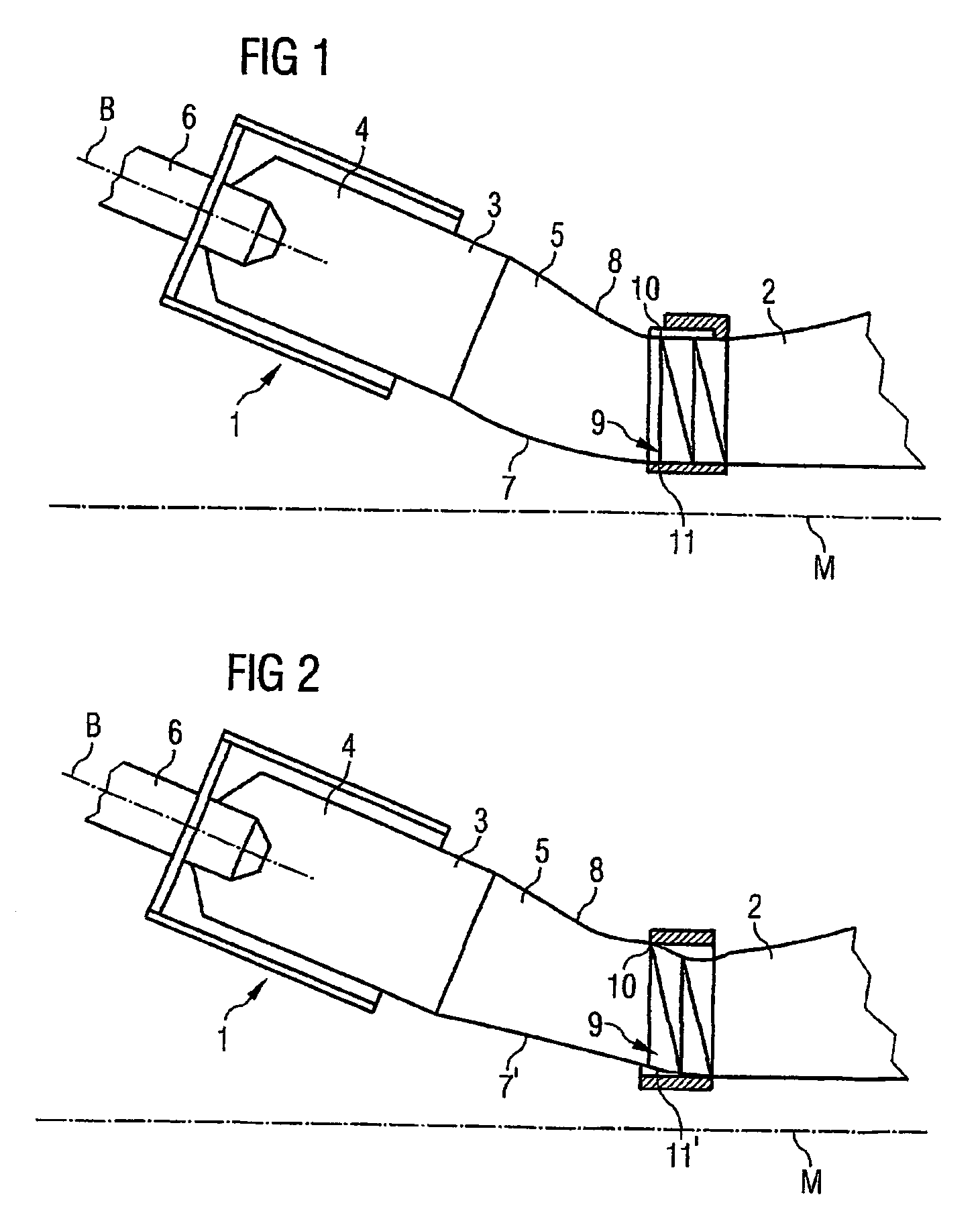

Gas turbine blade or vane and platform element for a gas turbine blade or vane ring of a gas turbine, supporting structure for securing gas turbine blades or vanes arranged in a ring, gas turbine blade or vane ring and the use of a gas turbine blade or vane ring

InactiveUS20070020102A1Improve efficiencyImprove gas efficiencyPropellersEngine manufactureAerospace engineeringGas turbines

The invention relates to a gas turbine blade or vane ring having a supporting structure and gas turbine blades or vanes secured to it. The gas turbine blades or vanes have a blade or vane root, which is successively adjoined by a platform and then a blade profile which is curved in the longitudinal direction, the blade or vane root running in the longitudinal direction of the blade profile, and the platform having two platform longitudinal edges which are bent parallel and run in the longitudinal direction. To provide an alternative gas turbine blade or vane ring with simplified assembly, it is proposed that the blade or vane root be shaped in such a manner that the suction-side or pressure-side blade or vane root surface of the associated platform longitudinal edge be curved convexly or concavely, respectively. Moreover, the invention relates to the use of a gas turbine blade or vane ring of this type.

Owner:SIEMENS AG

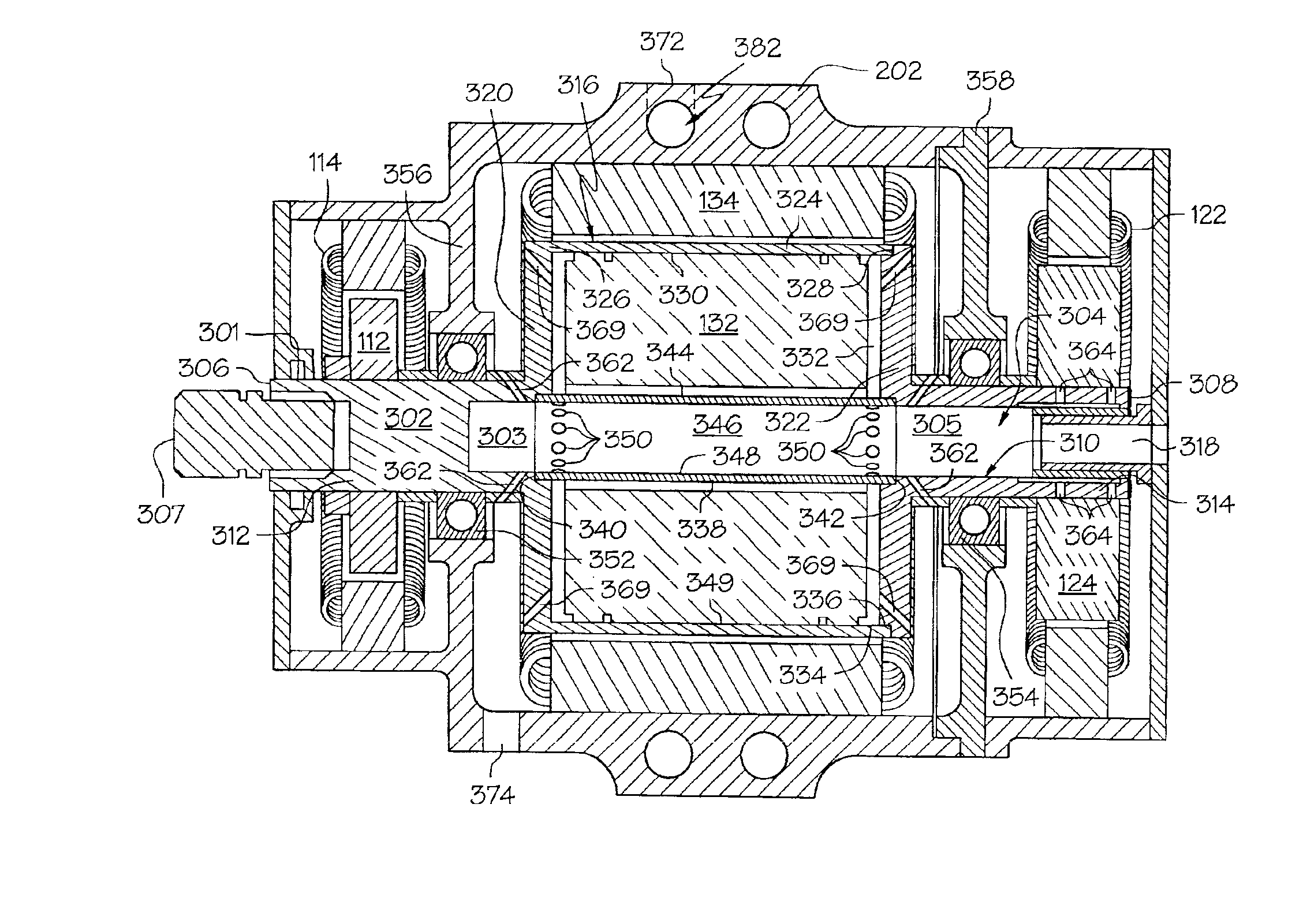

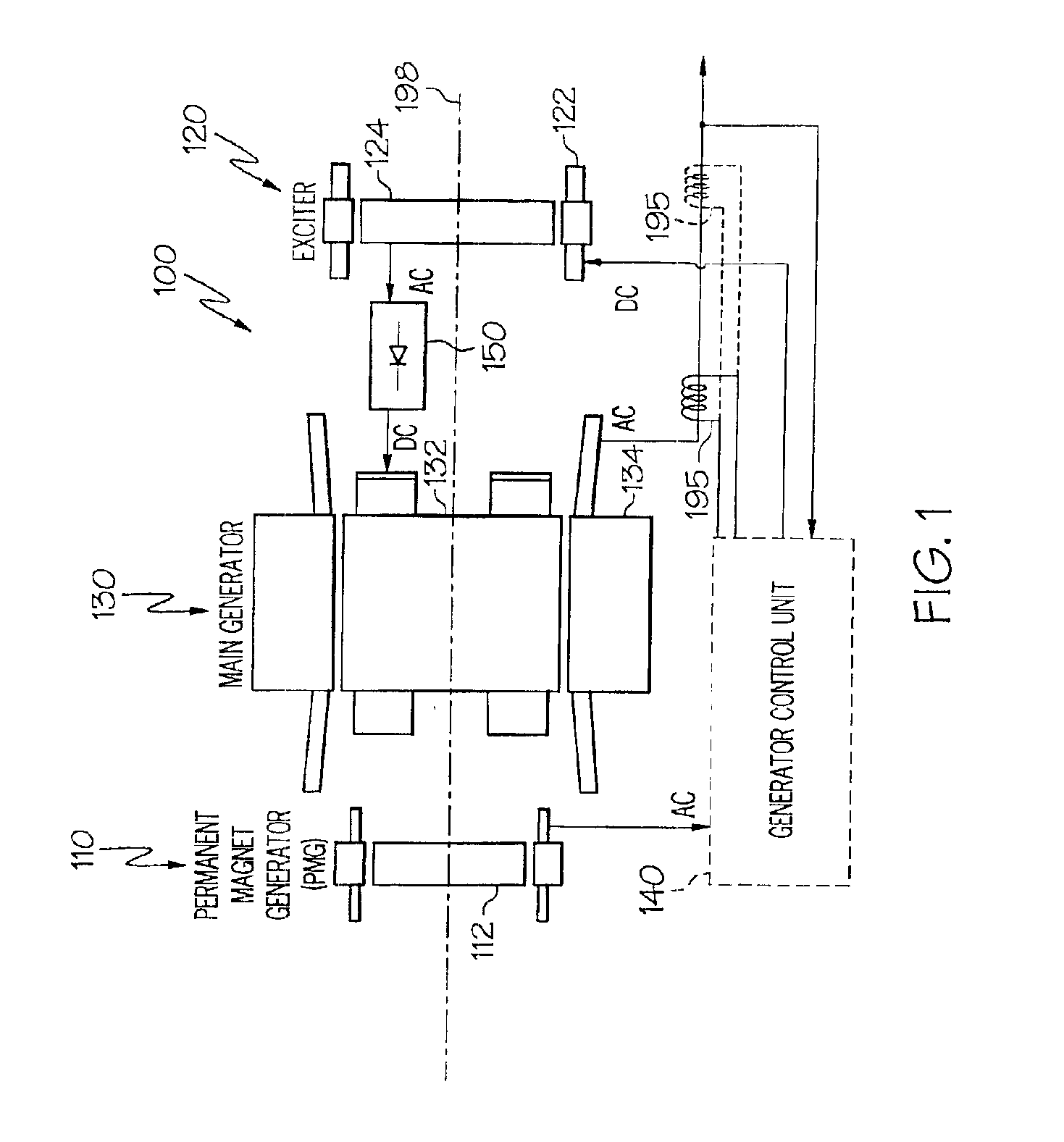

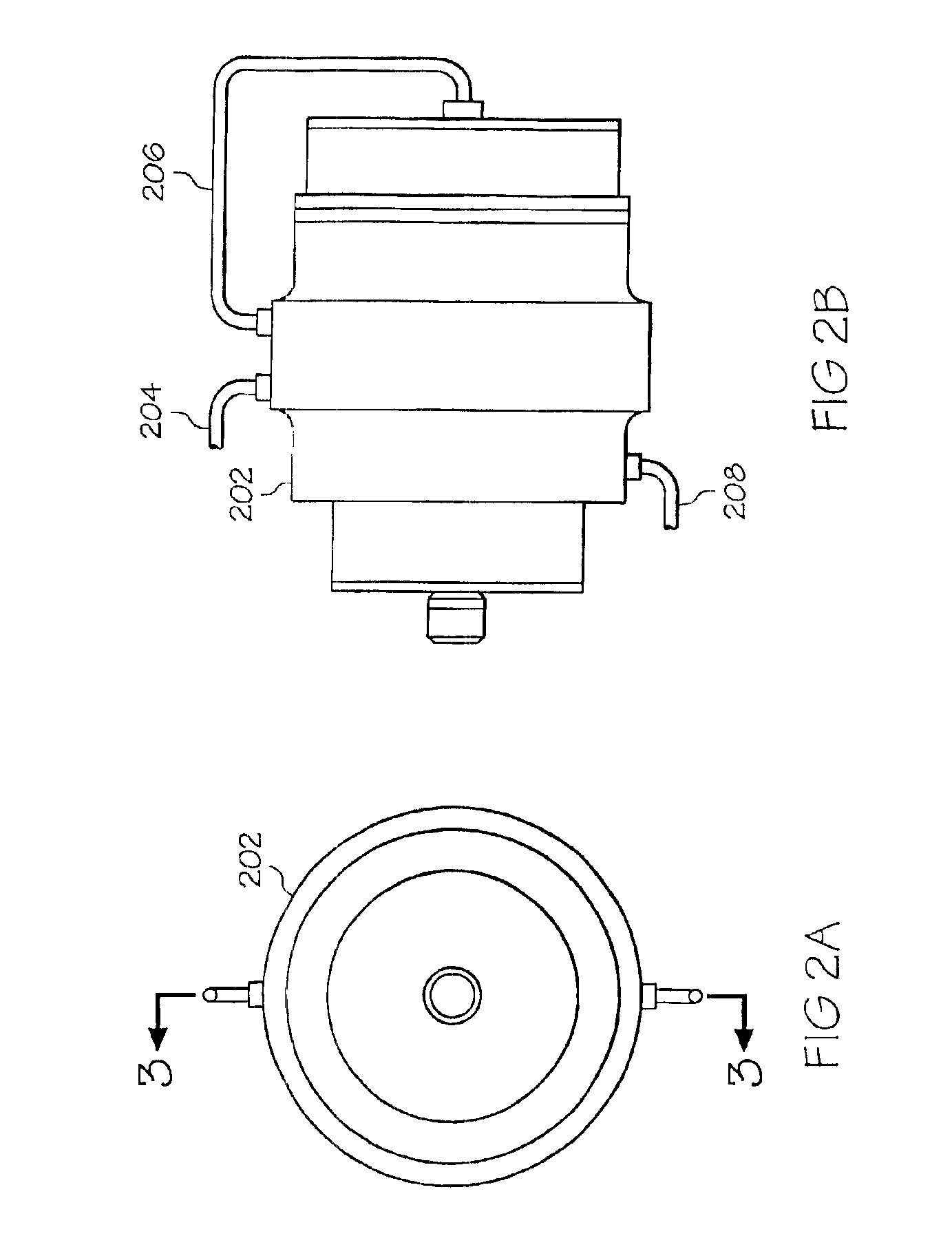

High speed generator with the main rotor housed inside the shaft

InactiveUS6897581B2Improves Structural IntegrityReduce material stressSynchronous generatorsMagnetic circuit rotating partsEngineeringTail rotor

A high speed generator has its main rotor located within the main generator shaft assembly. The main rotor is mounted on a substantially hollow rotor shaft, which is also mounted within the main generator shaft assembly. The main stator surrounds at least a portion of the main generator shaft assembly. Main rotor cooling supply orifices extend through the rotor shaft. Main stator cooling supply orifices, which are in fluid communication with the main rotor cooling supply orifices, extend through the main generator shaft assembly. Cooling fluid is directed into the main generator shaft assembly, and flows through the main rotor cooling supply orifices and the main stator cooling supply orifices. The main rotor and main stator cooling supply orifices are configured to supply the main rotor and main stator with a cooling fluid spray. This configuration reduces the rotational fluid mass associated with flood-cooled rotors, which increases structural integrity, lowers material stresses, improves rotor dynamics.

Owner:HONEYWELL INT INC

Gas turbine blade or vane and platform element for a gas turbine blade or vane ring of a gas turbine, supporting structure for securing gas turbine blades or vanes arranged in a ring, gas turbine blade or vane ring and the use of a gas turbine blade or vane ring

InactiveUS7300253B2Simpler and efficient coolingExtended service lifePropellersEngine manufactureTurbine bladeRoot surface

The invention relates to a gas turbine blade or vane ring having a supporting structure and gas turbine blades or vanes secured to it. The gas turbine blades or vanes have a blade or vane root, which is successively adjoined by a platform and then a blade profile which is curved in the longitudinal direction, the blade or vane root running in the longitudinal direction of the blade profile, and the platform having two platform longitudinal edges which are bent parallel and run in the longitudinal direction. To provide an alternative gas turbine blade or vane ring with simplified assembly, it is proposed that the blade or vane root be shaped in such a manner that the suction-side or pressure-side blade or vane root surface of the associated platform longitudinal edge be curved convexly or concavely, respectively. Moreover, the invention relates to the use of a gas turbine blade or vane ring of this type.

Owner:SIEMENS AG

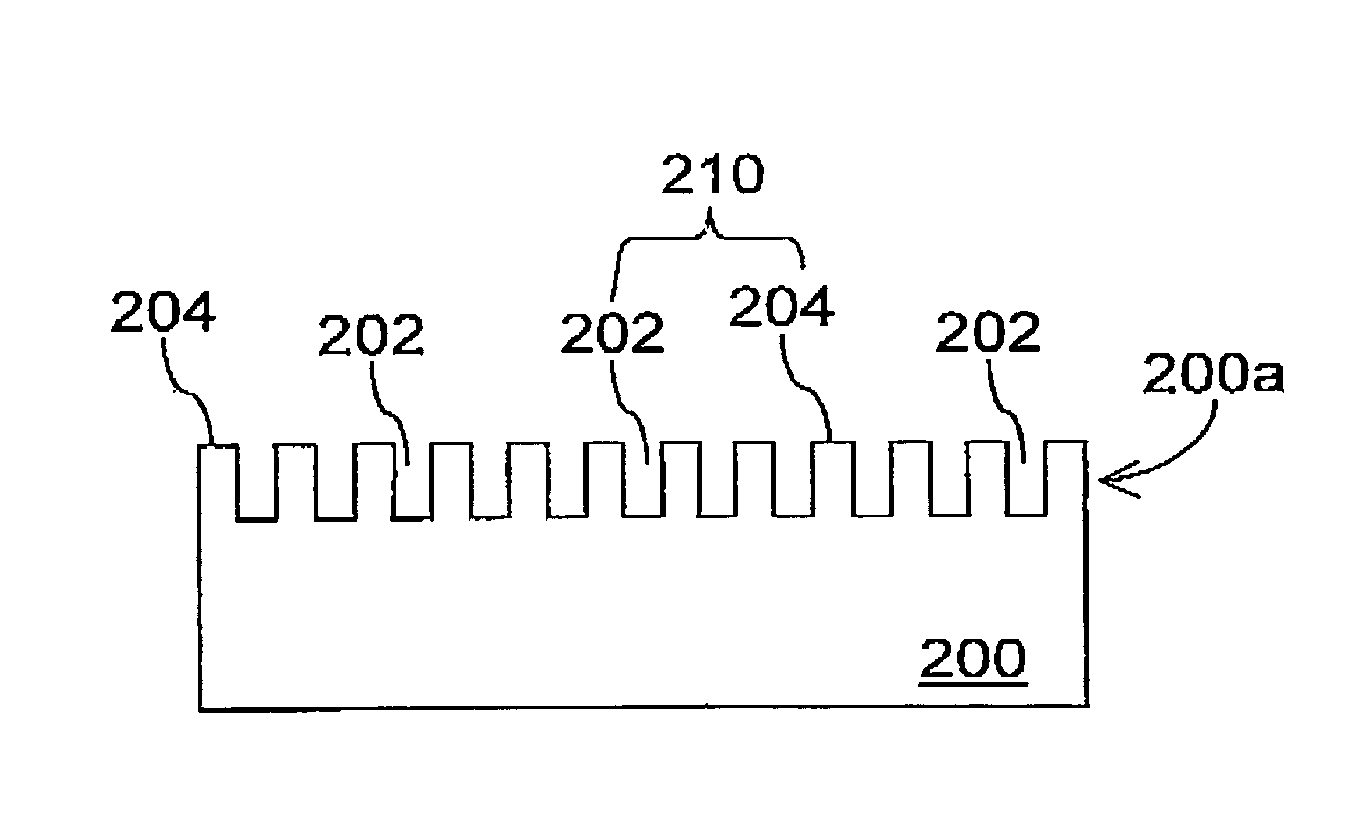

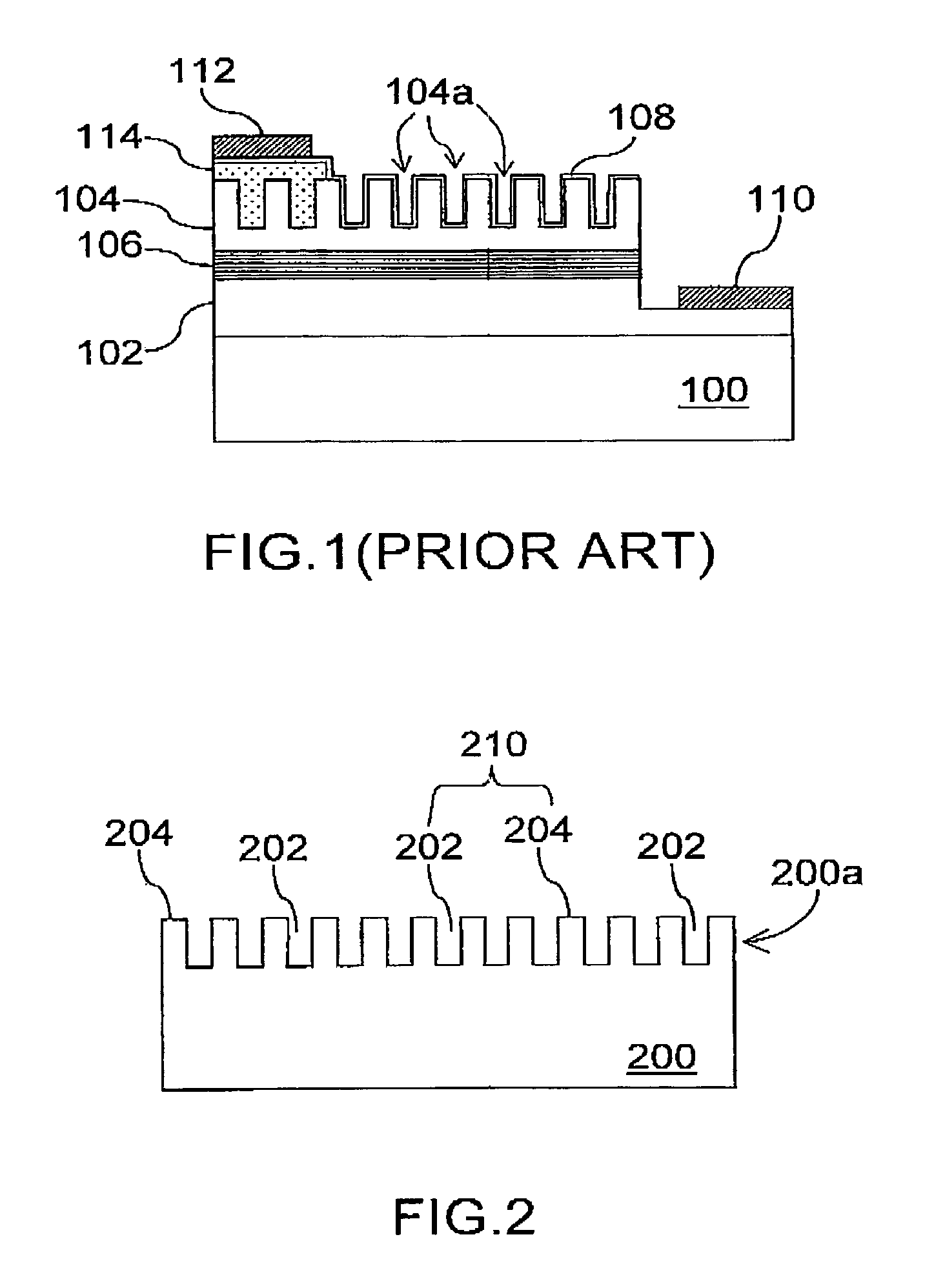

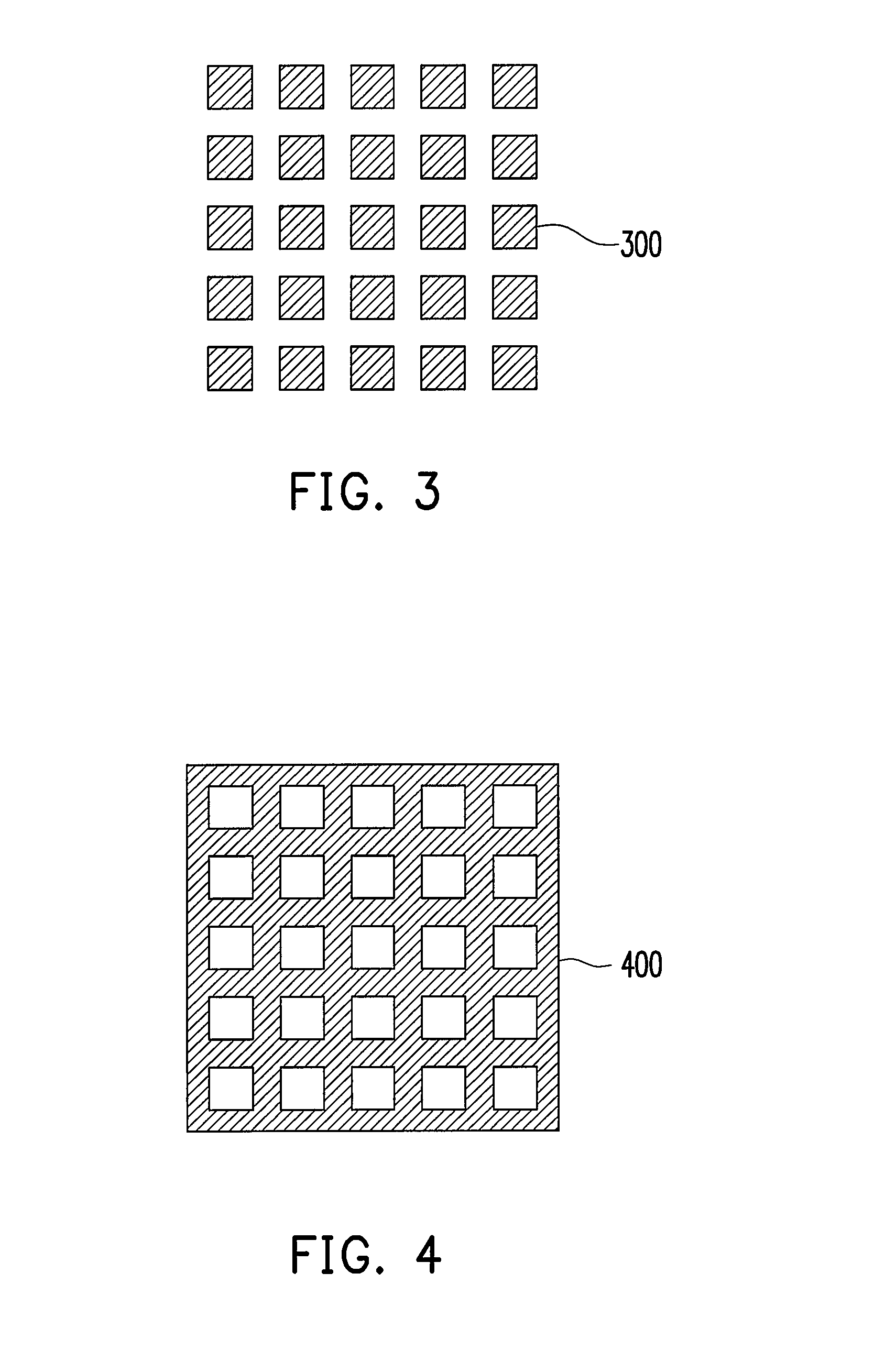

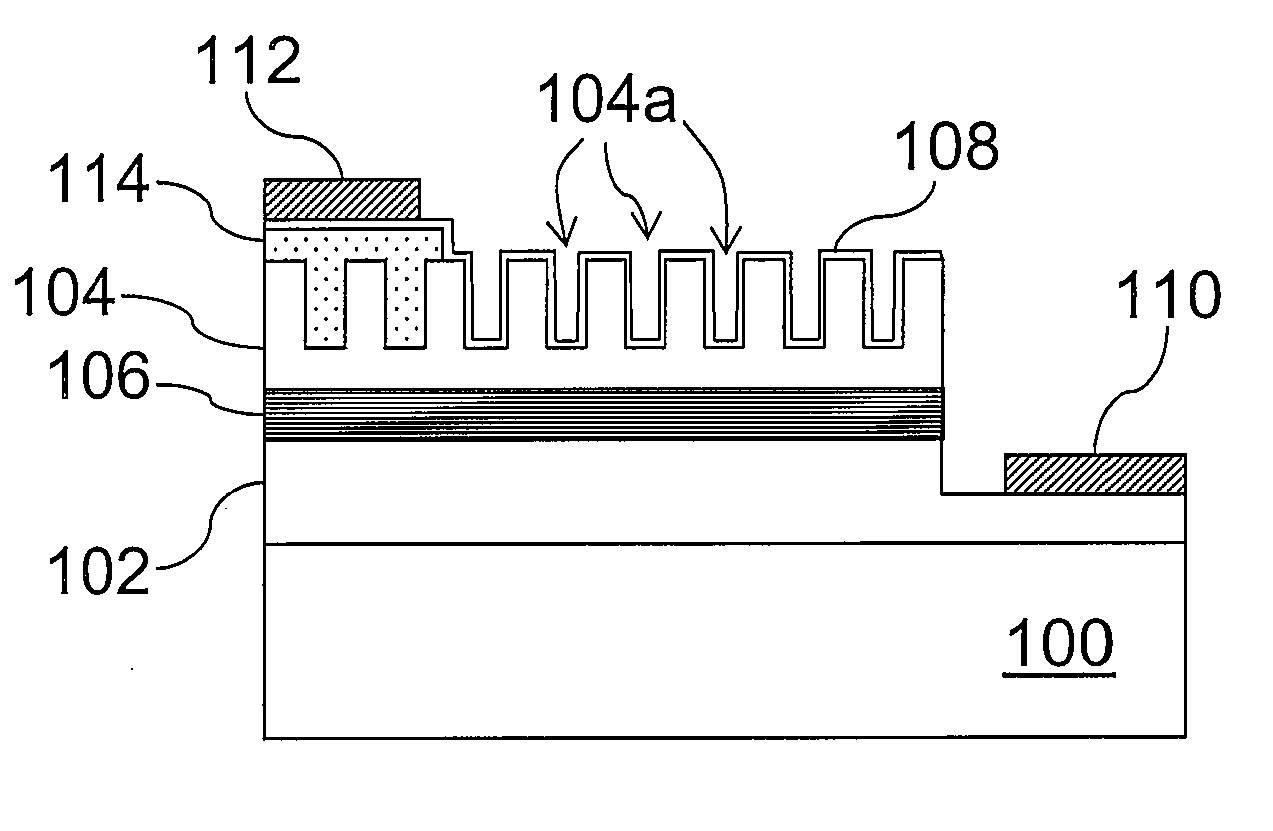

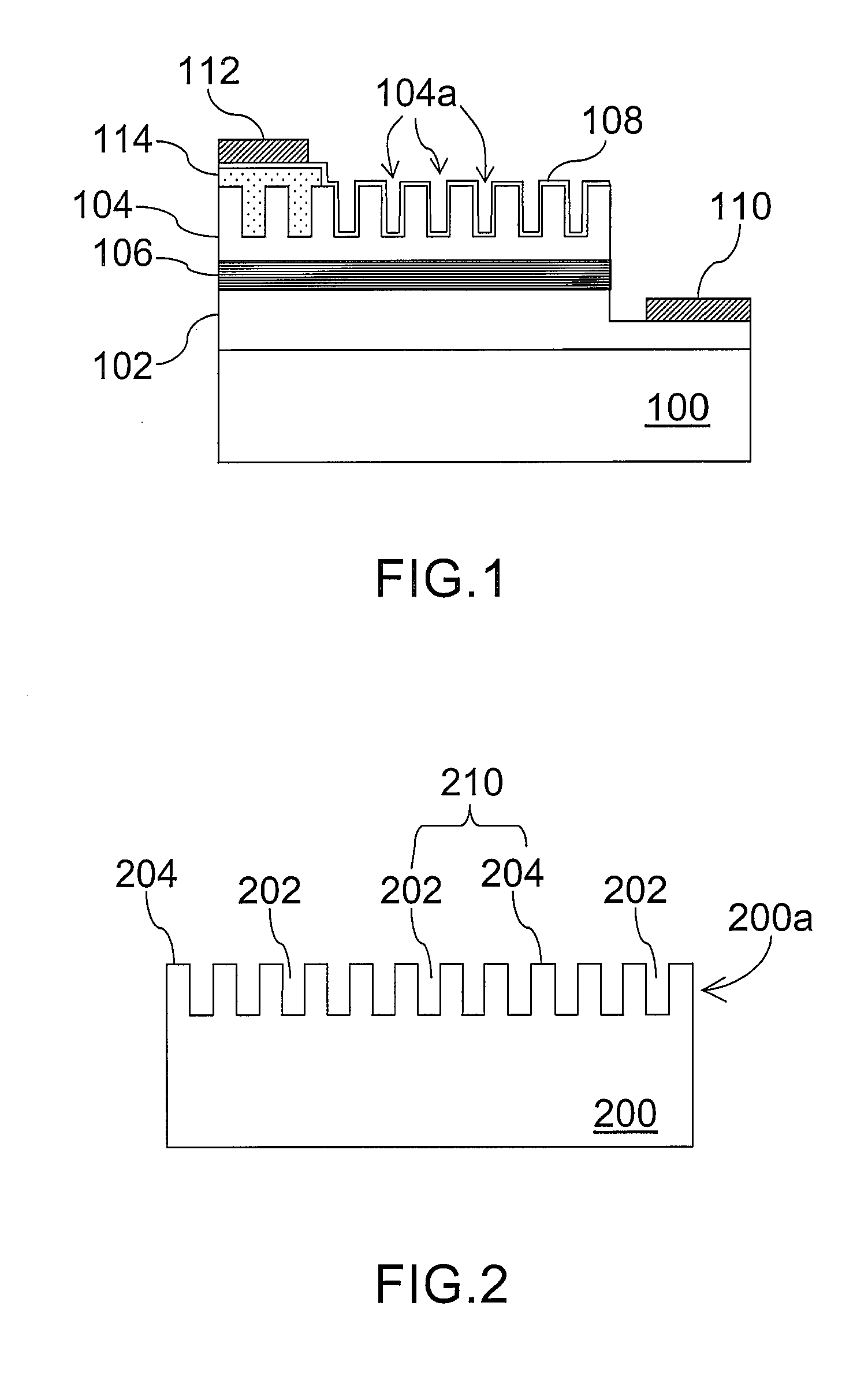

Semiconductor light emitting device substrate and method of fabricating the same

InactiveUS7427772B2Enhanced glowIncrease output powerSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor materialsSingle crystal

A substrate for semiconductor light emitting devices is provided. The substrate is characterized in that the substrate is a single crystal material and has a nanocrystal structure capable of diffracting an electromagnetic wave. The nanocrystal structure is disposed on a surface portion of the substrate and includes an etched region and an unetched region, wherein the etched region has a depth of 10-200 nm. Due to the periodicity of the nanocrystal structure, the semiconductor material grown on the substrate has fewer defects, and the material stress is reduced.

Owner:IND TECH RES INST

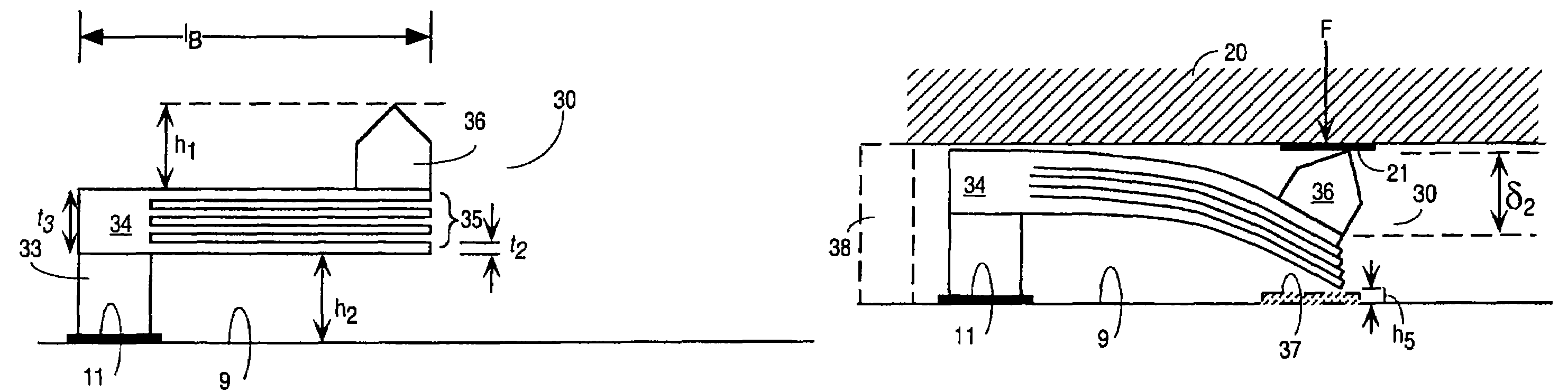

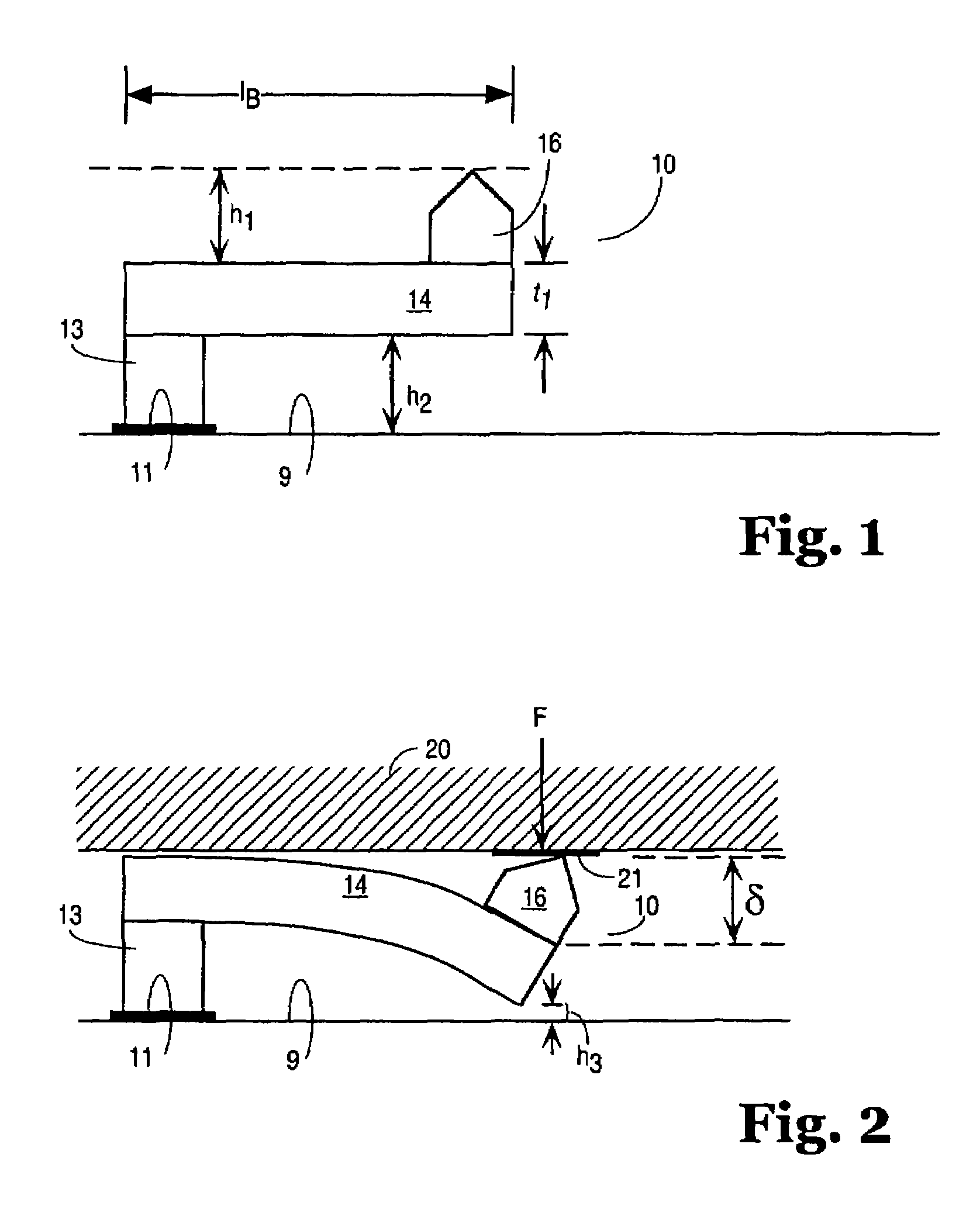

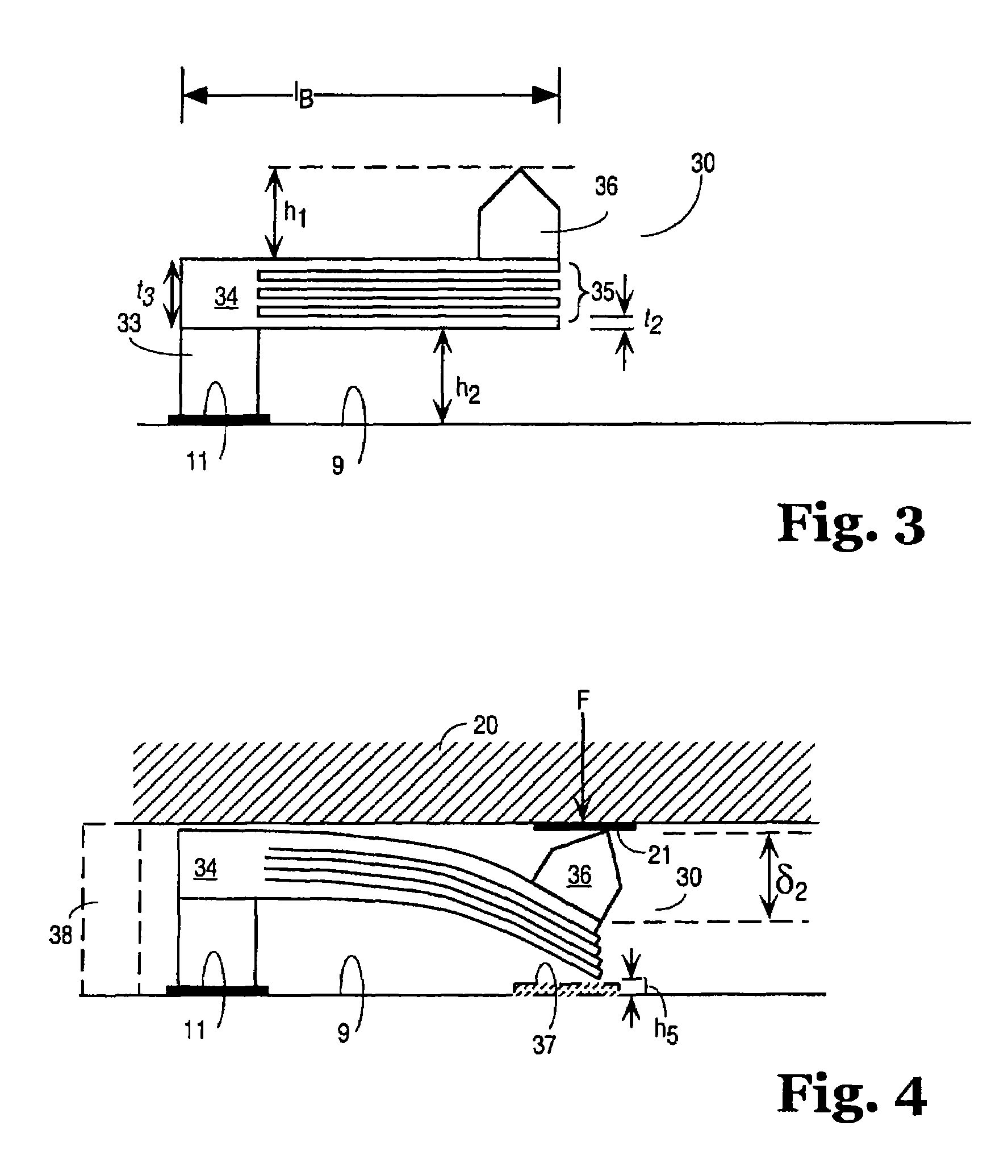

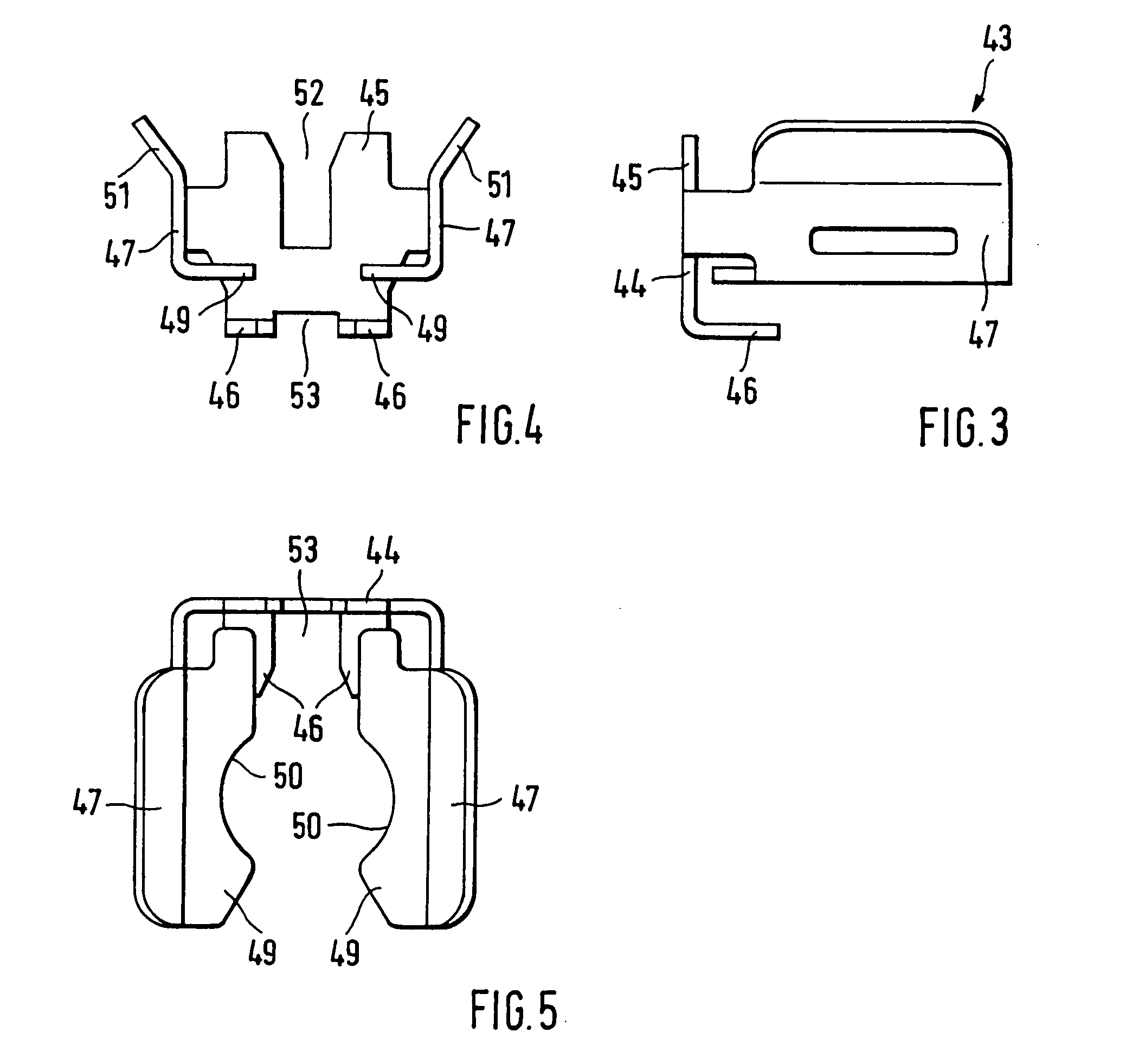

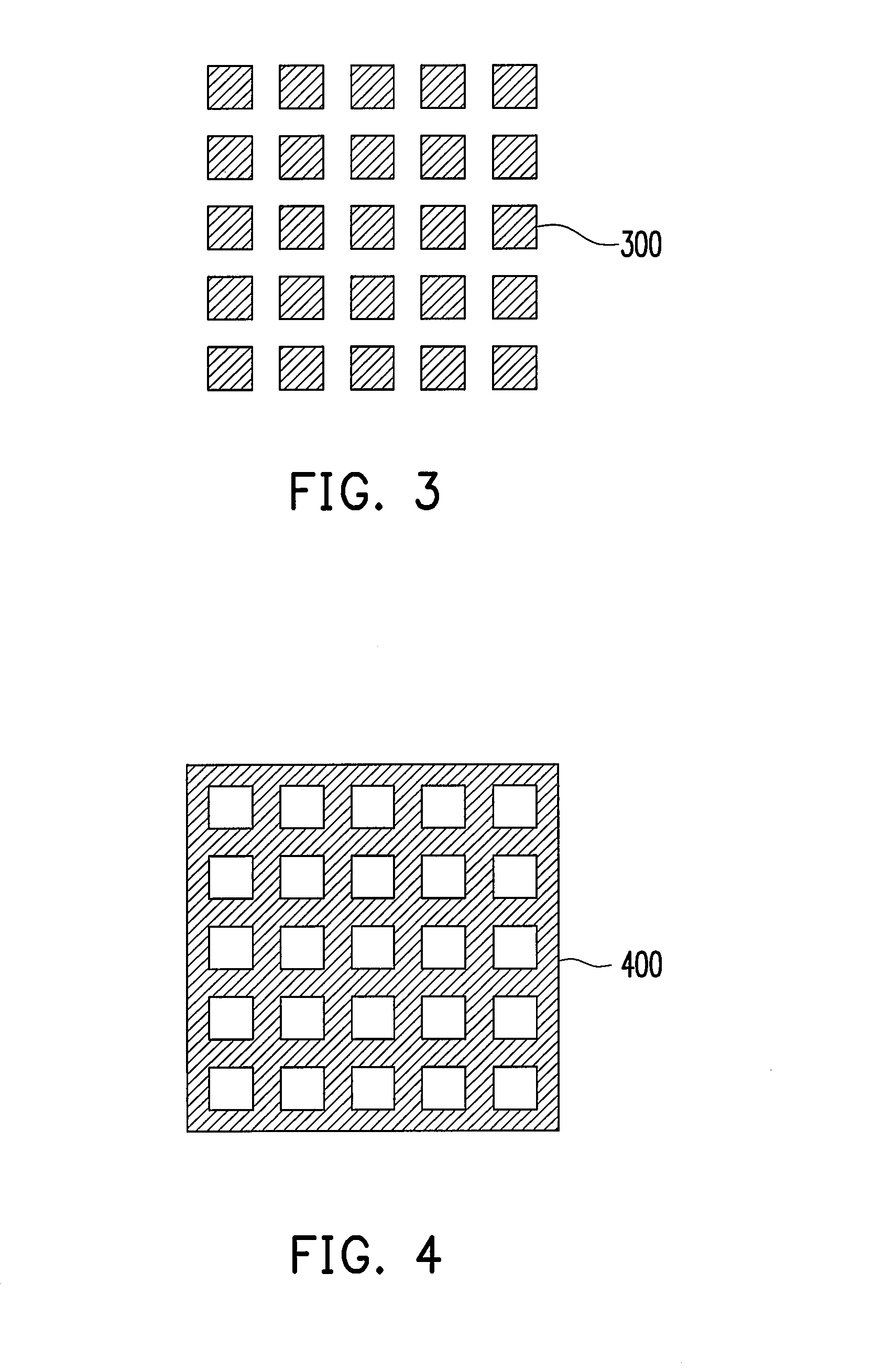

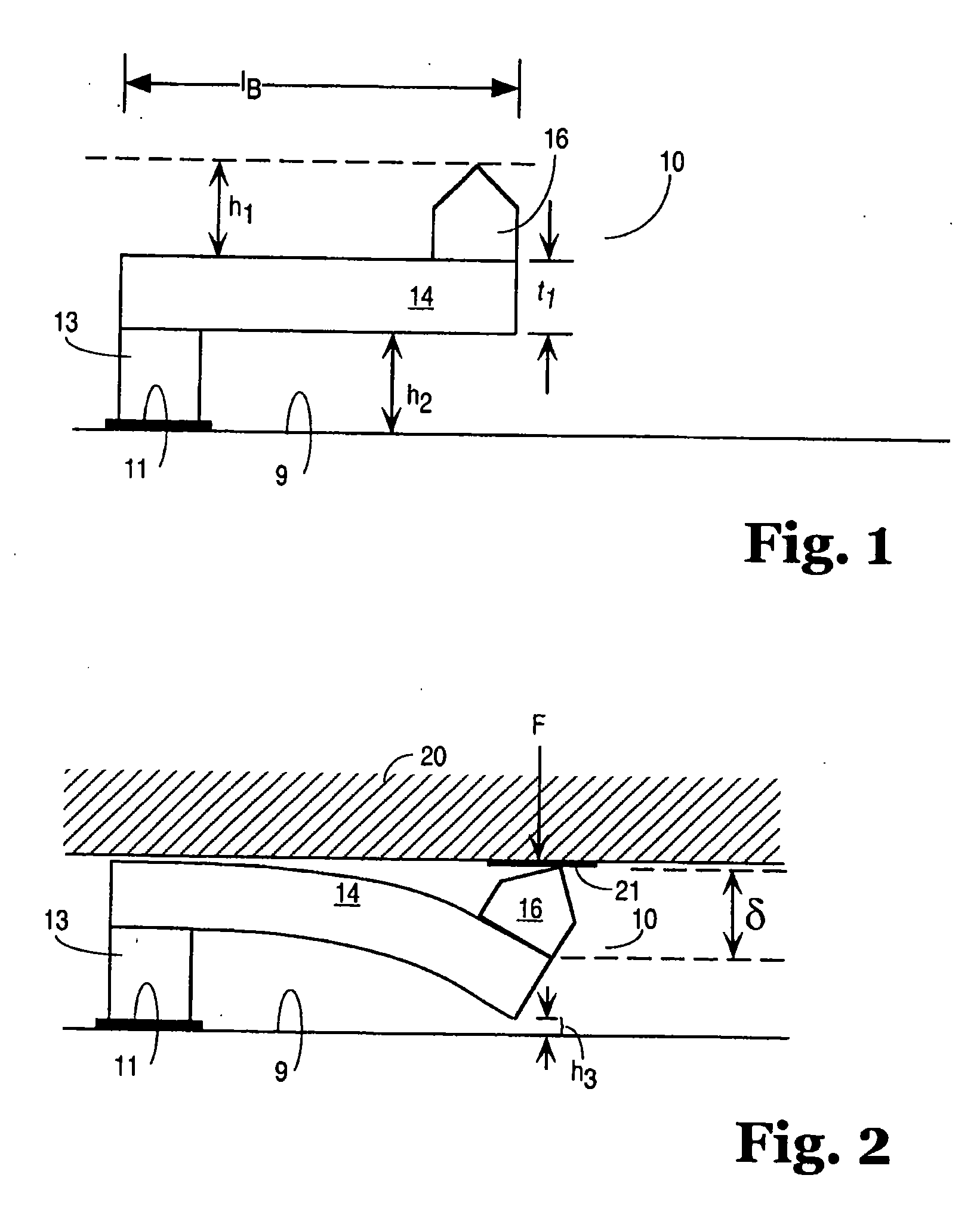

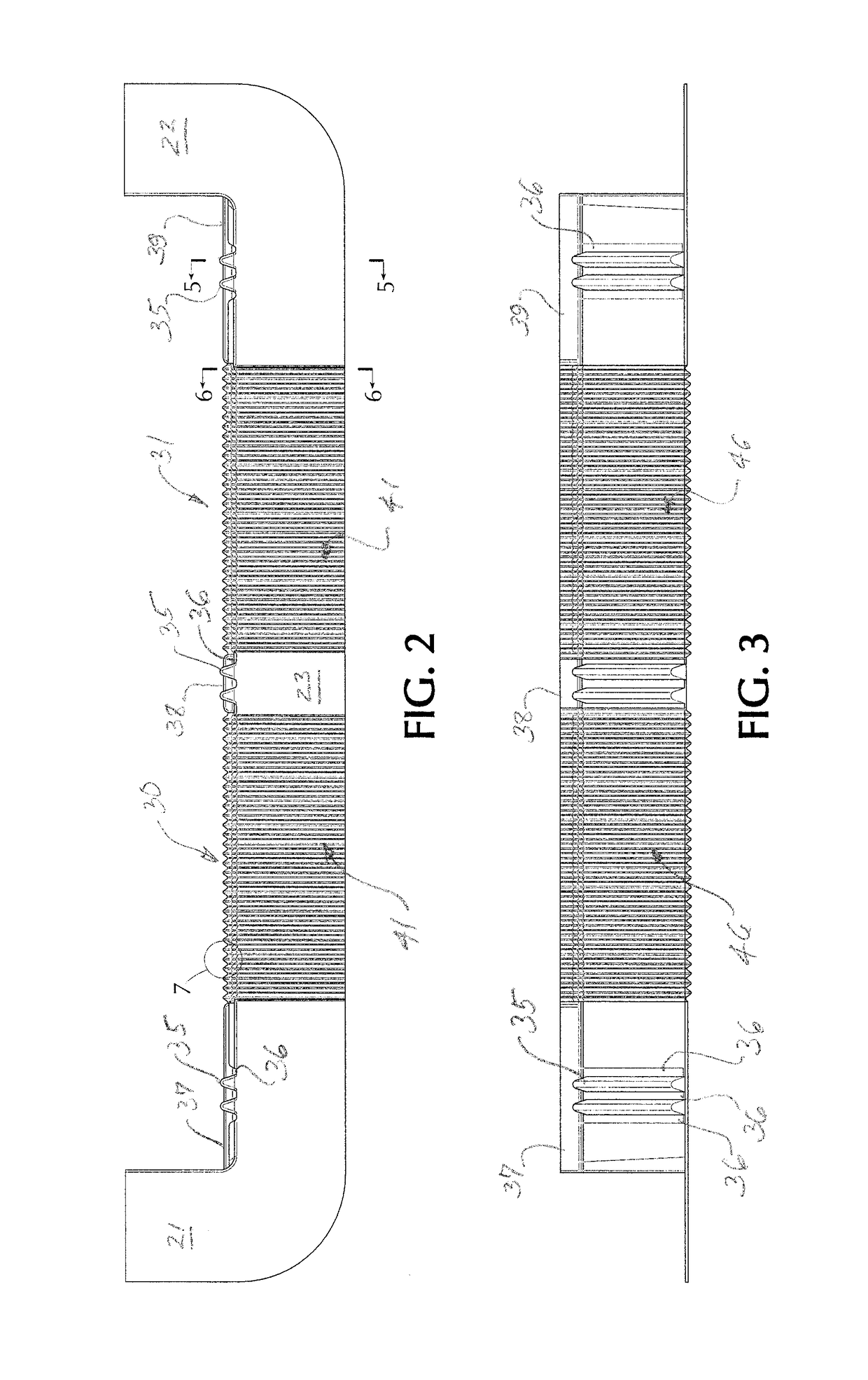

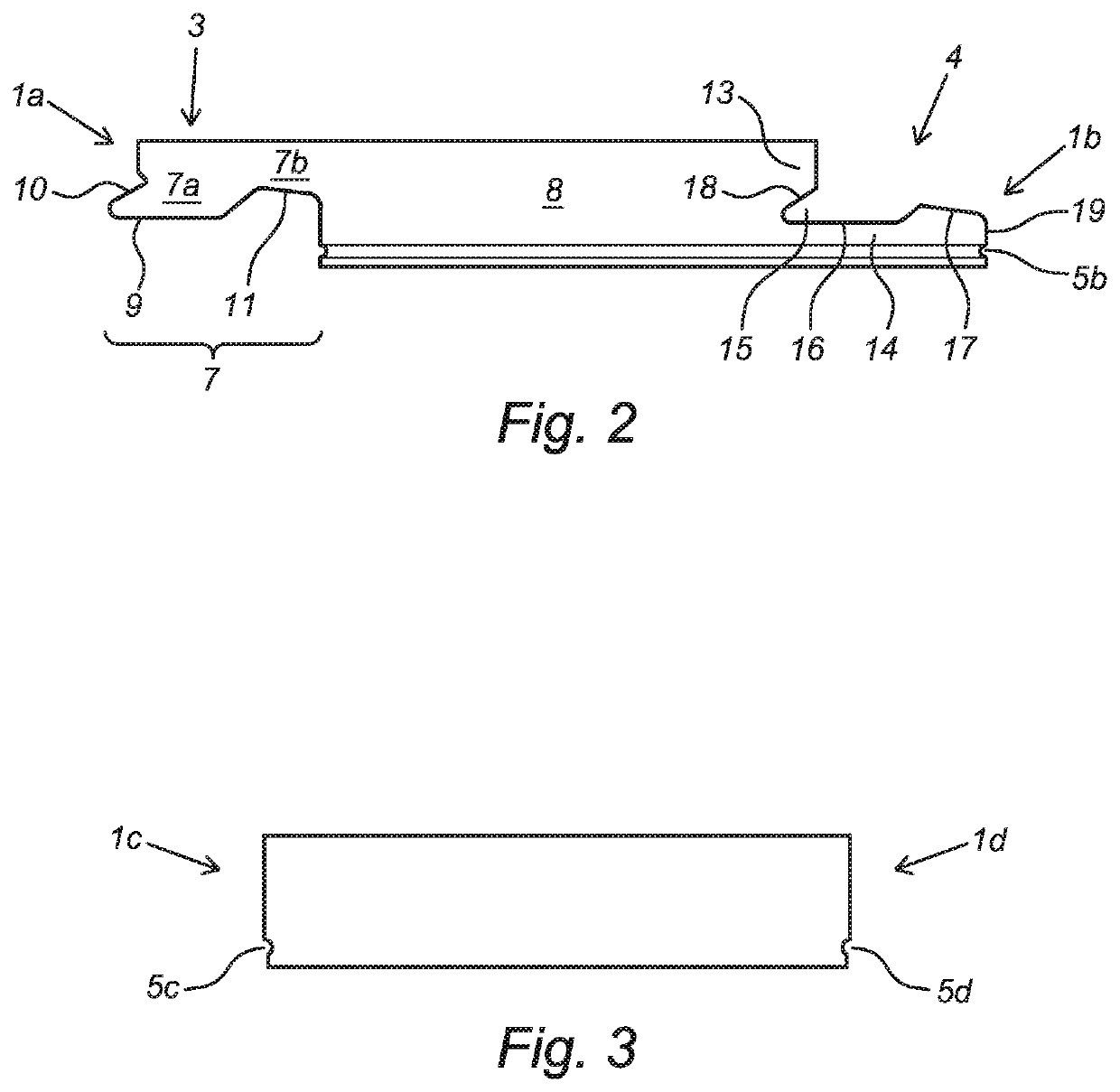

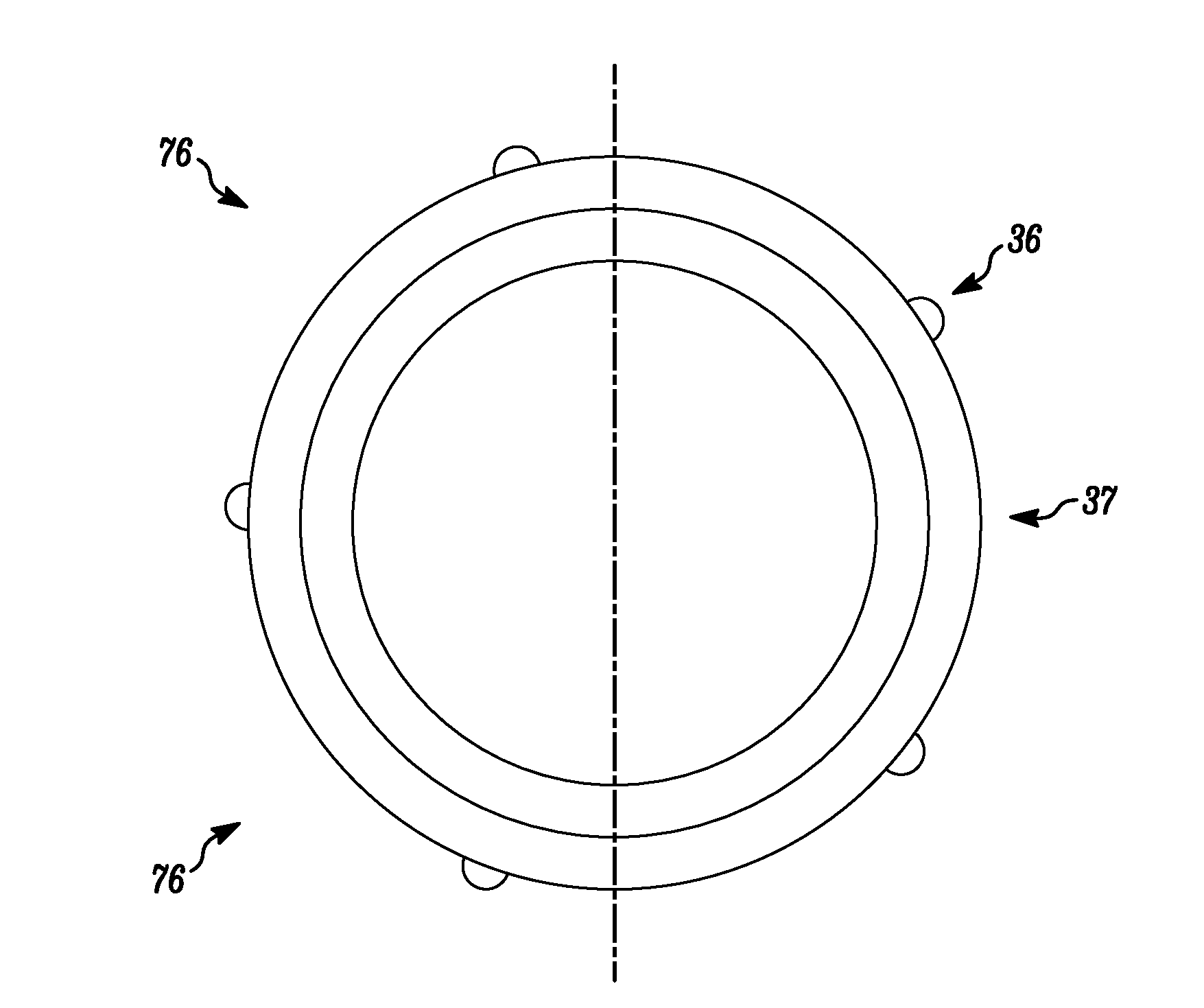

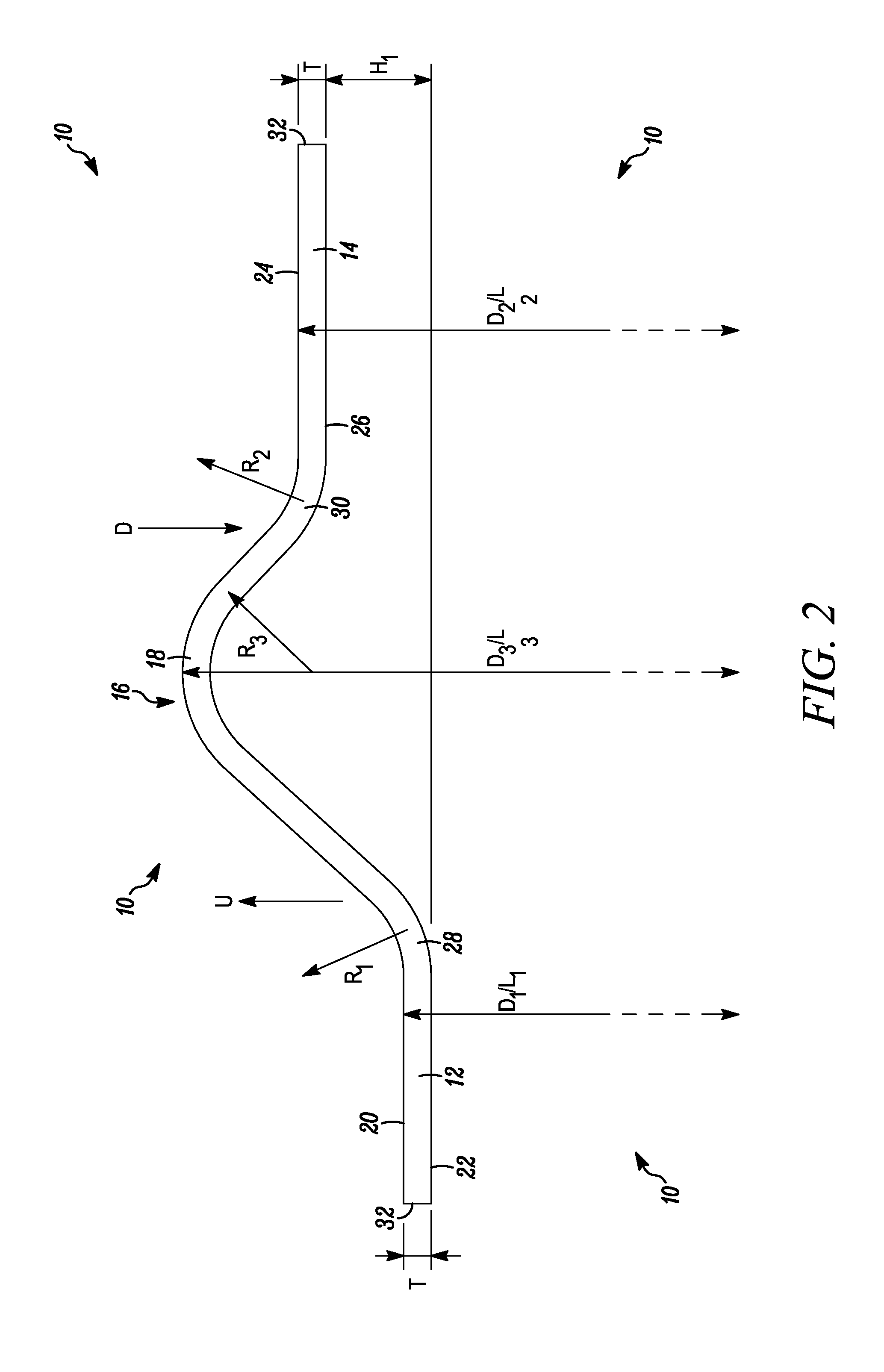

Spring interconnect structures

InactiveUS7553165B2Increase the spring constantImprove mechanical propertiesCoupling device connectionsSemiconductor/solid-state device testing/measurementInterconnectionEngineering

An interconnection element of a spring (body) including a first resilient element with a first contact region and a second contact region and a first securing region and a second resilient element, with a third contact region and a second securing region. The second resilient element is coupled to the first resilient element through respective securing regions and positioned such that upon sufficient displacement of the first contact region toward the second resilient element, the second contact region will contact the third contact region. The interconnection, in one aspect, is of a size suitable for directly contacting a semiconductor device. A large substrate with a plurality of such interconnection elements can be used as a wafer-level contactor. The interconnection element, in another aspect, is of a size suitable for contacting a packaged semiconductor device, such as in an LGA package.

Owner:FORMFACTOR INC

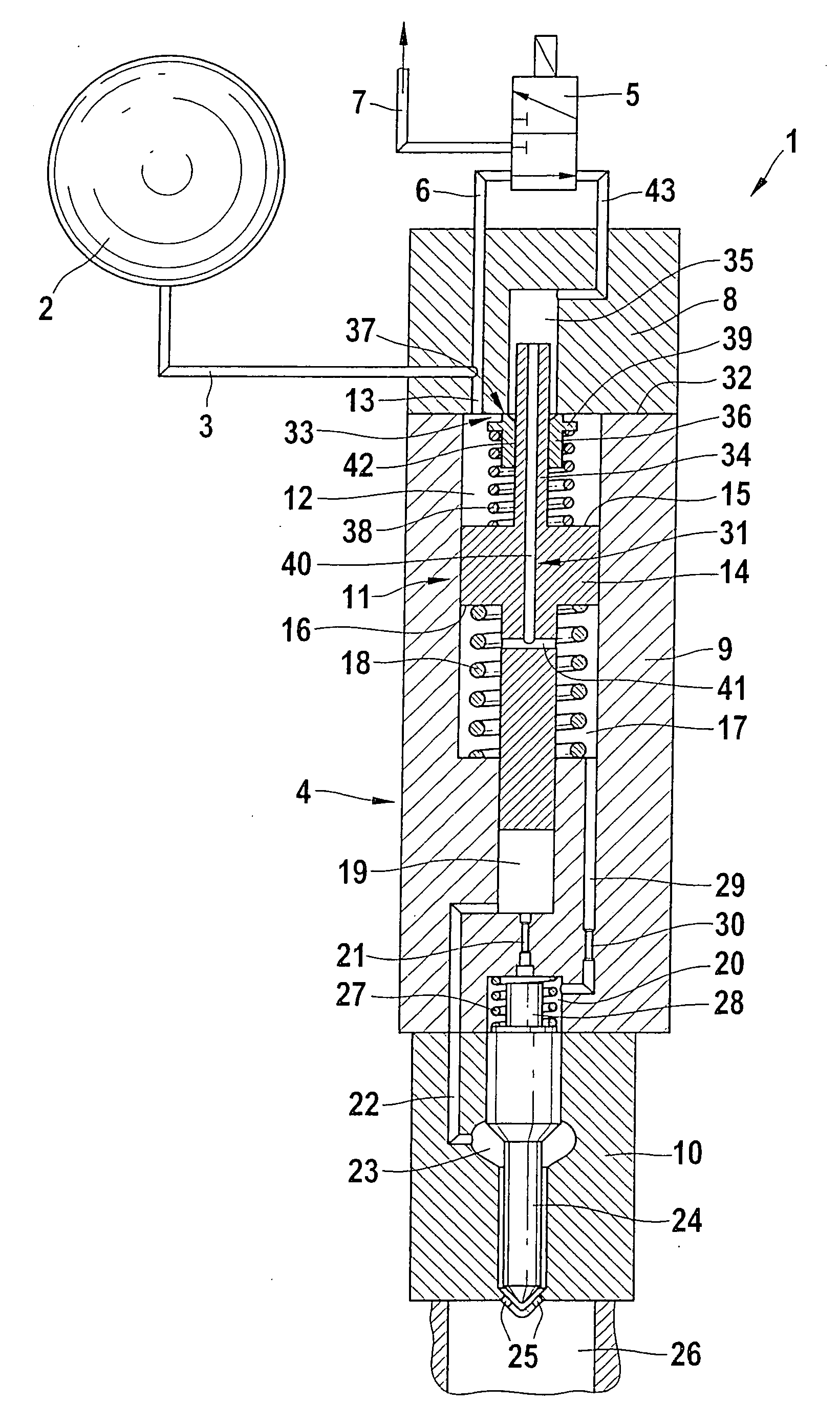

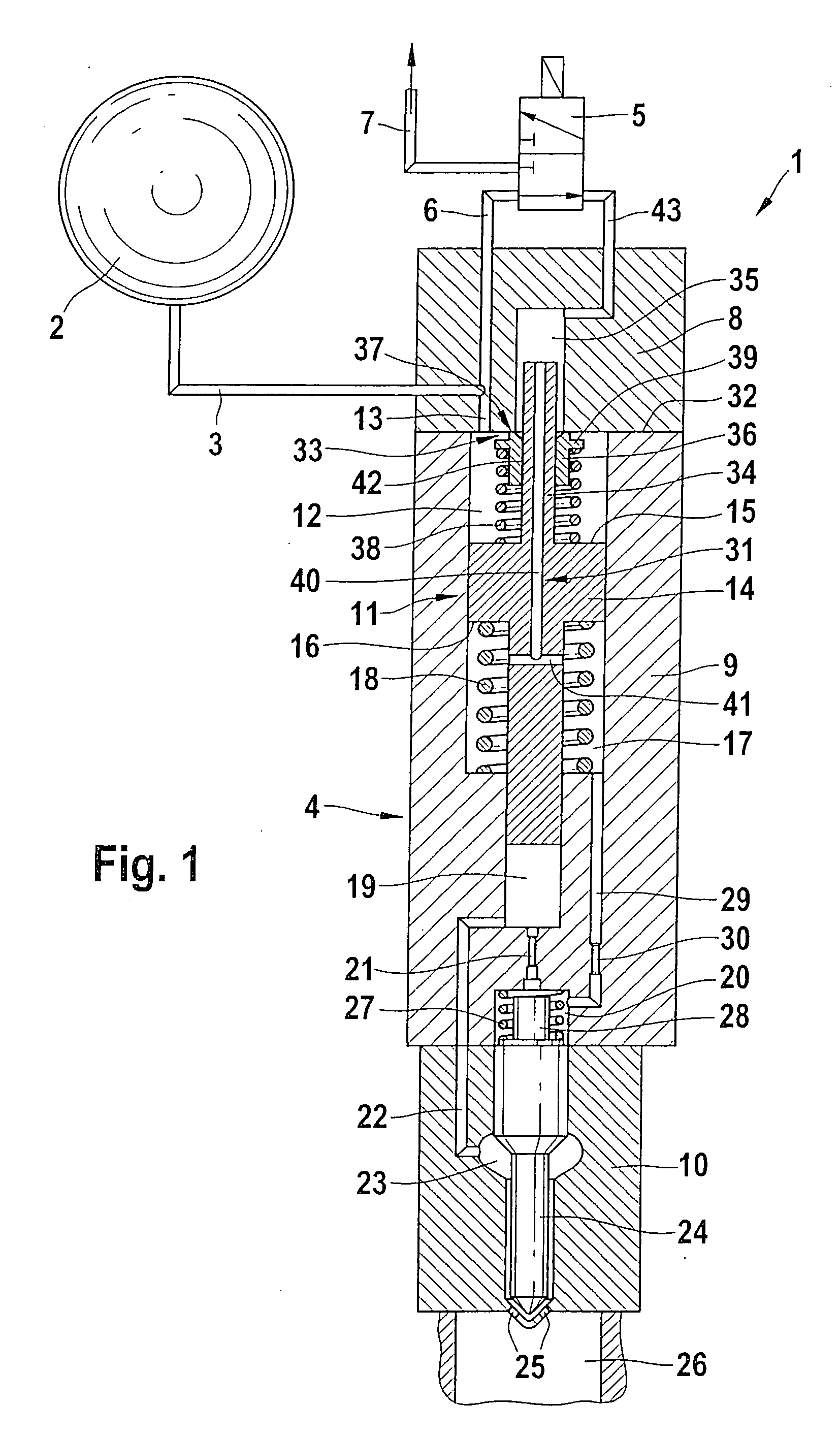

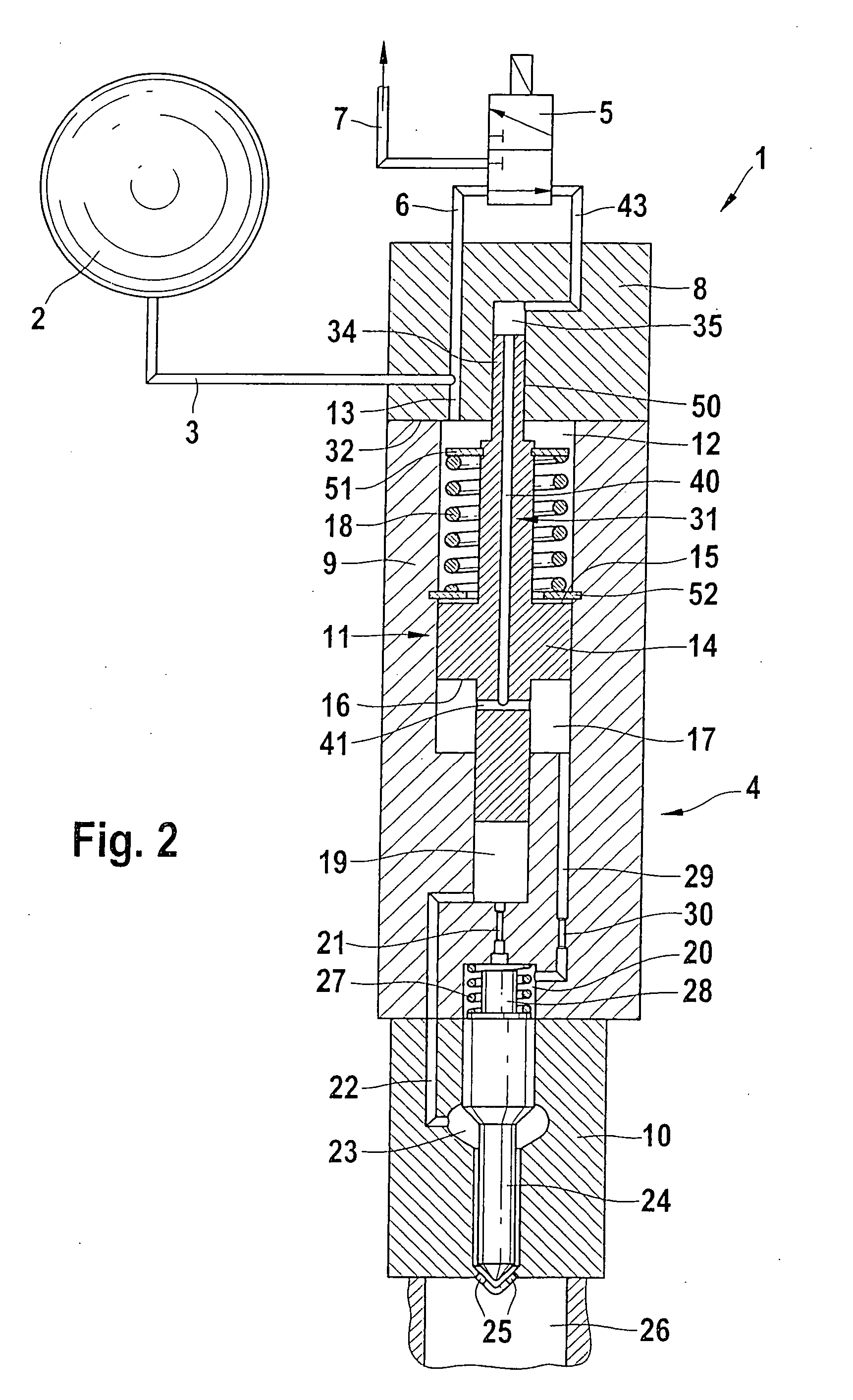

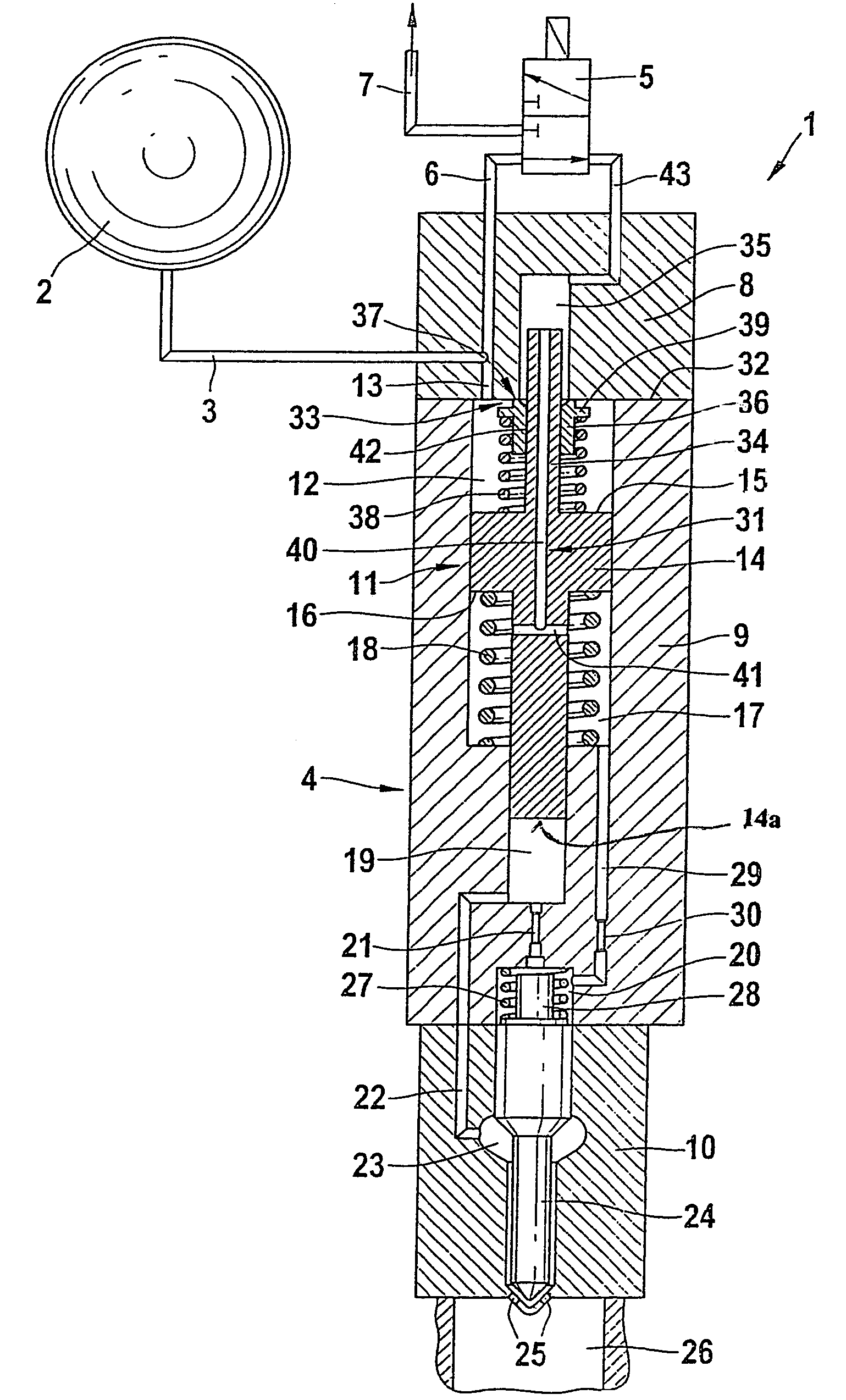

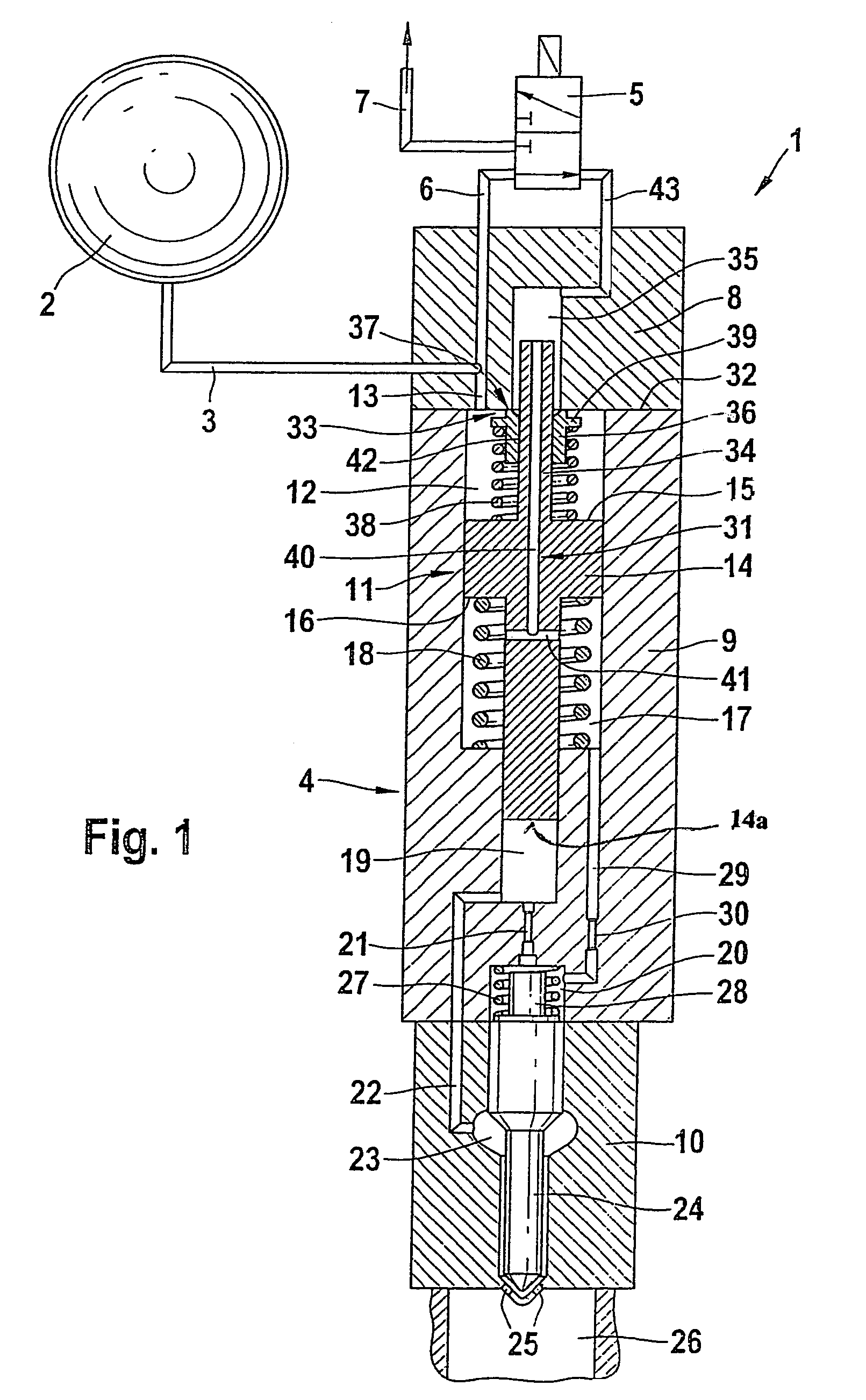

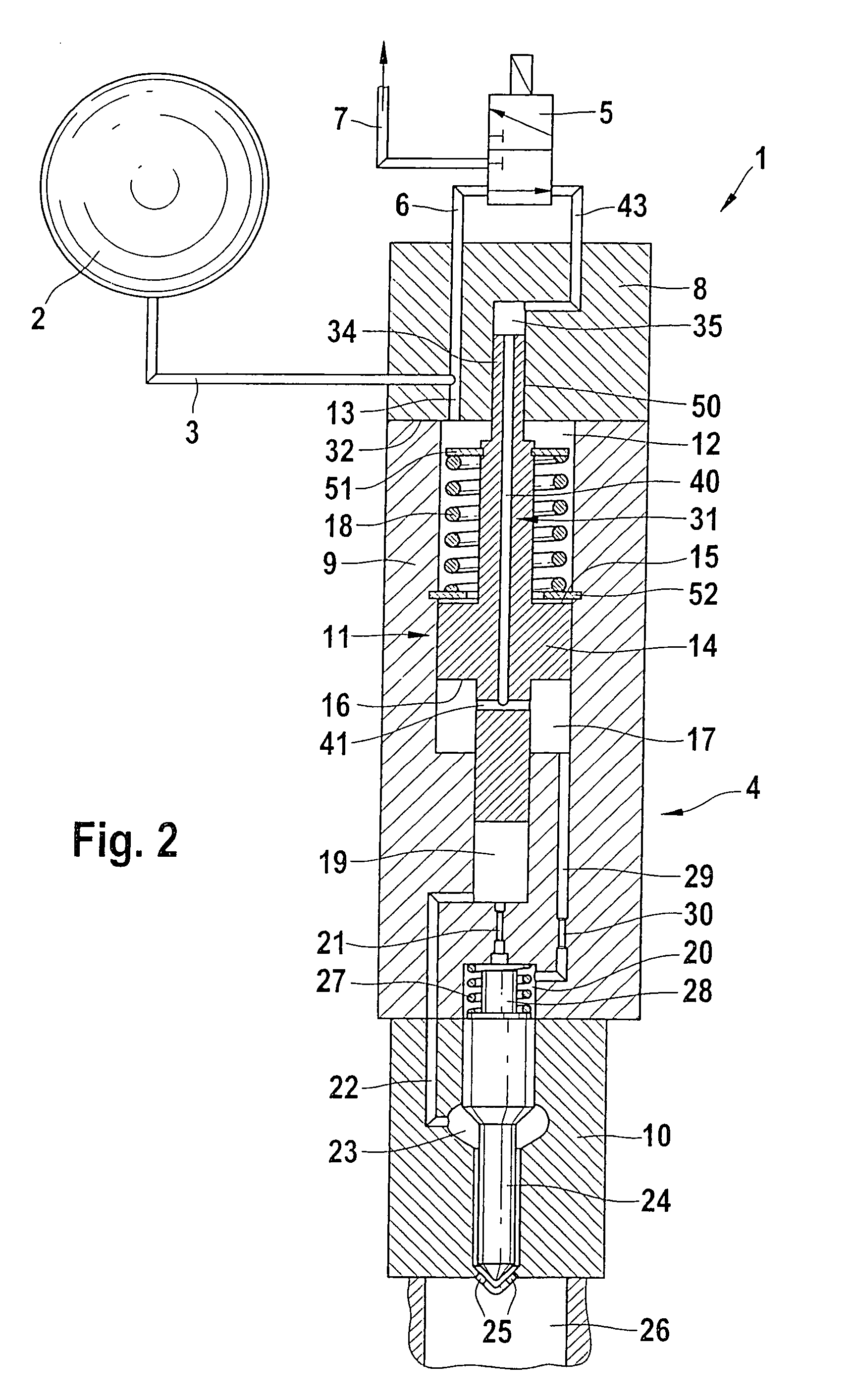

Pressure-boosted fuel injection device comprising an internal control line

InactiveUS20060043209A1Extended service lifeReduce material stressFuel injection apparatusMachines/enginesPistonFuel injection

The invention relates to a fuel injection device with a multi-part injector body containing a pressure booster that can be actuated by means of a differential pressure chamber, and includes a pressure booster piston that seals a working chamber off from the differential pressure chamber. An on-off valve, disposed above the injector body can actuate the fuel injection device. A pressure change in the differential pressure chamber occurs via a central control line that extends through the pressure booster piston of the pressure booster.

Owner:ROBERT BOSCH GMBH

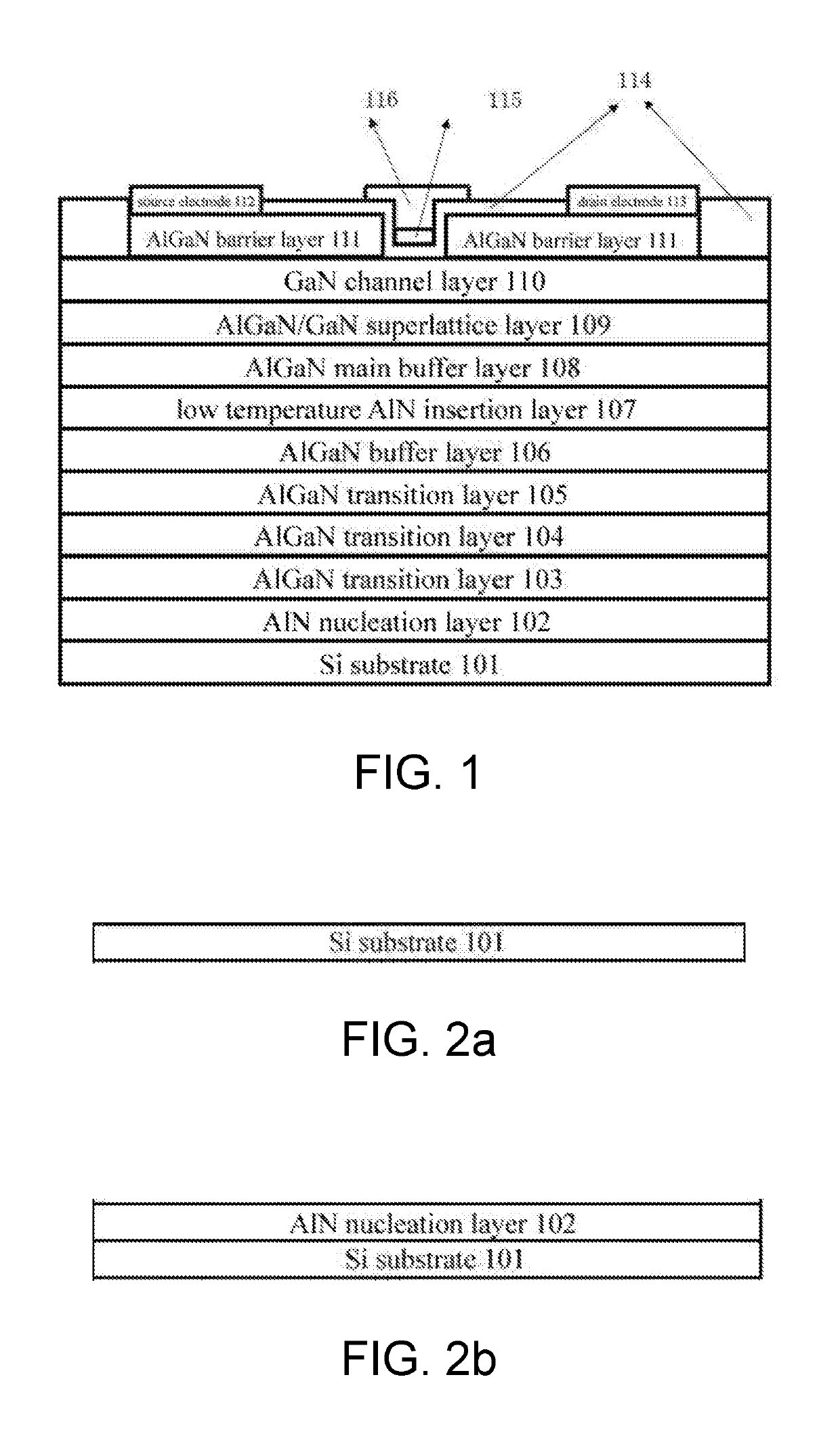

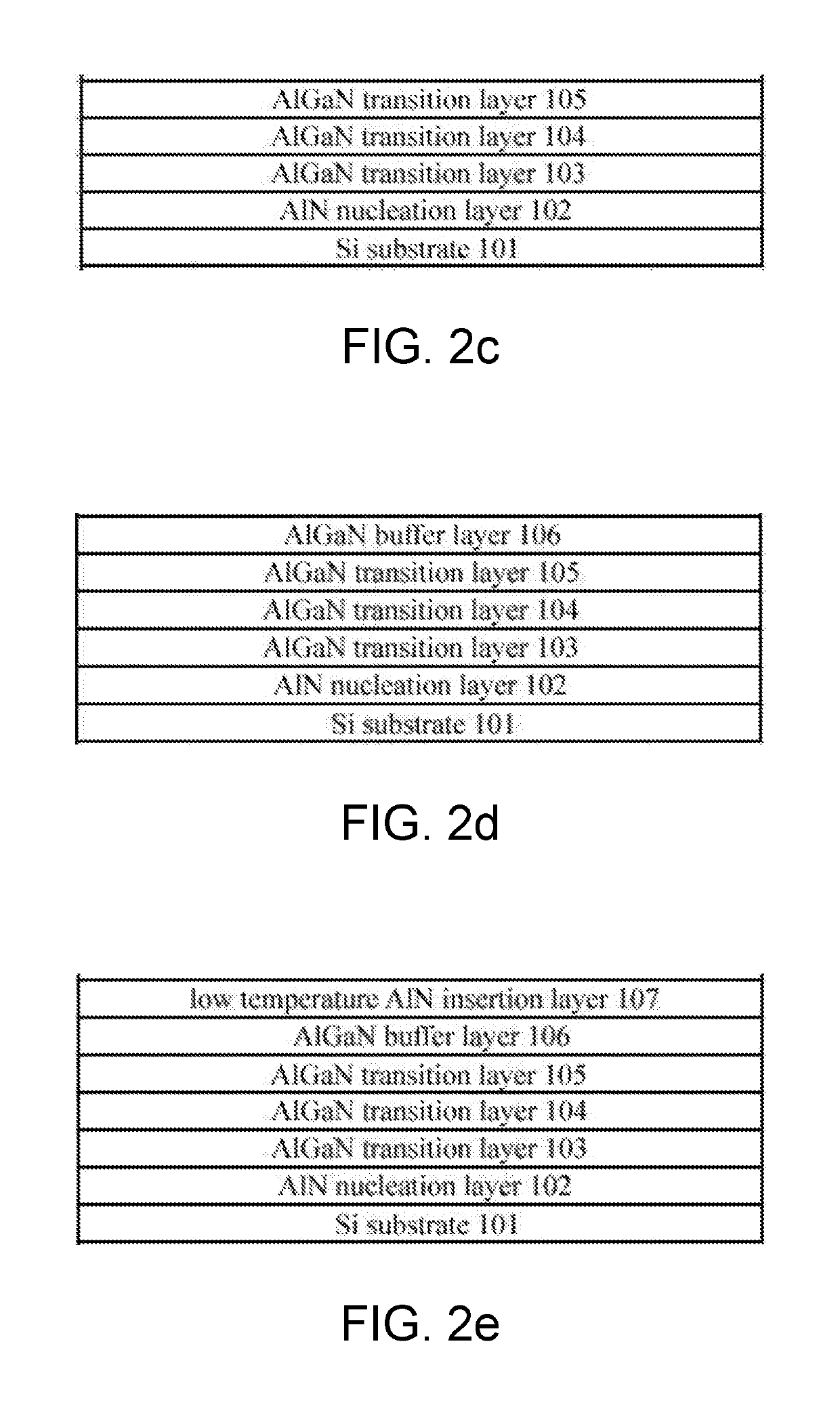

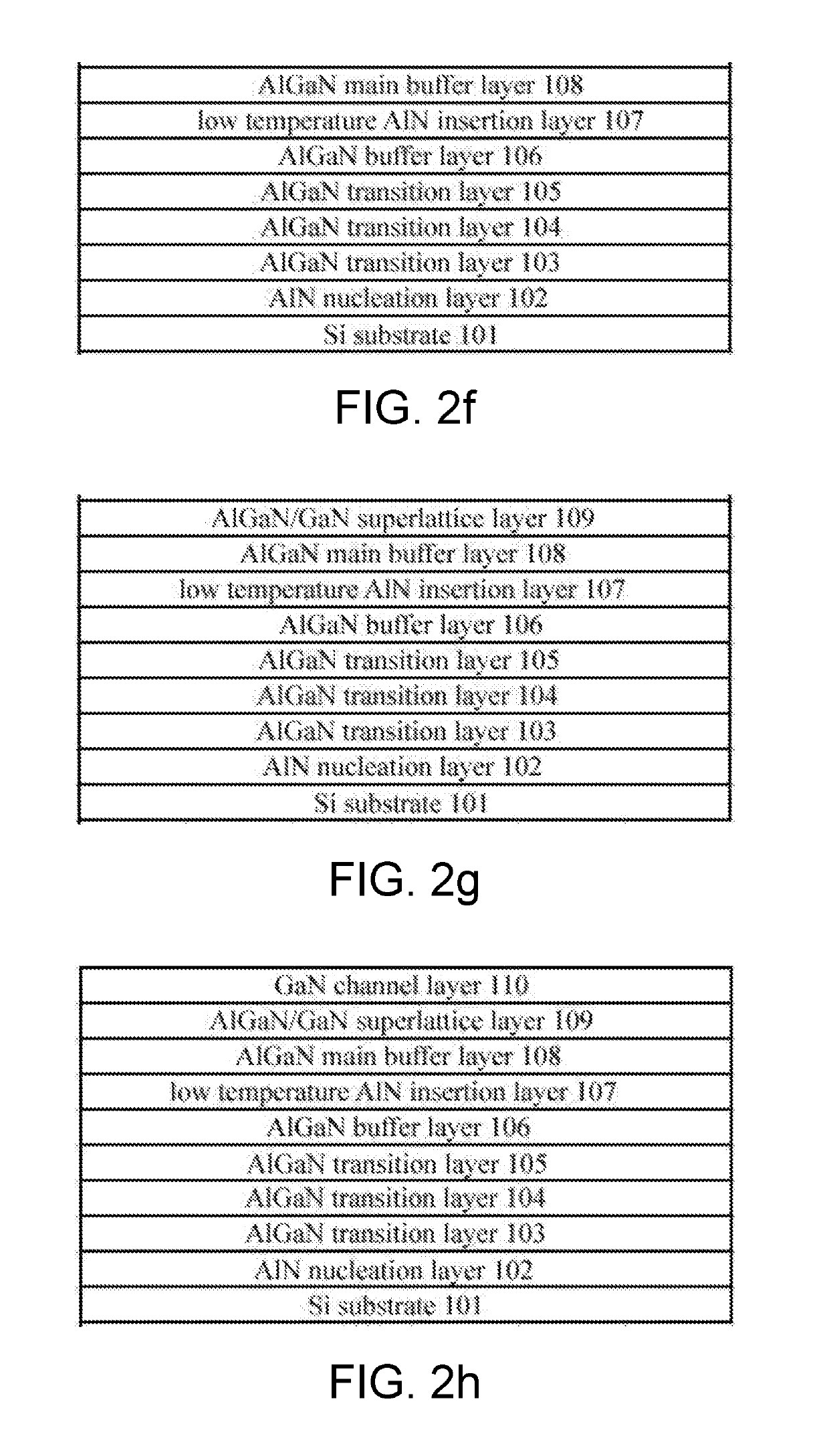

Enhancement-mode gan-based HEMT device on si substrate and manufacturing method thereof

ActiveUS20190109208A1Easy to achieve CMOS-compatibleSuppresses material failureSemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricEngineering

An enhancement-mode GaN-based HEMT device on Si substrate and a manufacturing method thereof. The device includes a Si substrate, an AlN nucleation layer, AlGaN transition layers, an AlGaN buffer layer, a low temperature AlN insertion layer, an AlGaN main buffer layer, an AlGaN / GaN superlattice layer, an GaN channel layer), and an AlGaN barrier layer. Both sides of a top end of the HEMT device are a source electrode and a drain electrode respectively, and a middle of the top end is a gate electrode. A middle of the AlGaN barrier layer is etched through to form a recess, and a bottom of the recess is connected to the GaN channel layer. A passivation protective layer and a gate dielectric layer are deposited on the bottom of the recess, and the gate electrode is located above the dielectric layer.

Owner:SOUTH CHINA UNIV OF TECH

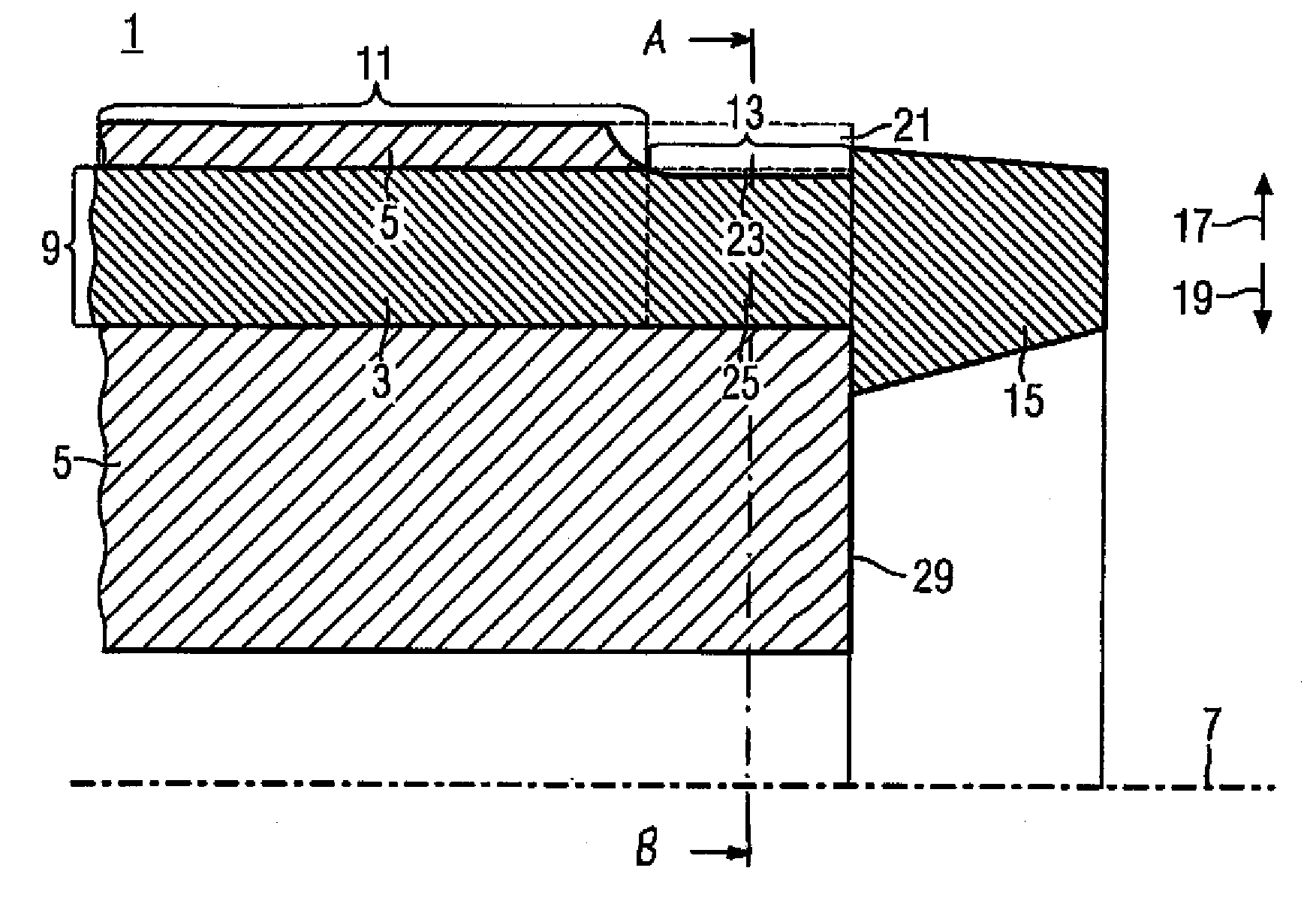

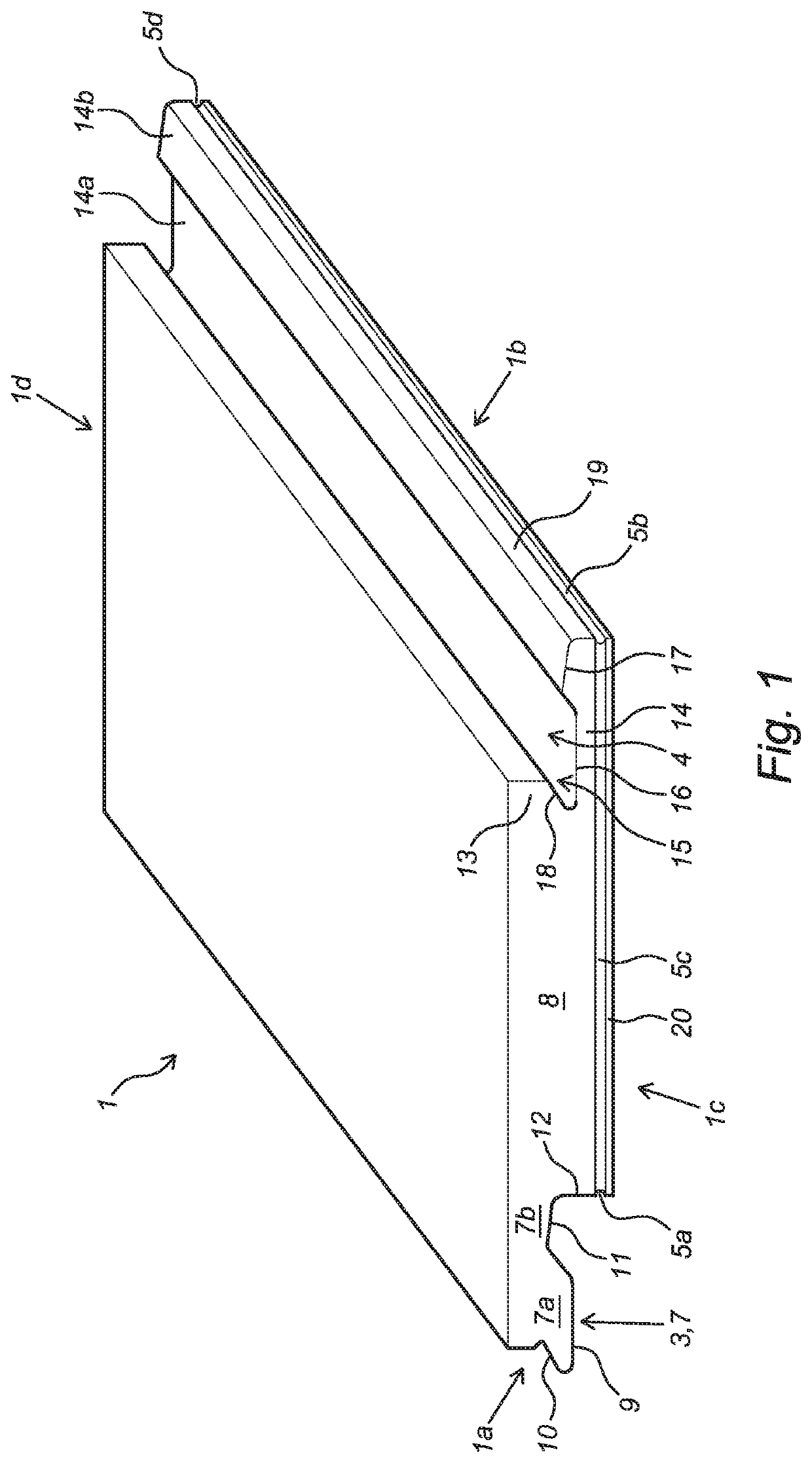

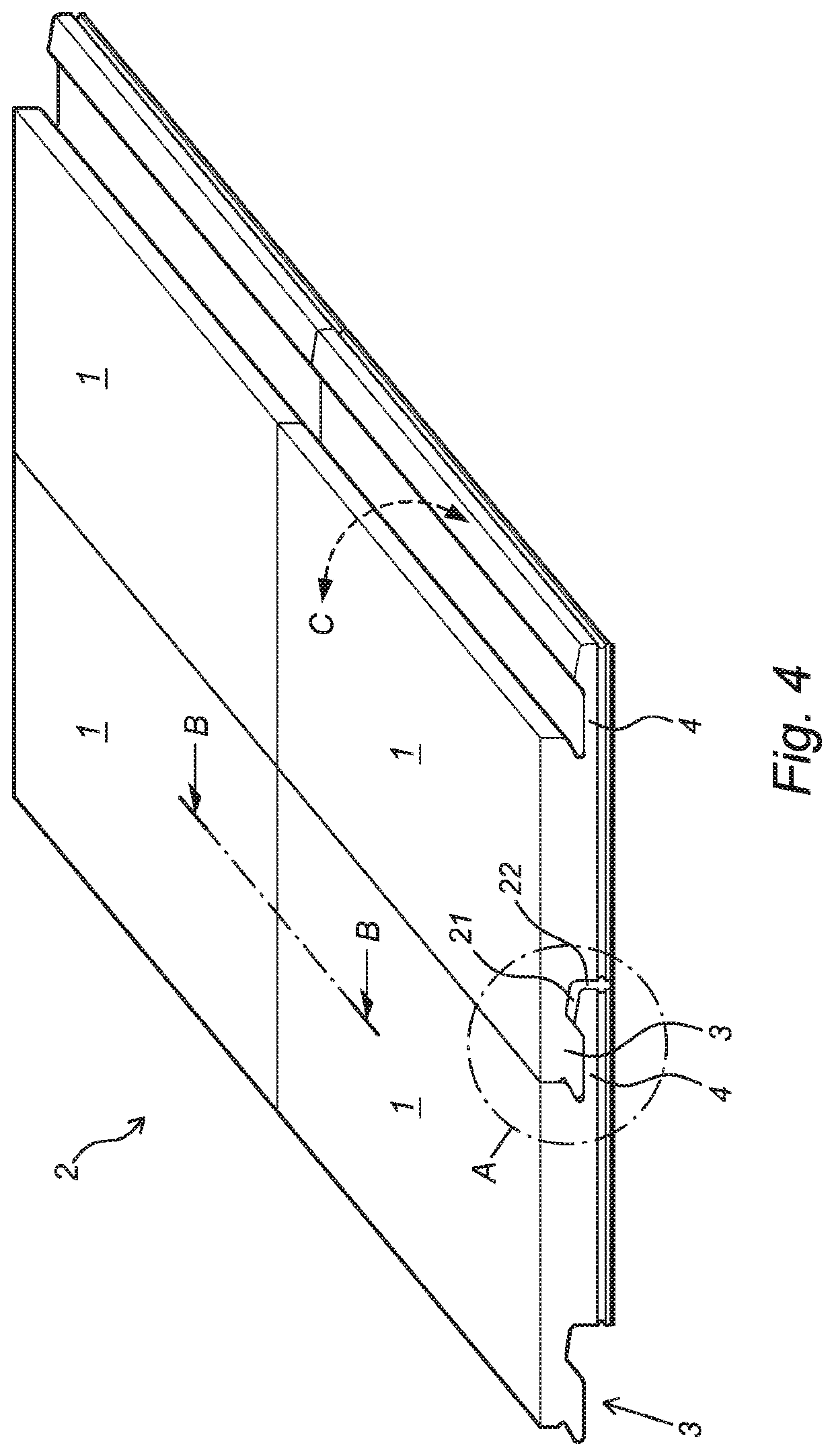

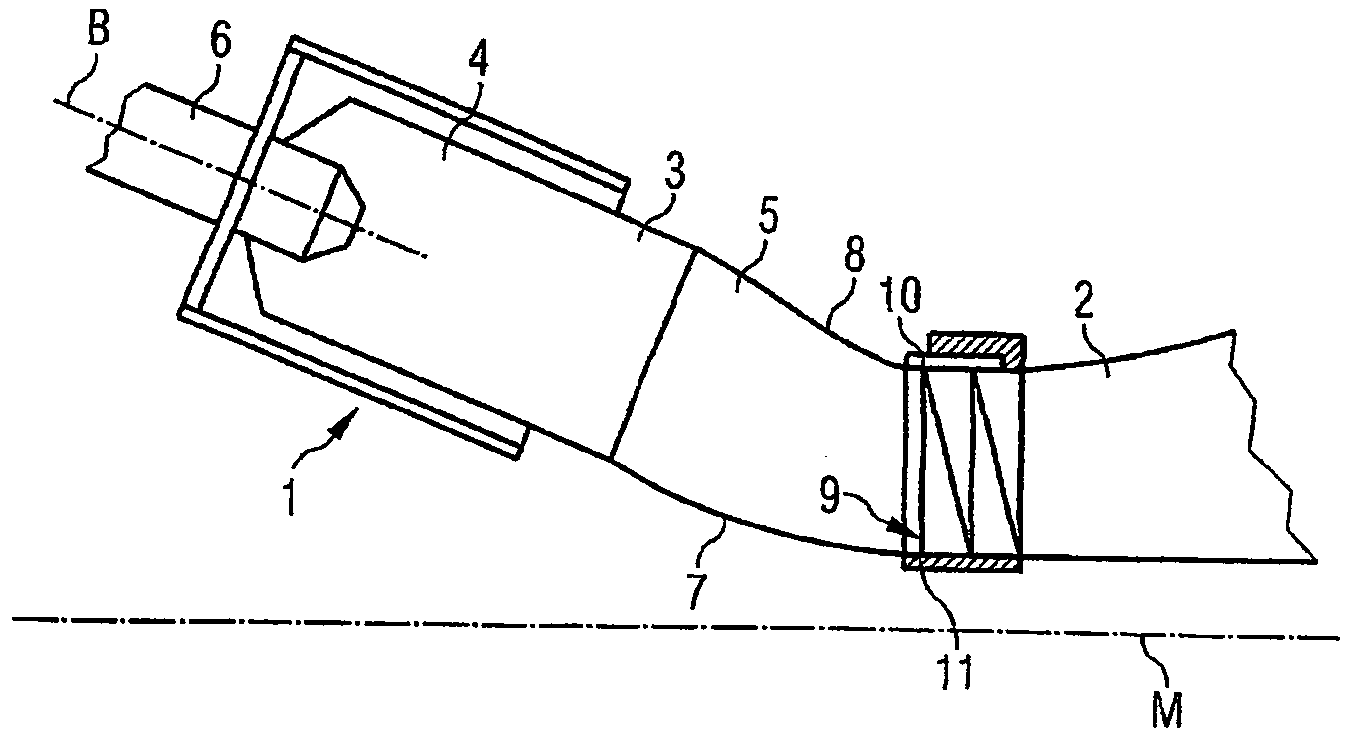

Squirrel-cage rotor

InactiveUS20070210667A1Improved squirrel-cage rotorReduce material stressSynchronous motorsStatorsElectrical conductorEngineering

A squirrel-cage rotor (1) includes squirrel-cage rotor conductors (3) and a carrier (5) for the squirrel-cage rotor conductors (3). The carrier (5) is provided with axial slots (9) in which the squirrel-cage rotor conductors (3) are accommodated. An axial slot (9) includes at least one closed slot portion (11) and an open slot portion (13), with the open slot portion (13) located between the closed slot portion (11) and a cage ring (15). In a method for producing a squirrel-cage rotor (1) having a carrier (5) for squirrel-cage rotor conductors (3), with the carrier (5) having closed slots (9), the squirrel-cage rotor conductors (3) are cast into the slots or are inserted therein as bars, whereupon carrier material is removed in the area of the end surfaces (29) of the carrier (5) in such a way that an open slot portion (13) is formed.

Owner:SIEMENS AG

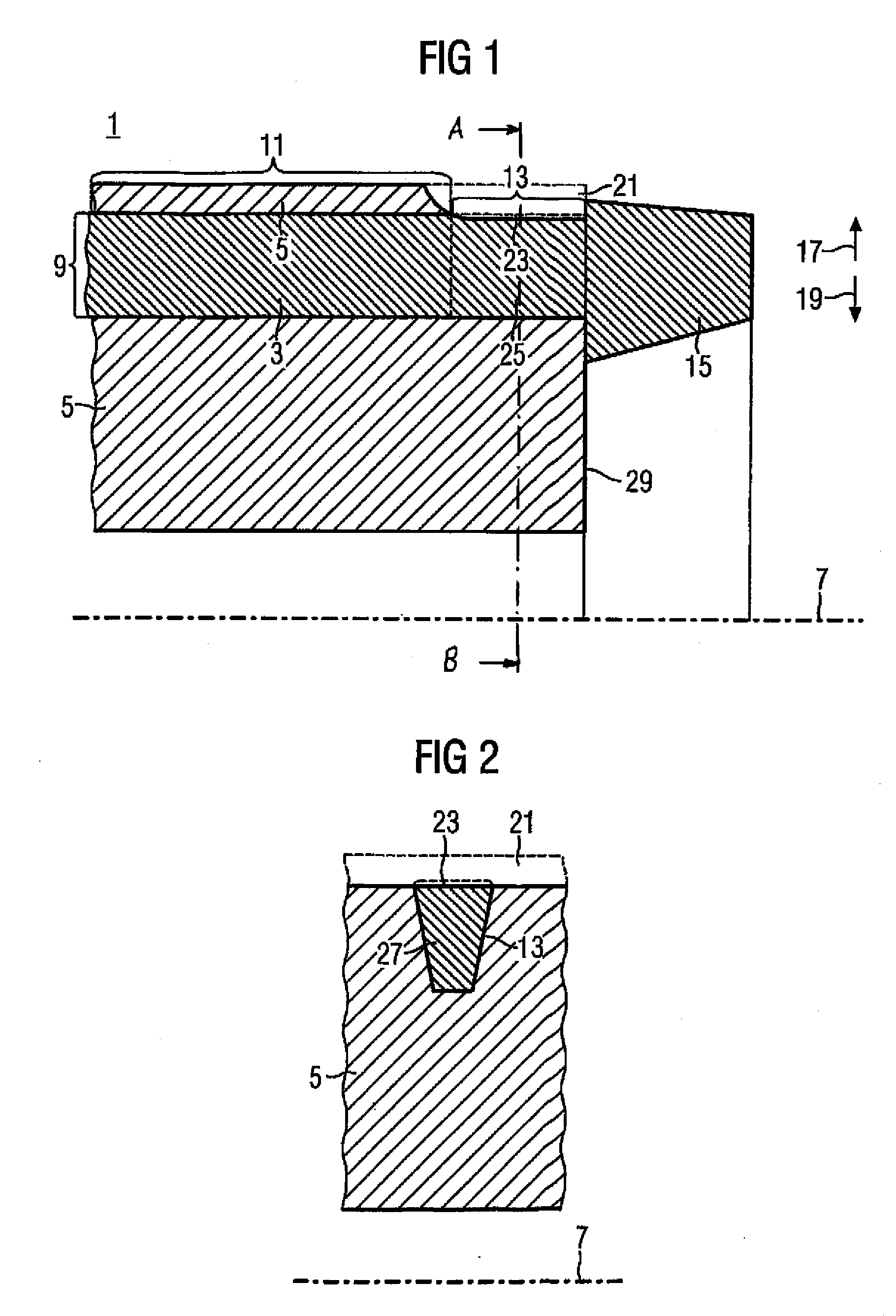

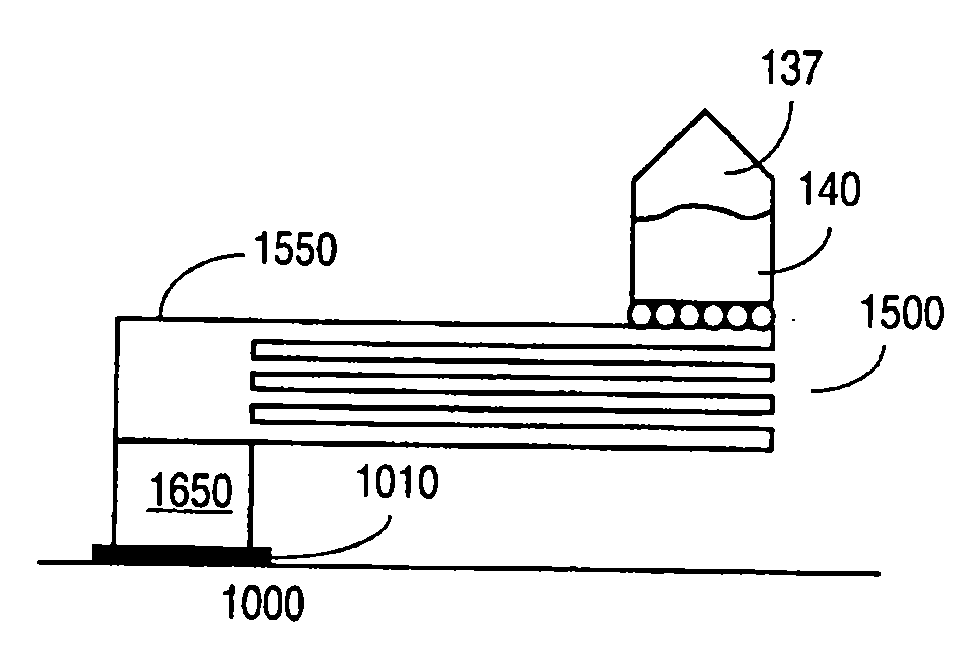

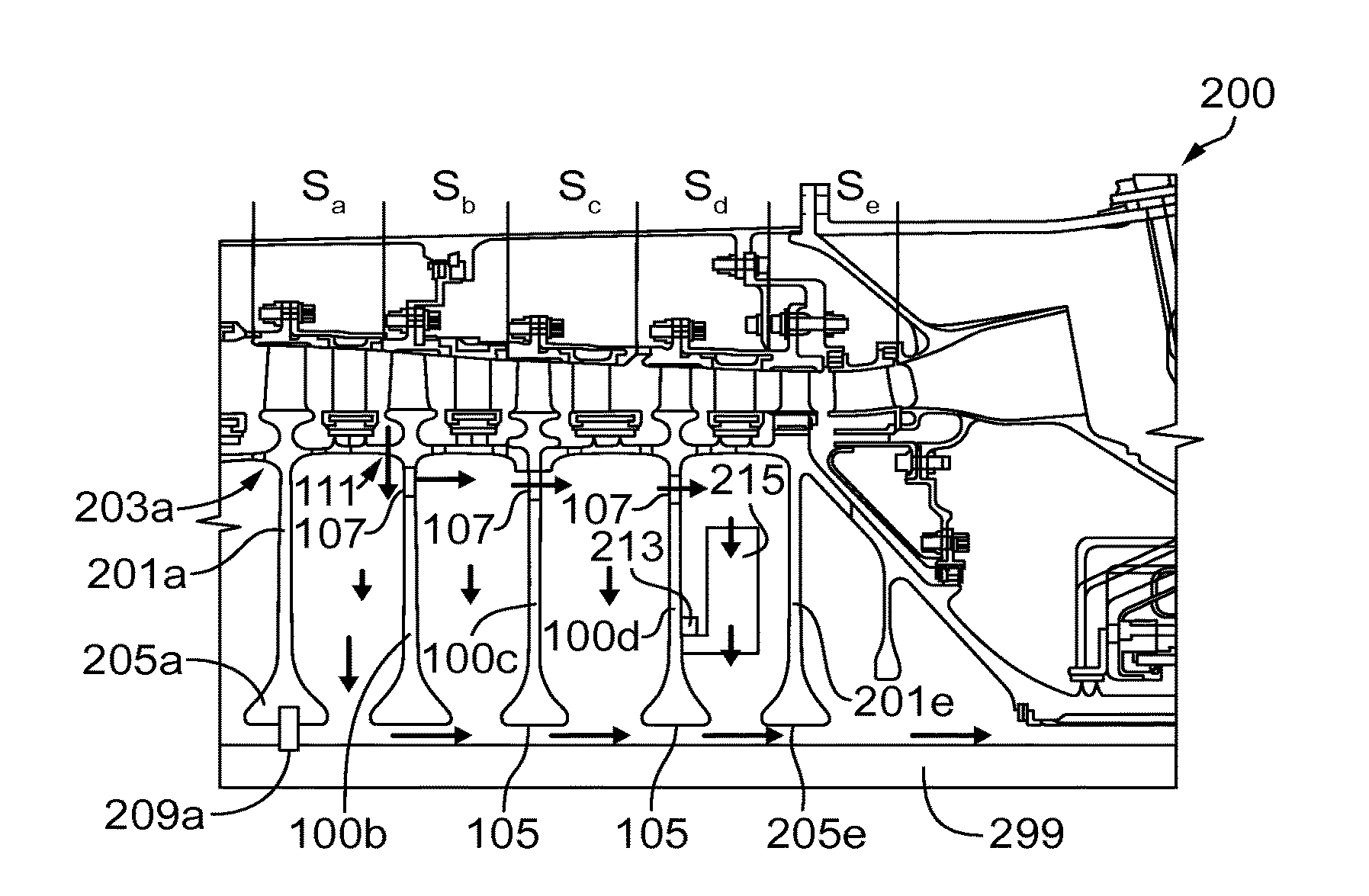

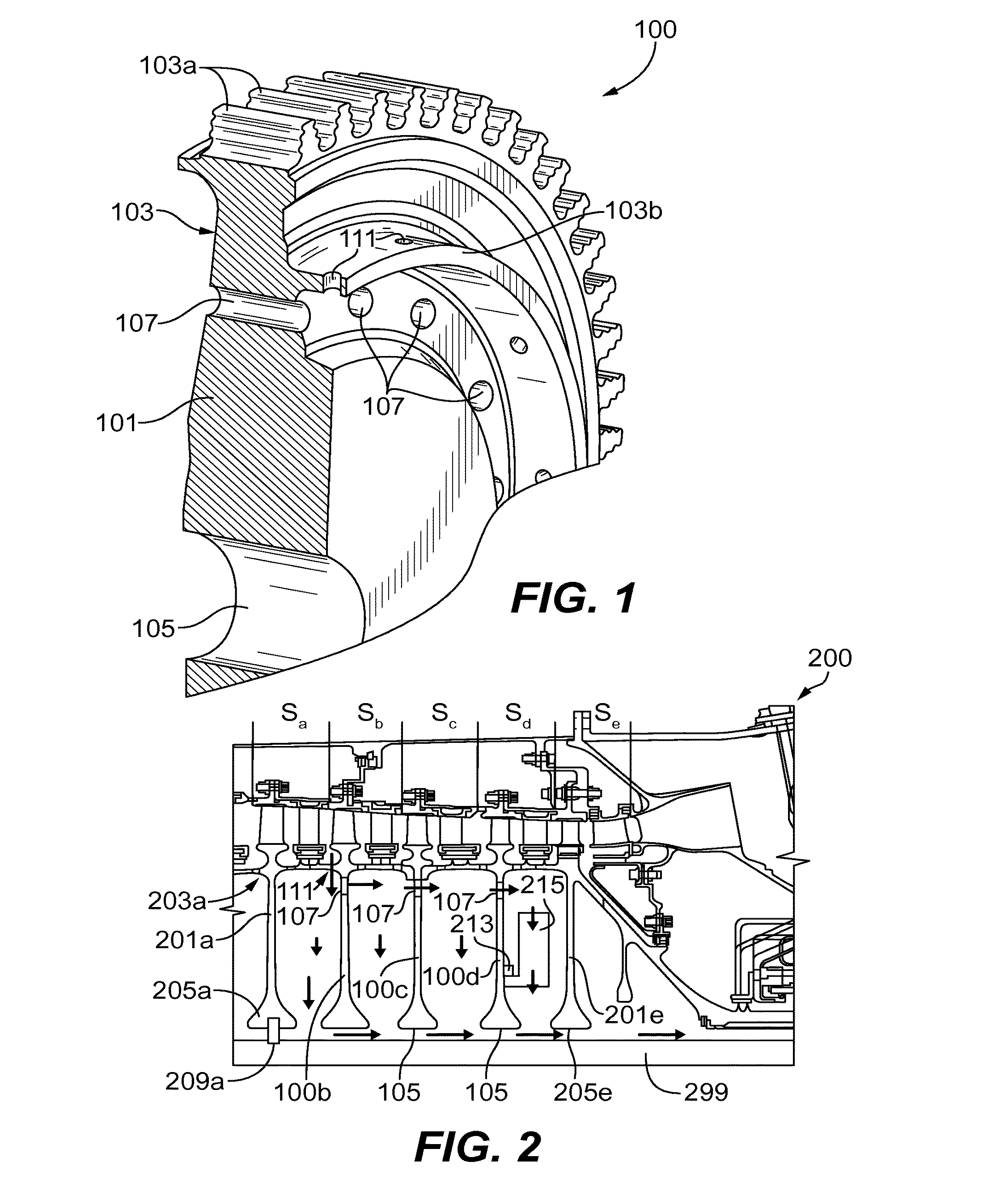

Turbomachine rotors with thermal regulation

ActiveUS10161251B2Reduce stressReduce material stressPump componentsTurbine/propulsion engine coolingEngineeringMechanical engineering

Owner:RTX CORP

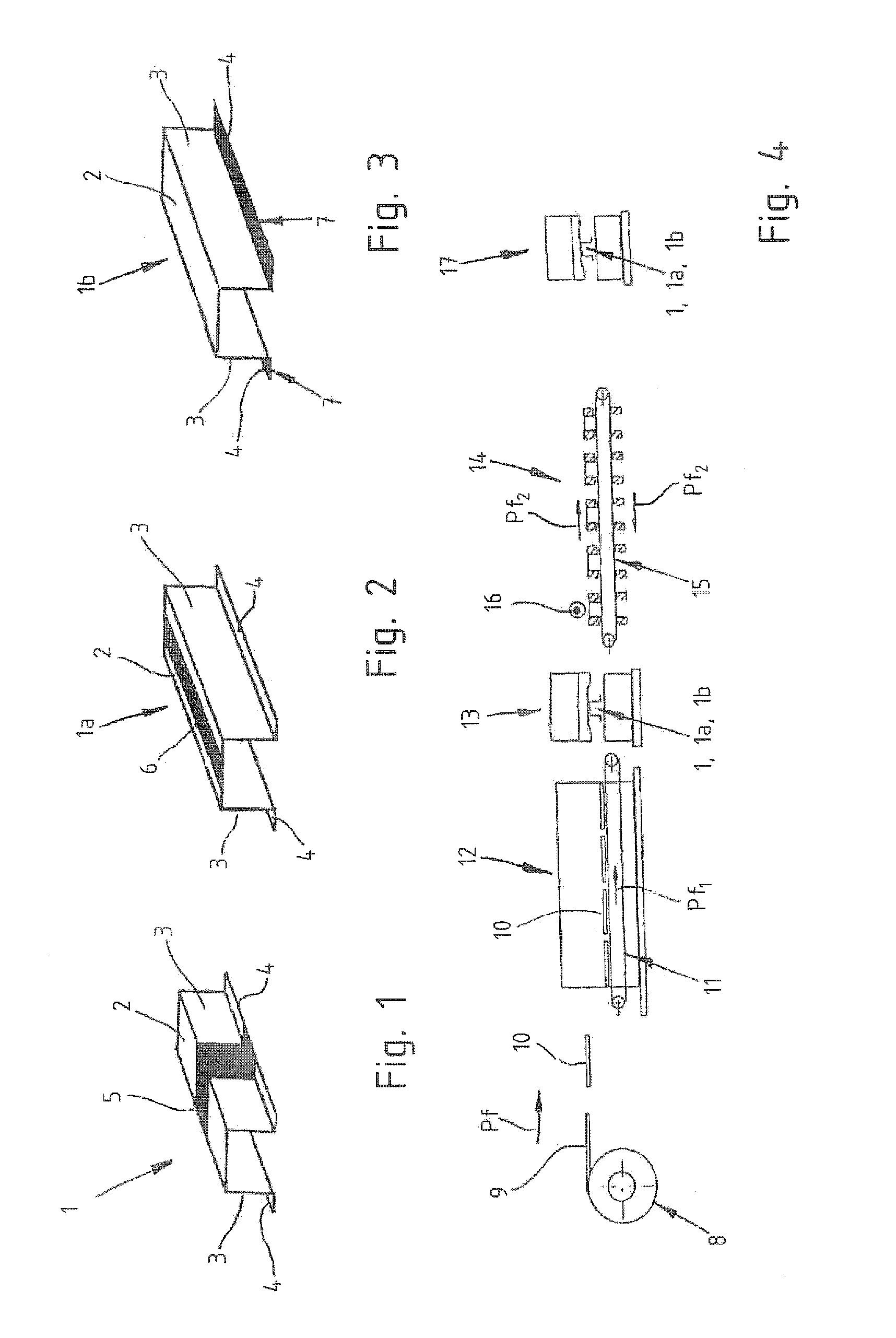

Method of making a shaped metal part for a motor vehicle component

InactiveUS20120023748A1Reduce material stressEasily malleableShaping toolsFurnace typesManganeseAlloy

In a method of making a shaped metal part for a motor vehicle component, a blank is made from a steel alloy containing, in weight percent: carbon (C) 0.18% to 0.3%, silicon (Si) 0.1% to 0.7%, manganese (Mn) 1.0% to 2.5%, phosphorus (P) maximal 0.025%, chromium (Cr) 0.1 to 0.8%, molybdenum (Mo) 0.1 to 0.5%, sulfur (S) maximal 0.01%, titanium (Ti) 0.02% to 0.05%, boron (B) 0.002% to 0.005%, aluminum (Al) 0.01% to 0.06%, balance iron and impurities resulting from smelting, The blank is heated to a temperature between 900° C. and 950° C., and formed in a press tool into a formed part which is quenched and tempered while still being in the press tool. At least one region of the formed part is then annealed to become soft by a heating operation within a time interval of less than 30 seconds to thereby provide the region with higher ductility.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

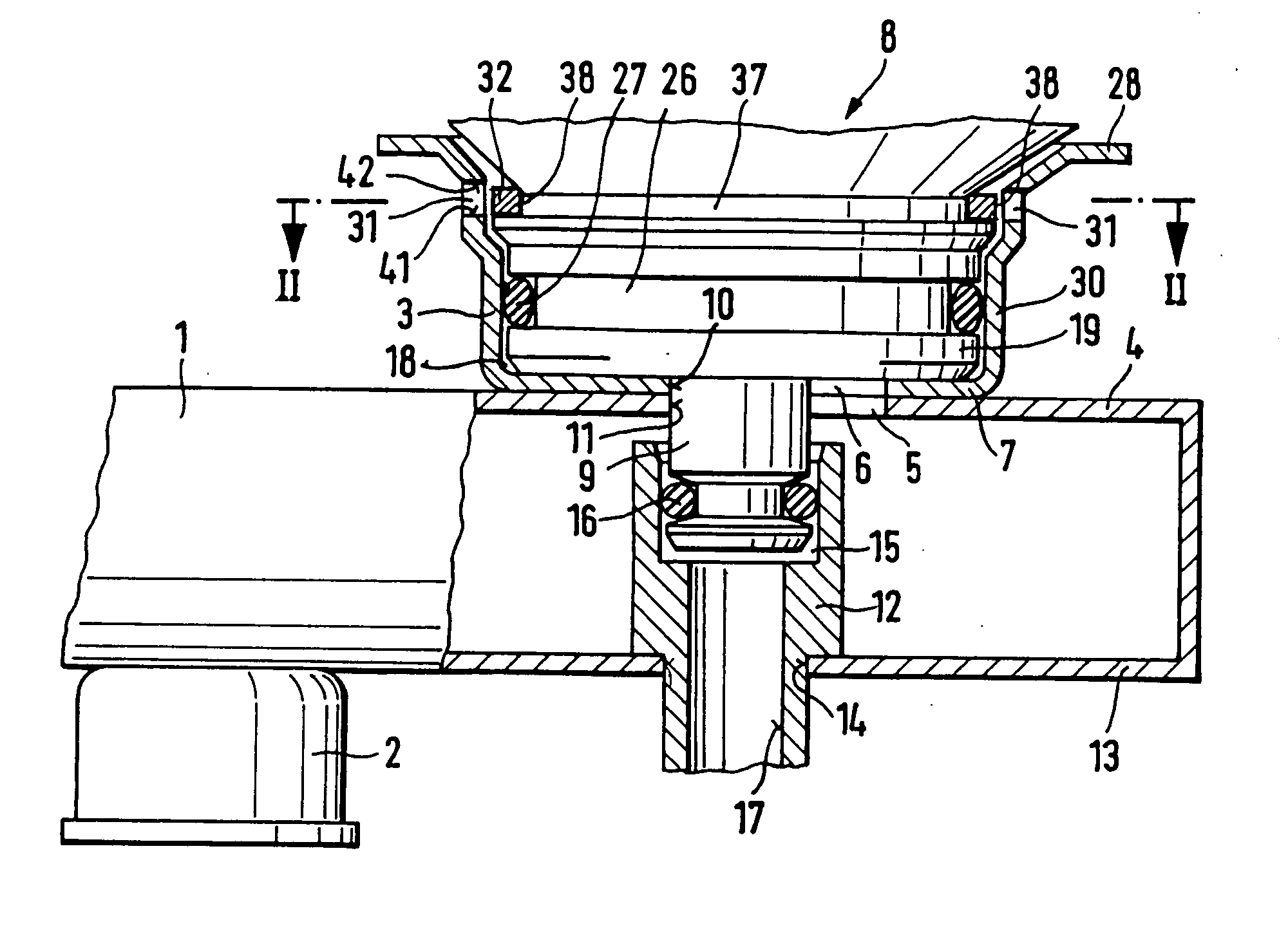

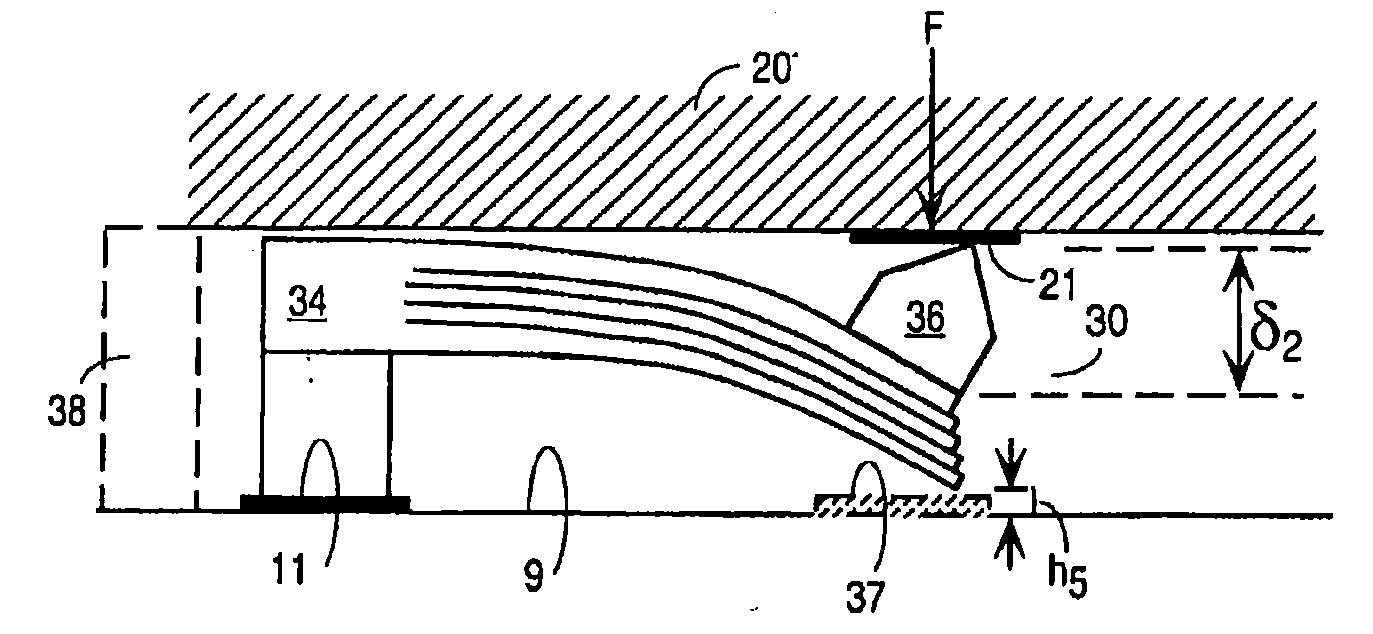

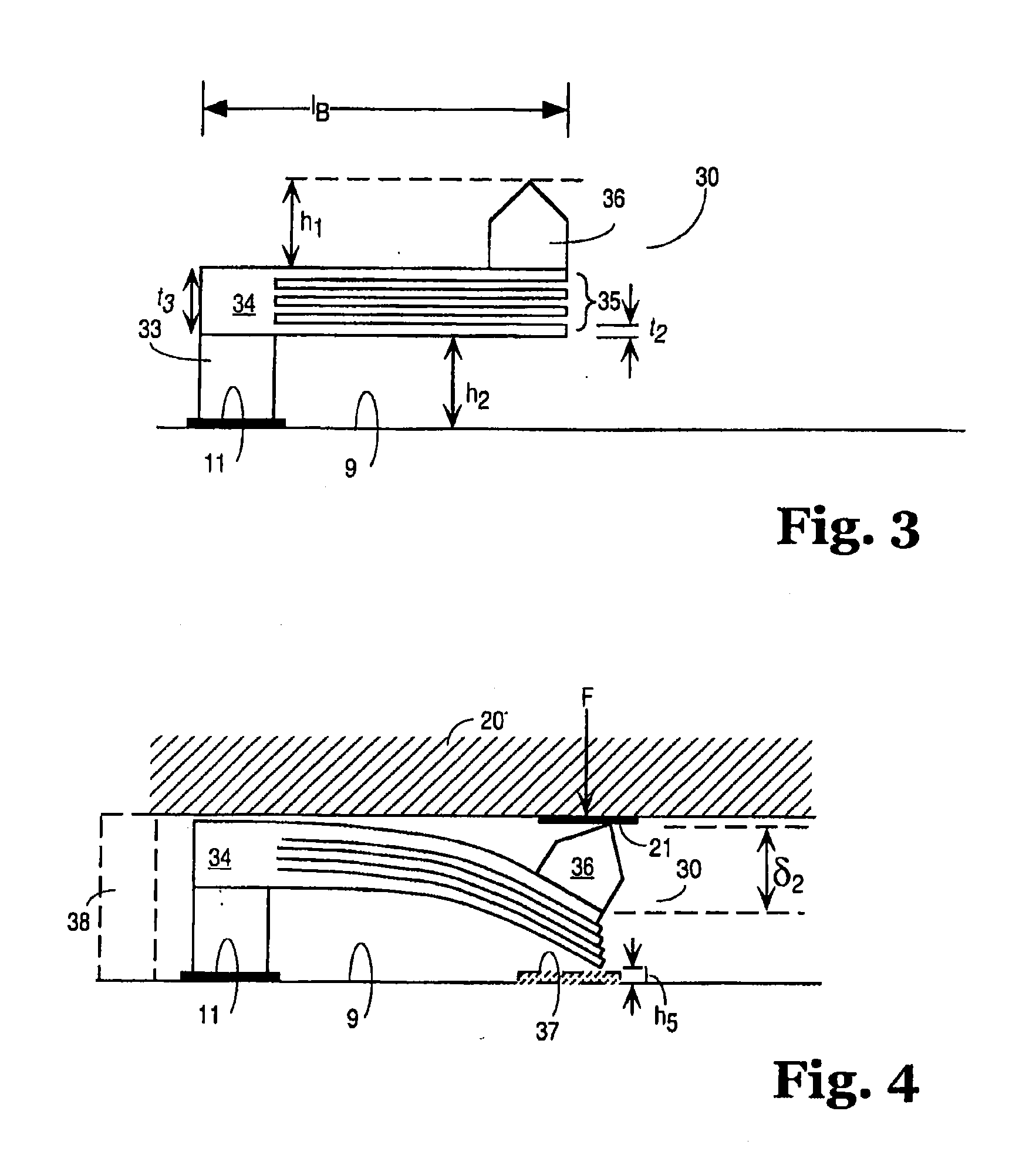

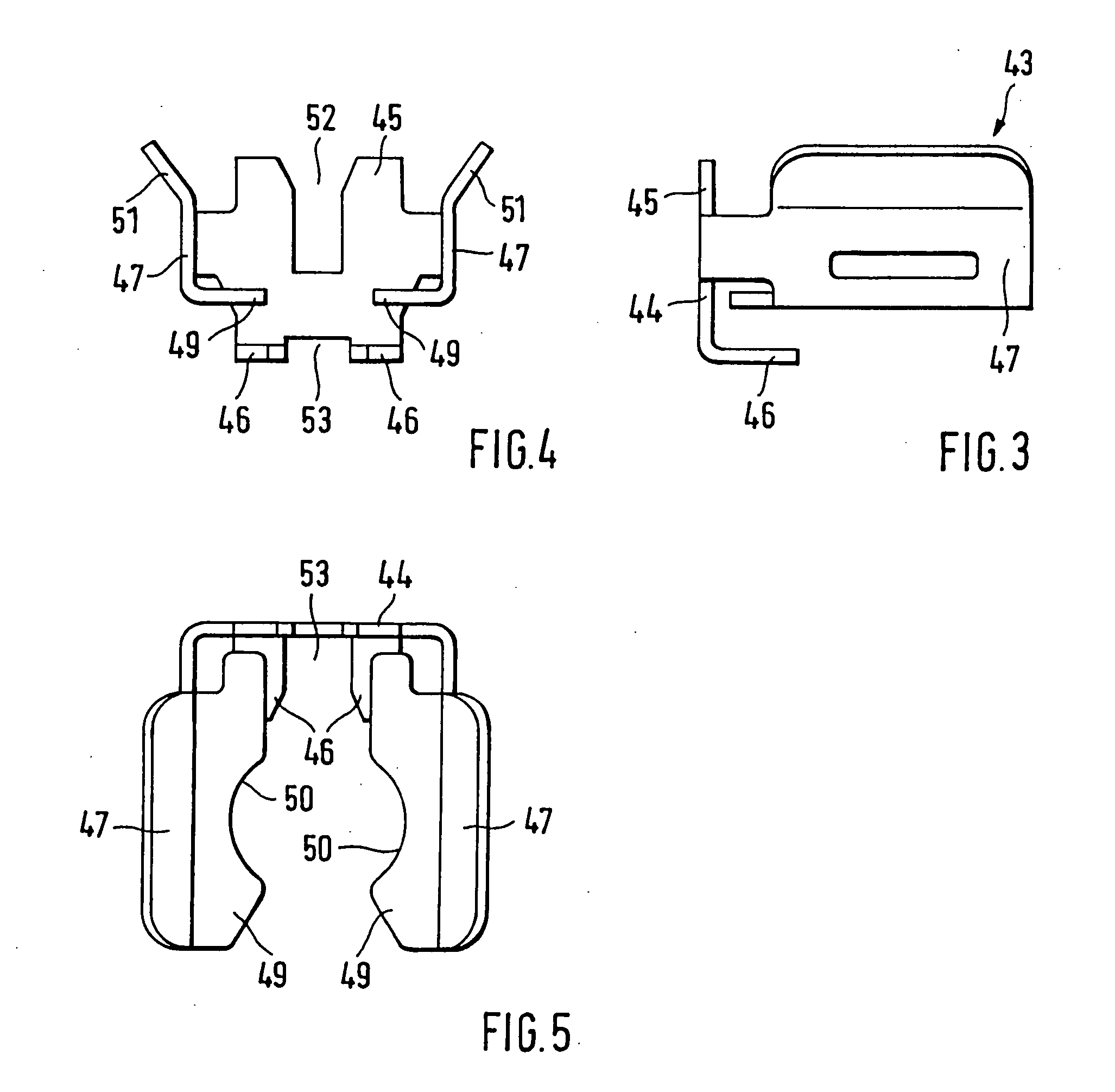

Connection by means of a retaining clip of two elements of a fuel supply system of an internal combustion engine that are coaxially disposed one behind the other

InactiveUS20040045530A1Reduce material stressAvoid electrochemical reactionsLow pressure fuel injectionMachines/enginesLine tubingEngineering

The invention relates to a connection of two coaxially in-line elements in a fuel supply system of an internal combustion engine, in which the first element is preferably a receiving bush of a fuel distributor line (1) with a guide opening, and the second element, embodied as a pressure regulating valve (8) or pressure chamber, is insertable by a guide portion (19) into the guide opening (18) of the receiving bush (3), which facing one another in a wall (30) has two retention openings (31), aligned both with one another and with a retention groove (37) in the pressure regulating valve (8), which openings a U-shaped retention clamp (32) projects through with its legs (34) and in so doing fixes the position of the first element (3) and second element (8) relative to one another, which elements, at least in the region of the retention clamp (32) have portions of stainless steel. Alternatively, the first element may be an injection valve, which is inserted by one end into a plug connection (2), forming the second element, of the fuel distributor line (1), where it is fixed by means of a securing clamp, and the injection valve and the plug connection (2), at least in the region of the securing clamp, have portions of stainless steel. The invention provides that the retention clamp (32) is formed by a spring wire and the securing clamp is formed of a spring band of stainless steel, in order to prevent contact corrosion.

Owner:ROBERT BOSCH GMBH

Spring interconnect structures

InactiveUS20090263986A1Increase the spring constantImprove mechanical propertiesCoupling device connectionsSemiconductor/solid-state device testing/measurementInterconnectionSemiconductor

An interconnection element of a spring (body) including a first resilient element with a first contact region and a second contact region and a first securing region and a second resilient element, with a third contact region and a second securing region. The second resilient element is coupled to the first resilient element through respective securing regions and positioned such that upon sufficient displacement of the first contact region toward the second resilient element, the second contact region will contact the third contact region. The interconnection, in one aspect, is of a size suitable for directly contacting a semiconductor device. A large substrate with a plurality of such interconnection elements can be used as a wafer-level contactor. The interconnection element, in another aspect, is of a size suitable for contacting a packaged semiconductor device, such as in an LGA package.

Owner:FORMFACTOR INC

Connection of two coaxially in-line elements in a fuel supply system of an internal combustion engine

InactiveUS20060124110A1Reduce material stressSmall radiusLow-pressure fuel injectionMachines/enginesEngineeringInternal combustion engine

The invention relates to a connection of two coaxially in-line elements in a fuel supply system of an internal combustion engine, in which the first element is preferably a receiving bush of a fuel distributor line with a guide opening, and the second element, embodied as a pressure regulating valve or pressure chamber, is insertable by a guide portion into the guide opening of the receiving bush, which facing one another in a wall has two retention openings, aligned both with one another and with a retention groove in the pressure regulating valve, which openings a U-shaped retention clamp projects through with its legs and in so doing fixes the position of the first element and second element relative to one another, which elements, at least in the region of the retention clamp have portions of stainless steel. Alternatively, the first element may be an injection valve, which is inserted by one end into a plug connection, forming the second element, of the fuel distributor line, where it is fixed by means of a securing clamp, and the injection valve and the plug connection, at least in the region of the securing clamp, have portions of stainless steel. The invention provides that the retention clamp is formed by a spring wire and the securing clamp is formed of a spring band of stainless steel, in order to prevent contact corrosion.

Owner:SCHOEFFLER JOCHEN

Semiconductor light emitting device substrate and method of fabricating the same

InactiveUS20070290188A1Improve light emission efficiencyEnhanced glowSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor materialsSingle crystal

A substrate for semiconductor light emitting devices is provided. The substrate is characterized in that the substrate is a single crystal material and has a nanocrystal structure capable of diffracting an electromagnetic wave. The nanocrystal structure is disposed on a surface portion of the substrate and includes an etched region and an unetched region, wherein the etched region has a depth of 10-200 nm. Due to the periodicity of the nanocrystal structure, the semiconductor material grown on the substrate has fewer defects, and the material stress is reduced.

Owner:IND TECH RES INST

Spring interconnect structures

InactiveUS20080254651A1Minimized pitchImprove mechanical propertiesCoupling device connectionsSemiconductor/solid-state device testing/measurementInterconnectionSemiconductor

An interconnection element of a spring (body) including a first resilient element with a first contact region and a second contact region and a first securing region and a second resilient element, with a third contact region and a second securing region. The second resilient element is coupled to the first resilient element through respective securing regions and positioned such that upon sufficient displacement of the first contact region toward the second resilient element, the second contact region will contact the third contact region. The interconnection, in one aspect, is of a size suitable for directly contacting a semiconductor device. A large substrate with a plurality of such interconnection elements can be used as a wafer-level contactor. The interconnection element, in another aspect, is of a size suitable for contacting a packaged semiconductor device, such as in an LGA package.

Owner:FORMFACTOR INC

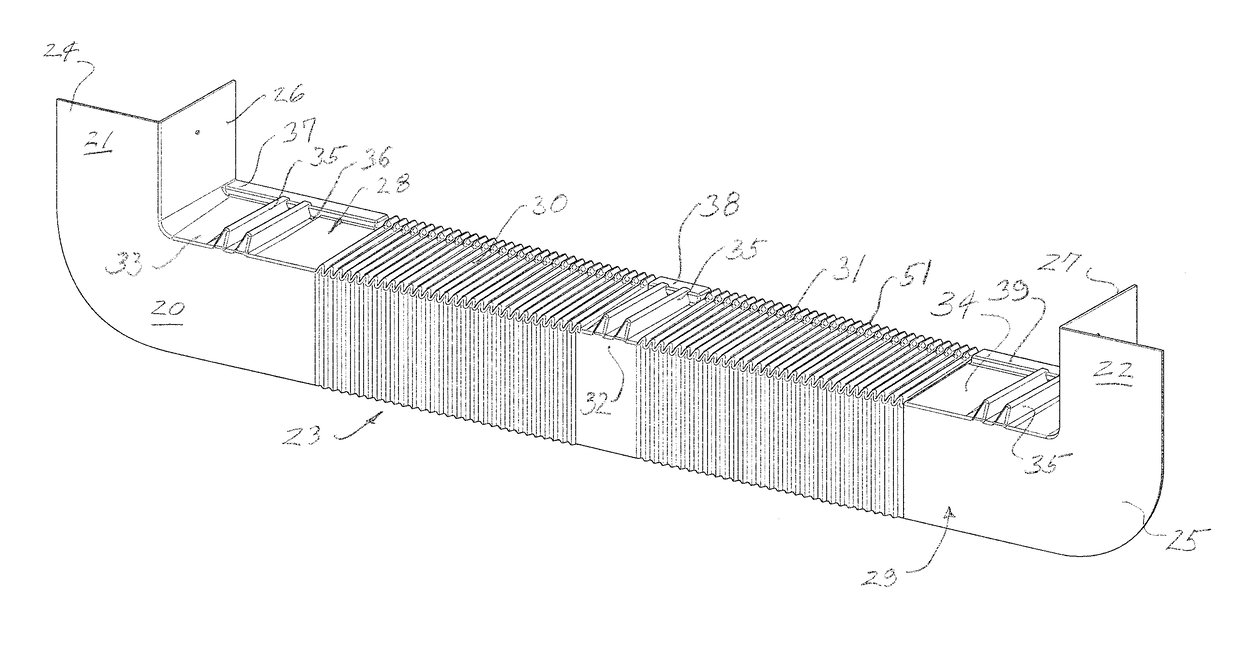

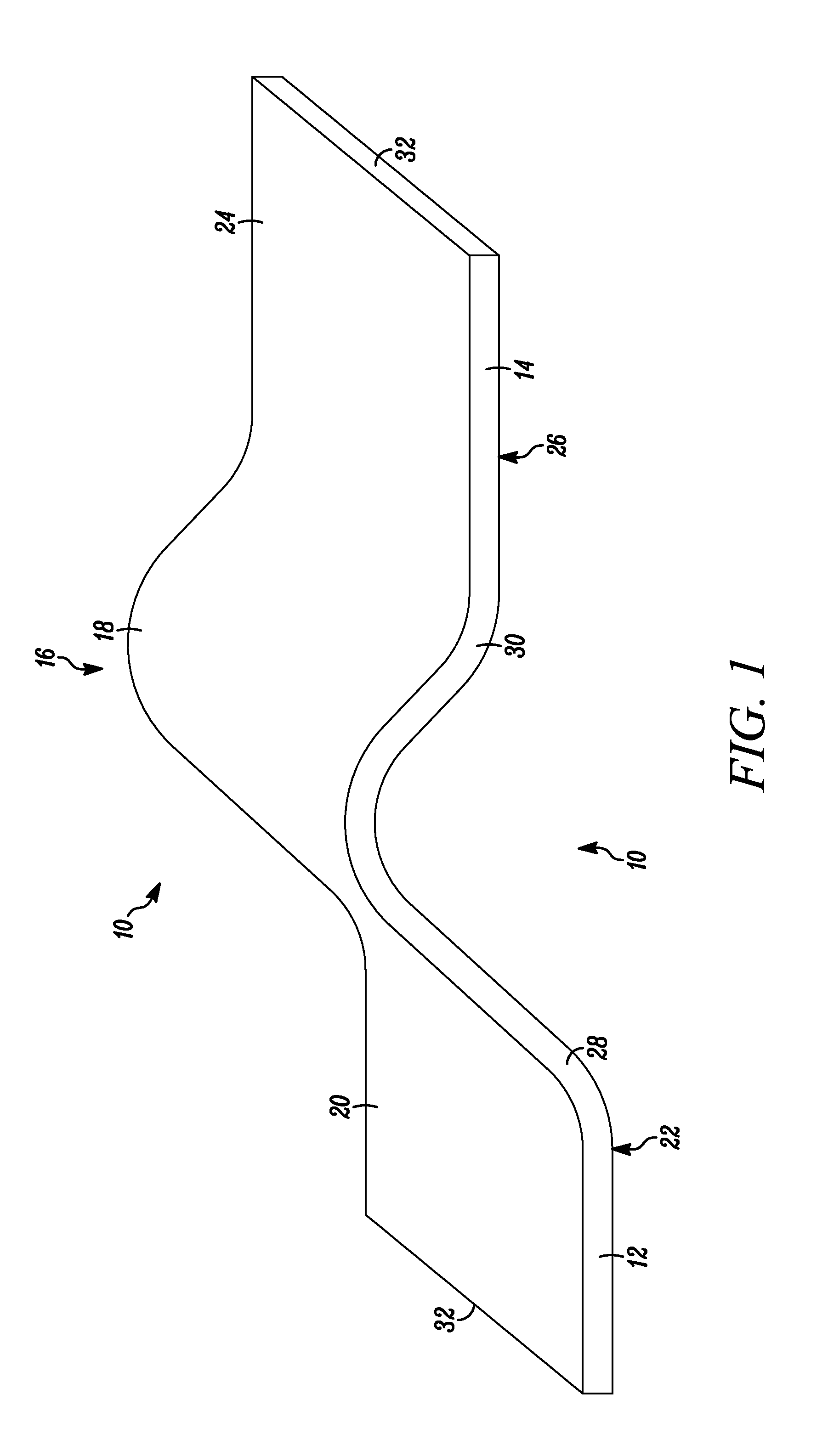

One-piece sill pan flashing

ActiveUS10024097B1Small inventoryStorage space is still occupiedCorner/edge jointsSills/thresholdWindow openingEngineering

A one-piece sill pan flashing is provided with one or more accordion sections. At least the accordion sections, and preferably the entire flashings, are formed of a single sheet of thermoplastic material, preferably by thermoforming, and include forwardly and downwardly inclined upper portions and vertical lower portions extending downward from the front of the upper portions. The accordion sections include upper and lower portions, formed of narrow panels, foldably connected along their lateral edges to form V-shaped accordion folds having a series of ridge folds and valley folds. The valley folds of the upper portions are aligned with the ridge folds of the lower portions and vice versa. The construction accommodates substantial extension or compression of the width of the flashing and enables one size of flashing width to be fitted to a wide range of sizes of rough-framed window openings.

Owner:SILL DRY IND LLC

Turbomachine rotors with thermal regulation

ActiveUS20160076378A1Reduce material stressReduce stressPropellersPump componentsEngineeringMechanical engineering

Owner:RAYTHEON TECH CORP

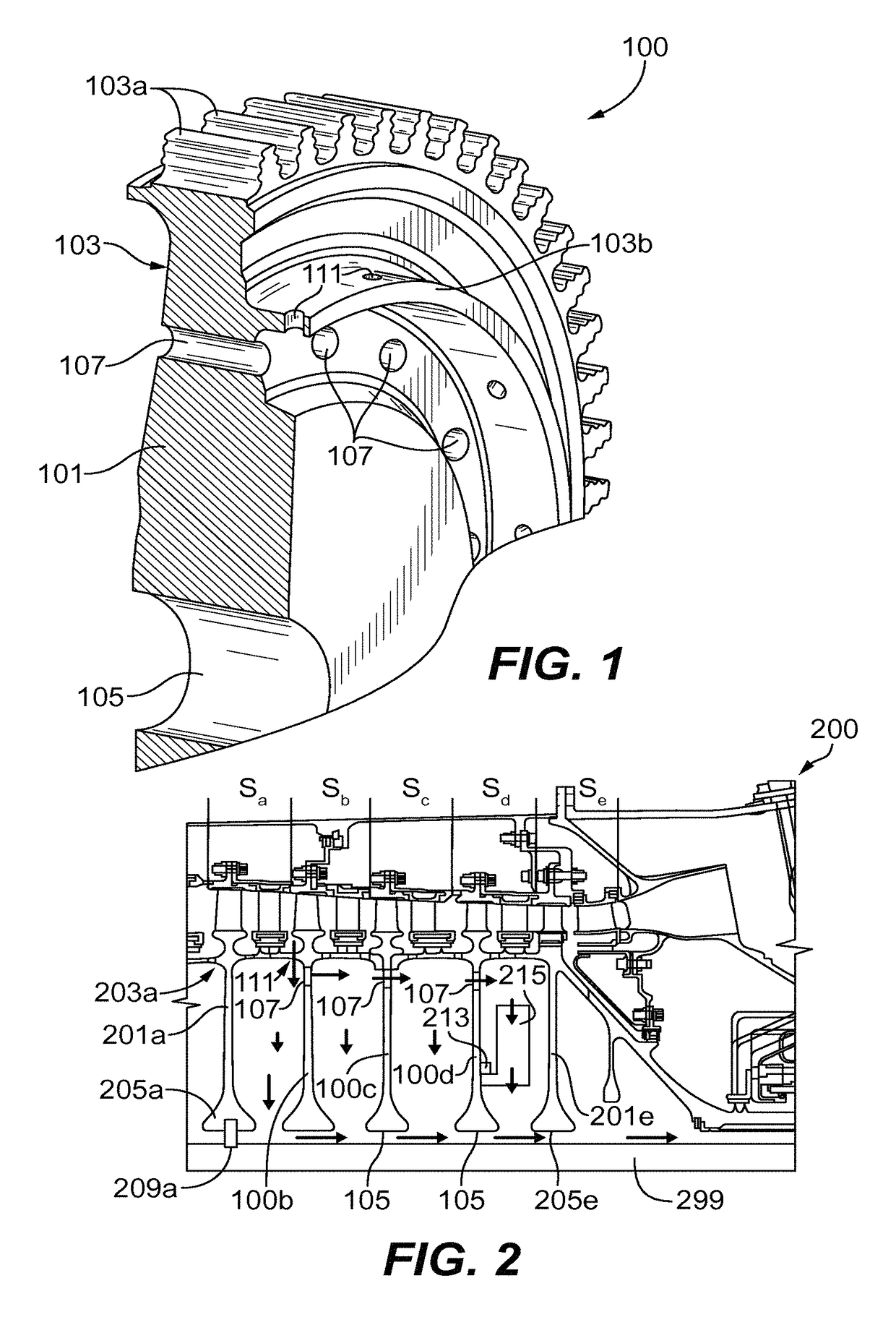

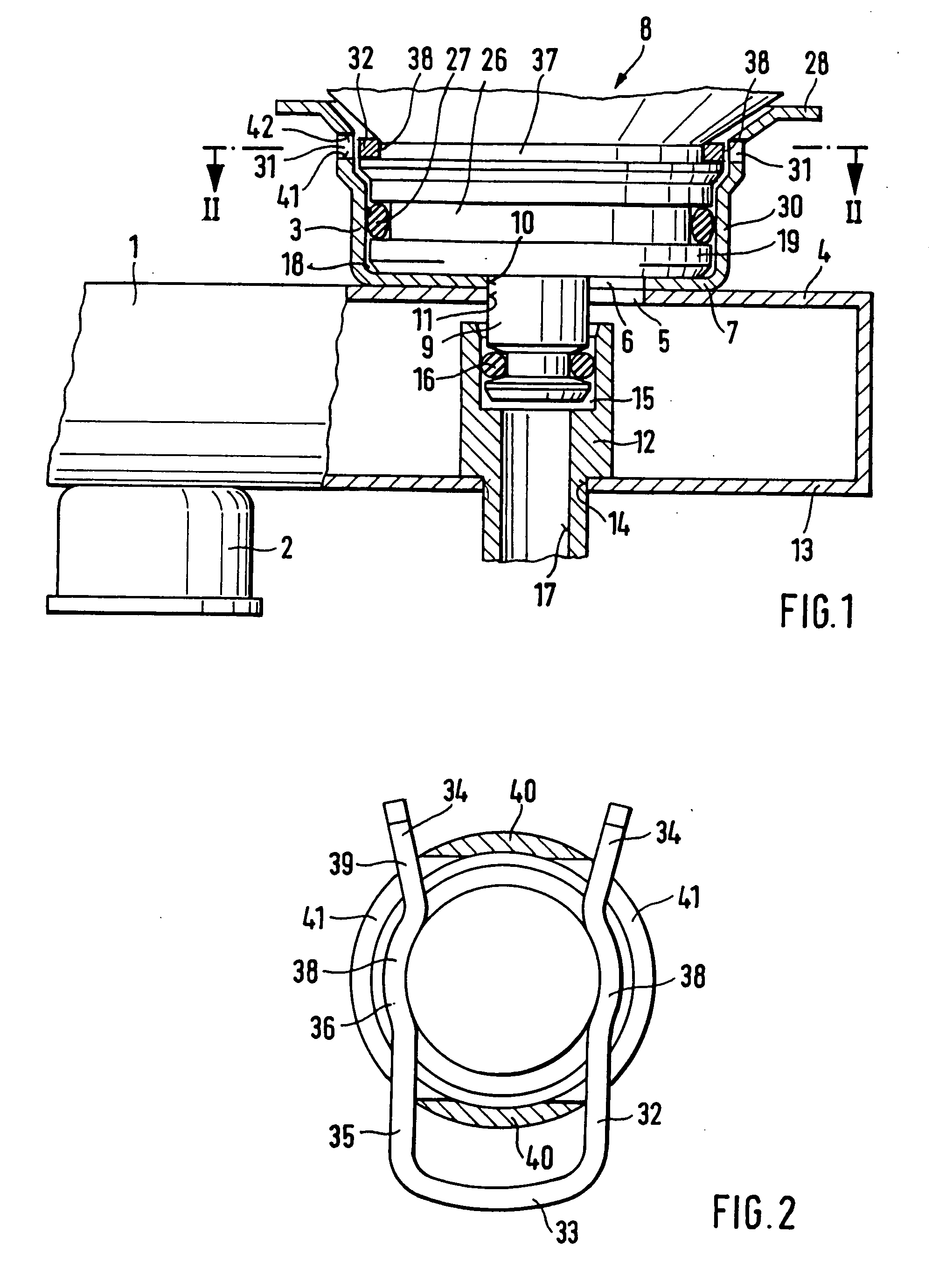

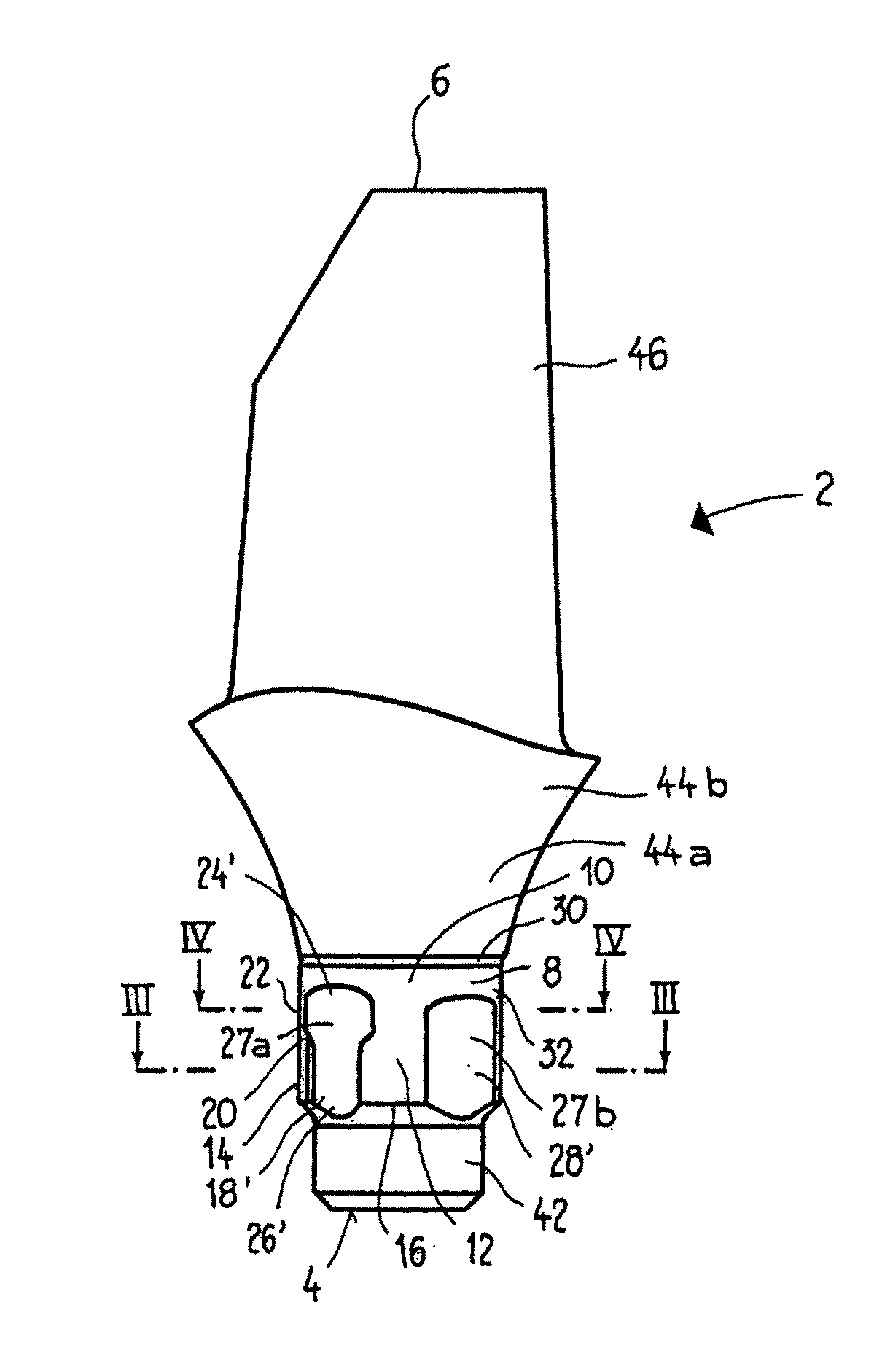

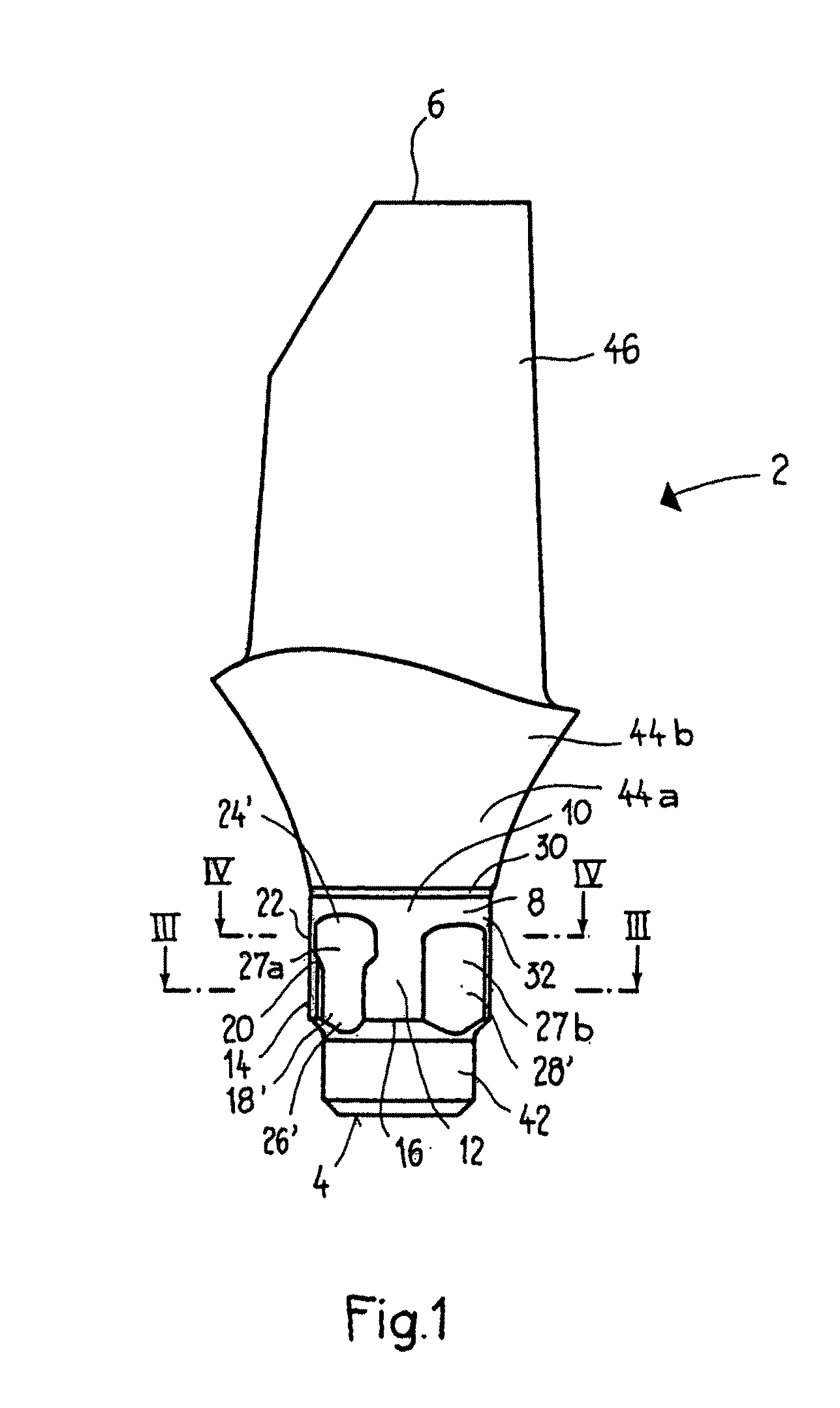

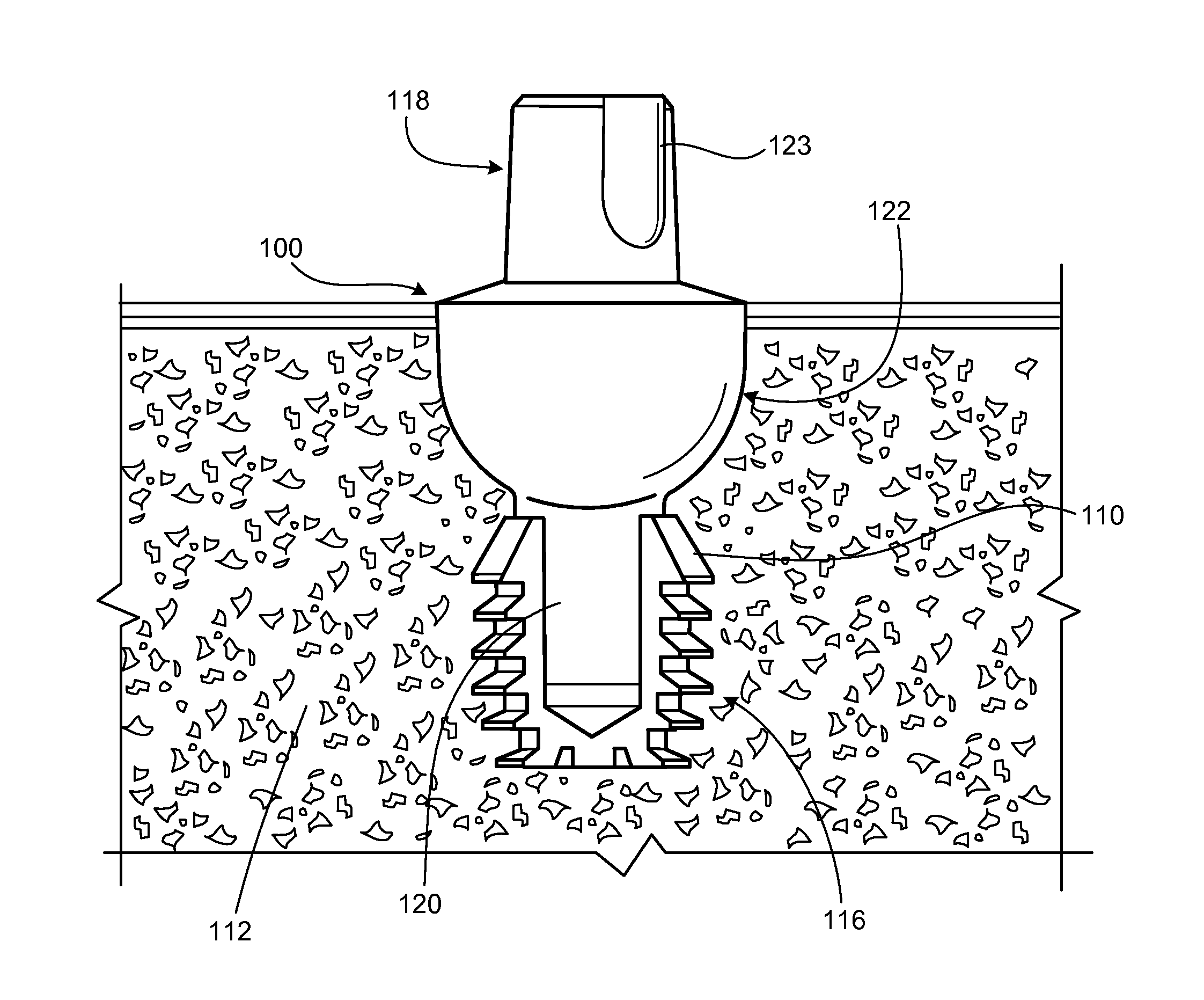

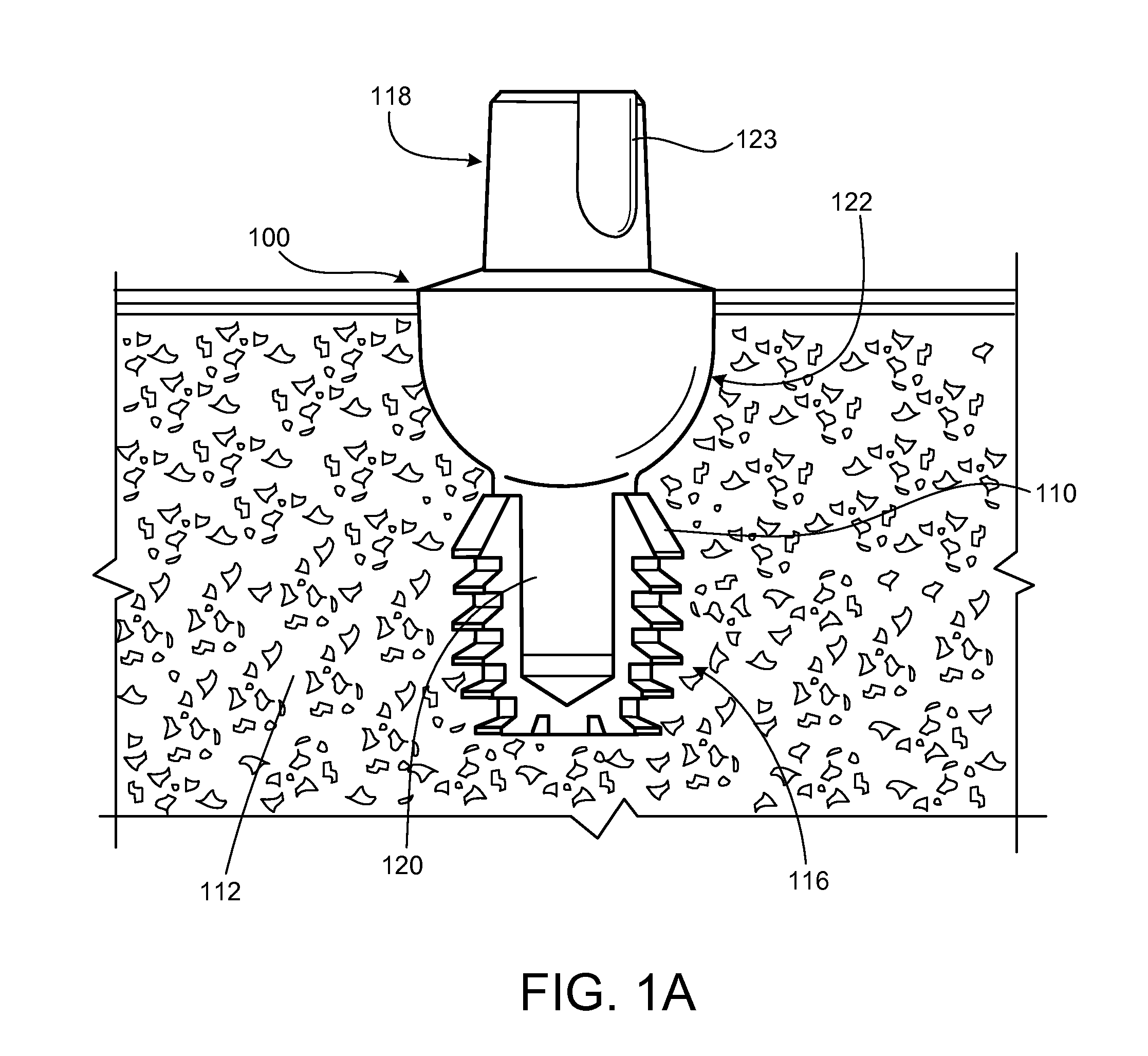

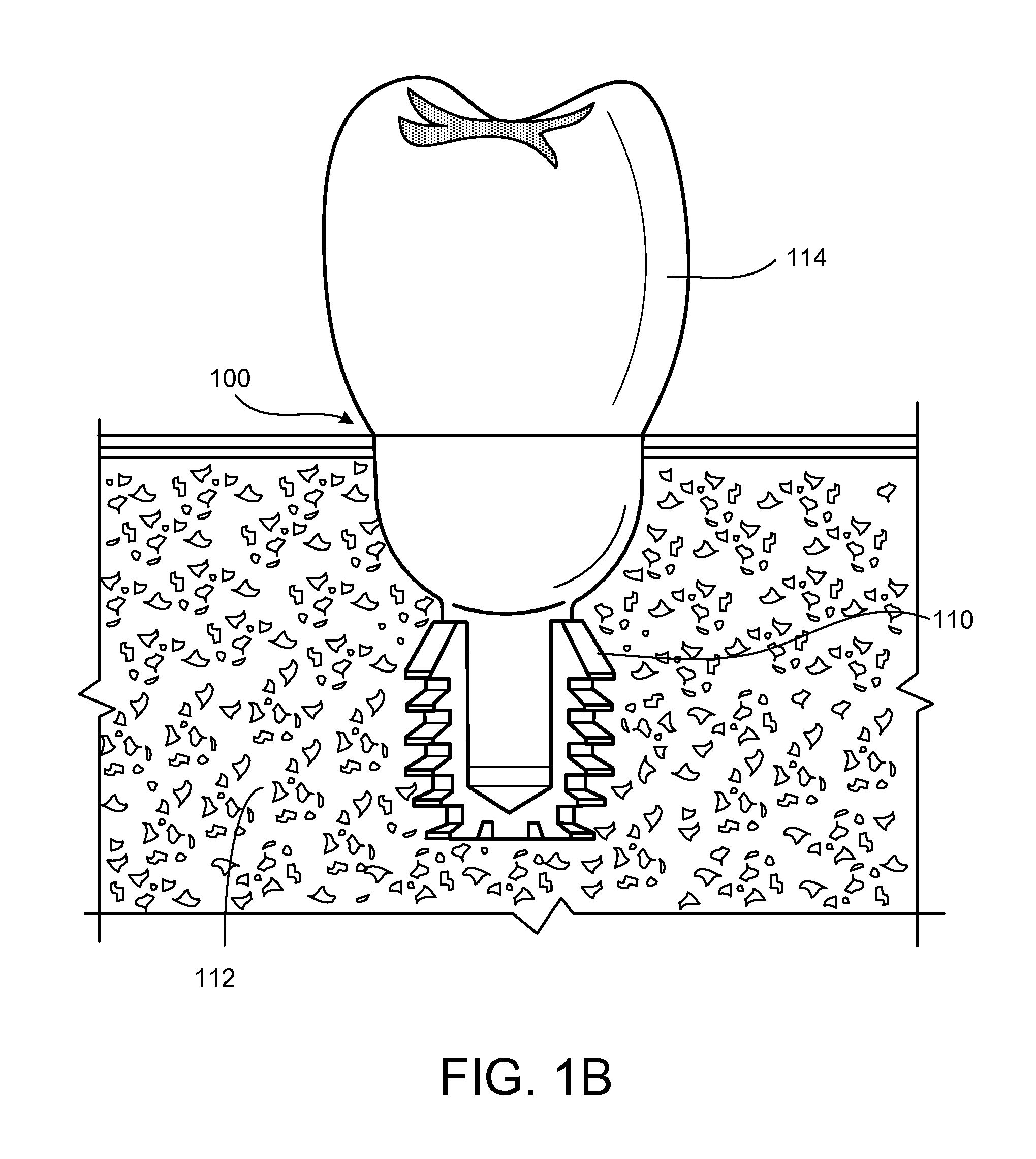

Abutment for a dental implant

InactiveUS20110306013A1Reduce material stressDental implantsFastening prosthesisBiomedical engineeringDental implant

Abutment for a dental implant (50), with an apical end (4) and with a coronal end (6) arranged opposite the apical end in the longitudinal direction. In the area of the apical end (4), the abutment has an insert portion (8) which is designed to be received by an opening of the dental implant and which has an anti-rotation segment (10) comprising at least one anti-rotation element (27) which is designed to cooperate with a corresponding mating anti-rotation element (53) of the dental implant (50). The anti-rotation element (27) comprises a groove (18′, 18″) which, from the edge of the anti-rotation segment (10) directed toward the apical end (4), extends in the coronal longitudinal direction along a groove portion (14) with a substantially constant groove width. The invention is characterized in that the groove (18′, 18″) is continuously widened in a transition portion (20) adjoining the groove portion (14), in order to merge into a bevel (24′, 24″) in a bevel portion (22) adjoining the transition portion (20).

Owner:IVOCLAR VIVADENT AG

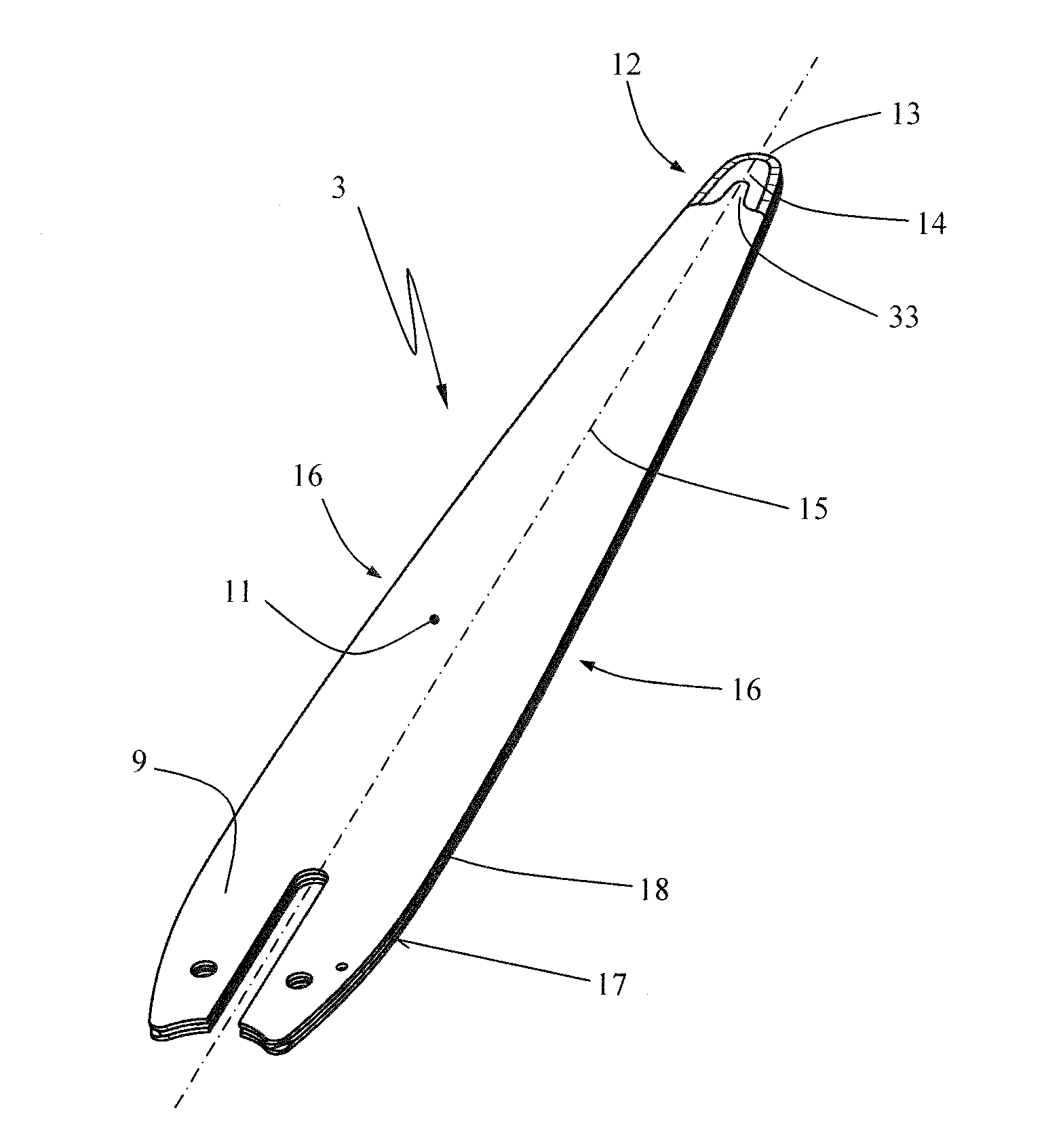

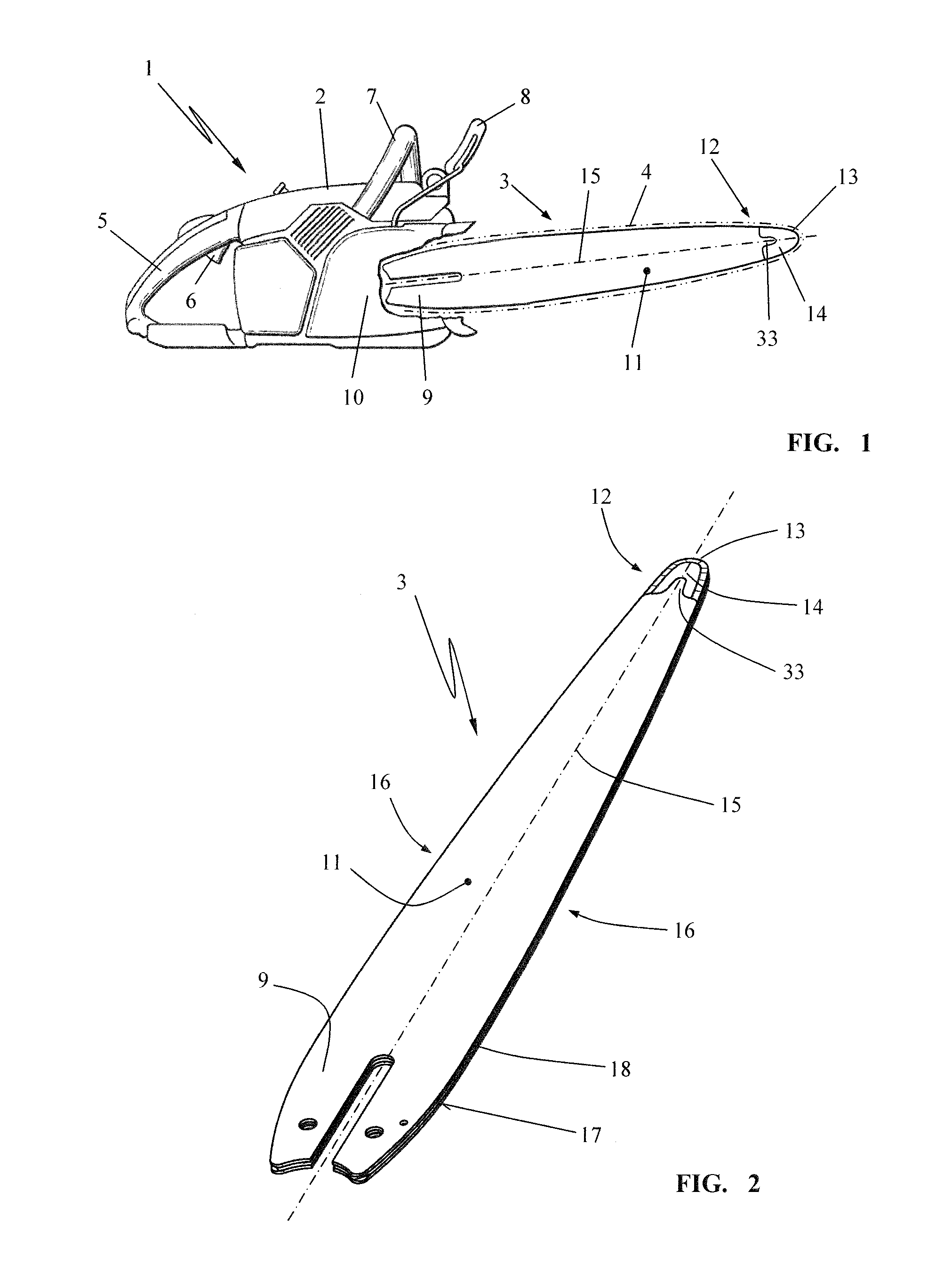

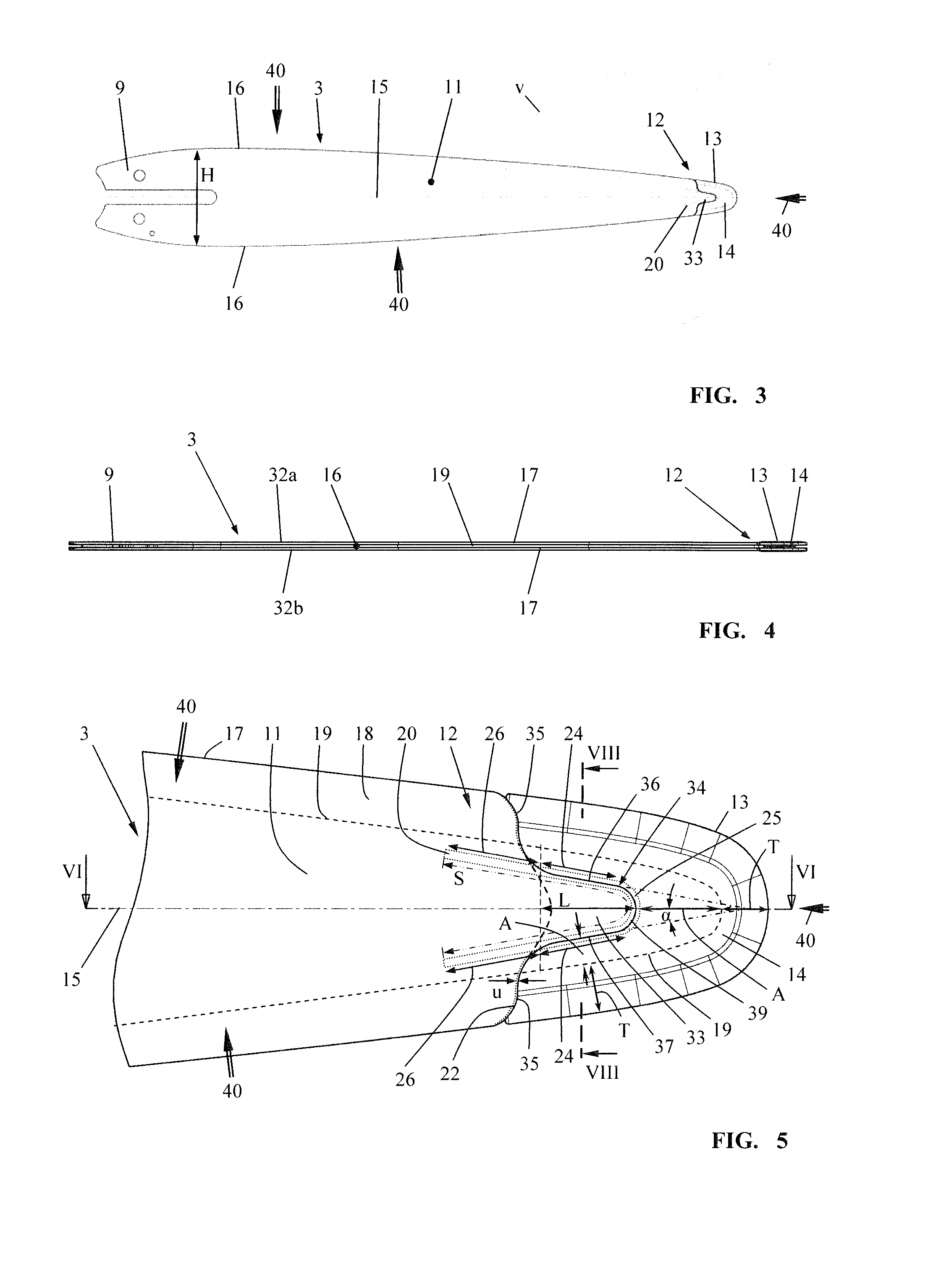

Guide bar for a saw chain having a reduced-wear direction-reversing section

ActiveUS20150052762A1Simple structureStrong and durable connectionMetal sawing devicesChain sawsWear resistantEngineering

A guide bar for a saw chain includes an elongate, flat base body made of a basic material. The base body extends along a longitudinal center axis and, in order to guide a saw chain, has a running surface formed on an outer periphery thereof and a guide groove formed in the outer periphery of the base body. The guide groove has a groove base. A direction-reversing section for the saw chain is provided at one end of the base body. The direction-reversing section includes at least one add-on component having a running surface made of more wear-resistant material than the basic material of the base body. The add-on component is secured to the base body of the guide bar by at least one weld seam. The weld seam extends between the add-on component and the base body and is located spatially beneath the groove base.

Owner:ANDREAS STIHL AG & CO KG

Combustion chamber intermediate part for a gas turbine

ActiveUS7299617B2Lower requirementReduce loadContinuous combustion chamberEfficient propulsion technologiesCombustion chamberTurbine

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Integrated Dental Implant Abutments

ActiveUS20160193016A1Easy to scanPrecise restorations of a tooth or teethDental implantsImpression capsProsthesisSloping shoulders

A dental abutment having a coronal portion for supporting a prosthesis separated from a post for seizing, galling or cold welding in a dental implant by a cylindrical portion and hemispheric base portion of length less than the combined length of the prosthetic head and locking taper post portions. The hemispherical portion of the abutment having a sloping shoulder with a surface that forms a small angle with a perpendicular to the cylindrical surface. A dental prosthesis system including such dental abutments.

Owner:BICON

Pressure-boosted fuel injection device comprising an internal control line

InactiveUS7513440B2Improve tightnessReduce overall form factorFuel injection apparatusMachines/enginesDifferential pressureControl line

The invention relates to a fuel injection device with a multi-part injector body containing a pressure booster that can be actuated by means of a differential pressure chamber, and includes a pressure booster piston that seals a working chamber off from the differential pressure chamber. An on-off valve disposed above the injector body can actuate the fuel injection device. A pressure change in the differential pressure chamber occurs via a central control line that extends through the pressure booster piston of the pressure booster.

Owner:ROBERT BOSCH GMBH

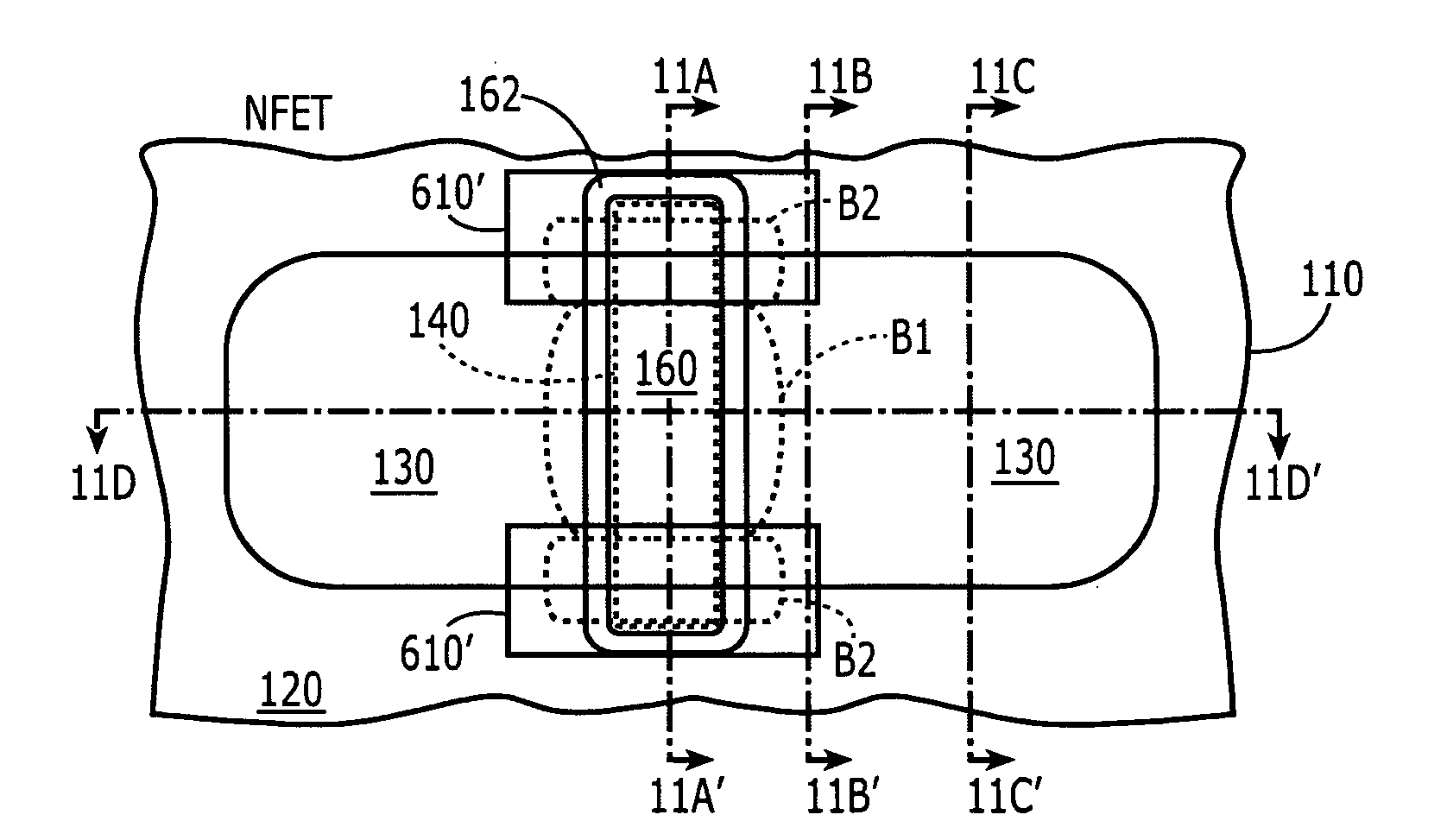

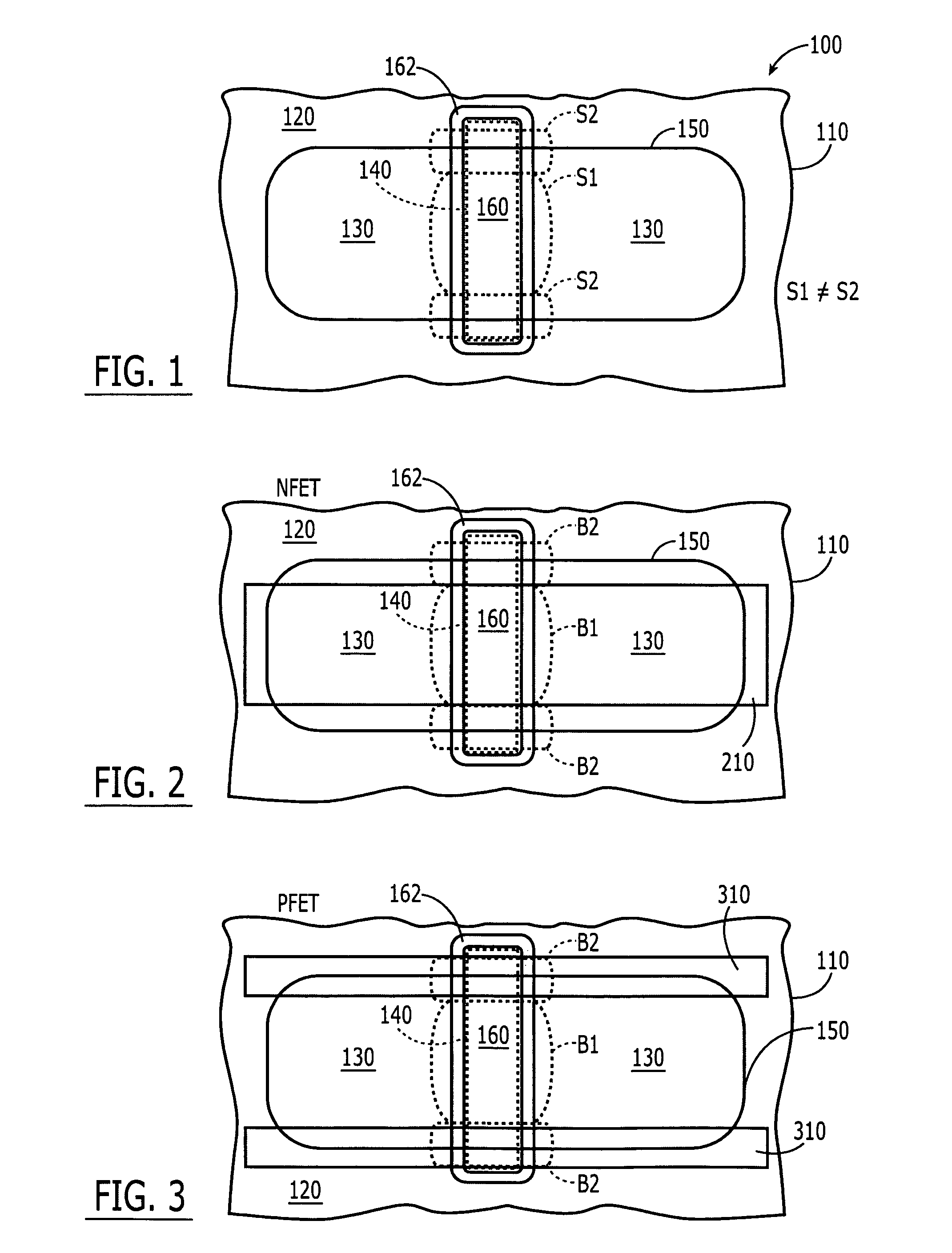

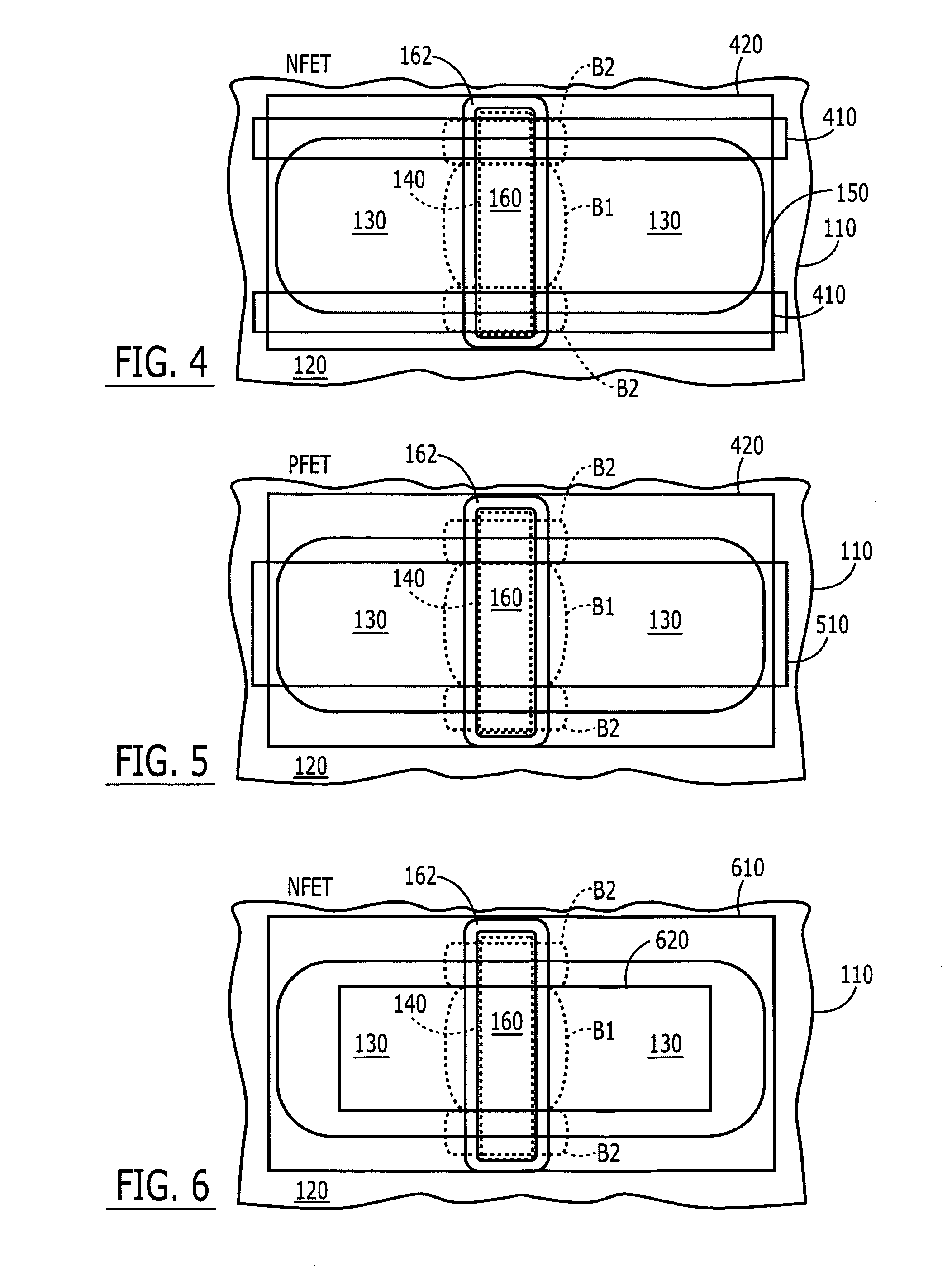

Differential mechanical stress-producing regions for integrated circuit field effect transistors

ActiveUS20070102779A1Material stress is sufficientReduce material stressTransistorSolid-state devicesEngineeringField-effect transistor

Integrated circuit field effect transistors include a substrate, an isolation region in the substrate that defines an active region in the substrate, spaced apart source / drain regions in the active region, a channel region in the active region between the spaced apart source / drain regions and an insulated gate on the channel region. A differential mechanical stress-producing region is configured to produce different mechanical stress in the channel region adjacent the isolation region compared to remote from the isolation region. The differential mechanical stress-producing region may be formed using patterned stress management films, patterned stress-changing implants and / or patterned silicide films, and can reduce undesired comer effects. Related fabrication methods also are described.

Owner:CHARTERED SEMICONDUCTOR MANUFACTURING +1

Glue-Down Decorative Floor Covering System

ActiveUS20210214952A1Increase contact surfaceSmooth connectionSynthetic resin layered productsConstructions elementsAdhesive glueMechanical engineering

The invention relates to a glue-down decorative floor covering system. The invention also relates to a glue-down floor covering realized by a plurality of tiles of the glue-down floor covering system according to the invention. The invention further relates to a tile for use in a glue-down floor covering system according to the invention.

Owner:I4F LICENSING NV

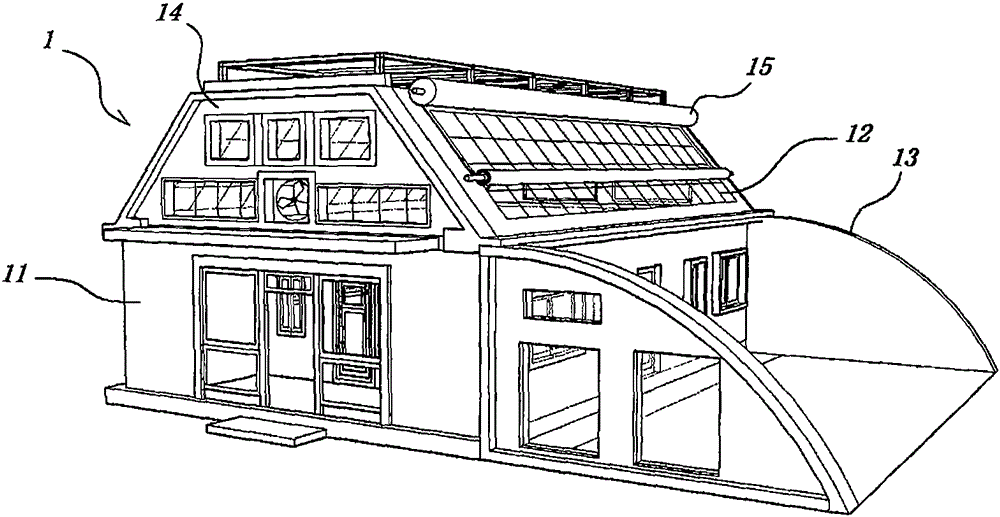

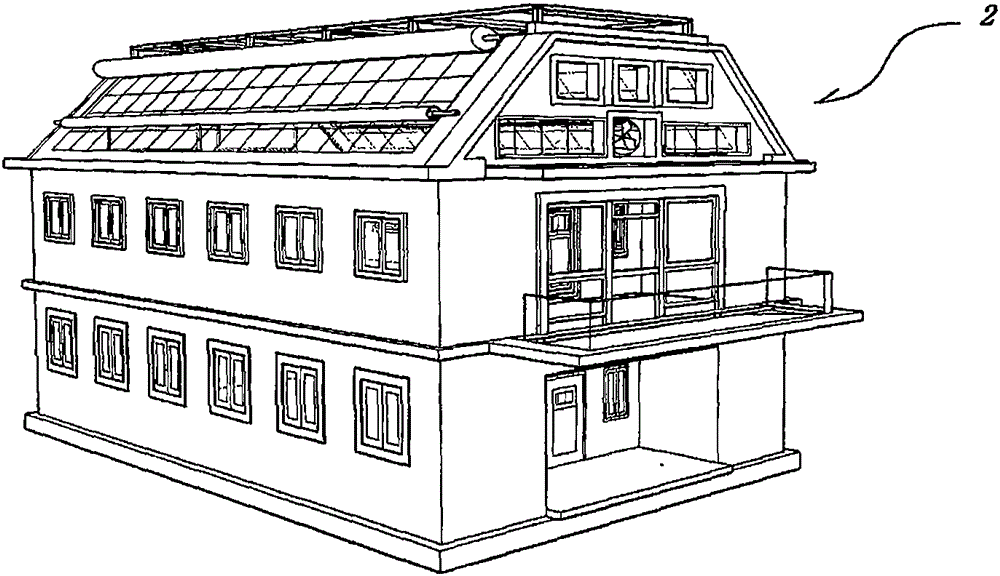

Structure net rib honeycomb concrete intervening building

InactiveCN106522588AImprove toughnessHigh toughness, its impact resistanceHotelsBuilding constructionsResidenceGreenhouse

The invention discloses a structure net rib honeycomb concrete intervening building. A traditional greenhouse structure is upgraded and organically combined with a traditional building, especially a residence house, and the greenhouse functions intervene in the residence environment. A sunlight greenhouse constructed through a transparent material and a sunlight awning arranged at the top of the building main body are additionally arranged on the sunny side of a building main body. The sunlight awning and the building main body are provided with internal spaces which are mutually isolated or connected into a whole. The multifunctional building can be arranged in the modes of a long-span warehouse or workshop structure with a single internal space, or a quadrangle courtyard with the sunlight awning arranged over the courtyard, or a residential area formed by surrounding the courtyard through the building main body, or a business street with a courtyard provided with the sunlight awning and the like. Due to the fact that the structure net rib honeycomb concrete structure breaking traditional thinking models is adopted, the diversity of the structure and layout are greatly facilitated, and the energy conservation effect is prominent; and the building is quite suitable for living, working and rest habits of our people with the combination with traditional residences and rural buildings, and the good atmosphere for people to live and work in peace and contentment is created advantageously.

Owner:李殿义

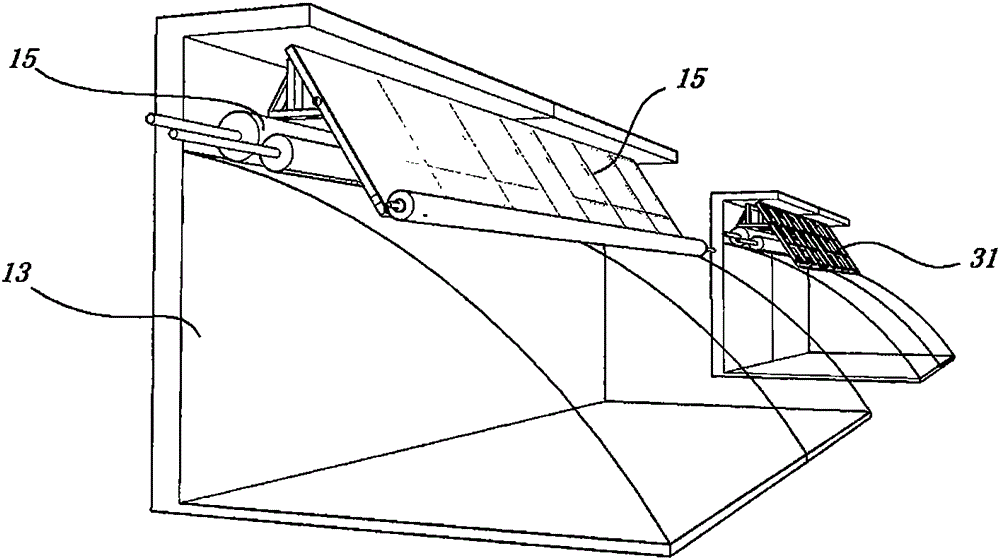

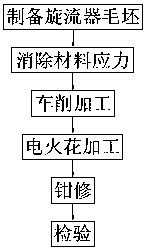

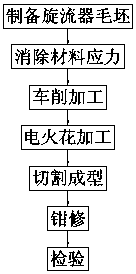

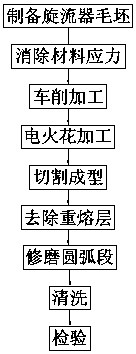

Technical method for manufacturing aero-engine cyclone through special processing technology

The invention relates to the field of aero-engines and gas turbines, and particularly relates to a technical method for manufacturing an aero-engine cyclone through a special processing technology. The method comprises the step of manufacturing a cyclone blank, wherein the cyclone bank is manufactured through a cylindrical forging piece. The method further comprises the step of manufacturing semi-finished cyclone and the step of finishing through pincers; the step of manufacturing the semi-finished cyclone is that the cyclone blank is sequentially subjected to turning processing and electric spark processing to obtain the semi-finished cyclone; the step of finishing through the pincers is that the semi-finished cyclone is finished based on the requirement on a finished cyclone so as to obtain the finished cyclone. According to the method, the forging piece is outstanding in mechanical property, and two processing modes are provided, so that the manufactured cyclone product is high in strength and toughness; the yield is increased; and the processing cost and the processing period are reduced; the manufactured cyclone product can stably run for a long time in an aero-engine combustion chamber; and the service life of the aero-engine combustion chamber cannot be influenced by the quality of the cyclone.

Owner:广汉天空动力机械有限责任公司

Combustion chamber intermediate part for a gas turbine

ActiveUS20050091987A1Lower requirementReduce mechanical loadContinuous combustion chamberGas turbine plantsCombustion chamberTurbine

This invention relates to a gas turbine having a combustion chamber arrangement and a turbine chamber connected downstream of said combustion chamber arrangement, wherein the combustion chamber arrangement includes a plurality of individual combustion chambers formed by input areas and transition areas converging in an annular gap leading to the turbine chamber and wherein the longitudinal axes of the individual combustion chambers are placed at an angle relative to an engine axis that is defined by the axial extension of the turbine chamber. In order to improve said gas turbine by visibly reducing the thermal and mechanical loads of the individual combustion chambers in the transition area so that cooling requirements can be lowered in said area, the transition area of at least one individual combustion chamber into the turbine chamber is deflected in the direction of the engine axis and substantially in the input area of the turbine chamber.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

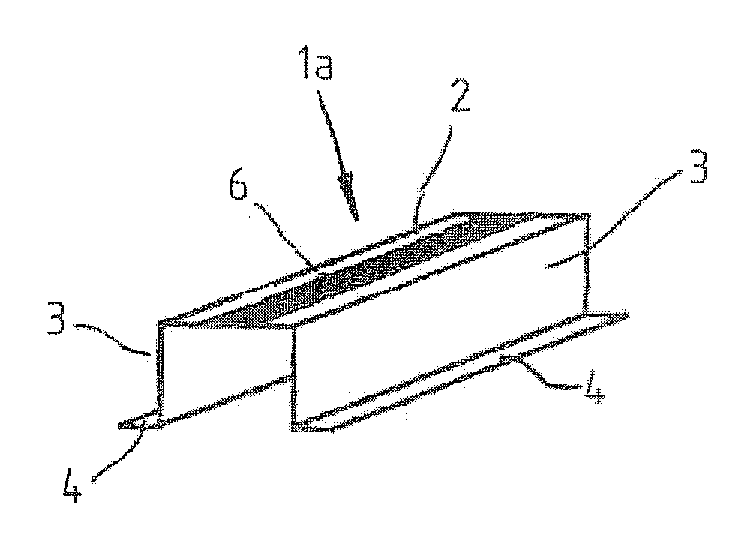

Tubular article

InactiveUS20110000573A1Reduce and even suppress effectHigh strengthContainers for annular articlesLayered productsEngineeringOil and natural gas

The present invention provides a strip and a tubular article formed from said strip which may, for example, be used in the oil and gas industry for transporting fluids which may be volatile fluids or corrosive fluids and which may be at elevated temperatures and / or pressure. The strip includes a plurality of combined step (joggle) and rib arrangements. In the finished assembled article, the strip is wound in helically self-overlapping relationship such as to allow corresponding step portions to sit one within the other. The step effectively provides the dual function of a joggle and a rib as known in the art and does so in a manner that reduces the forming stresses in the material and increases the strength of the final article.

Owner:ITI SCOTLAND

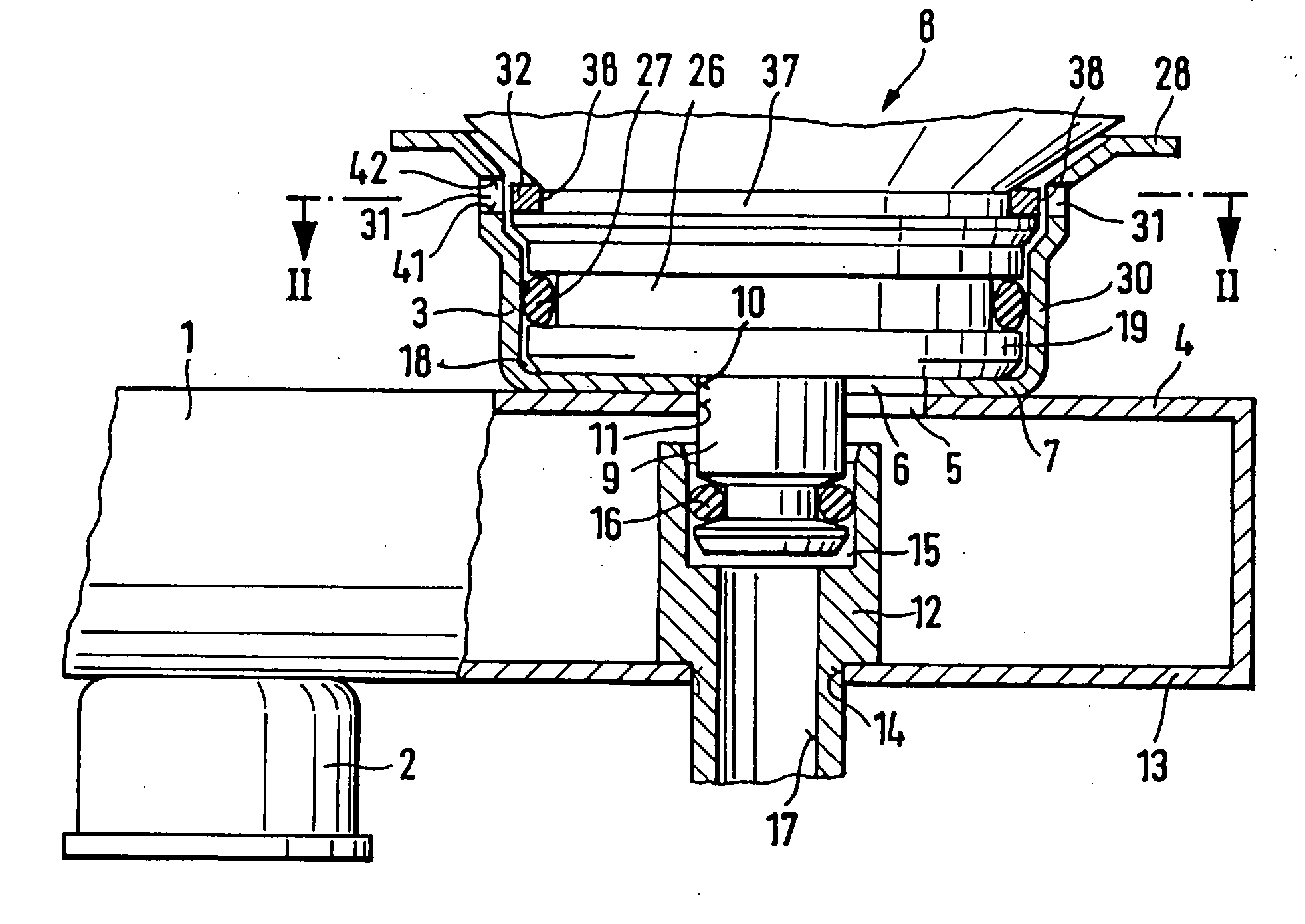

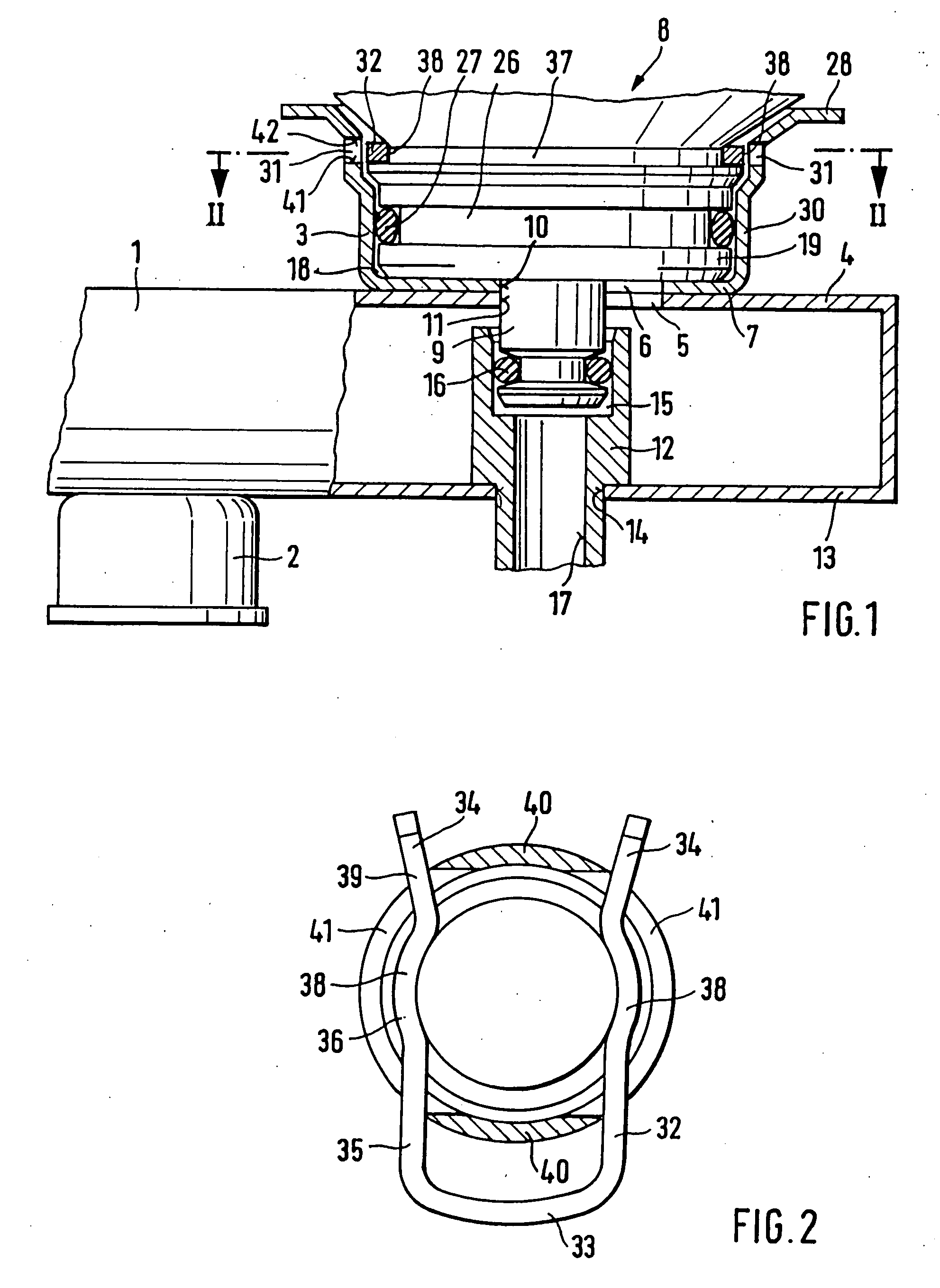

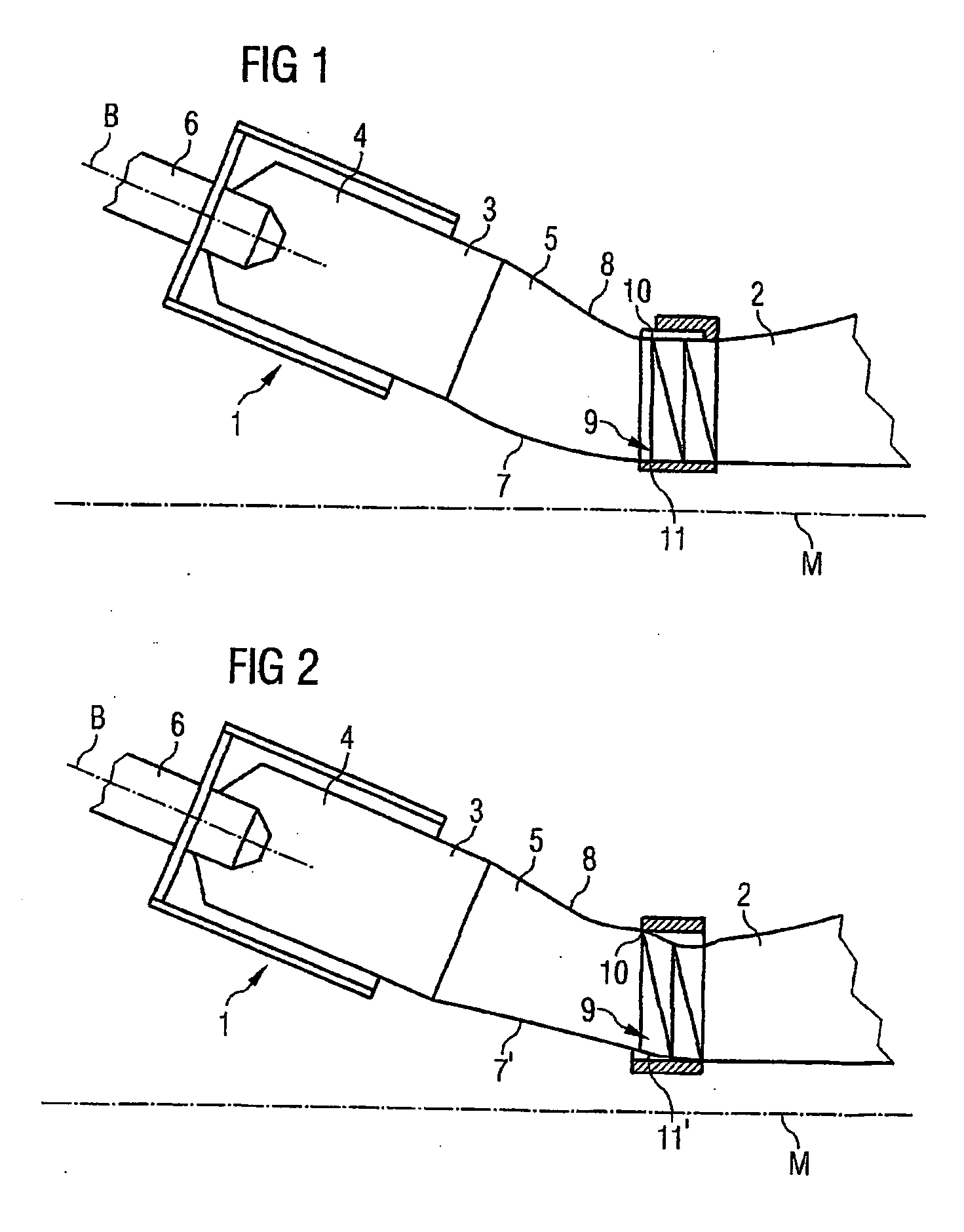

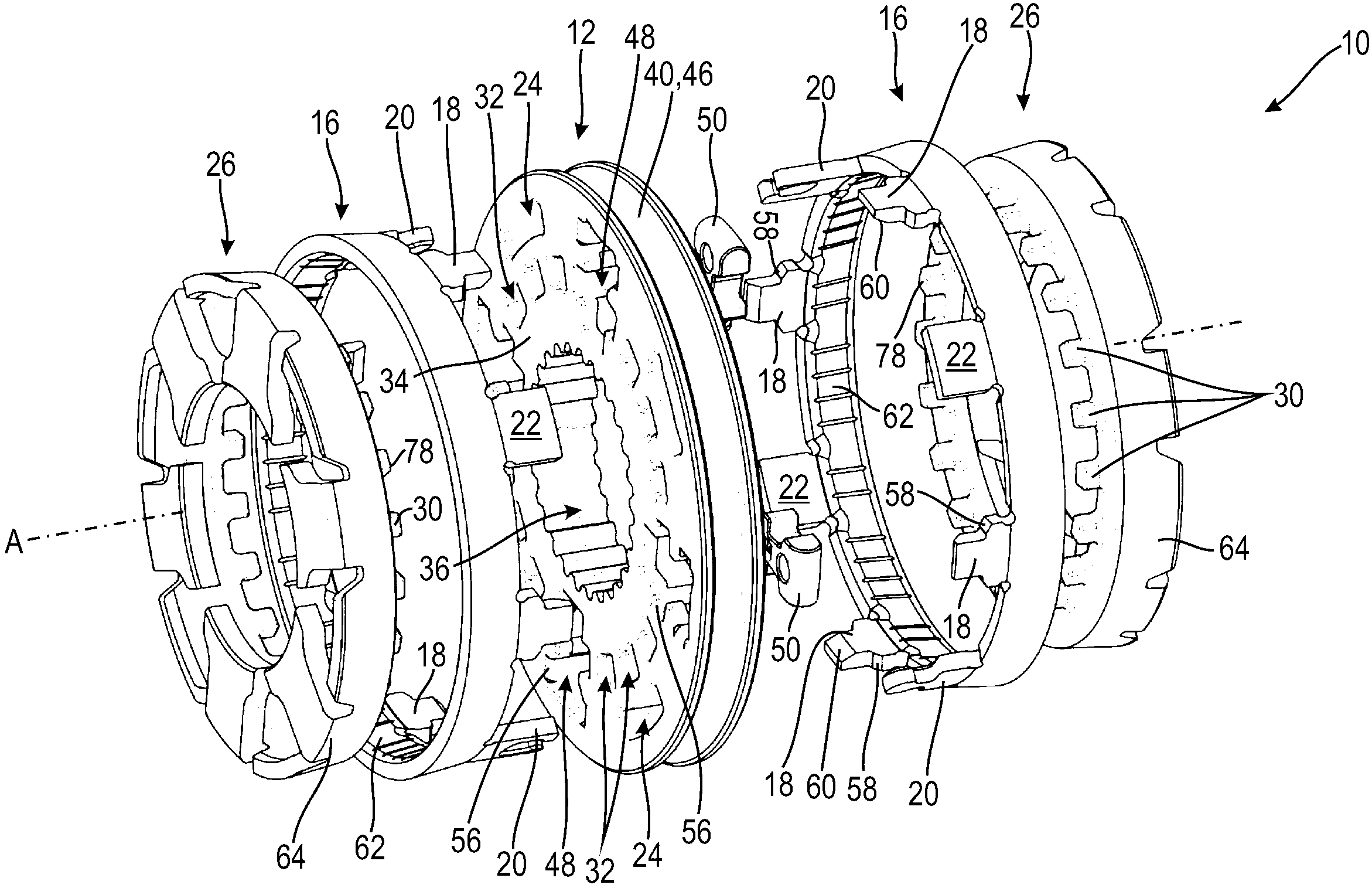

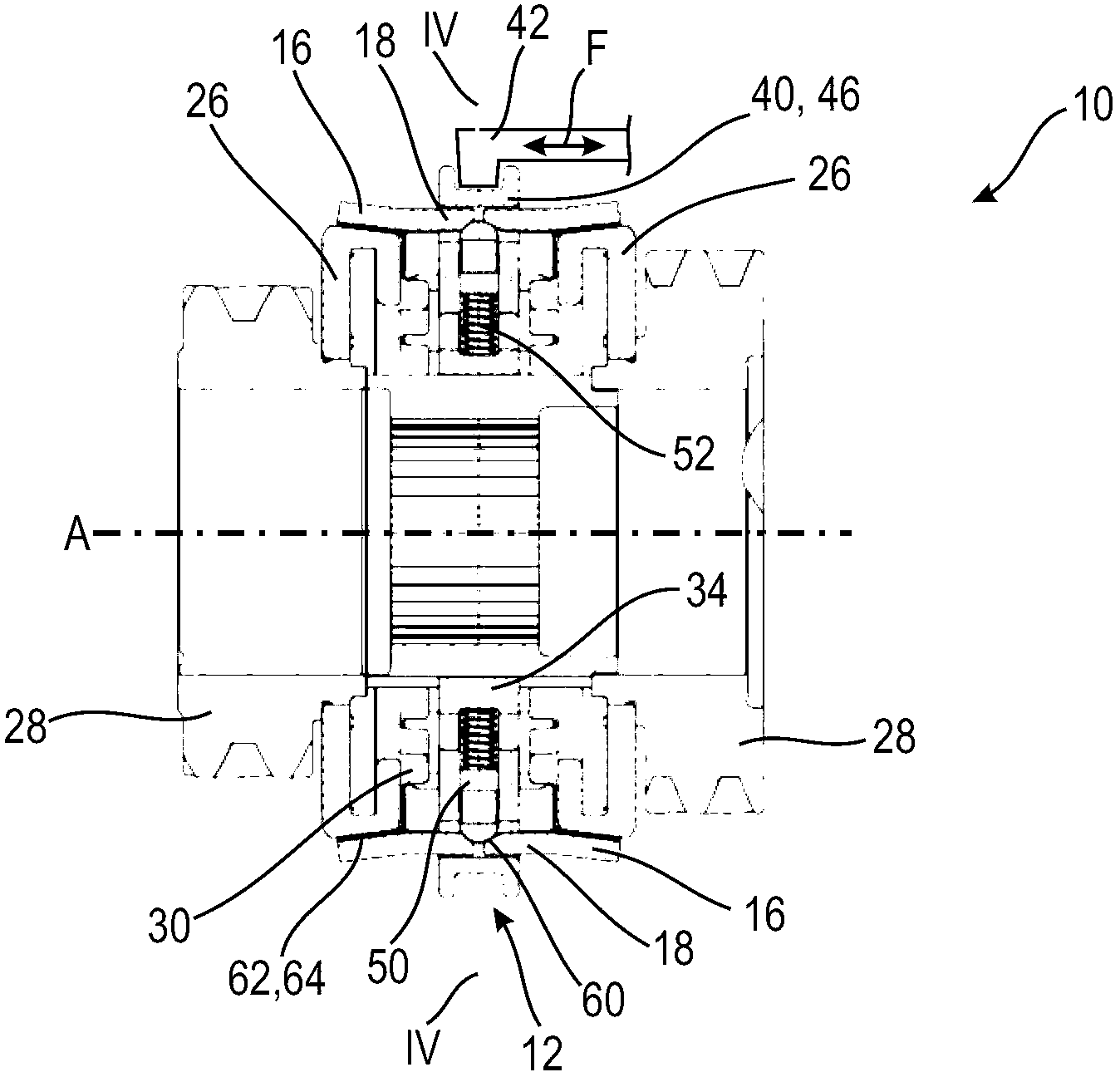

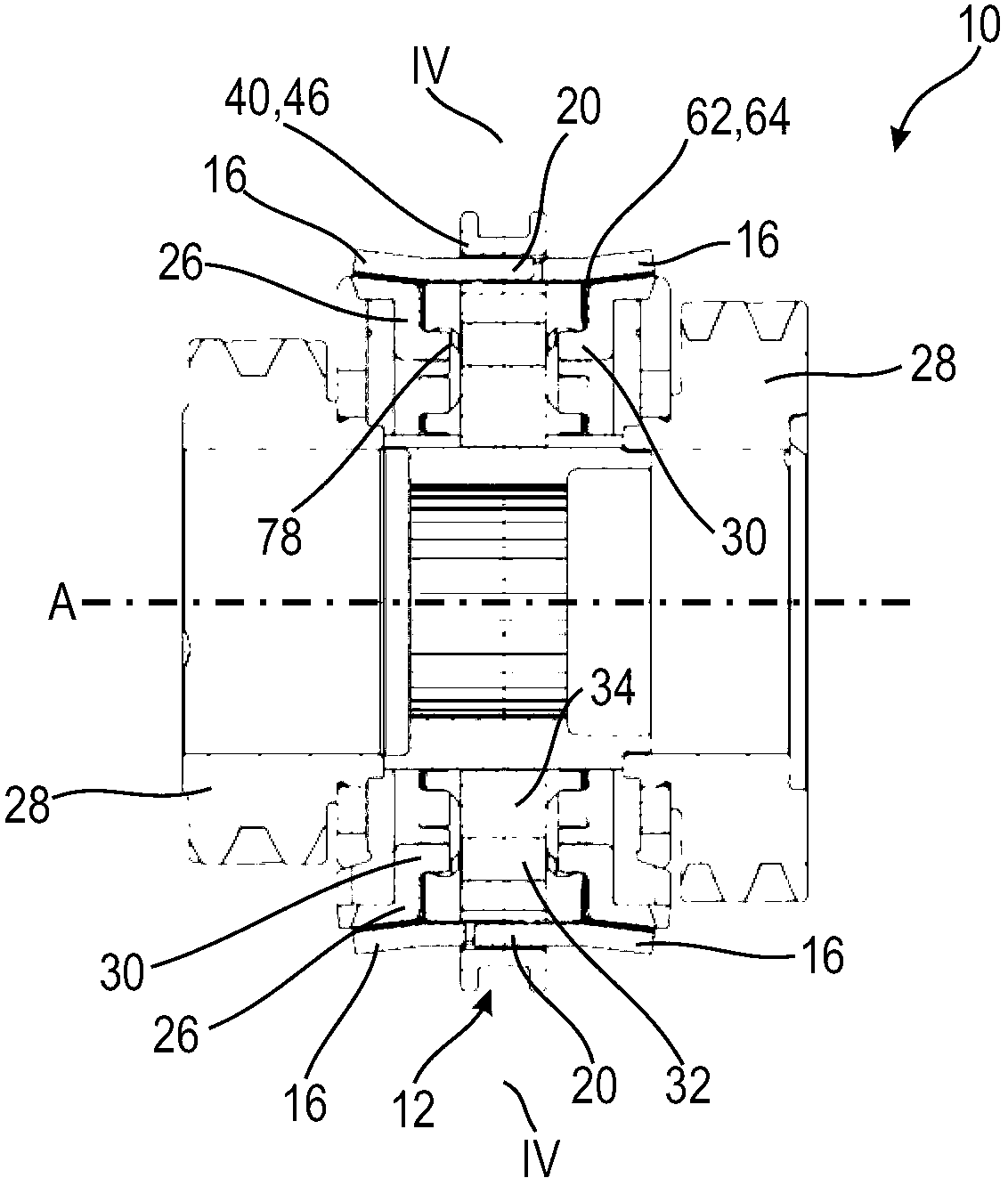

A shift gear driver of a flywheel synchronous transmission

ActiveCN103225655ASimple structureSimple and reliable pre-syncMechanical actuated clutchesToothed gearingsDrive shaftCoupling

The switching transmitter (12) has a one-piece annular body (34) rotatable around a transmission axis. The annular body has a contour (36) for rotationally fixed and axially movable coupling with a transmission shaft on its radial inner side and another contour (40) for axial coupling with an axially movable switching element on its radial outer side. The annular body has synchronization recesses (24) between the radial inner side and the radial outer side, where the axial extensions (18,20,22) of a friction ring (16) engage into the synchronization recesses. An independent claim is included for a lock-synchronized manual transmission with cams.

Owner:HOERBIGER ANTRIEBSTECHN HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com