Metal nanoparticle/diamond composite film with excellent field emission performance and preparation method

A technology of metal nanoparticles and diamond thin films, applied in the field of optoelectronic materials, can solve the problems of difficult formation of rectification and amplification device depletion layers, low electron mobility of diamond, and difficult electronic devices, etc., to achieve enhanced carrier mobility and Electrical conductivity, fast electron conduction, good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: the preparation method of Cu nanoparticle / micro-diamond composite film

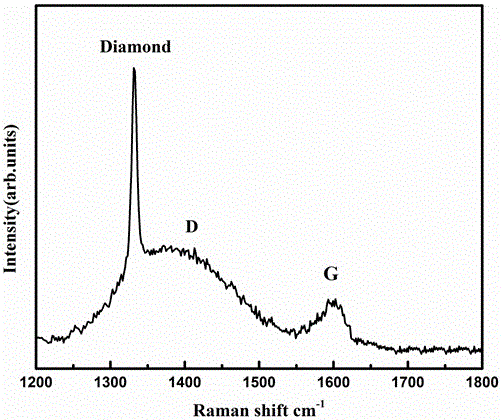

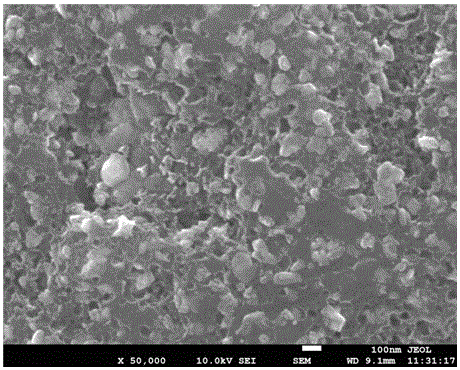

[0034] First, the grease on the surface of the Si substrate was cleaned with acetone and methanol solutions in sequence, and then the surface of the single crystal silicon substrate was ground with diamond powder with a particle size of 5 nm, and the substrate was ultrasonically cleaned in methanol solution for 45 minutes, and finally It is dried with hot air and used as a substrate for the growth of micron diamond films. A microcrystalline diamond film was grown on a silicon wafer with a diameter of 6 cm and a thickness of 1.2 cm by using microwave plasma chemical vapor deposition equipment with a frequency of 2.45 GHz. The volume ratio of the reaction gas used in the experiment is H 2 (98.6%) / CH 4 (1.4%), the microwave power was kept at 7 kW, the gas flow rate was 406 sccm, the total pressure was 10 kPa, the temperature was 850 °C, and the growth time was 10 h, and a diamond film ...

Embodiment 2

[0039] Embodiment 2: the preparation method of Cu nanoparticle / super nano-diamond composite film

[0040] Microwave plasma chemical deposition equipment was used to prepare ultra-nano-diamond film on single crystal silicon substrate. Firstly, the ethanol suspension of diamond micropowder (0.5 μm in particle size) was used to ultrasonically vibrate the silicon wafer for 30 minutes, and then cleaned with ethanol after ultrasonication. Then dry the silicon wafer with hot air as the substrate for the growth of micron diamond film. Microwave plasma chemical vapor deposition equipment with a frequency of 2.45 GHz was used to grow ultra-nano-diamond films on a 2×2 cm silicon wafer. The experiment used Ar, H 2, CH 4 The mixed gas, the total gas flow rate is 166sccm, and the flow rates of each gas are: Ar is 122sccm-136sccm, H 2 24-38sccm, CH 4 The deposition power is 0.8-1.0kW, the pressure is 15-17kPa, the deposition temperature is 830°C, and the deposition time is 5-6h. The gra...

Embodiment 3

[0046] First, the grease on the surface of the Si substrate was cleaned with acetone and methanol solutions in sequence, and then the surface of the single crystal silicon substrate was ground with diamond powder with a particle size of 5 nm, and the substrate was ultrasonically cleaned in methanol solution for 45 minutes, and finally It is dried with hot air and used as a substrate for the growth of micron diamond films. A microcrystalline diamond film was grown on a silicon wafer with a diameter of 6 cm and a thickness of 1.2 cm by using microwave plasma chemical vapor deposition equipment with a frequency of 2.45 GHz. The volume ratio of the reaction gas used in the experiment is H 2 (98.6%) / CH 4 (1.4%), the microwave power was maintained at 7 kW, the gas flow rate was 406 sccm, the total pressure was 10 kPa, the temperature was 850 °C, and the growth time was 10 h, and a diamond film with a grain size of 2-5 μm was prepared.

[0047] A metal vacuum vapor arc ion implante...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com