Preparation method and application of hydrogenated titanium dioxide nanotube array film

A nanotube array and titanium dioxide technology, applied in the manufacture of discharge tubes/lamps, nanotechnology, cold cathode manufacturing, etc., can solve the problems of polluting production equipment, demanding equipment, and high preparation temperature, and achieve high emission current density and open Low electric field and highly reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

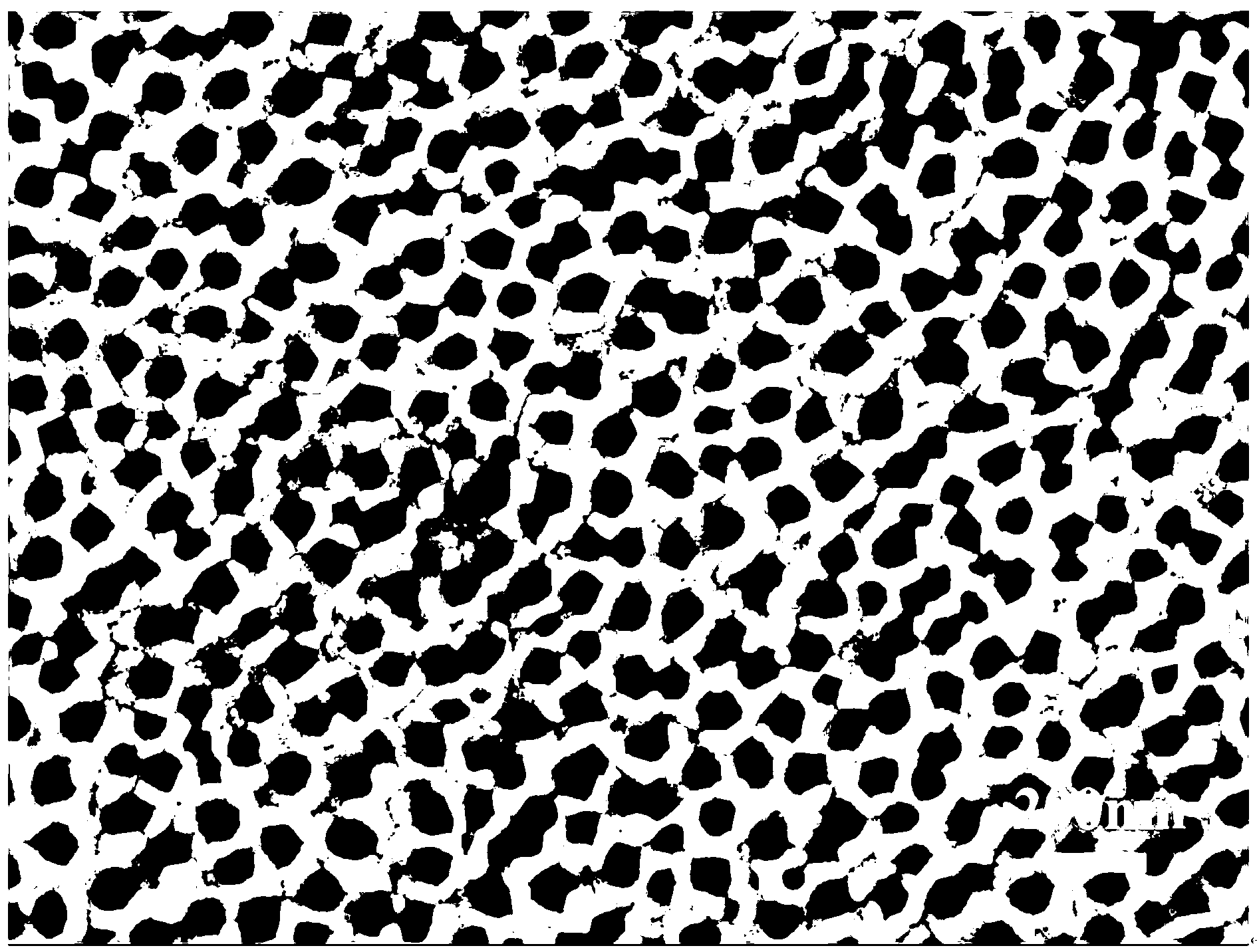

Image

Examples

Embodiment 1

[0034] Take industrial titanium sheets (purity 99.9%), and ultrasonically clean them in acetone, absolute ethanol and deionized water for 15 min respectively; A mixed solution composed of 36% concentrated hydrochloric acid was used to chemically polish the cleaned titanium sheet for 180 s; a constant voltage DC anodizing method was used to grow a titanium dioxide nanotube array film on the surface of the polished titanium sheet at room temperature: graphite was used as the cathode, and the titanium sheet was used as the anode , the distance between the two electrodes was kept at 3 cm, the electrolyte was ethylene glycol solution (analytical grade) containing 0.30 wt.% ammonium fluoride and 0.03 wt.% hydrofluoric acid, the oxidation voltage was 40 V, and the oxidation time was 500 min , and stir the electrolyte with a magnetic stirrer to ensure that the temperature of the system and the electrolyte are uniform. After the oxidation is completed, take out the titanium sheet, rinse...

Embodiment 2

[0040] Take industrial titanium sheets (purity 99.9%), and ultrasonically clean them in acetone, absolute ethanol and deionized water for 15 min respectively; A mixed solution of 38% concentrated hydrochloric acid was used to chemically polish the cleaned titanium sheet for 150 s; a constant voltage direct current anodic oxidation method was used to grow a titanium dioxide nanotube array film on the surface of the polished titanium sheet at room temperature: graphite was the cathode, and the titanium sheet was Anode, the distance between the two electrodes was kept at 2 cm, the electrolyte was ethylene glycol solution (analytical pure) containing 0.20 wt.% ammonium fluoride and 0.05 wt.% hydrofluoric acid, the oxidation voltage was 50 V, and the oxidation time was 600 min. Stir the electrolyte with a magnetic stirrer to ensure that the temperature of the system and the electrolyte are uniform. After the oxidation is completed, take out the titanium sheet, rinse it with deionize...

Embodiment 3

[0045]Take industrial titanium sheets (purity 99.9%), and ultrasonically clean them in acetone, absolute ethanol and deionized water for 15 min respectively; A mixed solution of 37% concentrated hydrochloric acid was used to chemically polish the cleaned titanium sheet for 100 s; a constant voltage DC anodizing method was used to grow a titanium dioxide nanotube array film on the surface of the polished titanium sheet at room temperature: graphite was used as the cathode, and the titanium sheet was used as the anode , the distance between the two electrodes was kept at 5 cm, the electrolyte was ethylene glycol solution (analytical grade) containing 0.25 wt.% ammonium fluoride and 0.02 wt.% hydrofluoric acid, the oxidation voltage was 30 V, and the oxidation time was 315 min , and stir the electrolyte with a magnetic stirrer to ensure that the temperature of the system and the electrolyte are uniform. After the oxidation is completed, take out the titanium sheet, rinse it with d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com