Field emission cathode structure and manufacturing method based on sea urchin type nickel particle template

A field emission cathode and nickel particle technology, which is applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve the problem of emission uniformity, poor stability, difficulty in controlling the distribution density of emission tips, and difficulty in effectively achieving vertical emission. Orientation, uniform dispersion of carbon nanostructures and other issues, to achieve the effect of stable electron emission and small open electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

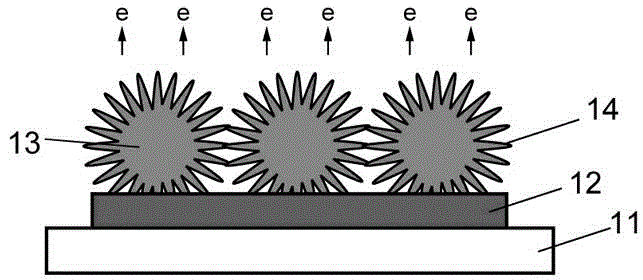

[0034] A field emission cathode structure based on a sea urchin-type nickel particle template provided in the first embodiment of the present invention includes: a substrate 11; a bottom electrode layer 12 disposed on the substrate; and sea urchin-type nickel particles 13 disposed on the The metal bottom electrode layer is used as a template; the surface of the template is covered with nanometer material 24 . In one embodiment of the present invention, the sea urchin-type nickel particles have a two-layer structure of inner and outer layers, and the outer layer is a nickel nanocone 14 to regulate the orientation and distribution of field emission points. The nickel nanocones are radially distributed in the The surface of the template, and part of the nickel nanocones point to the anode. The nickel particle size is 0.3-15 μm, and the cone-point spacing of the nickel nanocone is 0.05-2 μm. The nanomaterial can be a nickel oxide film prepared by in-situ thermal oxidation, or a t...

Embodiment 2

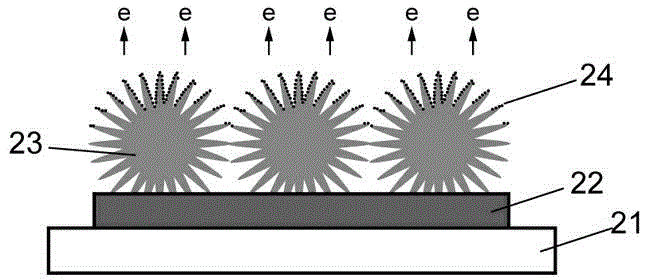

[0043] A method for preparing a field emission cathode structure based on a sea urchin-type nickel particle template provided in the second embodiment of the present invention includes the following steps:

[0044] (1) Prepare the bottom electrode layer 22 on the substrate 21 made of polyvinyl chloride PVC, the process is the same as step 1) of the first embodiment.

[0045] (2) The nickel particle template 23 is prepared on the bottom electrode layer 22 , the process is the same as step 2) of the first embodiment.

[0046] (3) The electron emission material 24 is prepared on the template 23 .

[0047]The material used for the electron emission material 24 can be zinc oxide, tin oxide, magnesium oxide, copper oxide, titanium oxide, manganese oxide, iron oxide, cobalt oxide, nickel oxide, silver oxide, tungsten oxide, lead oxide, bismuth oxide, aluminum nitride A nanomaterial or a composite material composed of multiple nanomaterials, or a nanomaterial or multiple nanomaterial...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com