Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

68results about How to "Increased emission current density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

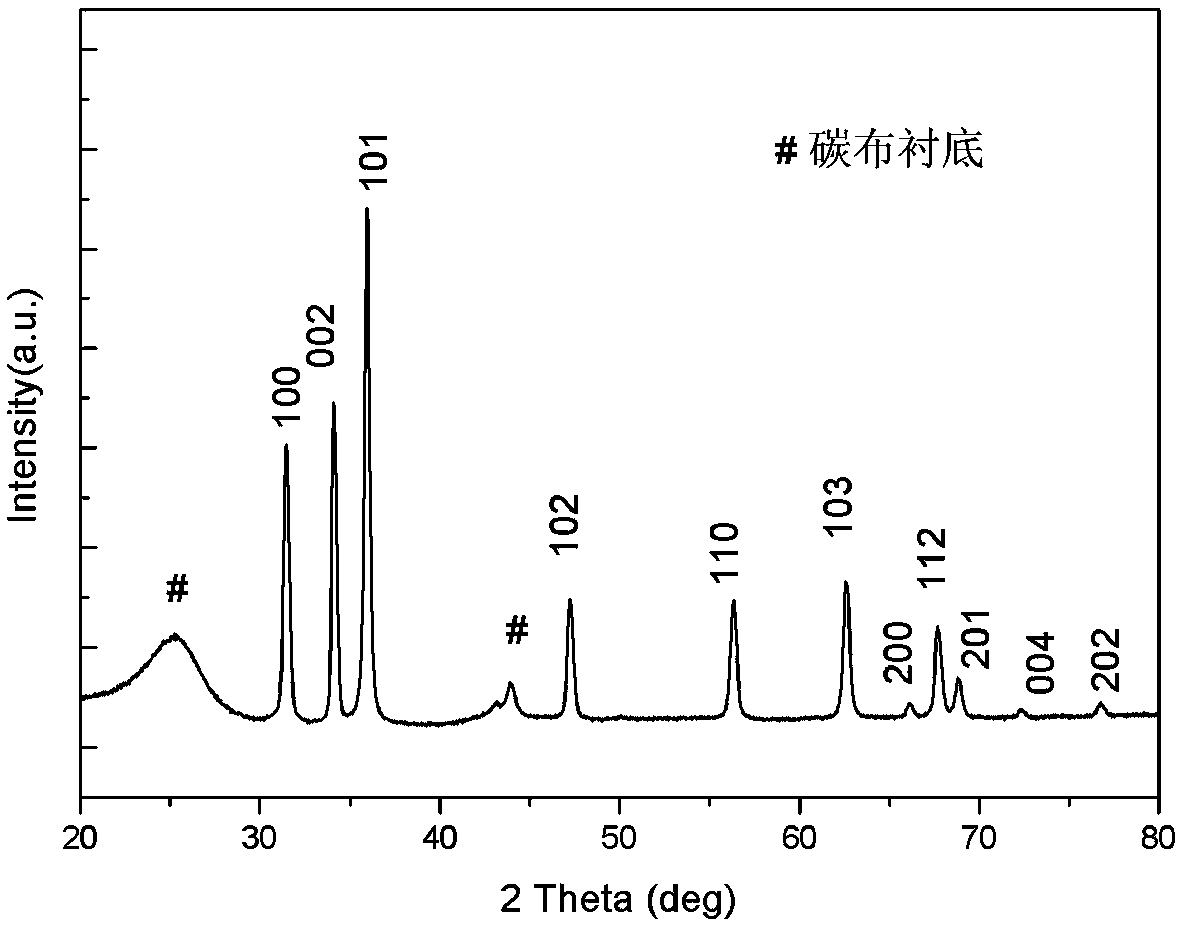

Emitting cathode based on composite material of graphene/zinc oxide nanowire and preparation of same

ActiveCN102157315AReduce the turn-on electric fieldIncreased emission current densityDischarge tube/lamp detailsCold cathode manufacturePower flowElectron source

The invention relates to a field electron emitting cathode based on the composite material of graphene / zinc oxide nanowire, comprising a conductive electrode and the composite material of graphene / zinc oxide nanowire, wherein the composite material of graphene / zinc oxide nanowire is positioned on the surface of the electrode, and consists of the graphene with the size ranging from 2 to 10 micronsand the zinc oxide nanowire with the length ranging from 1 to 2 microns and the diameter being 100 nanometers; and the turn-on field is lower than or equal to 1.7 volt / microns, and the threshold field is lower than or equal to 4 volt / microns. The filed emission electron source has the advantages of lower turn-on field, low threshold field, high emission current density, stable emission, easy preparation method and easy realization of industrialized volume production.

Owner:FUZHOU UNIV

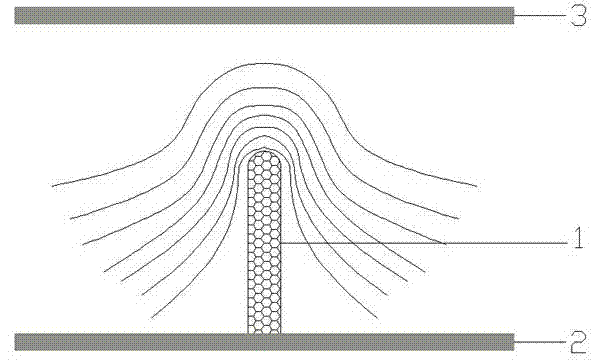

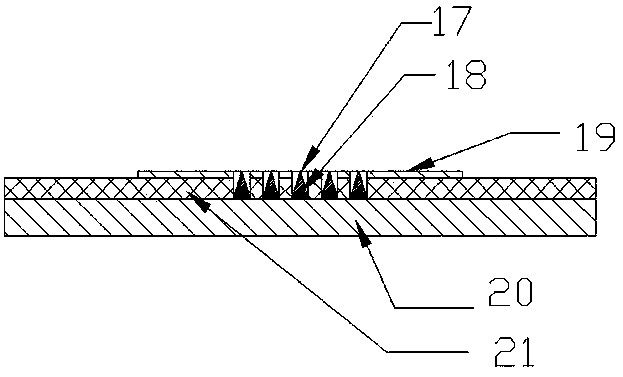

Field emission electron source and preparation method of carbon nanotube graphene composite structure thereof

ActiveCN103050346AImprove launch performanceImprove stabilityMaterial nanotechnologyDischarge tube/lamp detailsPower flowElectron source

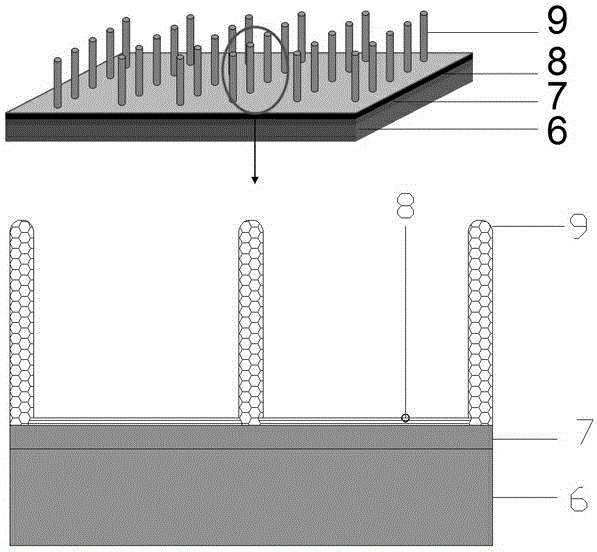

The invention discloses a field emission electron source and a preparation method of a carbon nanotube graphene composite structure thereof. The field emission electron source comprises a conductive substrate, a graphene film layer and a carbon nanotube array which is directionally perpendicular to the graphene film layer, wherein the graphene film layer is adhered onto the conductive substrate, and one end of each carbon nanotube in the carbon nanotube array is connected with the graphene film layer to form an integrated structure. The emission capacity and stability of the carbon nanotube array field emission electron source are greatly improved, so that the electron source obtains highly efficient and stable emission current, and can bear extremely high emission current density.

Owner:广州市昊志影像科技有限公司

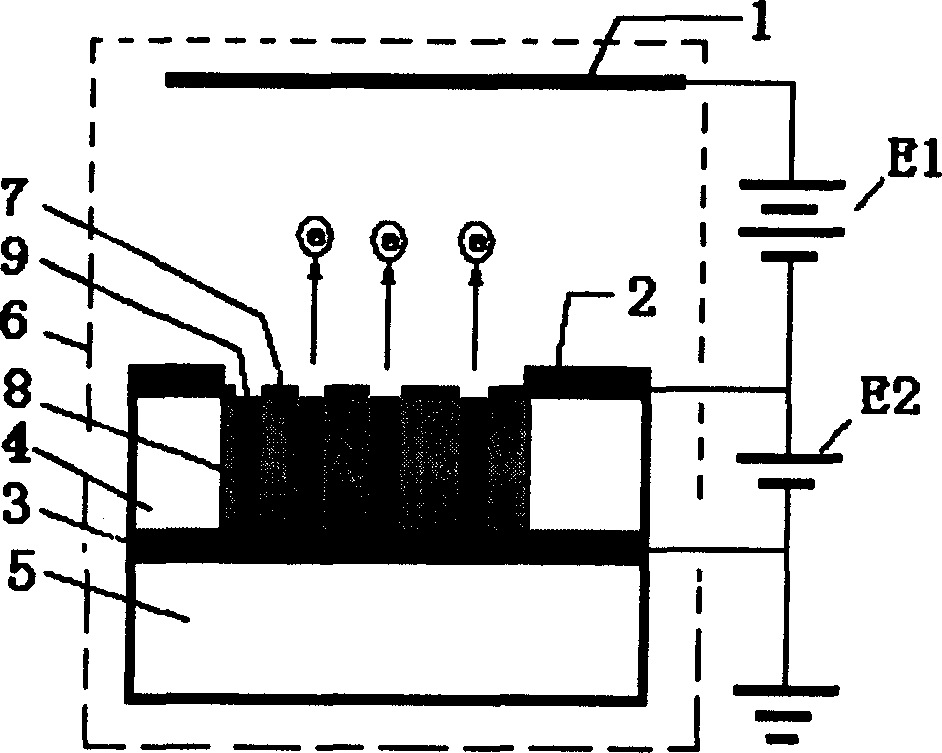

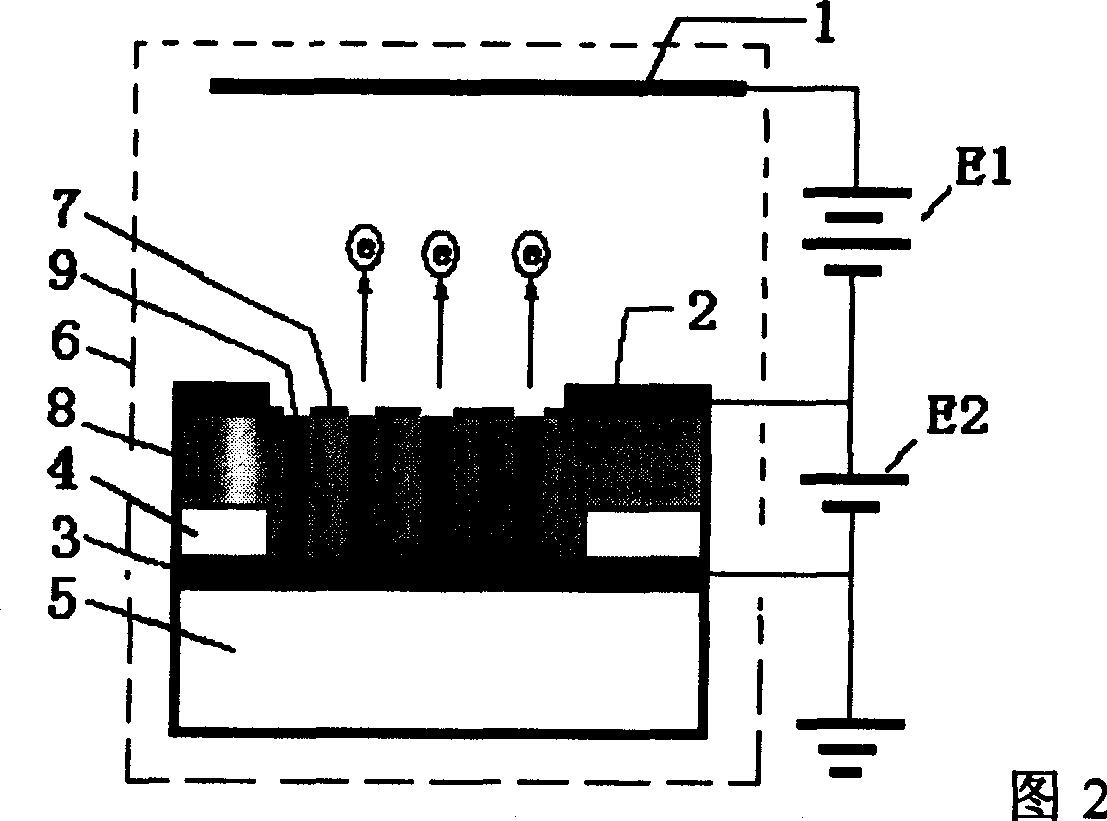

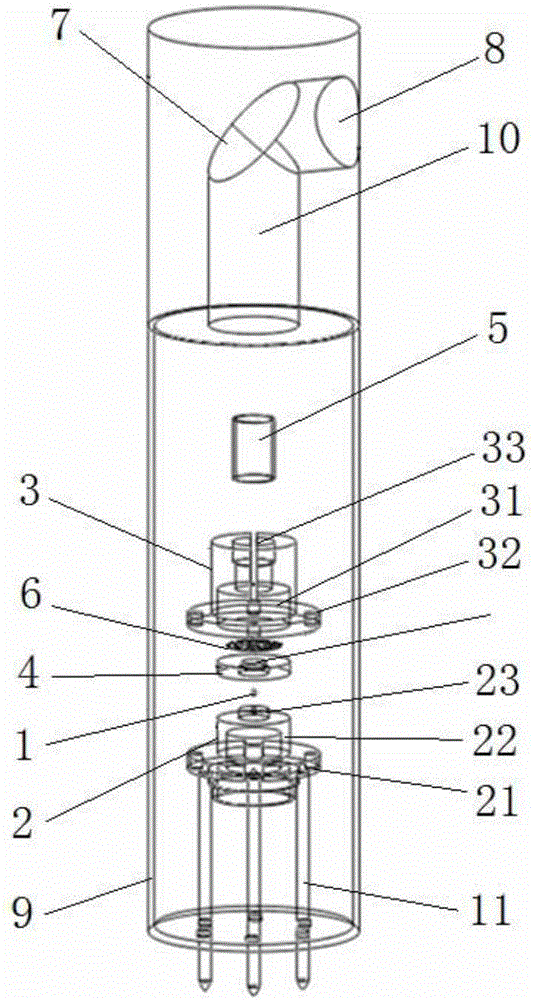

A manufacturing method of a field emission ion neutralizer chip based on an SOI process

ActiveCN109824009AAchieve mass productionAvoid short circuitTelevision system detailsSemiconductor/solid-state device detailsCarbon nanotubeEmission efficiency

The invention discloses a manufacturing method of a field emission ion neutralizer chip based on an SOI process. The manufacturing method comprises the following steps: (1) preparing an SOI substratewith a polished surface; (2) removing the top silicon and the silicon dioxide insulating layer in the target area by using photoetching and etching processes, and exposing the bottom silicon; (3) obtaining an array type photoresist pattern on the underlying silicon, and depositing a buffer layer and a catalyst layer to form a buffer layer-catalyst layer array; (4) forming a carbon nanotube array to obtain a cathode part; (5) preparing an array type through hole structure by using a silicon wafer as a grid substrate; (6) depositing a metal film on the through hole structure to obtain an anode part; and (7) bonding the cathode part and the anode part to obtain the field emission ion neutralizer chip. By improving the design and the like of the whole flow process of the preparation method, the obtained device can effectively overcome the field shielding effect and the heat effect, and has the advantages of being good in emission efficiency, low in power consumption and long in service life.

Owner:HUAZHONG UNIV OF SCI & TECH

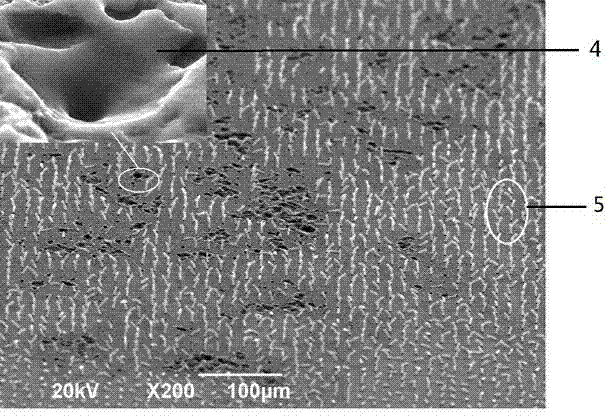

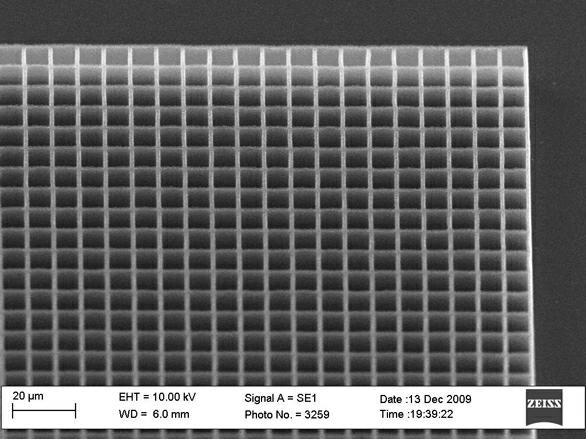

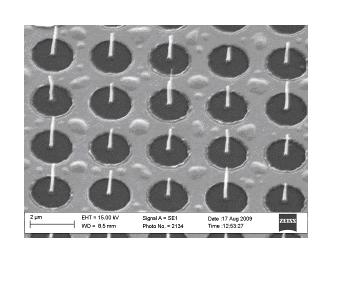

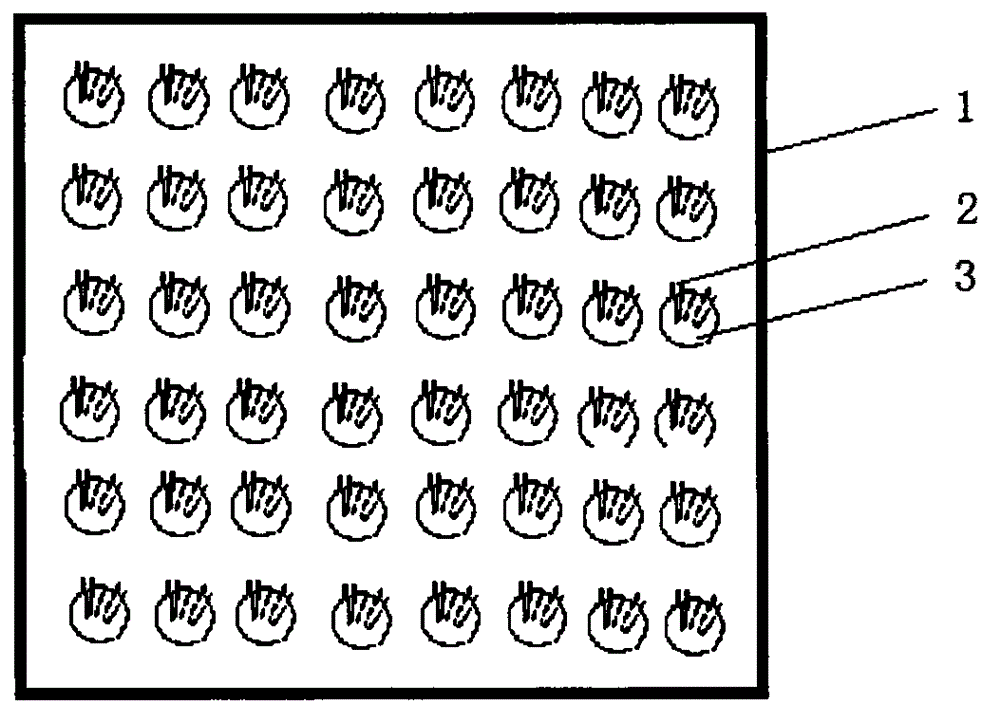

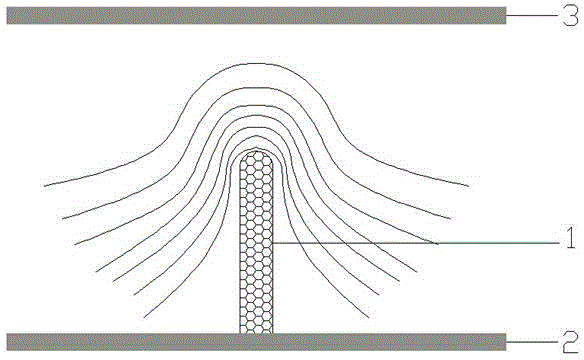

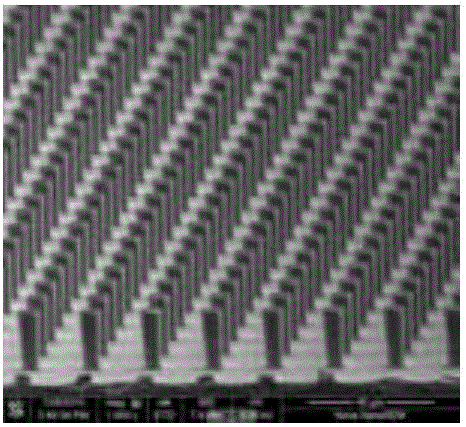

Orientated-growth latticed high-performance carbon nano-tube field emission array

InactiveCN102324350AImprove structural stabilityEnhance the edge effectDischarge tube/lamp detailsField emission deviceElectron source

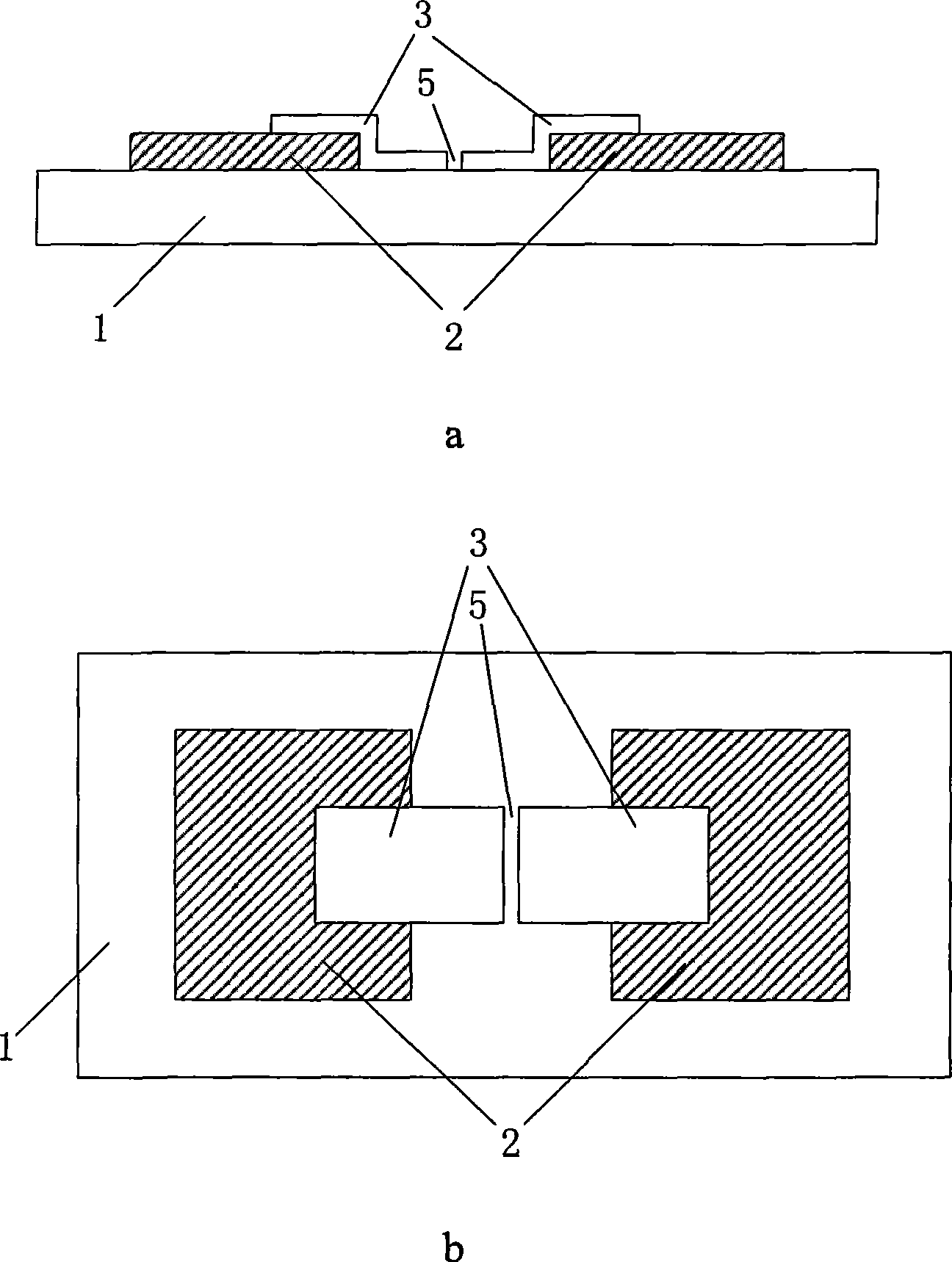

The invention discloses an orientated-growth latticed high-performance carbon nano-tube field emission array, which comprises a conductive substrate and latticed orientated carbon nano-tube arrays grown on the substrate, wherein the carbon nano-tube arrays are distributed into a latticed shape and form an integral structure. By the technical scheme, the structural stability of small-size carbon nano-tube arrays is improved, the edge effect of the carbon nano-tube arrays is enhanced, and then a turn-on electric field and a threshold electric field are reduced to improve the emission current density. The orientated-growth latticed high-performance carbon nano-tube field emission array is suitable for field emission devices having high requirements on current emission performance, such as electron sources in an X ray source, a microwave amplifier, a field emission scanning electron microscope and the like.

Owner:上海康众光电科技有限公司

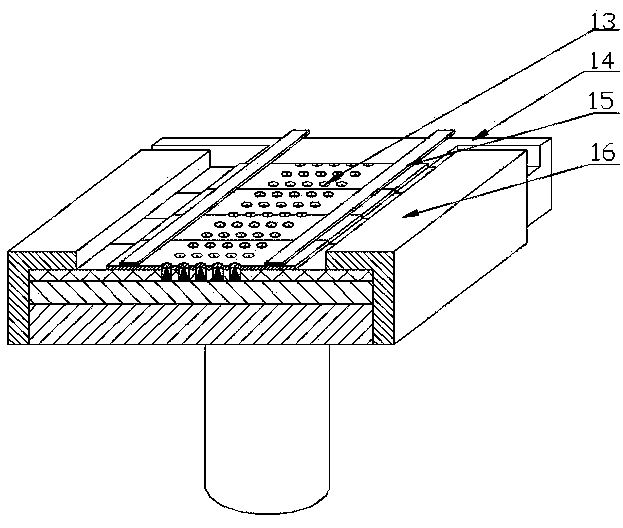

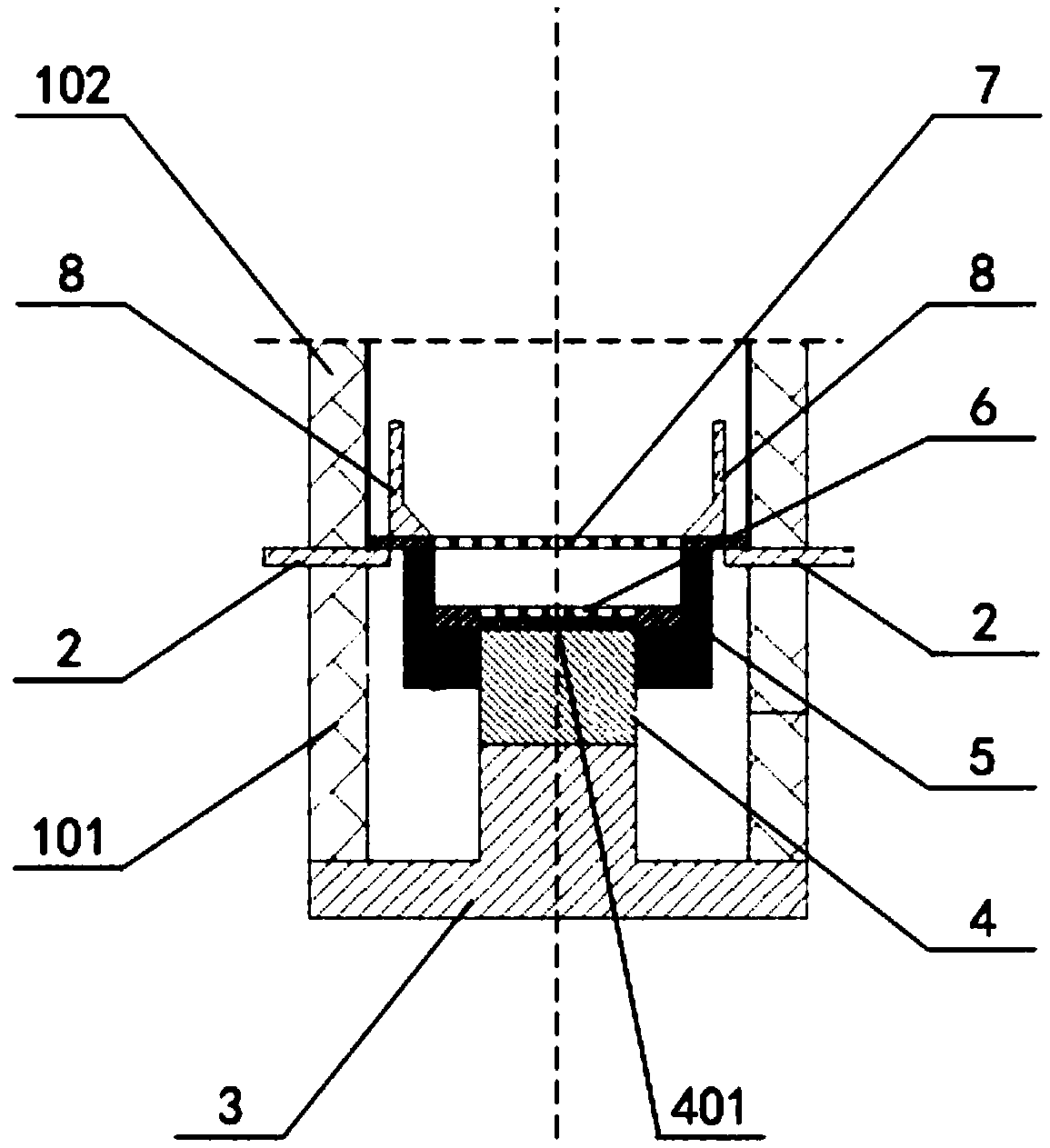

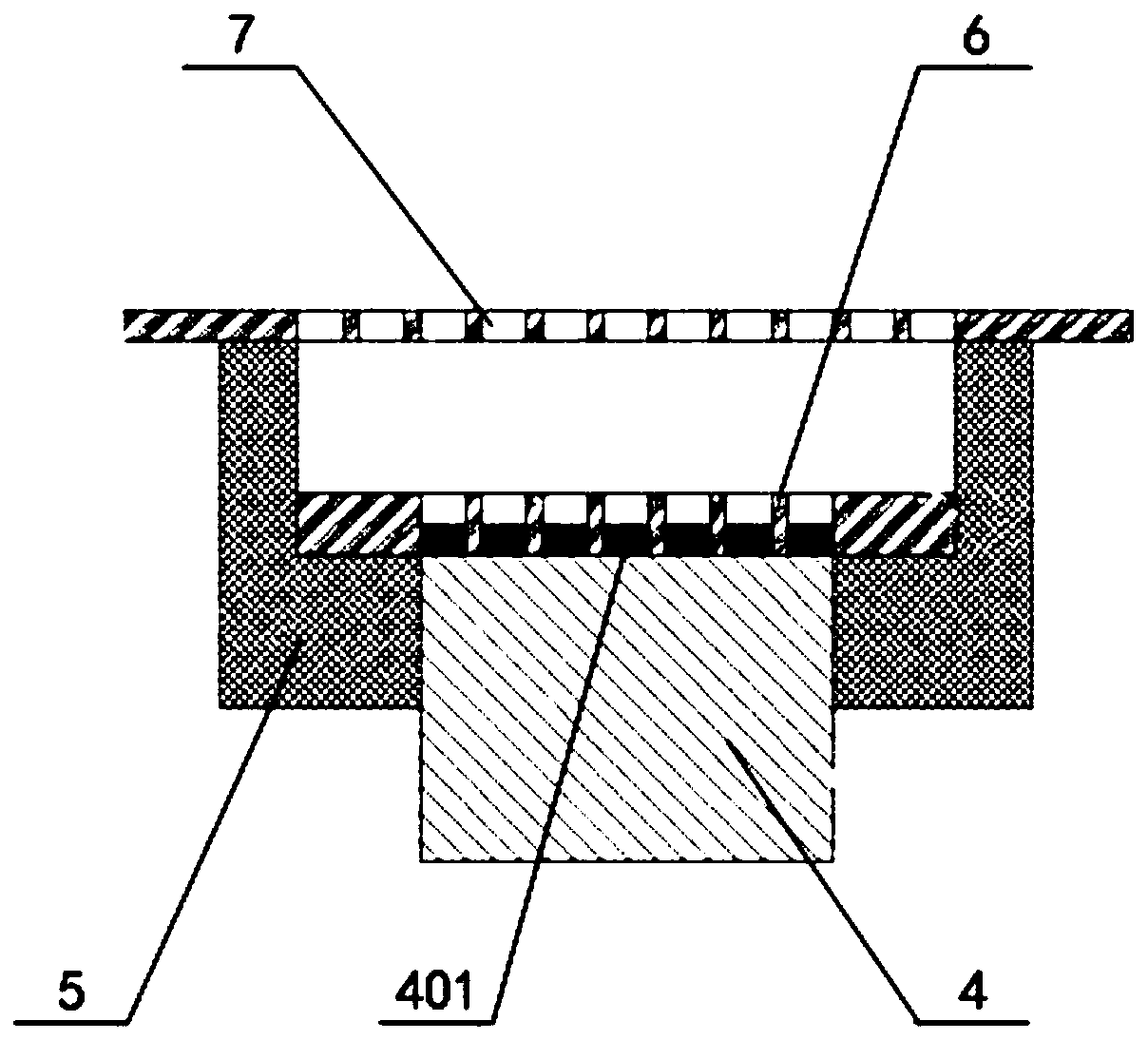

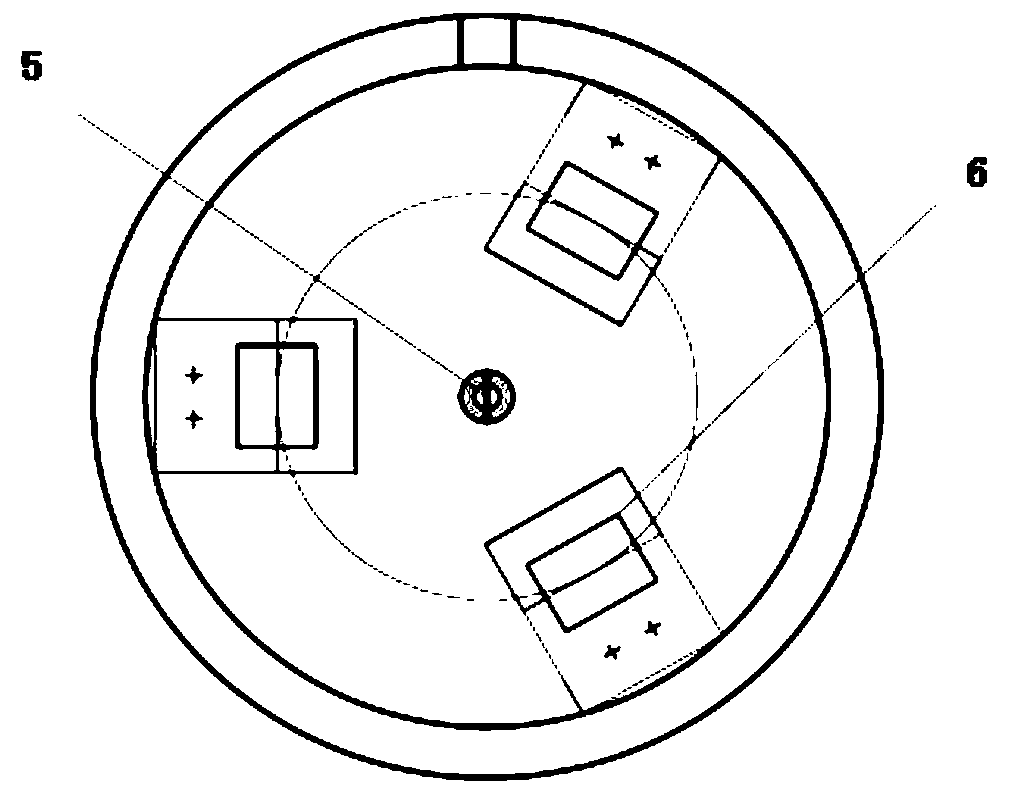

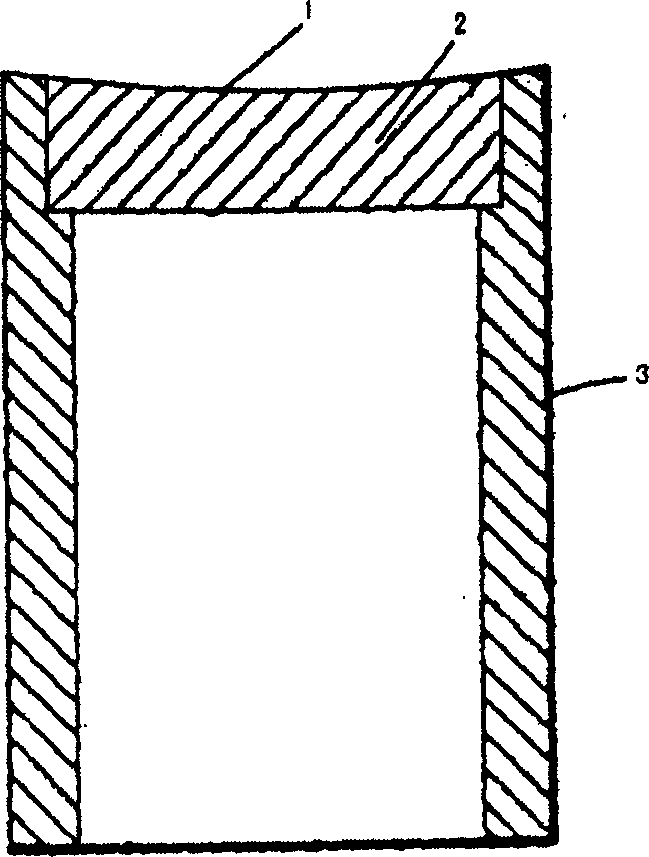

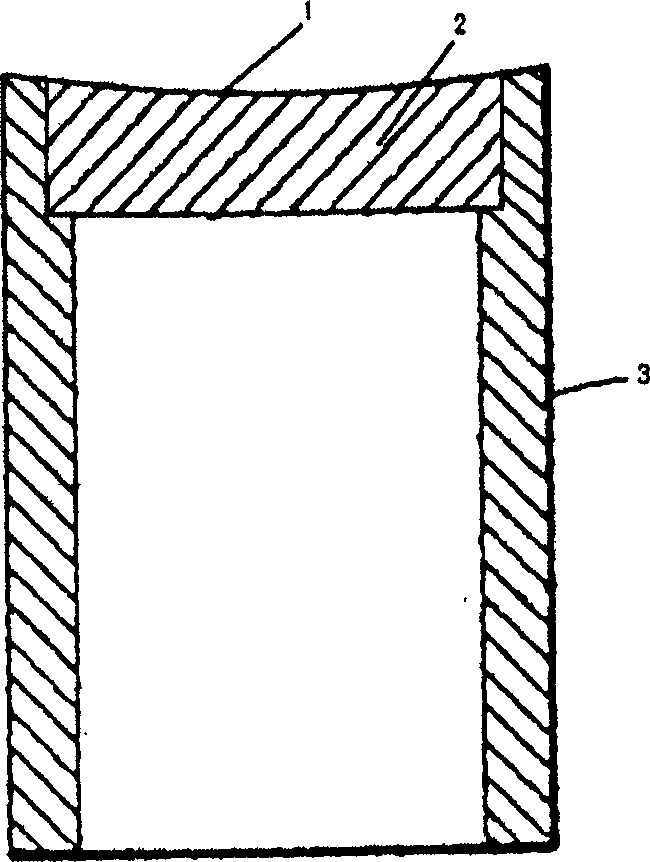

Pointed cone array cold cathode X light tube with large-emitting-area field emission composite materials

ActiveCN103400739ASatisfy the emission current requirementsOvercome the problem of poor consistencyX-ray tube electrodesElectricityPower flow

The invention relates to a pointed cone array cold cathode X light tube with large-emitting-area field emission composite materials. A cathode component comprises a plurality of pointed cone array cold cathode sheets in continuous splicing joint, a pointed cone array cold cathode comprises a base, an inner grid electrode sheet and a plurality of sub cathodes, the sub cathodes are distributed on the base and are in array-shaped arrangement, the inner grid electrode sheet is positioned above the sub cathodes, the center of the inner grid electrode sheet is provided with inner grid electrode holes in one-to-one correspondence to the positions of the sub pointed cone array cold cathodes, an insulating layer is also arranged between the base and the inner grid electrode sheet, and the cathode component also comprises an electric connection compressing structure which is used for fixing the pointed cone array cold cathode sheets and leading out the electrodes. The pointed cone array cold cathode X light tube has the advantages that the problem of poor consistency of pointed cone arrays at array center point and edge parts during the one-step preparation of single-sheet large-area cathode pointed cone arrays is solved, meanwhile, the requirement of the X light tube on the emitting current during great X dosage output is met, and high-quality X light imaging is obtained.

Owner:CHENGDU CHUANGYUAN ELECTRONICS

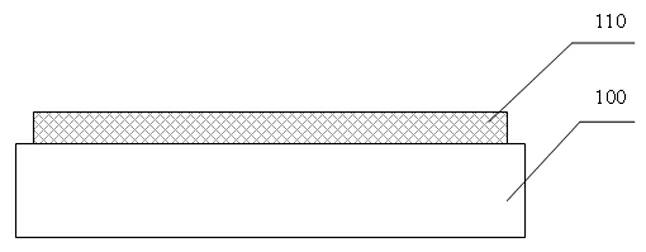

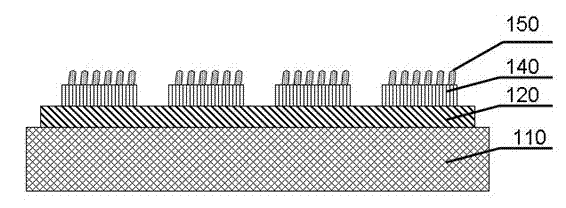

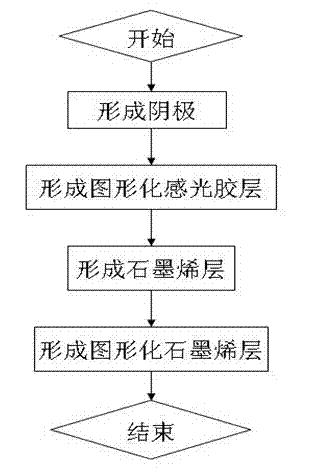

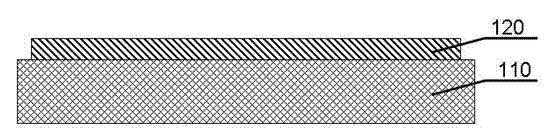

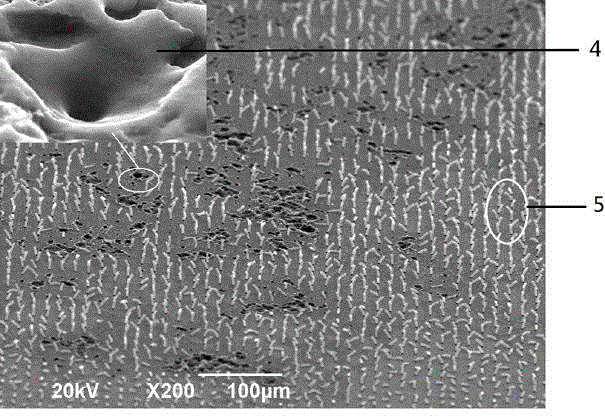

Patterned graphene field emission cathode and preparation method thereof

ActiveCN102339712AEmission is stable and evenRealize graphical preparationCathode ray tubes/electron beam tubesCold cathode manufactureLiquid-crystal displayField emission display

The invention discloses a patterned graphene field emission cathode and a preparation method thereof. The patterned graphene field emission cathode comprises a cathode substrate, a cathode arranged on the surface of the cathode substrate and a graphene layer arranged on the surface of the cathode, wherein a conductive adhesion layer is introduced between the cathode and the graphite, and the patterned preparation of the graphene layer is realized through a photoetching-stripping technology, and therefore the patterned field emission cathode is obtained. The graphene field emission cathode disclosed by the invention has the advantages of high emission current density, simple technological process, low cost and emission stability and uniformity, realizes patterned preparation and is suitable for a field emission display, a field emission flat light source, a field emission backlight source for a liquid crystal display and a cold cathode of a vacuum electronic device.

Owner:FUZHOU UNIV

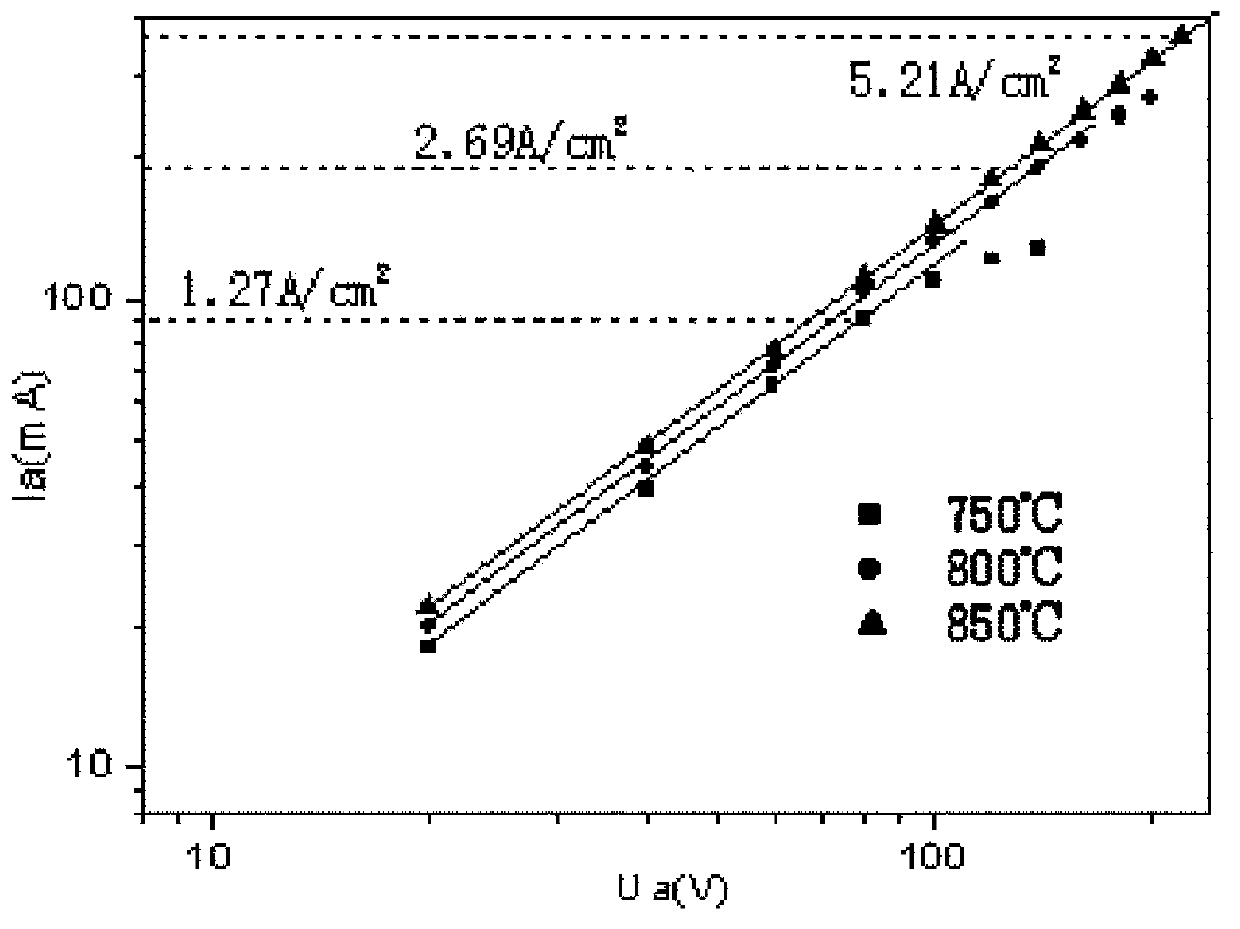

Preparation method for compacting scandium containing dispenser cathode

InactiveCN1909143AIncreased emission current densityEvenly distributedTungsten compoundsCold cathode manufactureRare earthAmmonium metatungstate

The invention relates to a method for producing compression scandium disperse cathode, wherein said method dissolves the Sc (NO3)3, Ba (NO3)2, Ca (NO3)2, Al (NO3)3 and ammonium metatungstate into water to be mixed, and adds citrate solution to be bathed, to form gel, then drying it to form gel, to be decomposed to obtain powder; reducing and compressing the powder into sample; sintering it under hydrogen gas to form cathode material. The invention has better repeat property, to apply batch production. And the elements of cathode material are uniformly distributed, with better emission property under 800Deg. C.

Owner:BEIJING UNIV OF TECH

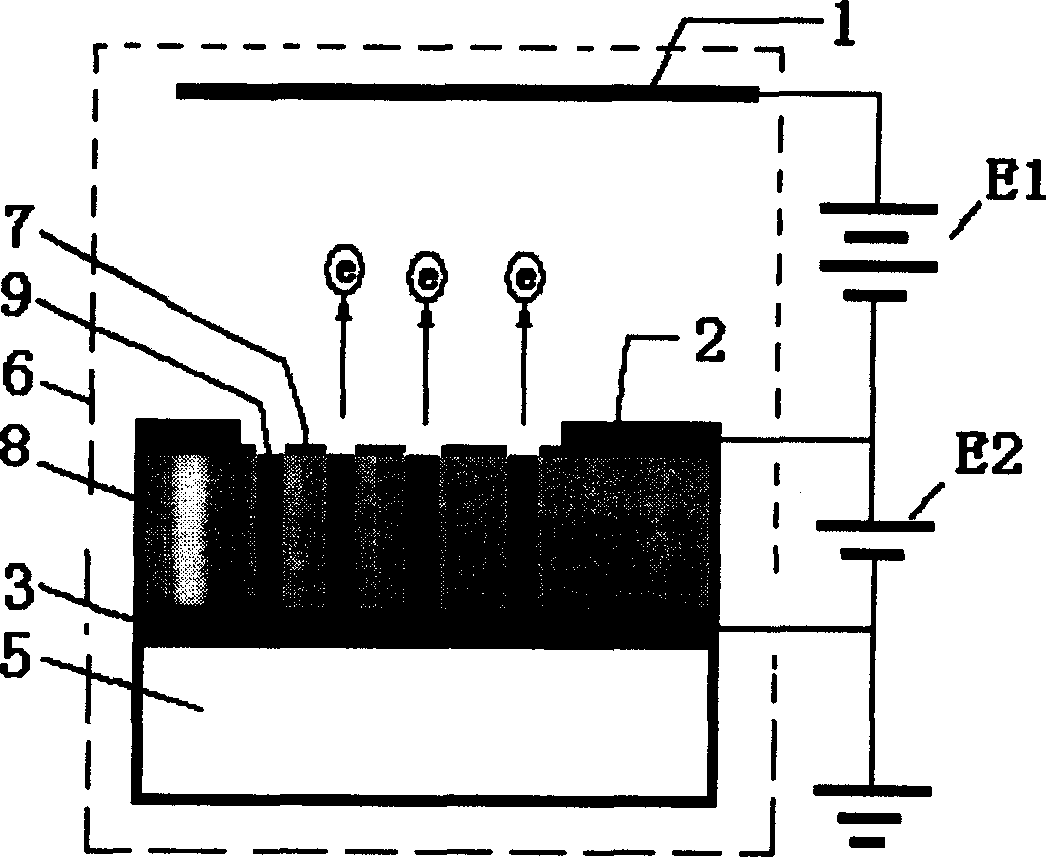

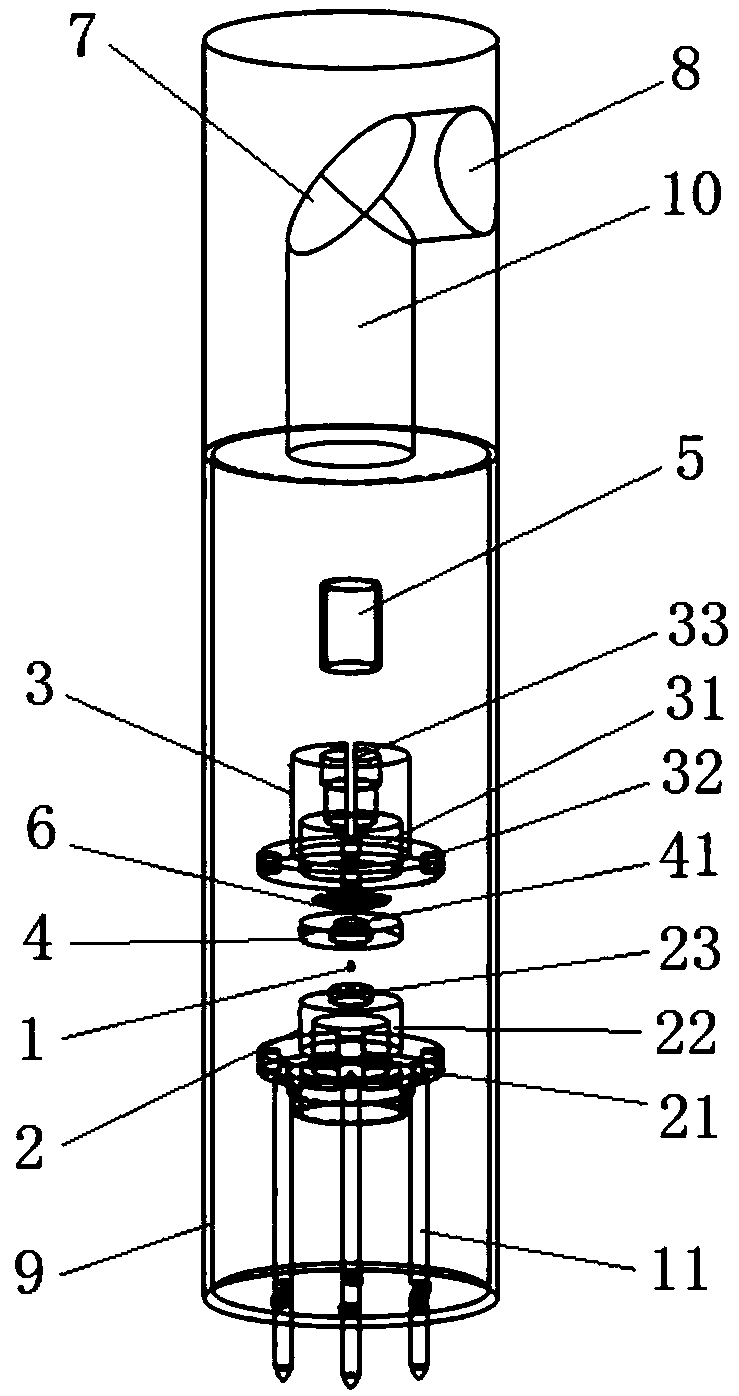

A double-grid controlled cold cathode electron gun and a preparation method thereof

ActiveCN109065428ASimple processExtended service lifeTransit-tube electron/ion gunsCold cathodesHigh densityElectron radiation

The invention relates to the technical field of vacuum electronic devices, and discloses a double-grid control type cold cathode electron gun and a preparation method thereof. In accordance with the present invention, A simple, a new type of electron gun with long service life and excellent performance is provided, the cold cathode is used as the emission source of the vacuum electronic device, Asurface of the cold cathode is arrayed by a cathode grid, which can effectively weaken the electrostatic shielding effect of electron emitted by large area cold cathode material, the emission currentof large area cold cathode material is increased, At the same time, the surface of the cathode substrate is designed as a whole plane so as to not only avoid machining burr and other problems, improveedge effect and spark phenomenon, but also make the electric field distribution on the surface of cathode substrate flat, which is conducive to improving the uniformity of emission current density and achieving the purpose of large current emission, so the electron gun can be used in vacuum electron radiation components or devices that generate large current and high density electron beam.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

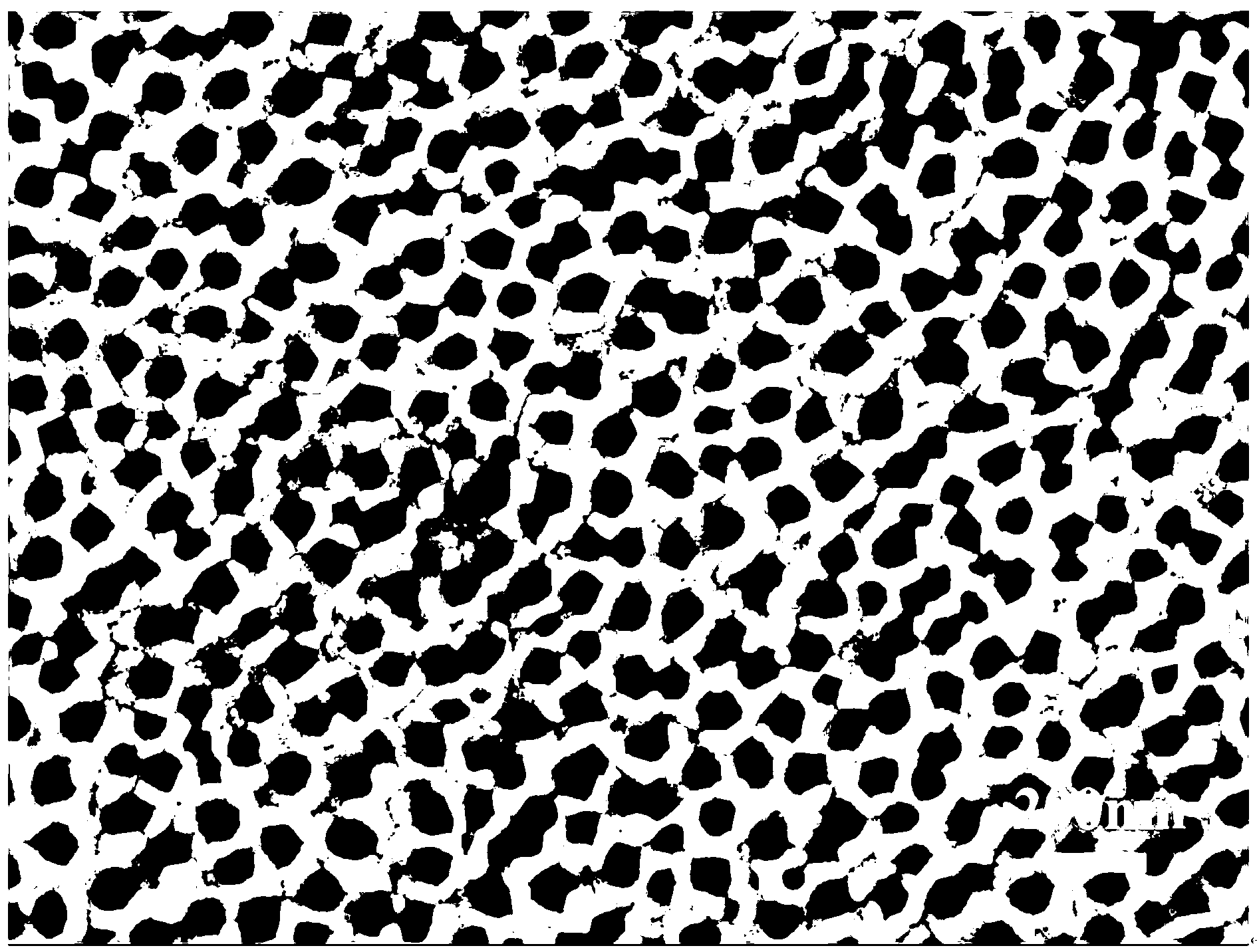

Preparation method and application of hydrogenated titanium dioxide nanotube array film

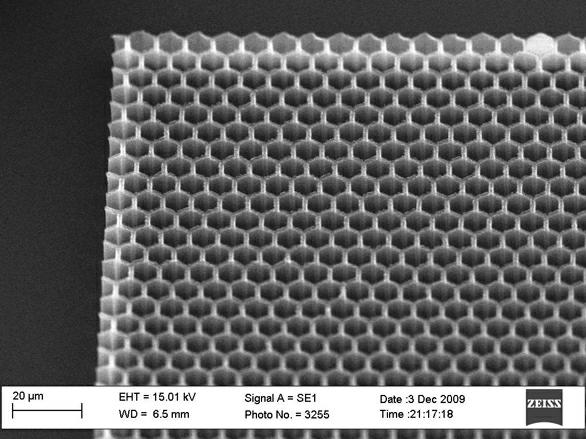

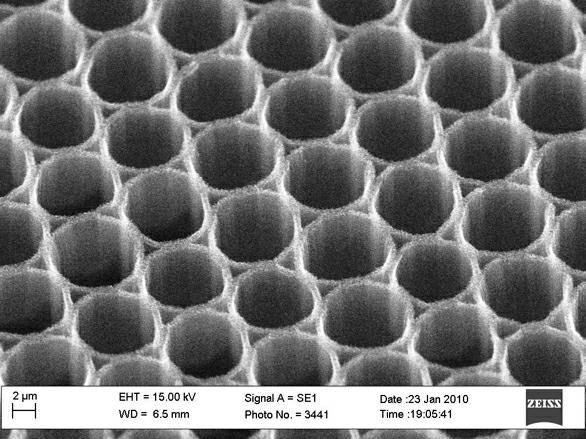

InactiveCN103060880AReduce the turn-on electric fieldIncreased emission current densitySurface reaction electrolytic coatingNanotechnologyArgon atmosphereField electron emission

The invention provides a preparation method and an application of a hydrogenated titanium dioxide nanotube array film. The preparation method comprises the following steps: cleaning an industrial titanium sheet, and chemically polishing; oxidizing at room temperature through a constant-voltage direct-current anodizing method; and carrying out heat treatment in a vacuum environment in a hydrogen-containing atmosphere, stopping the let-in of hydrogen, and naturally cooling to room temperature in an argon atmosphere to prepare the hydrogenated titanium dioxide nanotube array film. The hydrogenated titanium dioxide nanotube array film can be directly used as a field electron emission cold cathode. The preparation method enables the hydrogenated titanium dioxide nanotube array film having the characteristics of low turn-on field, large emission current density, good field emission stability, high repeatability and the like and directly used as the field electron emission to be prepared; and the preparation method can be used for the industrial production, enables the cold cathode field emitters having low prices to be prepared, and can be well applied in the field electron emission display cathode material field.

Owner:NORTHWEST NORMAL UNIVERSITY

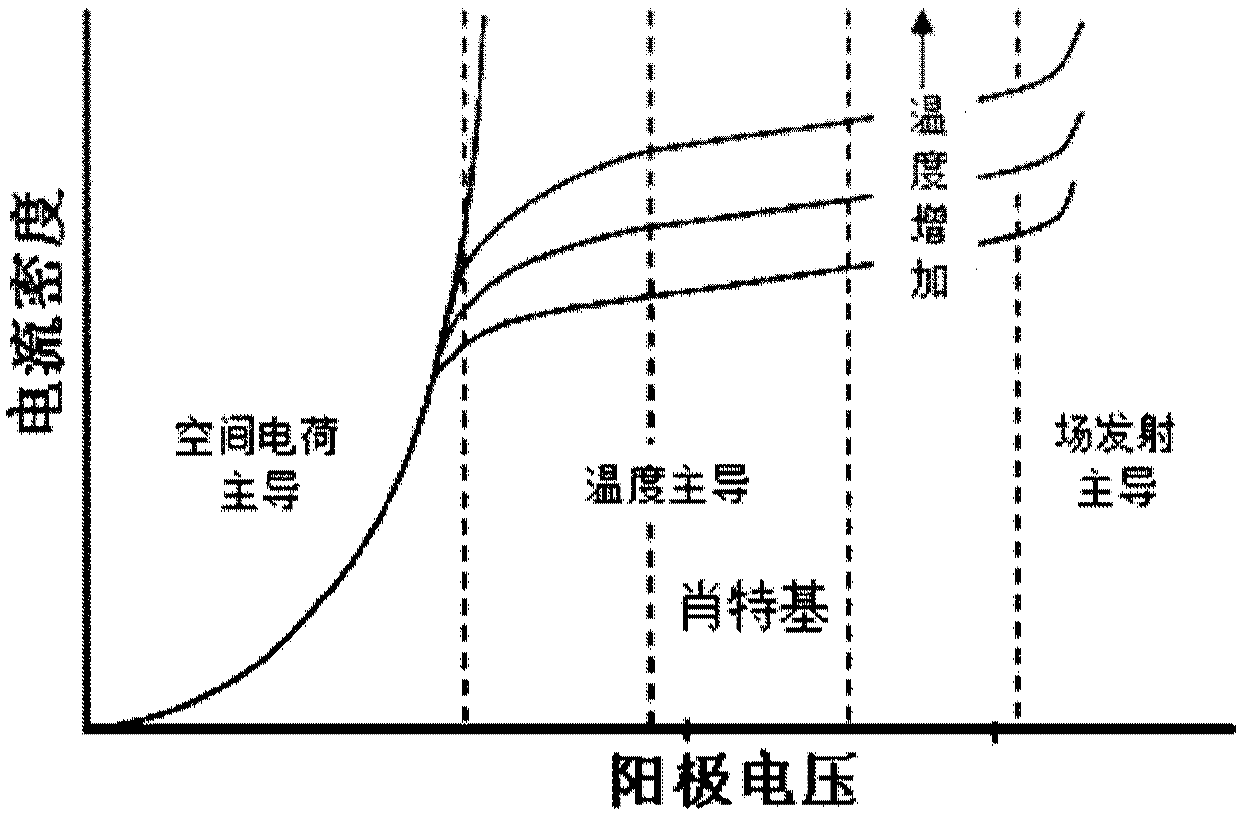

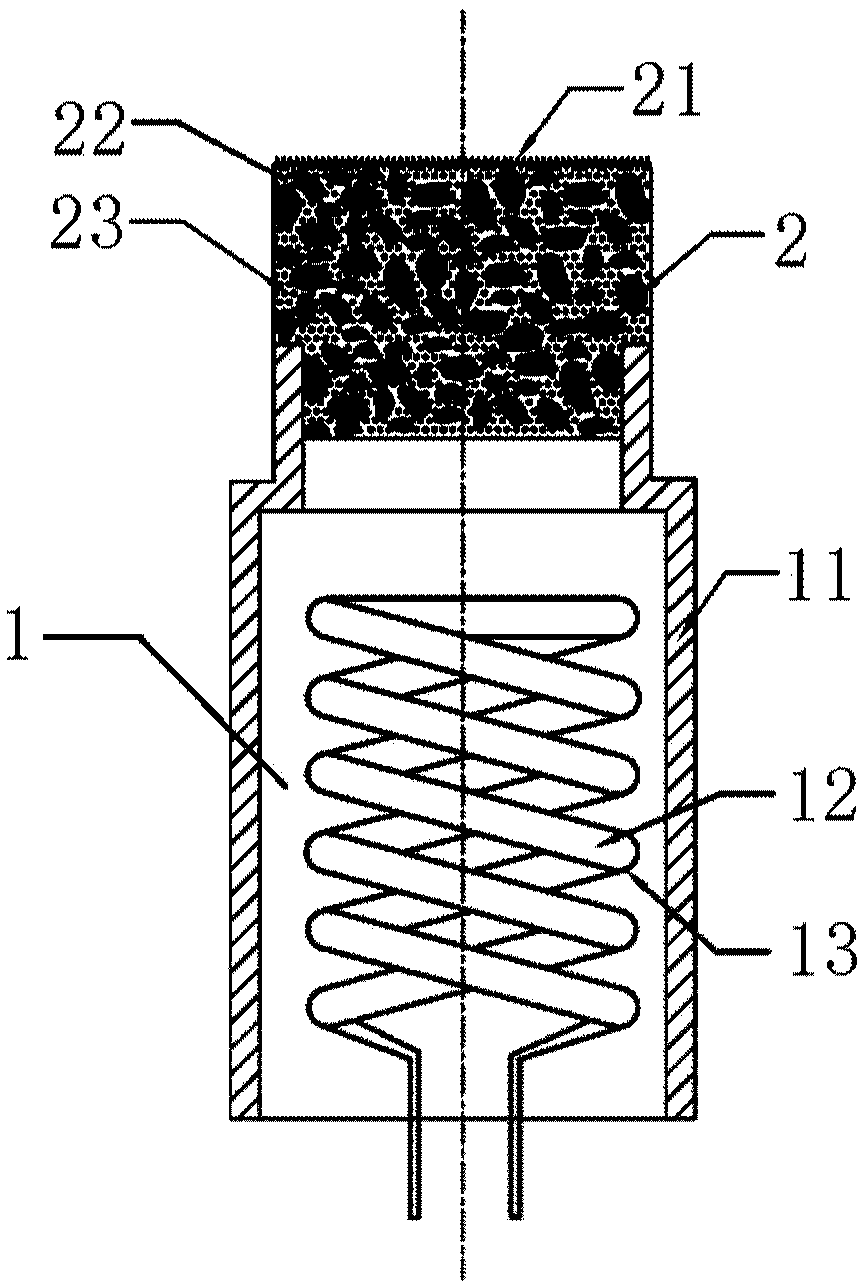

Thermal field emission cathode and preparation method thereof, and vacuum electronic device using same

ActiveCN107564783ALower working temperatureReduce power consumptionDischarge tube solid thermionic cathodesThermionic cathode manufacturePower flowWorking temperature

The invention discloses a thermal field emission cathode and a preparation method thereof, and a vacuum electronic device using same. The thermal field emission cathode comprises a molybdenum tube anda tungsten sponge body fixed on the molybdenum tube, wherein the upper surface of the tungsten sponge body has a microtip array, the microtip array is internally provided with pores, pores in the tungsten sponge body and pores in the microtip array form communicated pores, and the communicated pores are internally filled with an active substance. The microtip array is formed on the surface of thetungsten sponge body, the communicated pores from the tungsten sponge body directly to the pores in the microtip array are formed, and the communicated pores are filled with the active substance, sothat the active substance can reach the top of the microtip array under the action of thermal diffusion, thereby providing a condition for realization of low work function emission. Compared with traditional thermal emission cathode, the thermal field emission cathode is greatly lowered in working temperature and power consumption. Compared with traditional field emission cathode, the thermal field emission cathode has higher current emission density and stronger anti-ignition capability.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

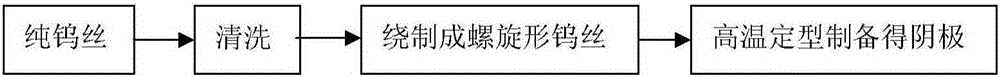

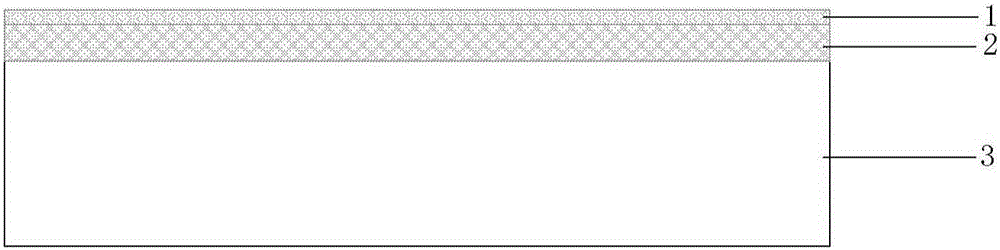

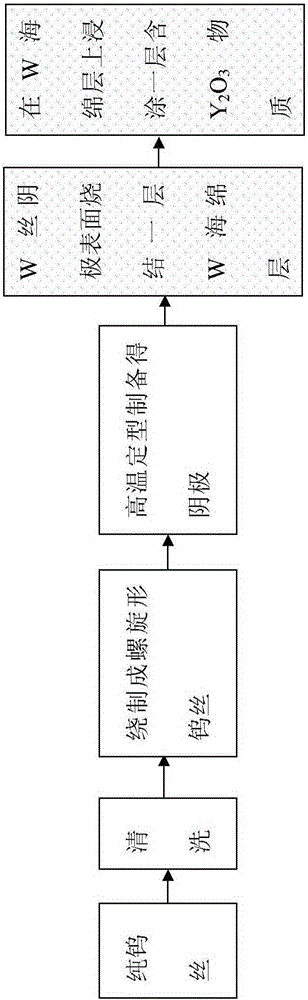

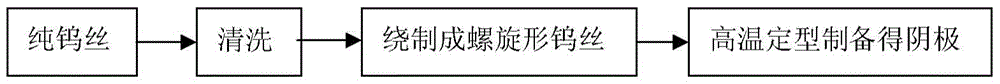

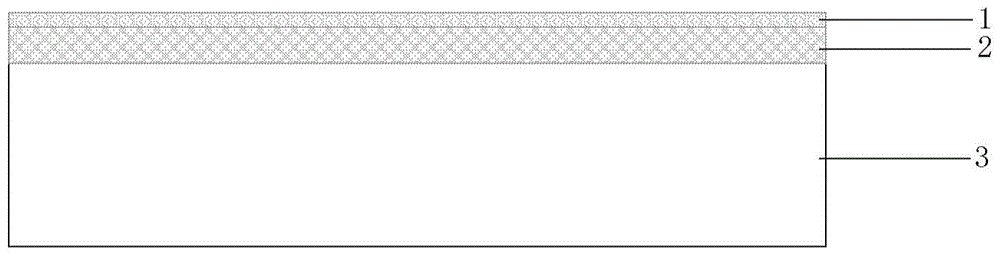

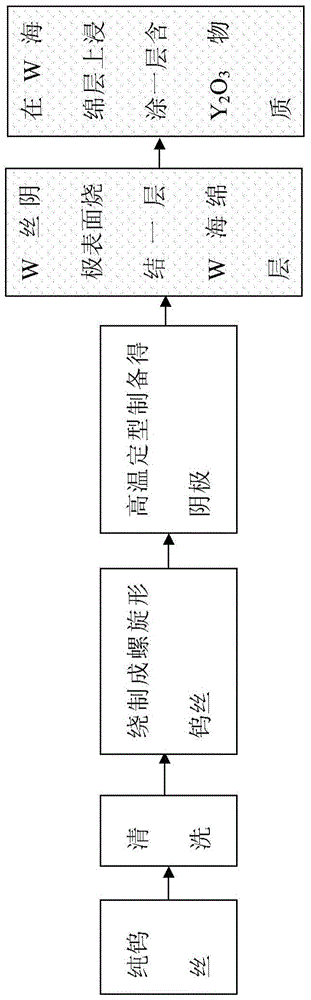

Directly heated cathode and preparation method thereof

ActiveCN105304436AIncreased emission current densityLower working temperatureTransit-tube cathodesPlant ingredientsDip-coatingTungsten filament

The invention discloses a directly heated cathode. A refractory oxide containing Y2O3 is adopted as an active substance; and the active substance is subjected to dip-coating on the surface of a pure tungsten filament cathode of which the surface is provided with a tungsten sponge layer to form the directly heated cathode. The invention further discloses a preparation method of the directly heated cathode. According to the directly heated cathode disclosed by the invention, the thermal emission current density of the pure tungsten filament cathode is greatly improved; and the working lifetime of the cathode is prolonged, so that the working lifetime of a high-power continuous wave magnetron is prolonged.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

Silicon-based filed emission cathode material with low threshold electric field and preparation method thereof

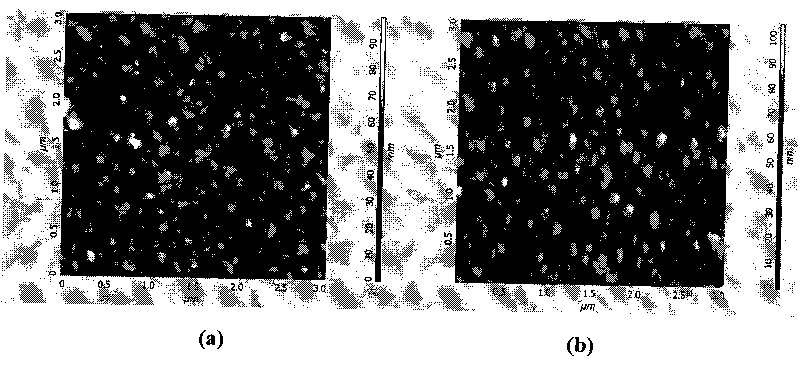

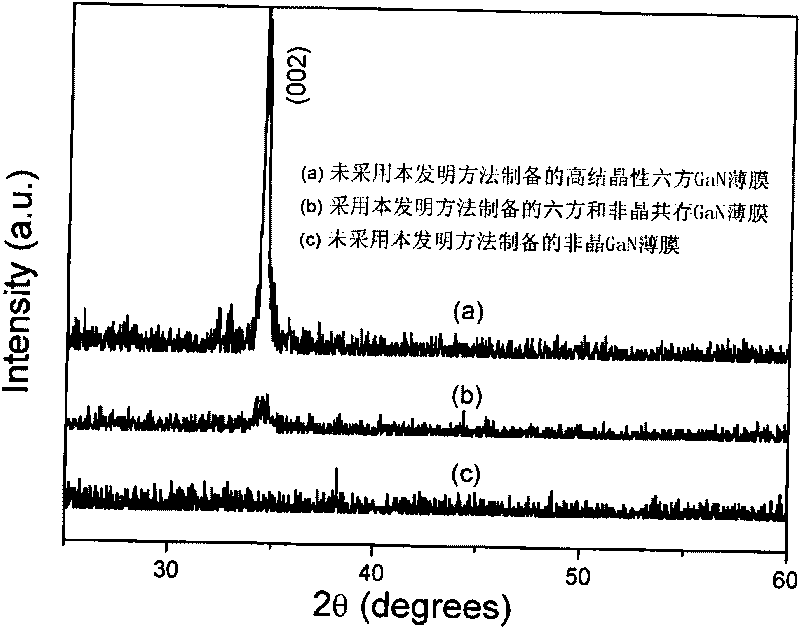

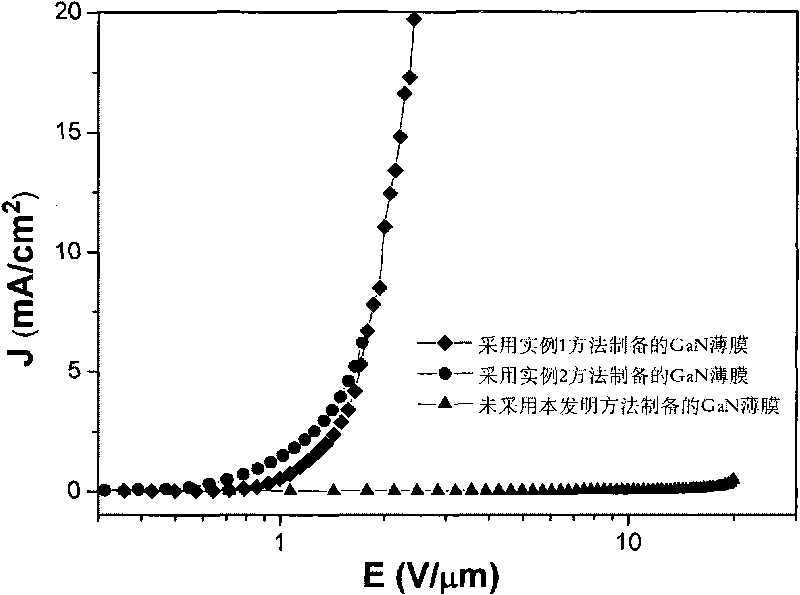

InactiveCN101728184ALowering the effective tunneling barrierHigh densityCathode ray tubes/electron beam tubesDischarge tube/lamp detailsElectronElectric field

The invention provides a silicon-based filed emission cathode material with a low threshold electric field and a preparation method thereof. The silicon-based filed emission cathode material can be GaN, AlN, BN, ZnO and ZnS and is characterized in that direct band gap semiconductor with the band gap width ranged from 3eV to 7eV can form a hexagonal wurtzite structure, and the material preferentially grows along the (002) crystal direction of the hexagonal wurtzite structure; the thickness thereof is more than 20mm and less than 50mm; and the material simultaneously has a hexagonal phase and an amorphous phase. The preparation method of the silicon-based filed emission cathode material comprises the following steps of carrying out laser pulse on a substrate which is silicon to deposit a film with certain thickness respectively through pretreatment and HF acid soaking so as to obtain a final product. A preparation technology is simple and easy, the prepared material has the low threshold electric field and electronic emission characteristics with high emission current density, and the cathode structure takes silicon as the substrate and can be integrated with other microelectronic devices easily; therefore, the cathode is an ideal cathode for manufacturing a vacuum microelectronic device.

Owner:BEIJING UNIV OF TECH

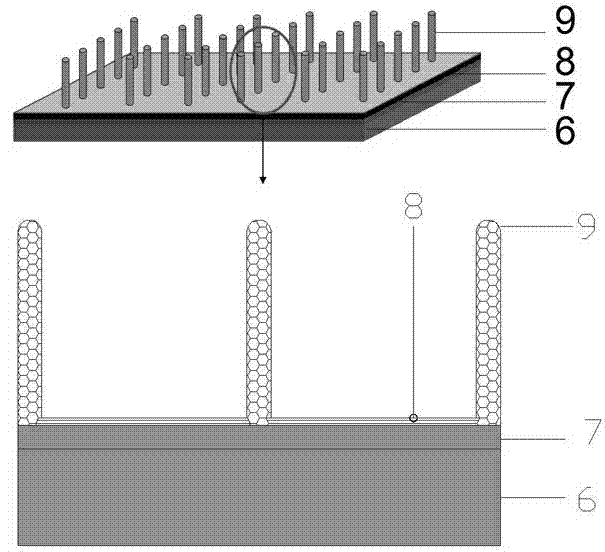

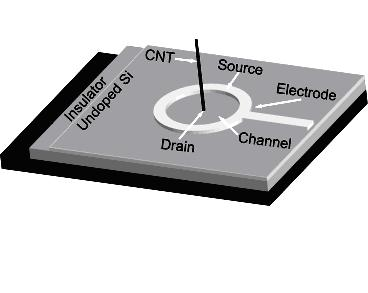

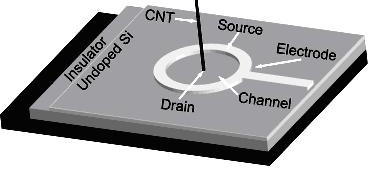

CNT (carbon nano tube) field emission array with current limiting transistors and preparation thereof

InactiveCN102306595AIncreased emission current densityHigh densityDischarge tube/lamp detailsCold cathode manufactureTransistor arrayCurrent limiting

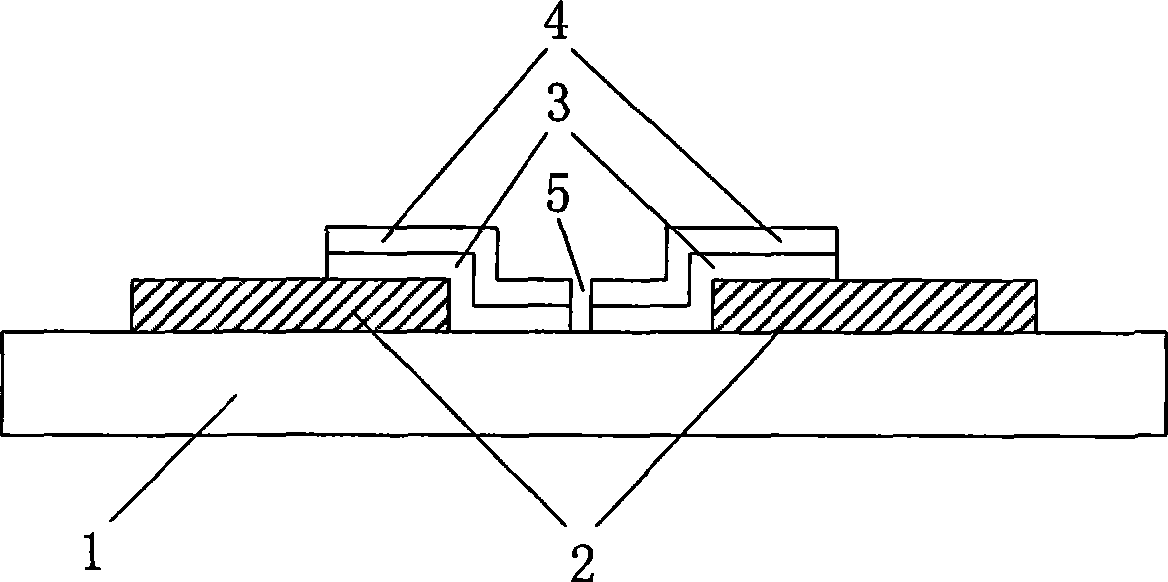

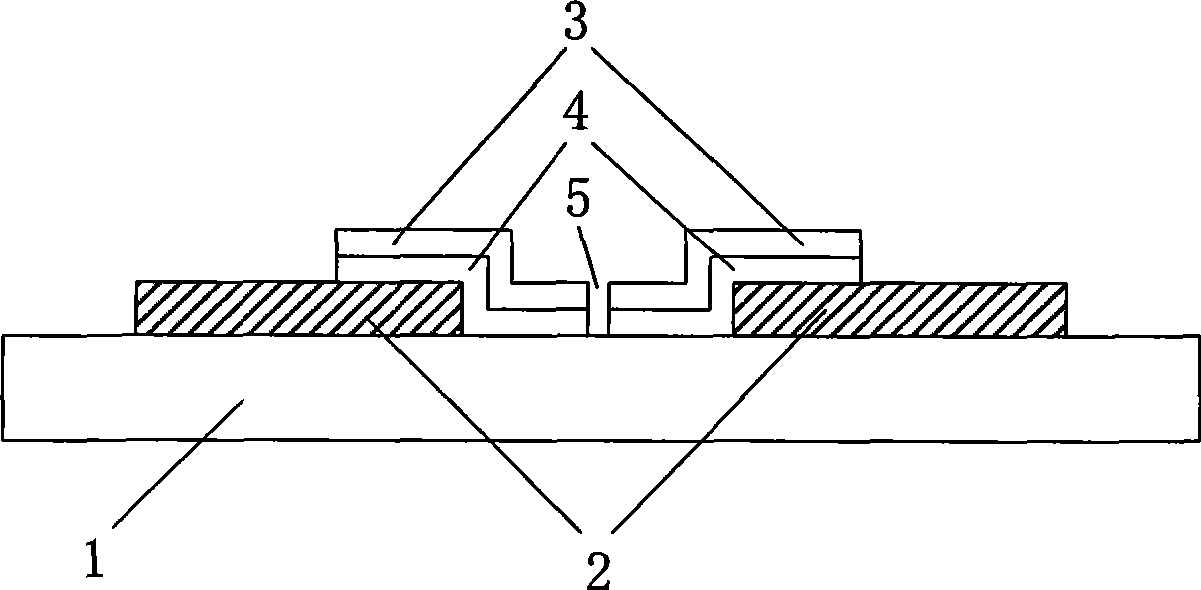

A CNT (carbon nano tube) field emission array with current limiting transistors comprises a cathode, a gate below the cathode, an insulating layer between the cathode and the gate and a semiconductor layer, wherein a conductive substrate is used as the gate; the insulating layer is arranged on the conductive substrate, a semiconductor film is arranged on the insulating layer; a grid-shaped or annular metal electrode which is used as the cathode is arranged on the semiconductor film; the central position of a grid-shaped or annular hole of the grid-shaped or annular metal electrode is provided with a single CNT which grows perpendicular to the substrate; one end of the CNT is electrically connected with the semiconductor layer, and the CNT is electrically connected with the cathode through the semiconductor layer; and CNT field emission elements with the current limiting transistors arrayed in a plane can form a field emission array, and the electrode is a grid-shaped metal electrode. In the invention, each CNT in the CNT field emission array is connected with a current limiting transistor in series, thus an emission element with the large emission current density and the high emission stability can be obtained.

Owner:上海康众光电科技有限公司

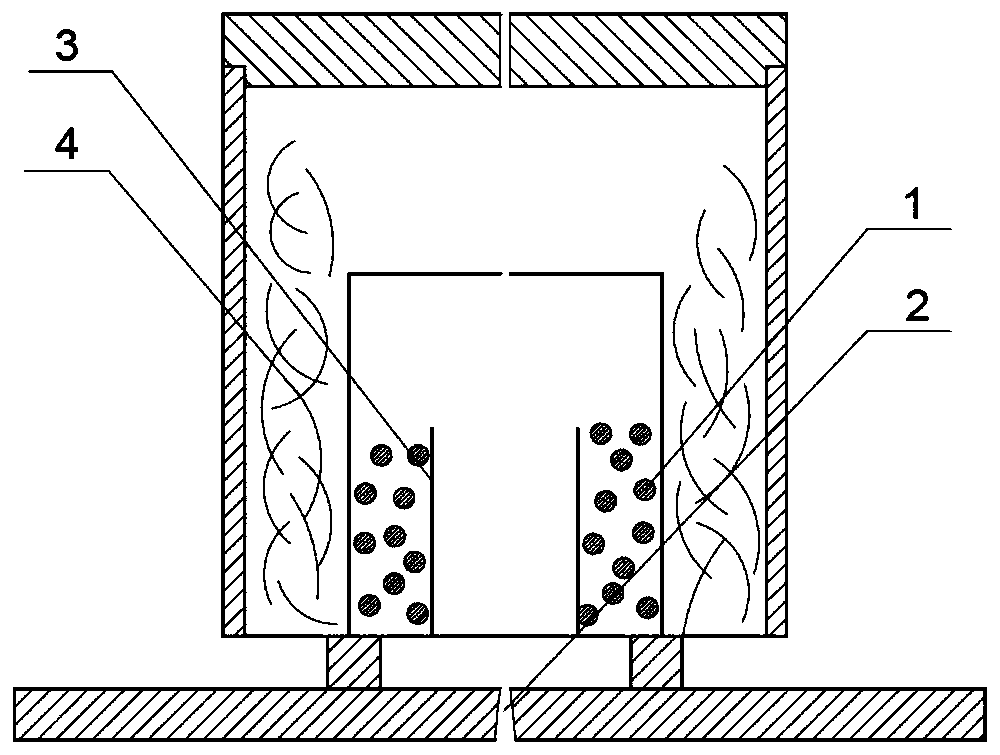

Field emitting electronic source device and its preparing process

InactiveCN1652283AReduce divergenceIncreased emission current densityElectric discharge tubesDischarge tube electron gunsDriving currentInsulation layer

The disclosed device consists of electron source of field emission and anode sealed in vacuum container. The electron source includes cathode, grid pole and interlayer prepared on base plate. Insulation layer is positioned between thick metallic membrane, which leads out grid pole, and cathode. Compound body layer is located between thin metallic membrane of possessing large numbers of micropores connected to the said thick metallic membrane and cathode. Interlayer structure includes insulation layer, semiconductor layer and compound body layer positioned between cathode and grid layer. Preparation method includes steps: preparing compound body layer on the cathode fabricated on base plate of silicon or glass etc. through microelectronic technique; preparing grid pole of thin metallic membrane on compound body layer; sealing the prepared device and anode in vacuum container. Advantages are simple technique, reasonable structure, low driving current and high emissivity etc.

Owner:OCEAN UNIV OF CHINA

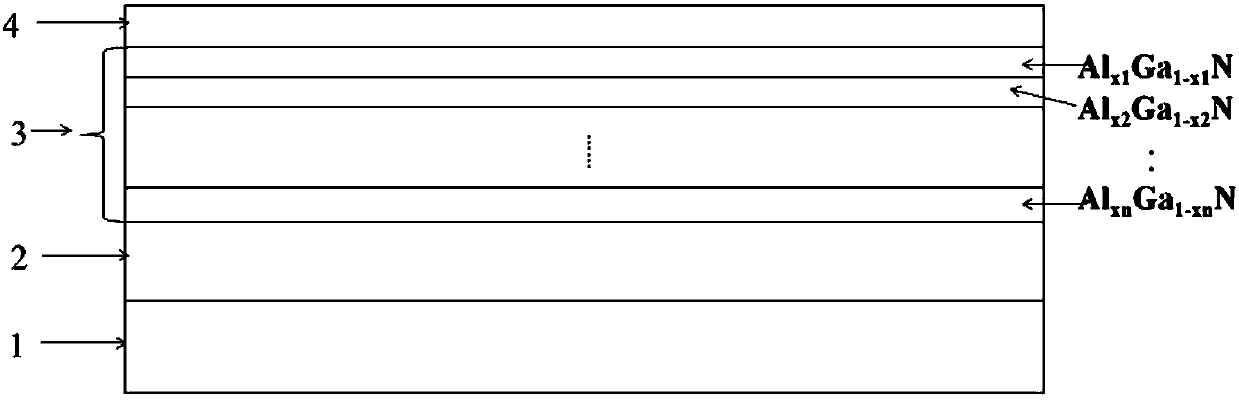

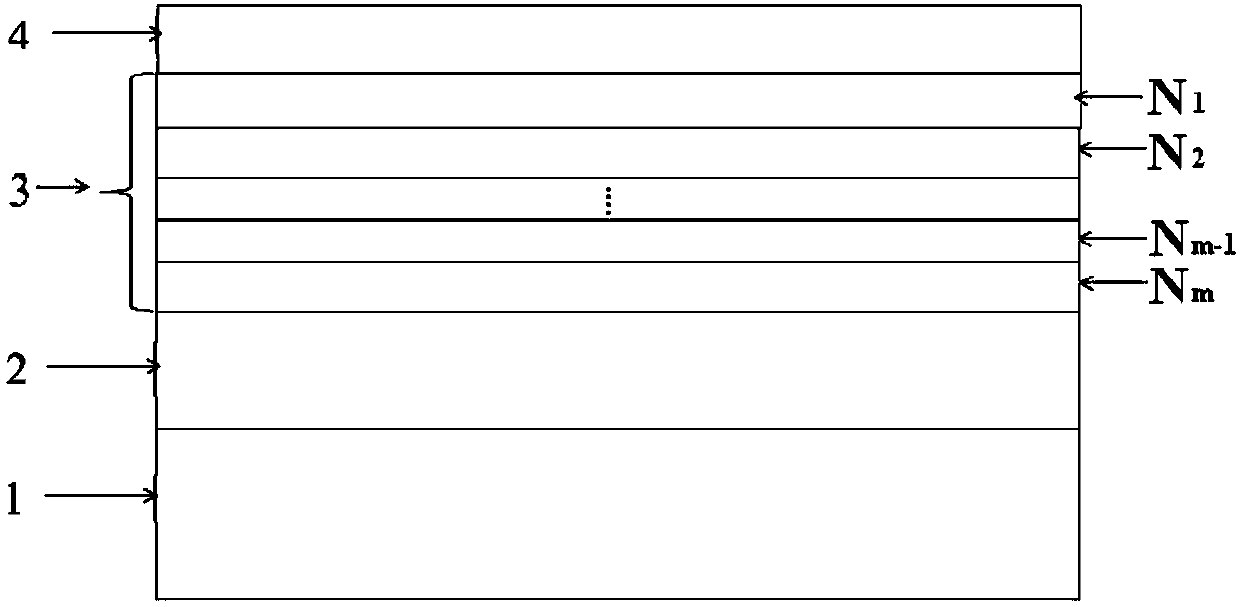

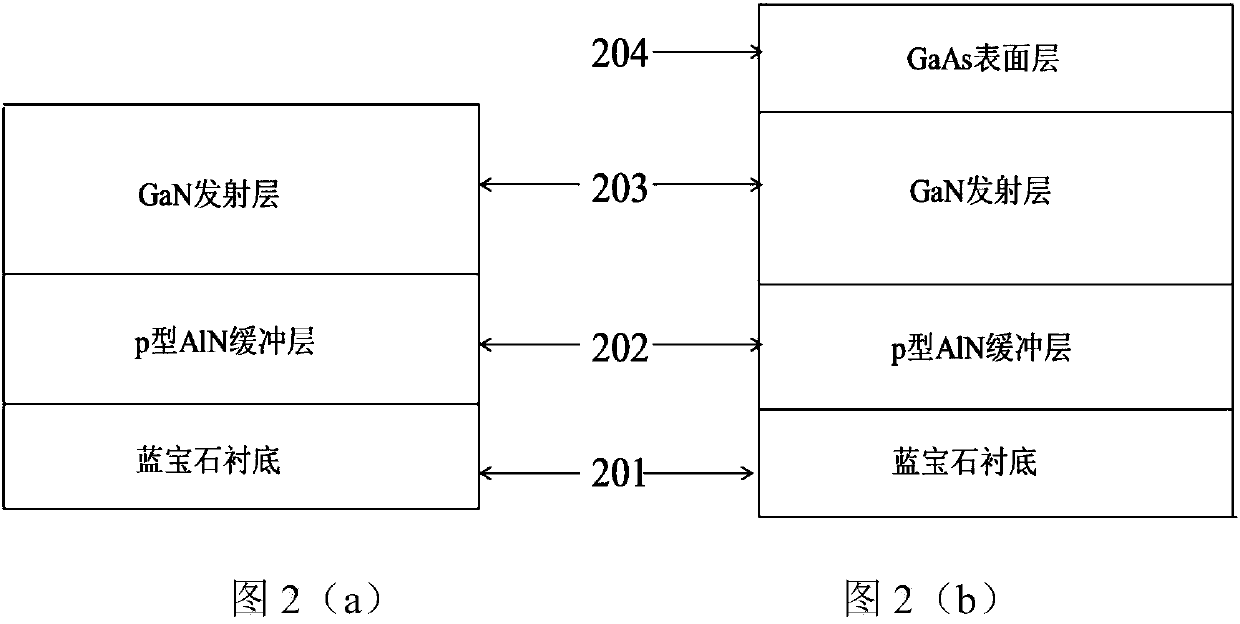

Photoelectric cathode and preparation method thereof

PendingCN107895681AImprove stabilityStrong resistance to ion bombardmentPhoto-emissive cathodesPhoto-emissive cathodes manufactureSurface layerSemiconductor materials

The invention discloses a photoelectric cathode, which comprises a substrate, a p-type AlN buffer layer formed on the substrate, a p-type AlxGa1-xN emitting layer formed on the p-type AlN buffer layer, and a narrow bandgap semiconductor surface layer formed on the p-type AlxGa1-xN emitting layer. The bandgap width of the semiconductor material of the narrow bandgap semiconductor surface layer is less than or equal to 2. 3eV at the room temperature. The range of x in the p-type AlxGa1-xN emitting layer is 0 < = x < 1. According to the photoelectric cathode disclosed by the invention, the narrowbandgap semiconductor surface layer is grown on the p-type AlxGa1-xN emitting layer. The atoms of the narrow bandgap semiconductor surface layer and the atoms of the p-type AlxGa1-xN emitting layer are combined in a covalent bond mode, so that the surface energy band structure of the AlxGa1-xN material is effectively improved. The surface work function of the photoelectric cathode is reduced. Theelectron tunneling probability of the surface of the photoelectric cathode is improved.

Owner:NO 12 RES INST OF CETC

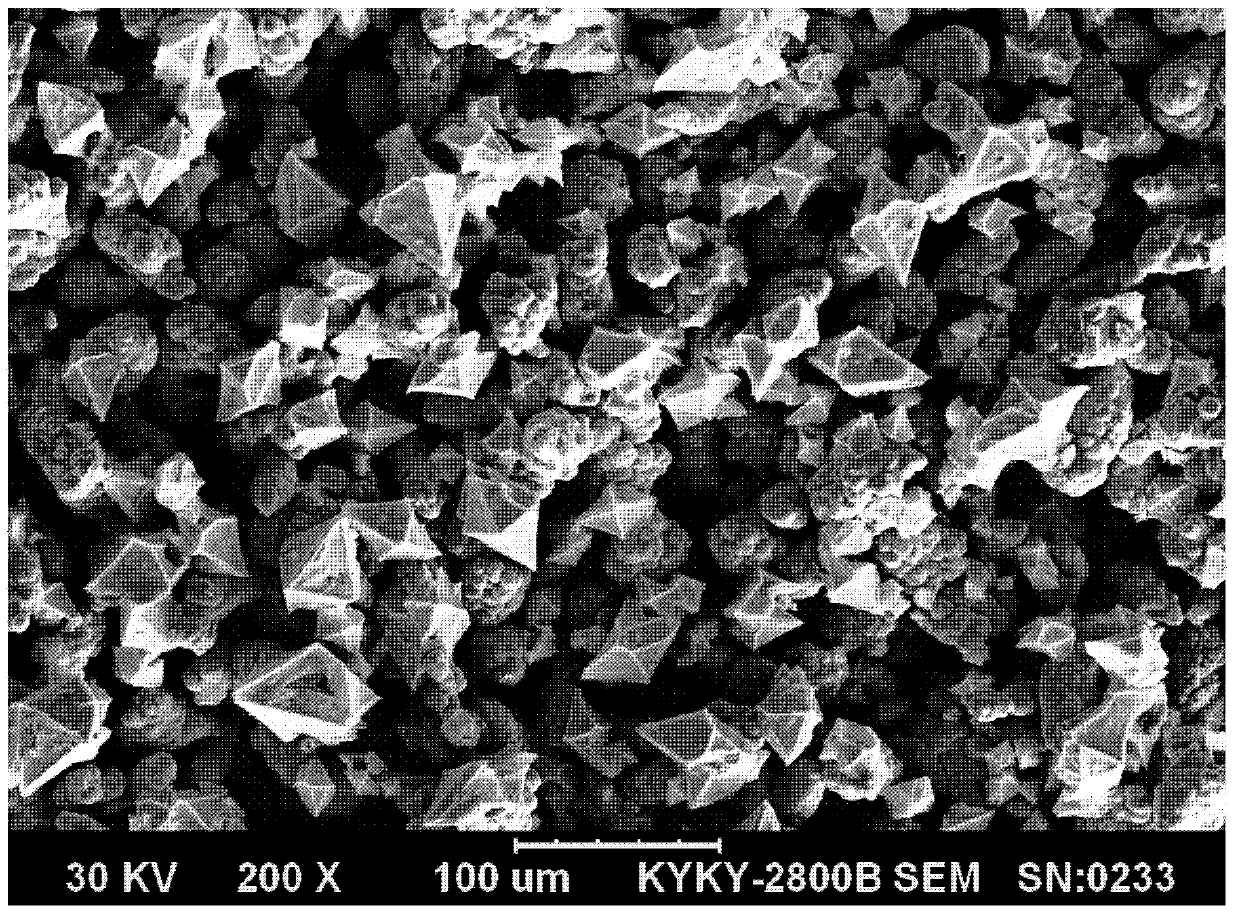

A diamond film flat field emission cathode and method for making same

InactiveCN1567506AImplement injectionReduce compoundingDischarge tube/lamp detailsCold cathode manufactureElectron injectionMetal silicide

The invention belongs to a diamond film planar field emission cathode applied to plate display and its making method. It includes: a substrate, where a measuring metal electrode is deposited on one surface of the substrate and a measuring lead wire is connected with them; there is a diamond film layer on the other surface of the substrate; a metal silicide transition layer is situated between the substrate and diamond film layer. Its making method includes: firstly making a metal silicide transition layer on one surface of the substrate; then adopting various traditional methods to grow a diamond film on the metal silicide, because it is difficult in directly growing diamond film on the metal silicide, normally nucleating at bias voltage and then growing the diamond film; adopting spurting or depositing process to deposit 300-1000 nm thick Au electrode on the other surface of the substrate. The metal silicide transition layer provides two interface barriers tunneled by electron resonance, thus realizing high-density electron injection. And the making method is easy to spread.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

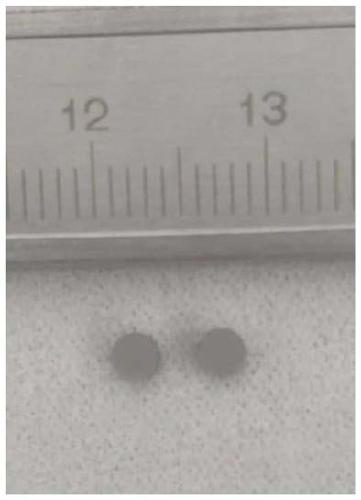

Method for preparing pressing type barium-tungsten cathode through microwave sintering

InactiveCN109807326AInhibit growthImprove microstructureTurbinesOther manufacturing equipments/toolsAmmonium metatungstateMicrowave sintering

The invention provides a method for preparing a pressing type barium-tungsten cathode through microwave sintering, and belongs to the technical field of refractory metal cathode materials. Ammonium metatungstate, barium nitrate, calcium nitrate and aluminium nitrate of an analytical reagent are dissolved in deionized water, and after liquid-liquid doping is completed, submicron-order active salt doped tungsten powder is obtained through the combination of spray drying and a two-stage reduction method. Then, the barium-tungsten cathode with a submicron structure is obtained through pressing andmicrowave sintering processes. The experimental result shows that compared with a method for preparing a cathode through conventional sintering, the sintering temperature of the microwave sintering process is low, the sintering time is short, and the sintering power is greatly reduced. The microstructure of the cathode prepared through microwave sintering is obviously improved, the emitting performance of the cathode is improved to a certain degree, the drawn pulse emission current density can reach 6.52 A / cm<2> at the temperature of 1,050 DEG Cb, and compared with the drawn emission currentdensity, being 3.46 A / cm<2>, of the cathode prepared through conventional sintering at the temperature of 1,050 DEG Cb, the pulse emission current density is obviously increased.

Owner:BEIJING UNIV OF TECH

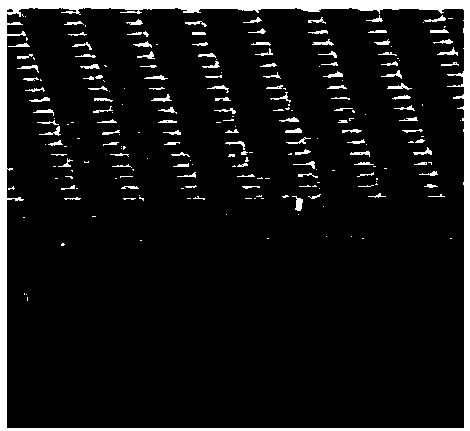

Carbon nanotube fiber array cold cathode preparation method

The invention provides a carbon nanotube fiber array cold cathode preparation method. The method includes the steps that a super-long orientation carbon nanotube is composited on a silicone substrate provided with a plurality of layers of metal catalysts in a deposition mode through a chemical vapor deposition method, and laddering and spinning are conducted on the composited carbon nanotube through a spinning method to continuously prepare orientation carbon nanotube fibers; then, microhole arrays are prepared in a conductive substrate in an etching mode or a laser boring mode, the spinning carbon nanotube fibers are implanted into the microhole arrays, and the length of the fibers is clipped according to the proper requirement; next, metal nanometer powder or metal micrometer powder is prepared into slurry, microholes in the conductive substrate are filled with the slurry in a microhole grouting mode, and then the conductive substrate is placed in a vacuum furnace; finally, annealing treatment is conducted on the conductive substrate at the temperature ranging from 400 DEG C to 900 DEG C under the protection of inert gases, or hydrogen reduction annealing treatment is conducted in the hydrogen atmosphere, or laser ablation is conducted under the protection of the inert gases, and the conductive substrate generated after the annealing treatment or the laser ablation treatment is conducted is the carbon nanotube fiber array cold cathode.

Owner:谢曌东

Method for preparing Ni-Re sponge oxide cathode

InactiveCN103681162AGood synthesis effectImprove doping uniformityCold cathode manufactureOxide cathodeAqueous solution

The invention discloses a method for preparing a Ni-Re sponge oxide cathode. The method comprises the following steps: immersing a Ni net sintered with a Ni sponge layer in NH4ReO4 water solution to enable the Ni sponge layer to absorb NH4ReO4; sintering the Ni net to enable the Ni sponge layer containing NH4ReO4 to be converted into a Ni-Re sponge layer; and applying carbonate in the sponge holes and on the surface of the Ni sponge layer of the Ni net. By the adoption of the method of the invention, the emission current density of the Ni sponge oxide cathode can be improved, the working temperature of the cathode can be reduced and the activity of the cathode can be enhanced.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

Method for preparing metal nanometer thin film dipped barium-tungsten cathode

InactiveCN1801427AHigh surface to volume ratioLower work functionCold cathode manufactureMicrowaveEvaporation

The disclosed preparation method for metal nano film dipping Ba-W cathode in microwave device has large emission current density and low evaporation by depositing one layer of 10-100nm metal grain film of Os, Ir, Rh, Ru or other with thickness as 0.1-0.6um.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

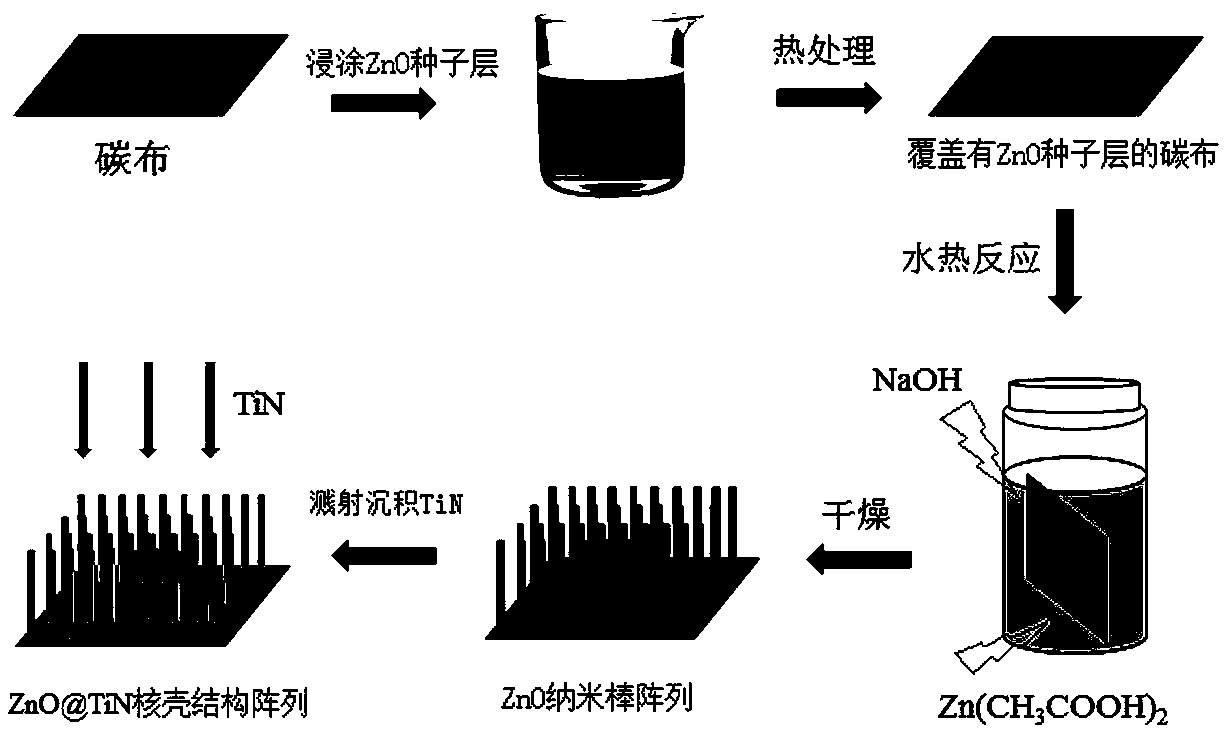

Flexible ZnO@TiN core-shell structure array cathode and preparation method thereof

InactiveCN111180293AReduce openingIncreased emission current densityElectric discharge tubesDischarge tube/lamp detailsElectron sourceFluid phase

The invention relates to a flexible ZnO@TiN core-shell structure array cathode and a preparation method thereof. The ZnO@TiN core-shell structure array cathode comprises carbon cloth, two side surfaces of the carbon cloth are coated with ZnO seed layers, ZnO nanorod arrays are arranged on the ZnO seed layers on the two side surfaces, and TiN is deposited on the ZnO nanorod array on one side surface to form a core-shell structure array. The preparation method comprises the following steps of: (1) preparing the ZnO seed layers on two side surfaces of carbon cloth by adopting a sol-gel method, (2) preparing ZnO nanorod arrays on the ZnO seed layers on the two side surfaces by adopting a liquid phase method, and (3) depositing TiN on the ZnO nanorod array on one side surface by adopting a magnetron sputtering method so as to prepare the ZnO@TiN core-shell structure array cathode. The ZnO@TiN core-shell structure array cathode is low in opening and threshold electric field, high in emissioncurrent density and good in electron transport and conductivity, and can be applied to a vacuum field emission electron source device.

Owner:FUJIAN UNIV OF TECH

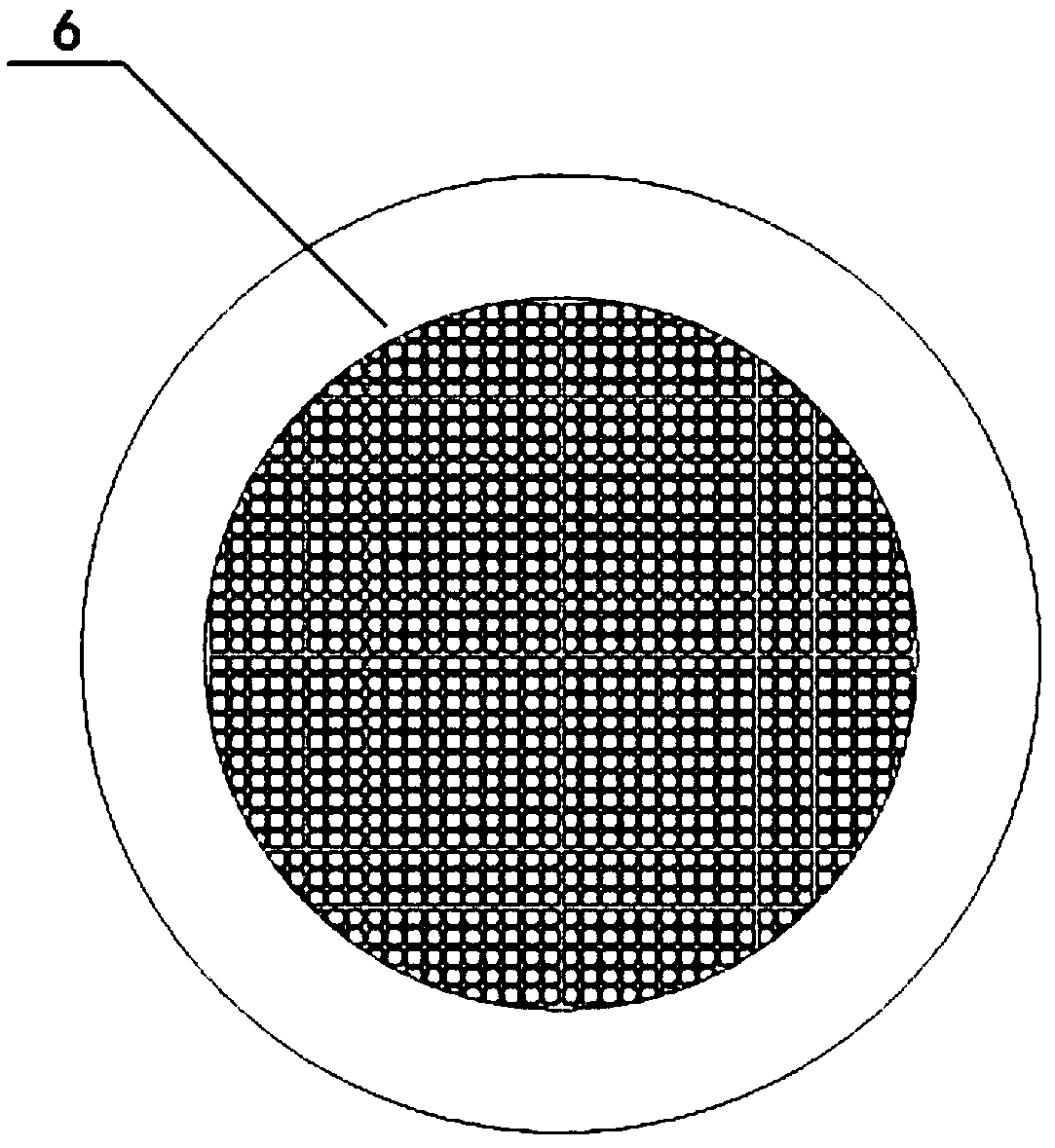

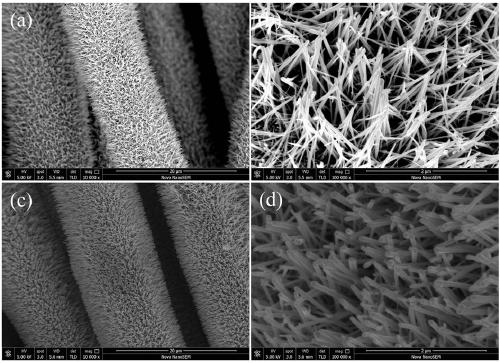

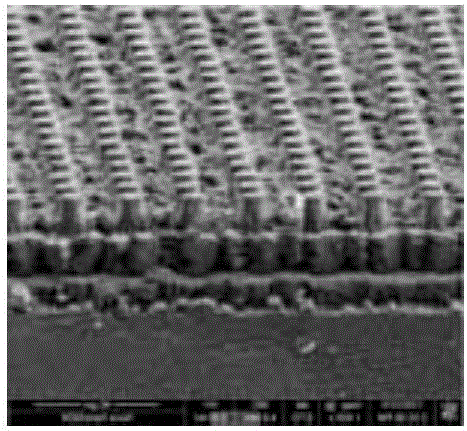

Field Emission Electron Source and Preparation Method of Its Carbon Nanotube Graphene Composite Structure

ActiveCN103050346BImprove launch performanceImprove stabilityMaterial nanotechnologyDischarge tube/lamp detailsElectron sourceField electron emission

The invention discloses a field emission electron source and a preparation method of a carbon nanotube graphene composite structure thereof. The field emission electron source comprises a conductive substrate, a graphene film layer and a carbon nanotube array which is directionally perpendicular to the graphene film layer, wherein the graphene film layer is adhered onto the conductive substrate, and one end of each carbon nanotube in the carbon nanotube array is connected with the graphene film layer to form an integrated structure. The emission capacity and stability of the carbon nanotube array field emission electron source are greatly improved, so that the electron source obtains highly efficient and stable emission current, and can bear extremely high emission current density.

Owner:广州市昊志影像科技有限公司

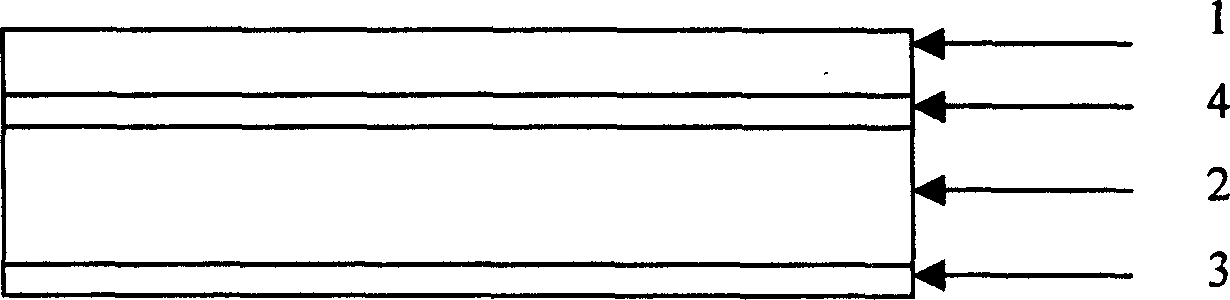

Construction of surface conductive field emission electronic source conductive film

InactiveCN101383258ALow emission threshold voltageImprove mobilityCathode ray tubes/electron beam tubesDischarge tube/lamp detailsComposite filmCharge carrier mobility

The invention discloses a conducting film structure of a surface conduction field emission electron source, namely, a conducting film of an electron source is formed by a multilayer composite film which is formed by a palladium oxide film (PdO) and an amorphous carbon film, the electron transmitting performance of the conducting film can be improved by using the good electron emission stability of the palladium oxide film and the lower effective work function, the large carrier mobility, the high breakdown voltage, the wide forbidden bandwidth and the high heat conduction coefficient of the amorphous carbon film, and consequently, the emission current density and the electron emissivity of the field emission electron source are increased.

Owner:XI AN JIAOTONG UNIV

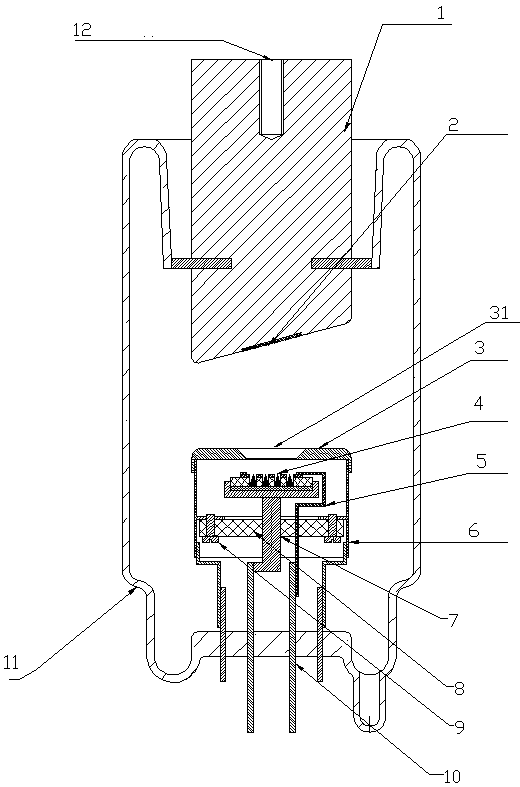

Reflective X-ray source structure of patterned carbon nanotube cathode

The invention provides a reflective X-ray source structure of a patterned carbon nanotube cathode. The reflective X-ray source structure comprises a carbon nanotube, a conductive base, an insulation cover, an insulation gasket, a focus barrel, a grid mesh, an anode target, a berylium window and a sphere tube. The bottom of the insulation cover matches the conductive base. The carbon nanotube, the insulation gasket and the grid mesh are mounted on the top of the conductive base in sequence from bottom to top. The focus barrel is arranged on the top of the insulation cover. After voltages are applied on the conductive base and the grid mesh until a threshold value arrives, the intensity of a current generated by the carbon nanotube is controlled through the grid mesh; electrons are pulled out from the end face of the carbon nanotube; the electrons are focused through the focus barrel, light spots are formed and hit the anode target; and X rays are generated and are transmitted towards the berylium window. Through adoption of the reflective X-ray source structure, the problem that the working temperature is high, the power consumption is high, the starting speed is slow, the service life is short and a ray source is not easy to realize due to the fact that a thermionic cathode is taken as an electron source of a traditional X-ray source can be solved, and moreover, field emission is controlled.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

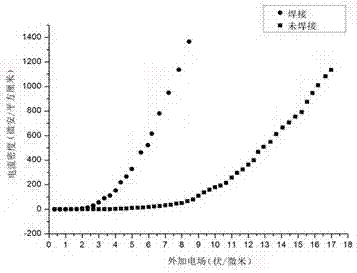

Method for enhancing field emission performance of single-walled carbon nanotube films by laser nano-welding

ActiveCN105513922BImprove stabilityIncreased emission current densityMaterial nanotechnologyNanostructure manufactureShock waveSurface layer

The invention discloses a method for enhancing field emission performance of a single-wall carbon nanotube film by use of laser nanometer welding. The method is characterized by comprising the following steps: 1, the surface of a metal substrate is preprocessed, the metal substrate is placed into an absolute ethyl alcohol or acetone solution, ultrasonic cleaning is performed in an ultrasonic pool; 2, the single-wall carbon nanotube film is precipitated on the processed surface of the metal substrate in the first step by use of a precipitation method; and 3, laser nanometer welding is applied to the single-wall carbon nanotube film precipitated on the surface of the metal substrate in the second step, under the common effect of laser energy and shock waves, the single-wall carbon nanotube film is pressed into a melted metal substrate surface layer, as melted metal is cooled rapidly after laser scanning, the single-wall carbon nanotube film is embedded into the surface of the metal substrate, stable connection between a nanom material and the metal substrate is formed, and the single-wall carbon nanotube film with enhanced field emission performance is obtained. The method provided by the invention is suitable for application in enhancement of field emission performance of a single-wall carbon nanotube film by use of laser nanometer welding.

Owner:SHANGHAI OCEAN UNIV

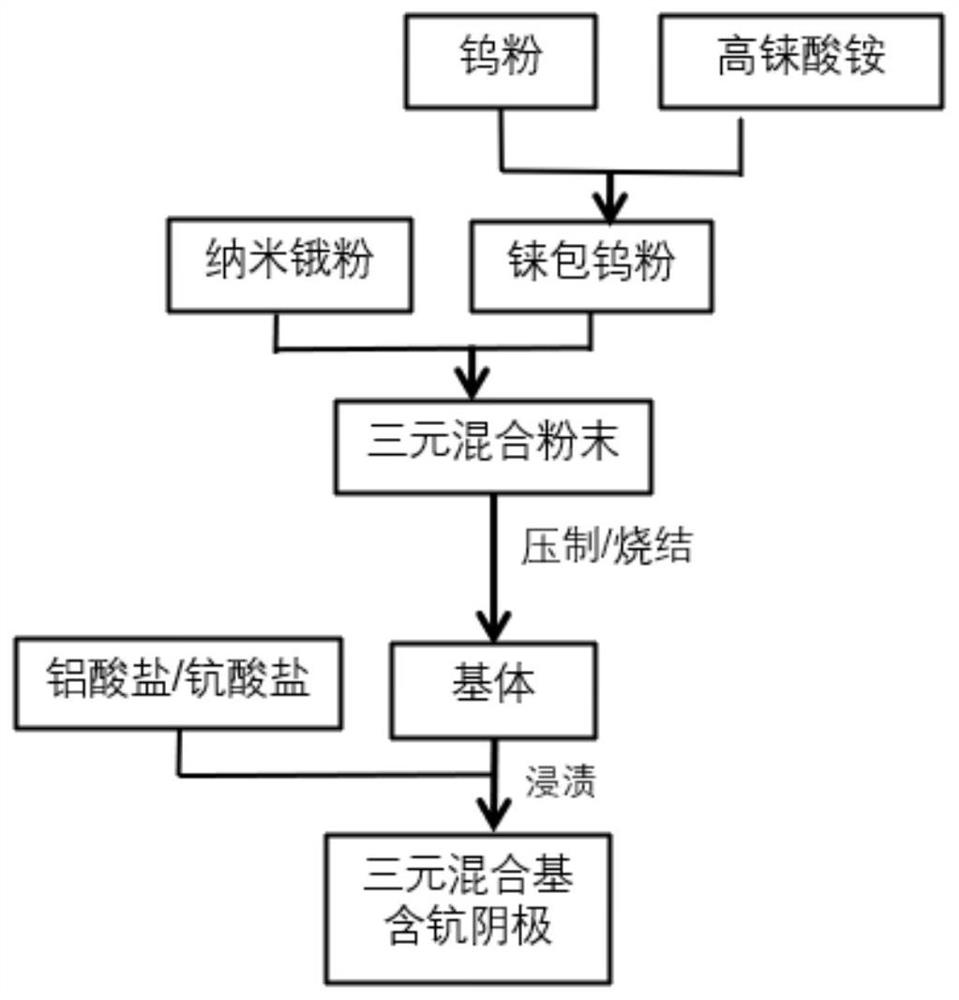

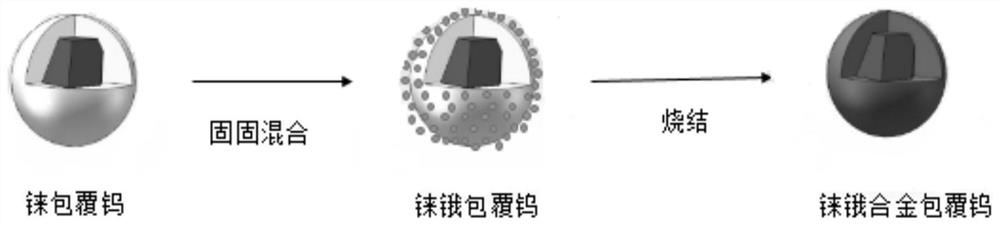

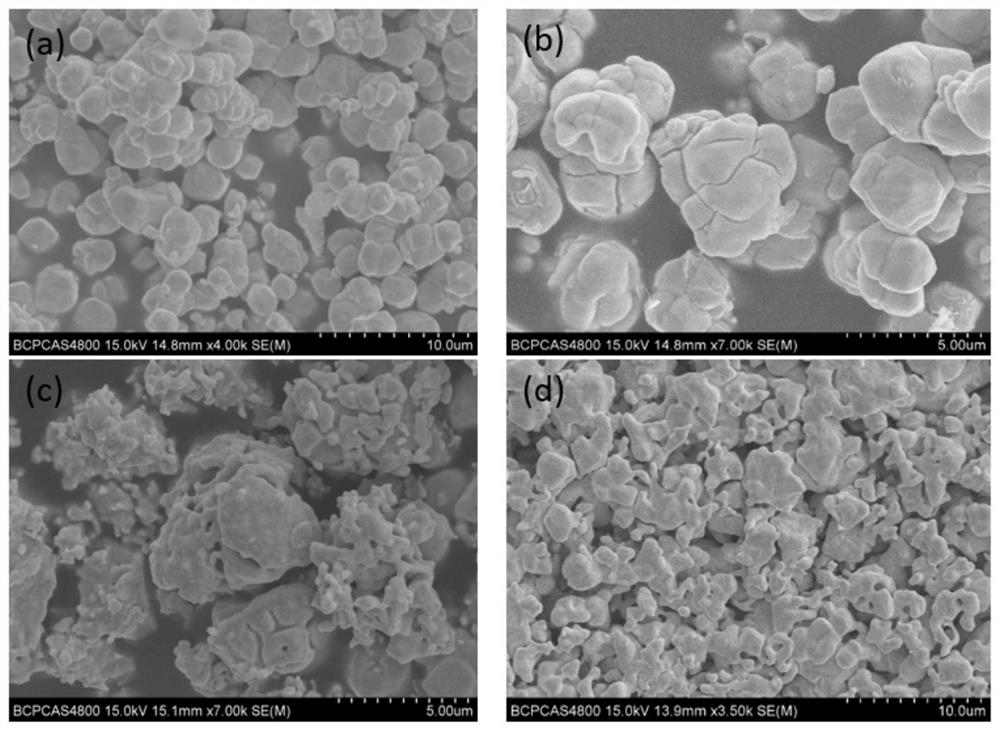

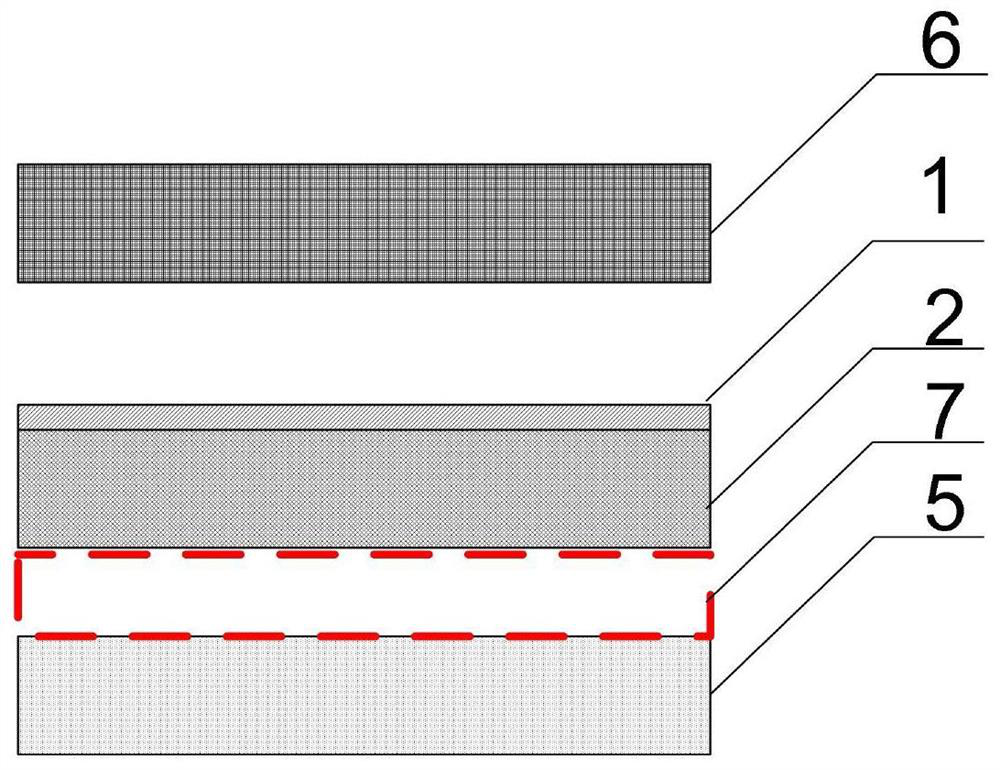

Preparation method of dipping type tungsten-rhenium-osmium ternary mixed base diffusion cathode

ActiveCN113936981AIncreased emission current densityHigh rhenium and osmium contentDischarge tube/lamp detailsThermionic cathode manufactureRheniumManufacturing technology

The invention discloses a preparation method of a dipping type tungsten-rhenium-osmium ternary mixed base diffusion cathode, which relates to a microwave electric vacuum device manufacturing technology. Nano-grade osmium powder is added on the basis of micron-grade particle powder with a rhenium-coated tungsten structure, and after ternary mixed powder is sintered, special-structure powder with rhenium-osmium alloy coated tungsten particles can be formed. In the cathode matrix sintering and cathode dipping process, internal tungsten can be diffused outwards, a stable tungsten-rhenium-osmium ternary alloy film layer is formed on the surface of the cathode, and the electron emission density of the cathode can be improved due to the existence of rhenium and osmium.

Owner:BEIJING UNIV OF TECH

Graphene coated tungsten-based hot cathode and preparation method thereof

PendingCN112117170AImprove launch performanceImprove stabilityDischarge tube/lamp detailsThermionic cathode manufactureGraphiteSingle layer graphene

The graphene coated tungsten-based hot cathode comprises a graphene layer and a tungsten-based cathode layer, the upper surface of the tungsten-based cathode layer is coated with the graphene layer, and a lamp filament is arranged below the tungsten-based cathode layer. The preparation method comprises the following steps: (1) preparing a tungsten substrate with a smooth surface; (2) coating the tungsten substrate with a graphene layer; and (3) assembling the cathode heater assembly. The invention provides a metal coated tungsten-based hot cathode which is simple in structure, easy to prepareand excellent in emission performance. Simulation shows that the surface work function of the metal coated tungsten-based hot cathode is 1.745 eV under the condition that the surface of the metal coated tungsten-based hot cathode is coated with single-layer graphene.

Owner:SOUTHEAST UNIV

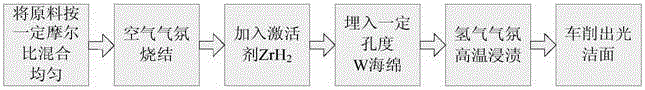

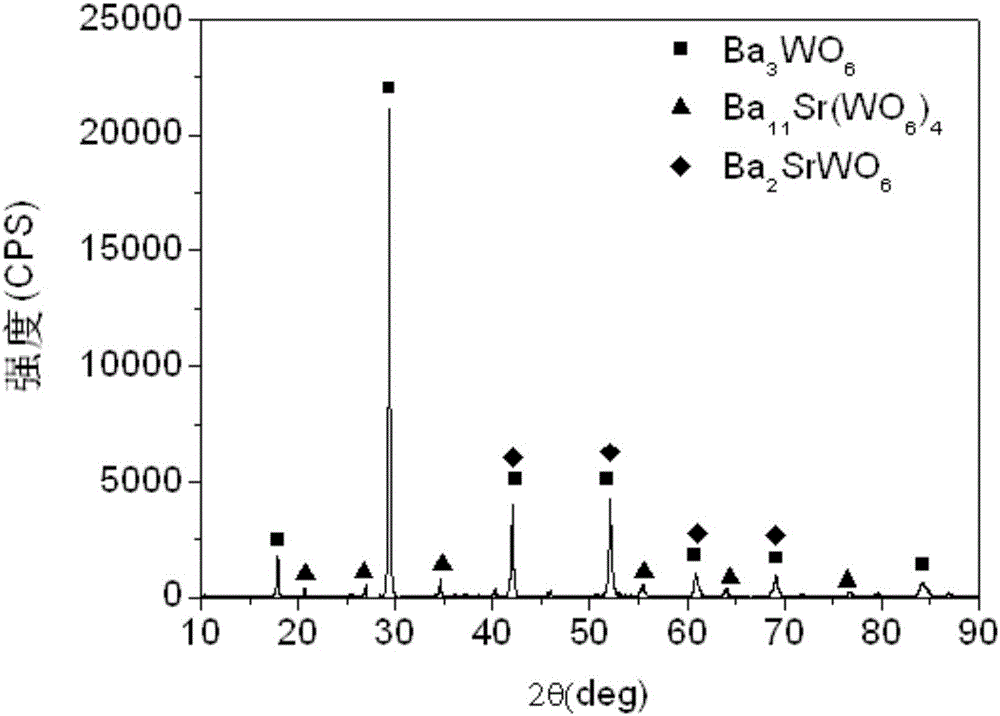

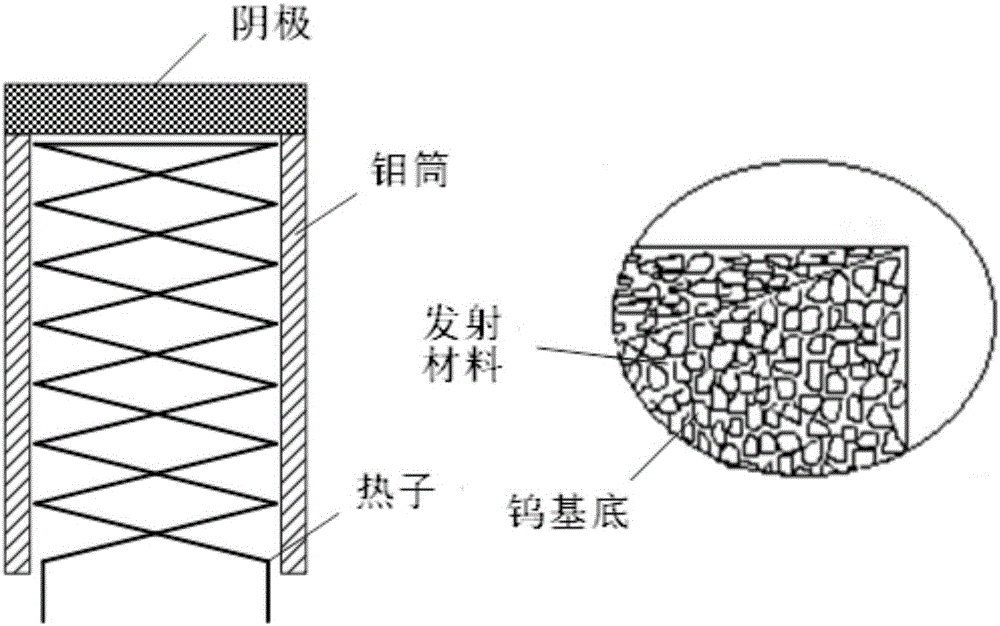

Impregnated Ba5Sr(WO6)2 cathode and preparation method thereof

InactiveCN105788999AReduce evaporation rateIncrease varietyDischarge tube/lamp detailsThermionic cathode manufactureNumerical controlTungstate

The invention discloses an impregnated Ba5Sr(WO6)2 cathode and a preparation method thereof. The method comprises the following steps that (1) ball-mill mixing is carried out on BaCO3, SrCO3 and WO6 in the mol ratio of (4.8-5.2): (0.9-1.1): (1.8-2.2) for 65 to 75 hours, and then a mixture is pressed into a block; (2) the block is sintered for 3 to 4 hours at the temperature of 1400 + / -50 degree C to synthesize a tungstate; (3) the tungstate is mixed with an activating agent and then ground to obtain an active substance; (4) a cathode whose top end is welded with a tungsten sponge body is embedded into the active substance and dipped in a hydrogen furnace at high temperature; and (5) the obtained cathode is arranged in a numerical control lathe and turned to remove the residual tungstate so that a smooth end surface is exposed, and thus, the impregnated Ba5Sr(WO6)2 cathode is obtained. The preparation method can be used to improve the density of emission current of the Ba5Sr(WO6)2 cathode, improve the reliability of the Ba5Sr(WO6)2 cathode, prolong the service life of the Ba5Sr(WO6)2 cathode, and fundamentally solve the problem that a traditional tungstate cathode is hard to apply.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

A Reflective X-ray Source Structure of Patterned Carbon Nanotube Cathode

ActiveCN106783486BHigh aspect ratioSmall radius of curvatureX-ray tube electrodesLight spotWorking temperature

The invention provides a reflective X-ray source structure of a patterned carbon nanotube cathode. The reflective X-ray source structure comprises a carbon nanotube, a conductive base, an insulation cover, an insulation gasket, a focus barrel, a grid mesh, an anode target, a berylium window and a sphere tube. The bottom of the insulation cover matches the conductive base. The carbon nanotube, the insulation gasket and the grid mesh are mounted on the top of the conductive base in sequence from bottom to top. The focus barrel is arranged on the top of the insulation cover. After voltages are applied on the conductive base and the grid mesh until a threshold value arrives, the intensity of a current generated by the carbon nanotube is controlled through the grid mesh; electrons are pulled out from the end face of the carbon nanotube; the electrons are focused through the focus barrel, light spots are formed and hit the anode target; and X rays are generated and are transmitted towards the berylium window. Through adoption of the reflective X-ray source structure, the problem that the working temperature is high, the power consumption is high, the starting speed is slow, the service life is short and a ray source is not easy to realize due to the fact that a thermionic cathode is taken as an electron source of a traditional X-ray source can be solved, and moreover, field emission is controlled.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Direct heating cathode and preparation method thereof

ActiveCN105304436BIncreased emission current densityLower working temperatureTransit-tube cathodesPlant ingredientsDip-coatingTungsten filament

The invention discloses a directly heated cathode. A refractory oxide containing Y2O3 is adopted as an active substance; and the active substance is subjected to dip-coating on the surface of a pure tungsten filament cathode of which the surface is provided with a tungsten sponge layer to form the directly heated cathode. The invention further discloses a preparation method of the directly heated cathode. According to the directly heated cathode disclosed by the invention, the thermal emission current density of the pure tungsten filament cathode is greatly improved; and the working lifetime of the cathode is prolonged, so that the working lifetime of a high-power continuous wave magnetron is prolonged.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com