Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

158results about How to "Small radius of curvature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

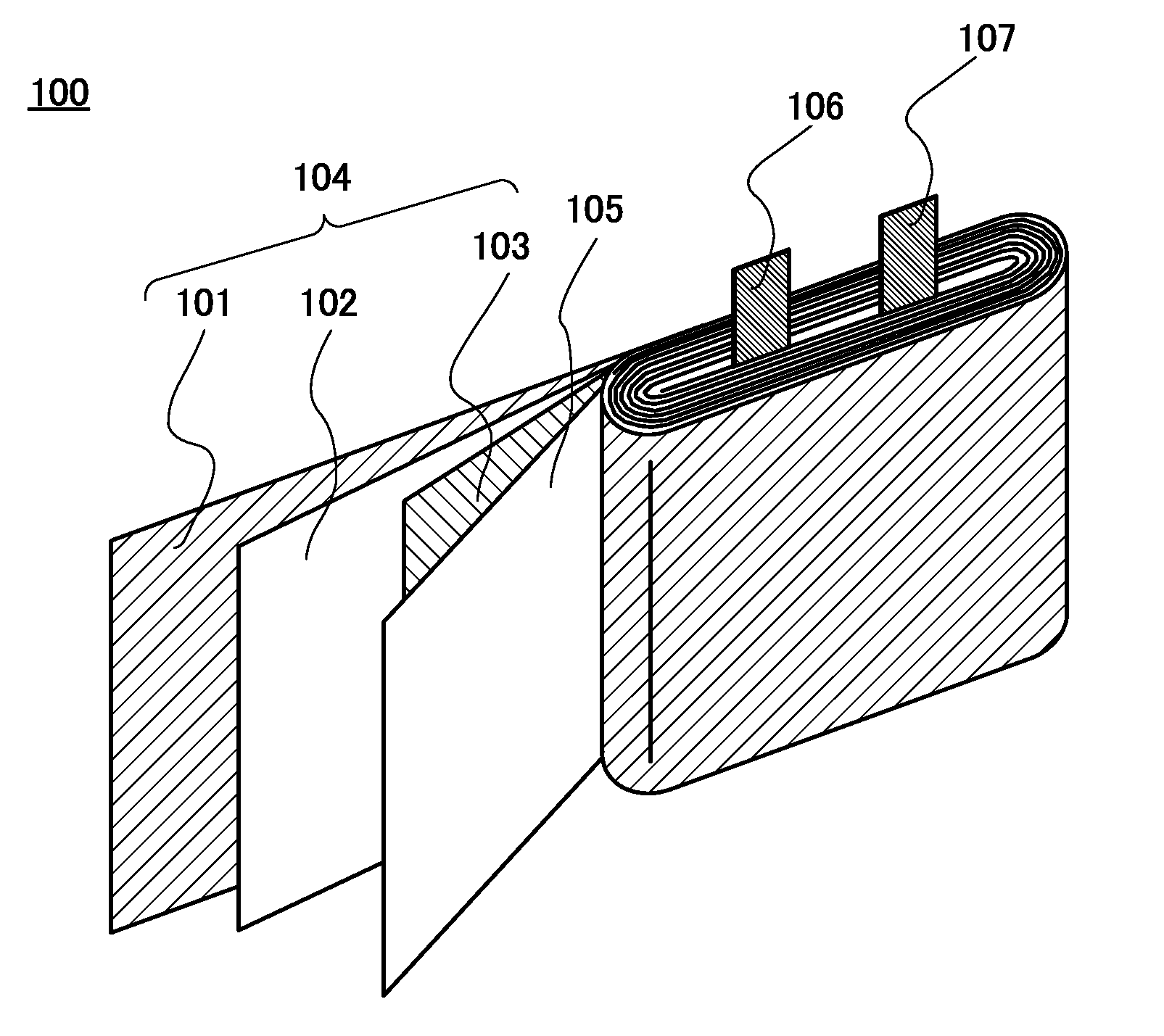

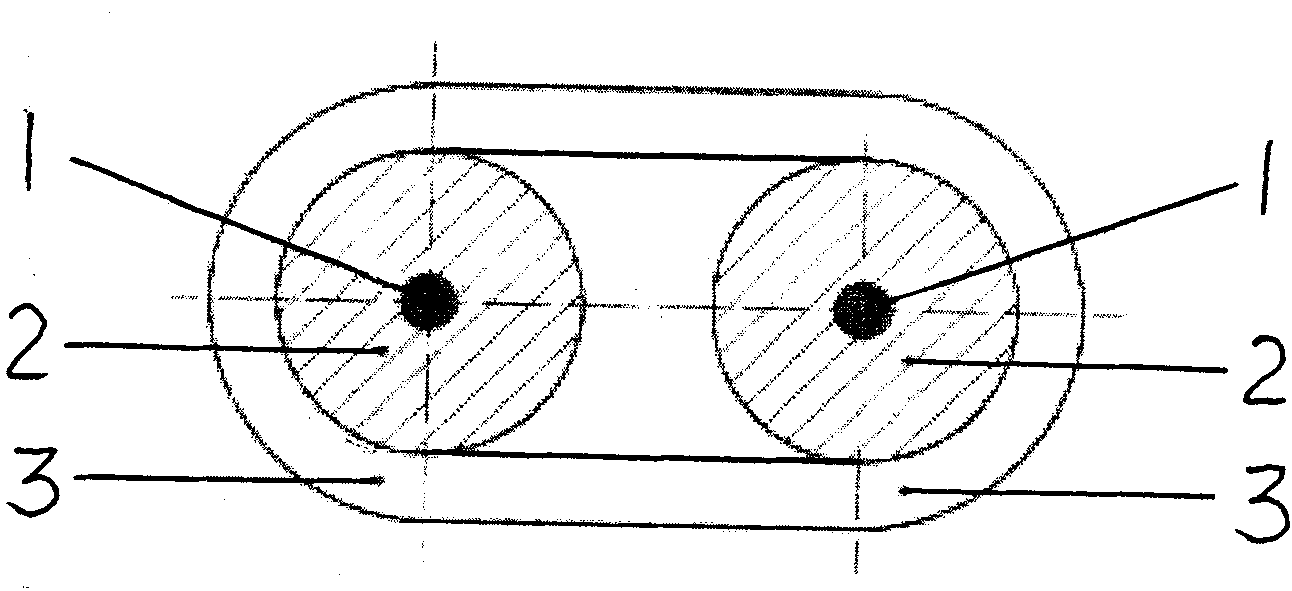

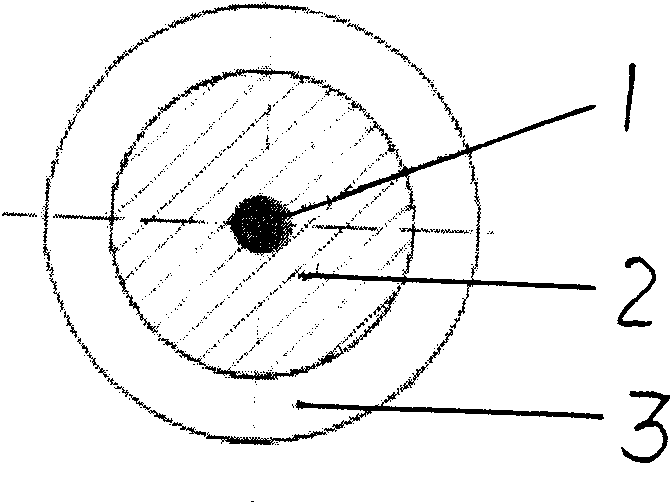

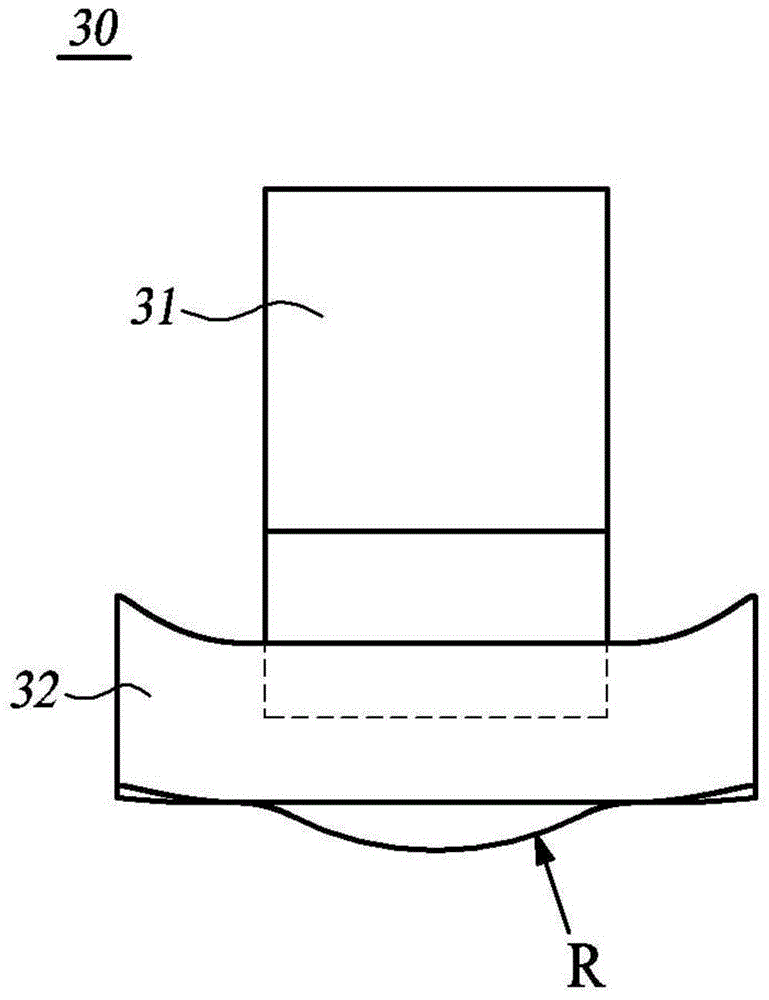

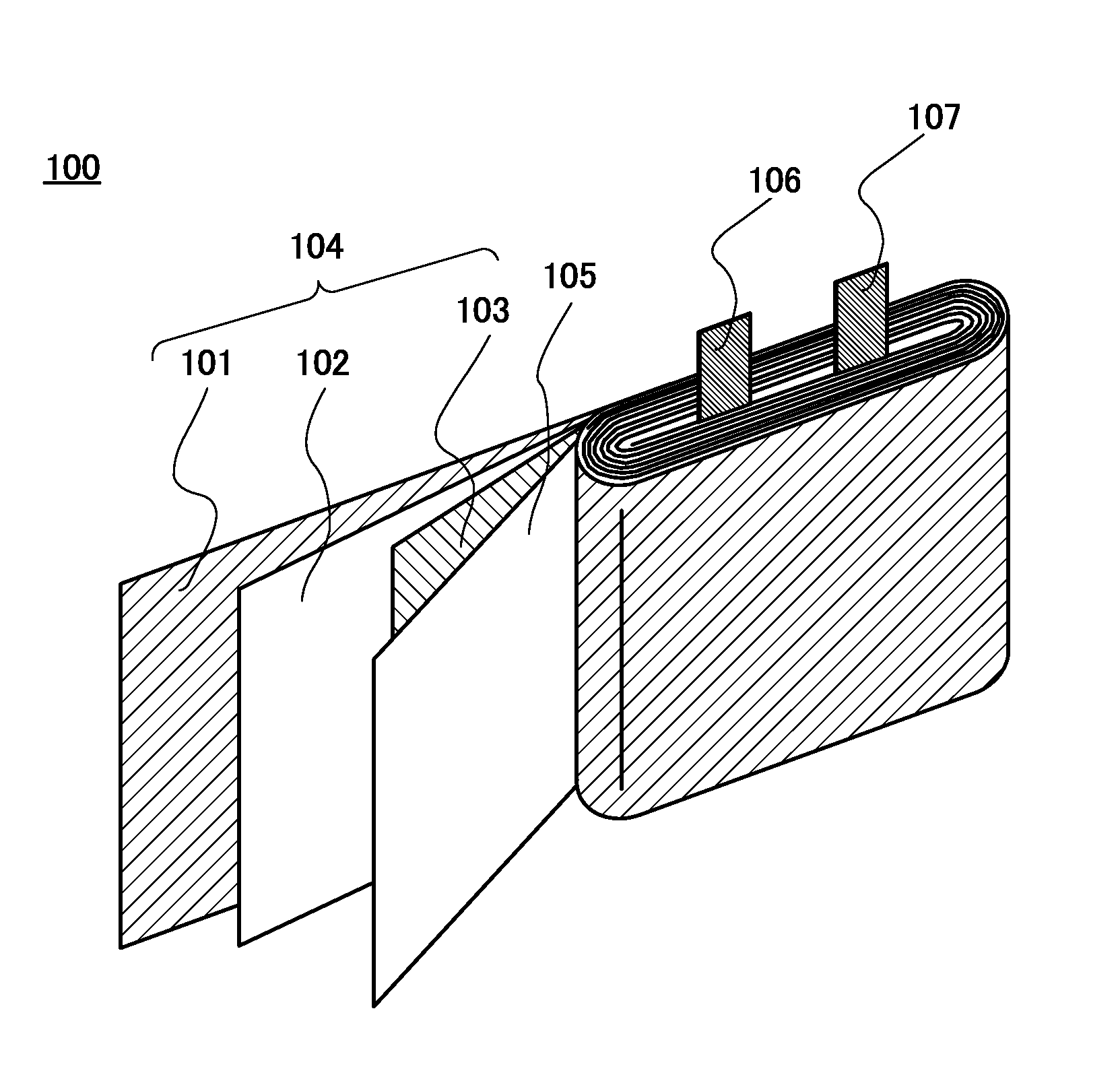

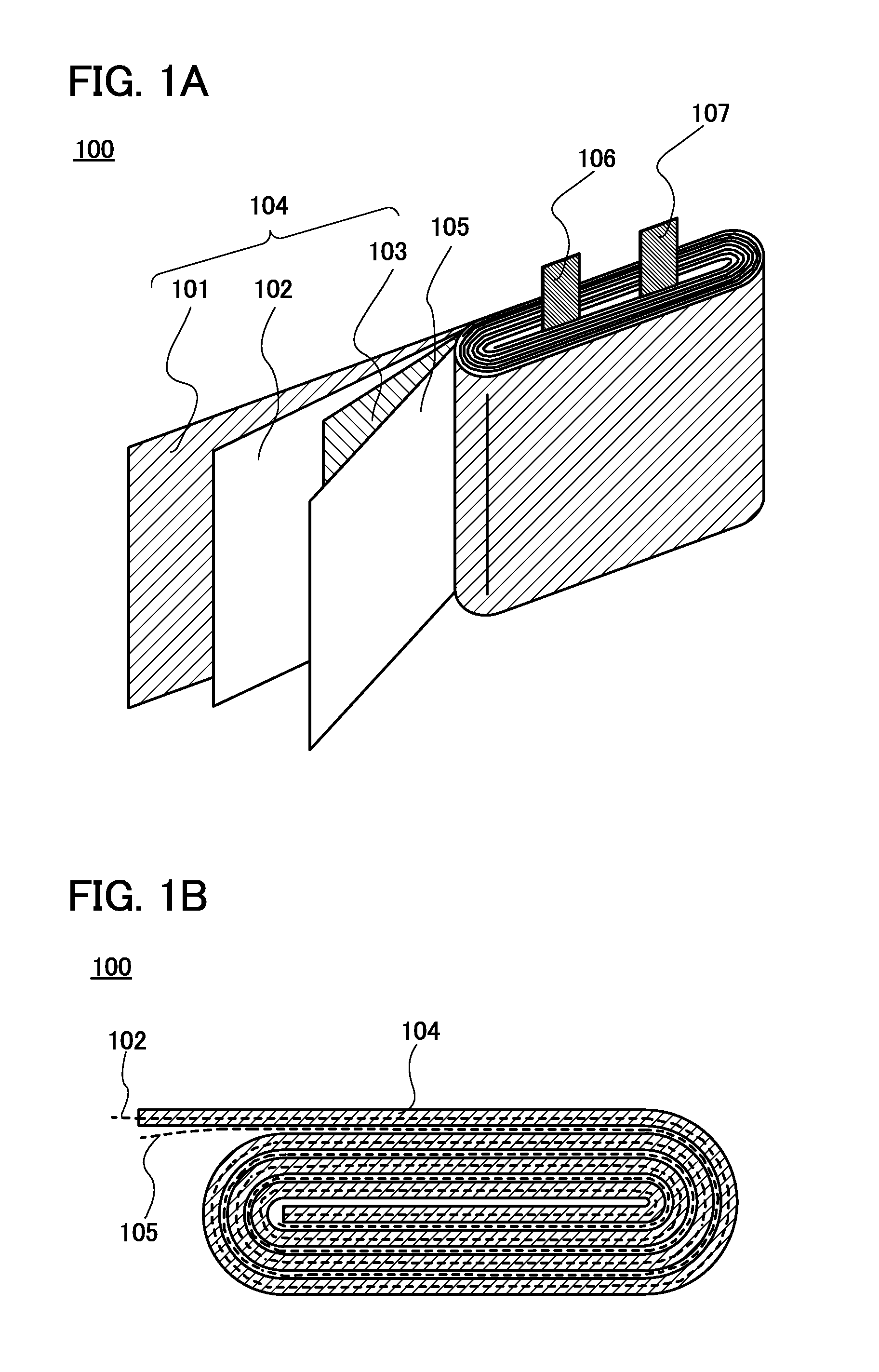

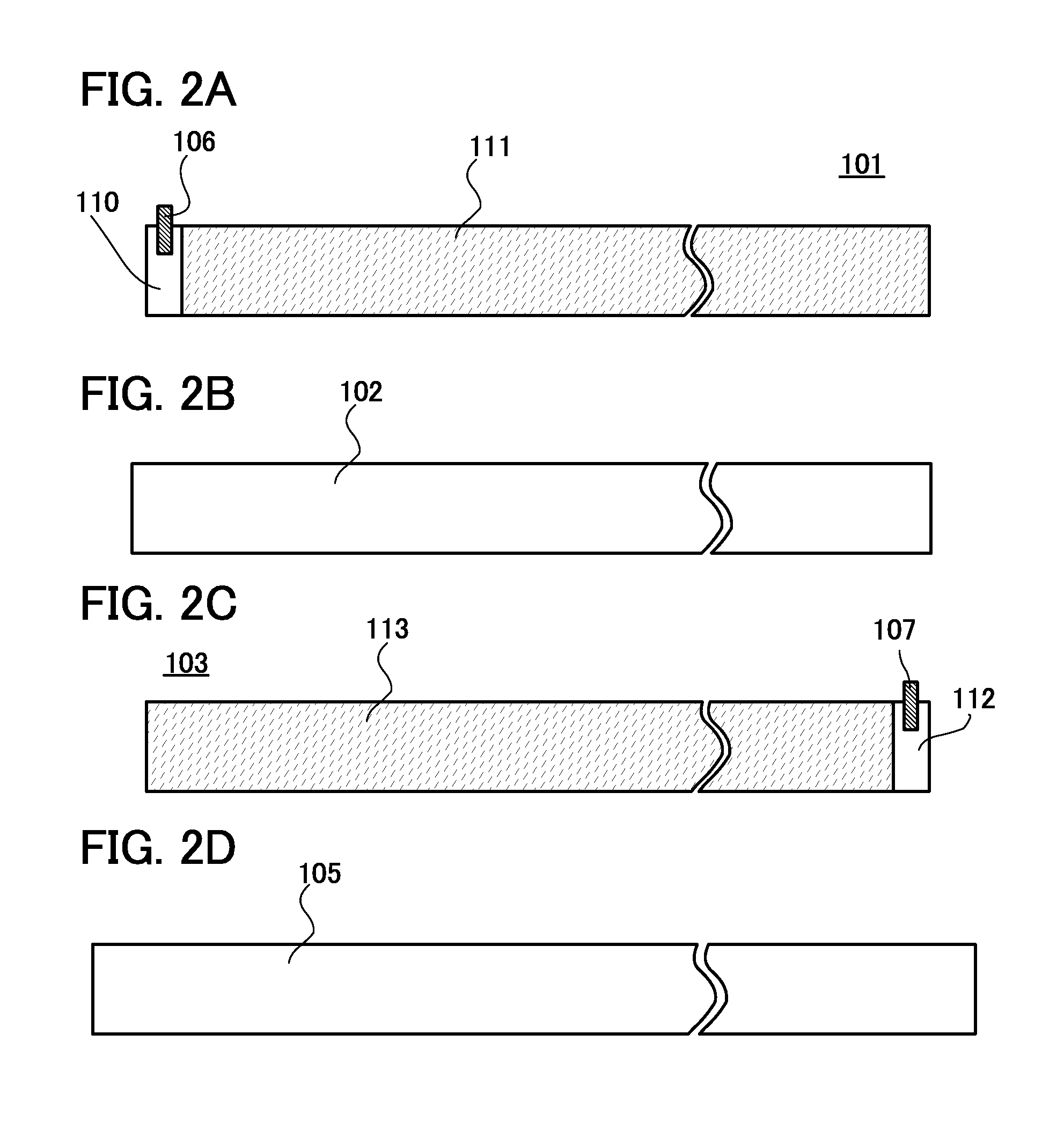

Square lithium secondary battery

ActiveUS20130143090A1Improve discharge capacityHigh densityCell electrodesFinal product manufactureLithiumElectrical battery

A square lithium secondary battery includes a wound body in which a collective sheet in which a positive electrode sheet and a negative electrode sheet overlap each other with a first separator interposed therebetween is wound while a second separator is put inside the collective sheet. An active material mixture layer on one or both surfaces of at least one of the positive electrode sheet and the negative electrode sheet includes a region with a plurality of openings and a region with no opening. At least a bent portion of the collective sheet is covered with the region with the plurality of openings.

Owner:SEMICON ENERGY LAB CO LTD

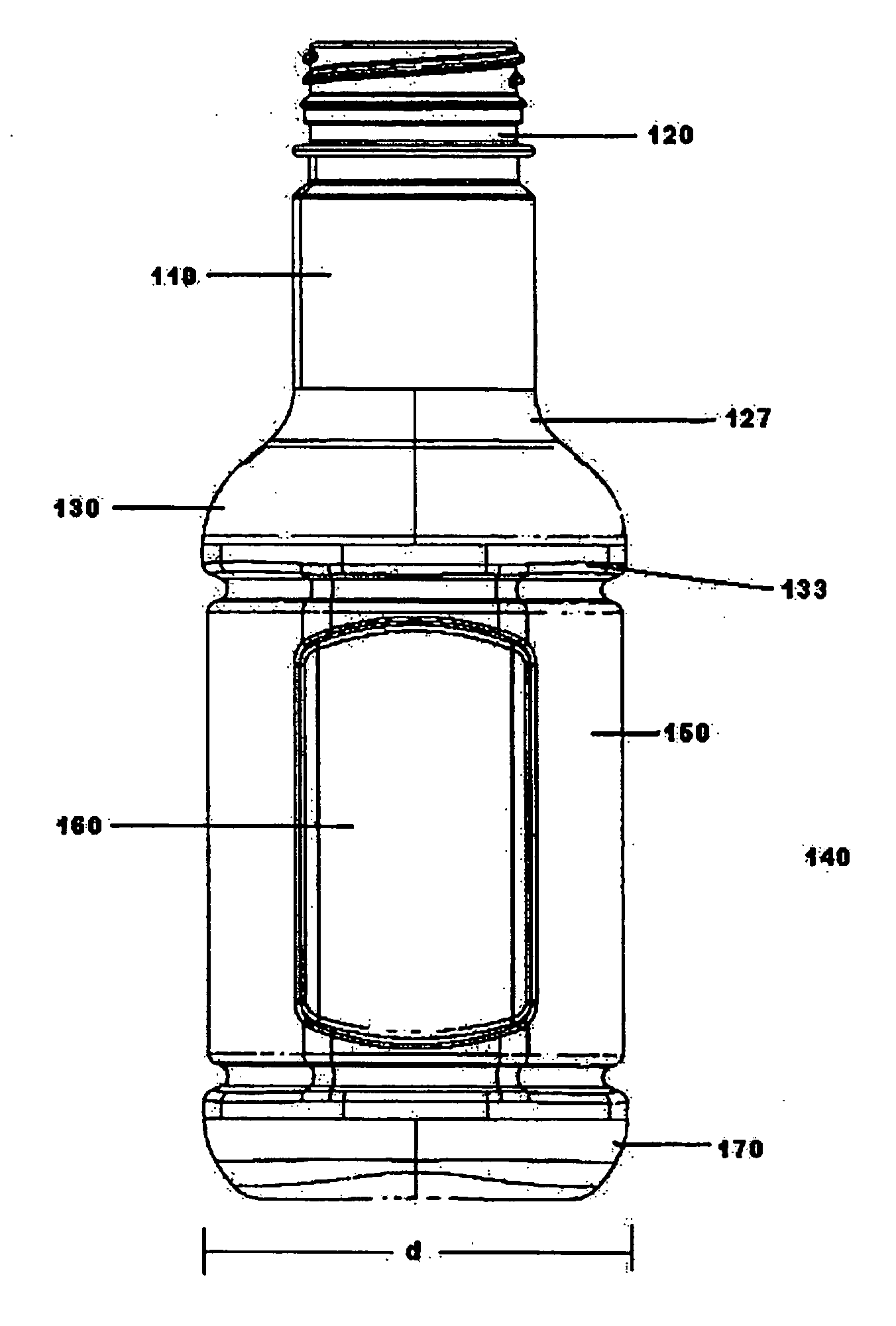

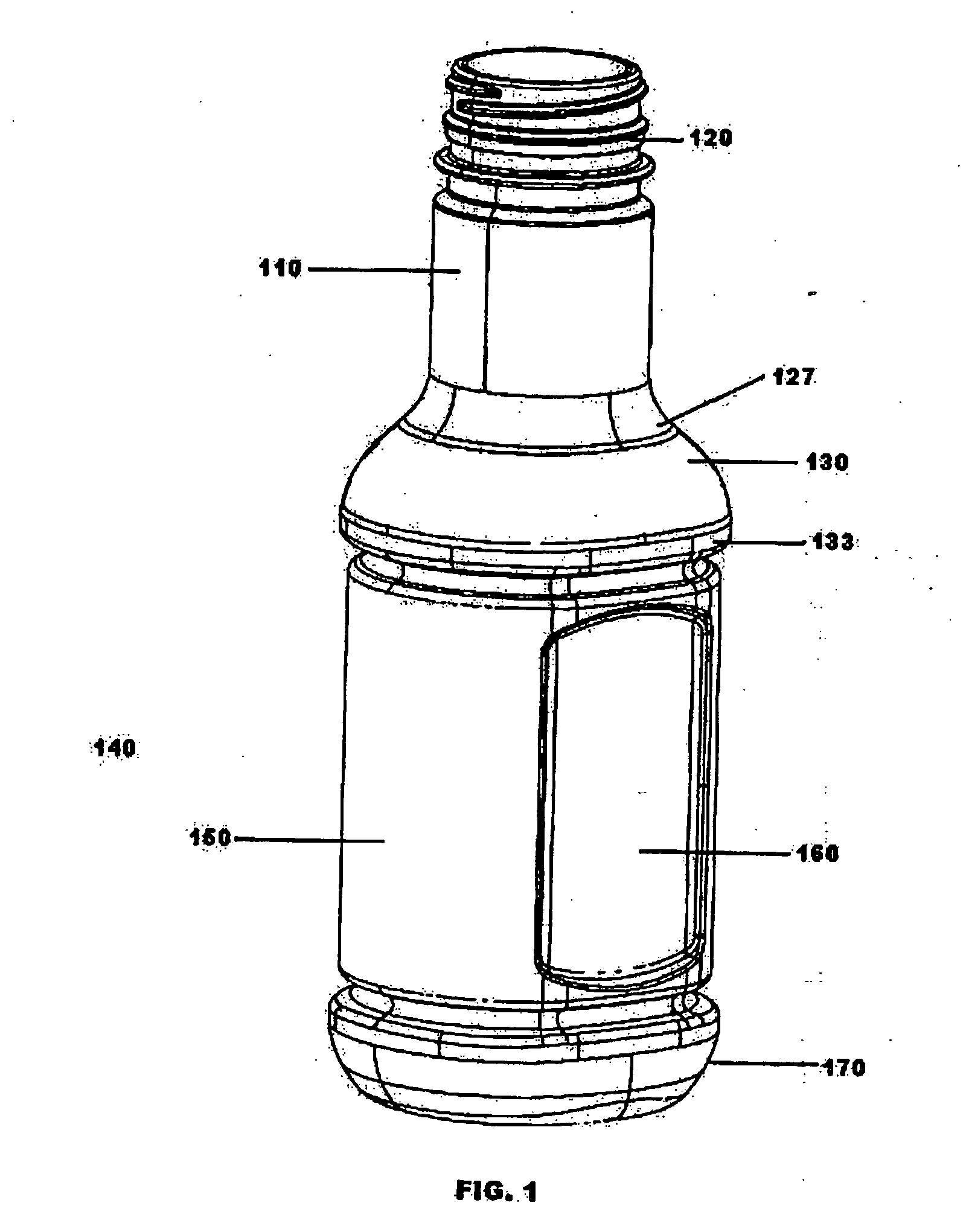

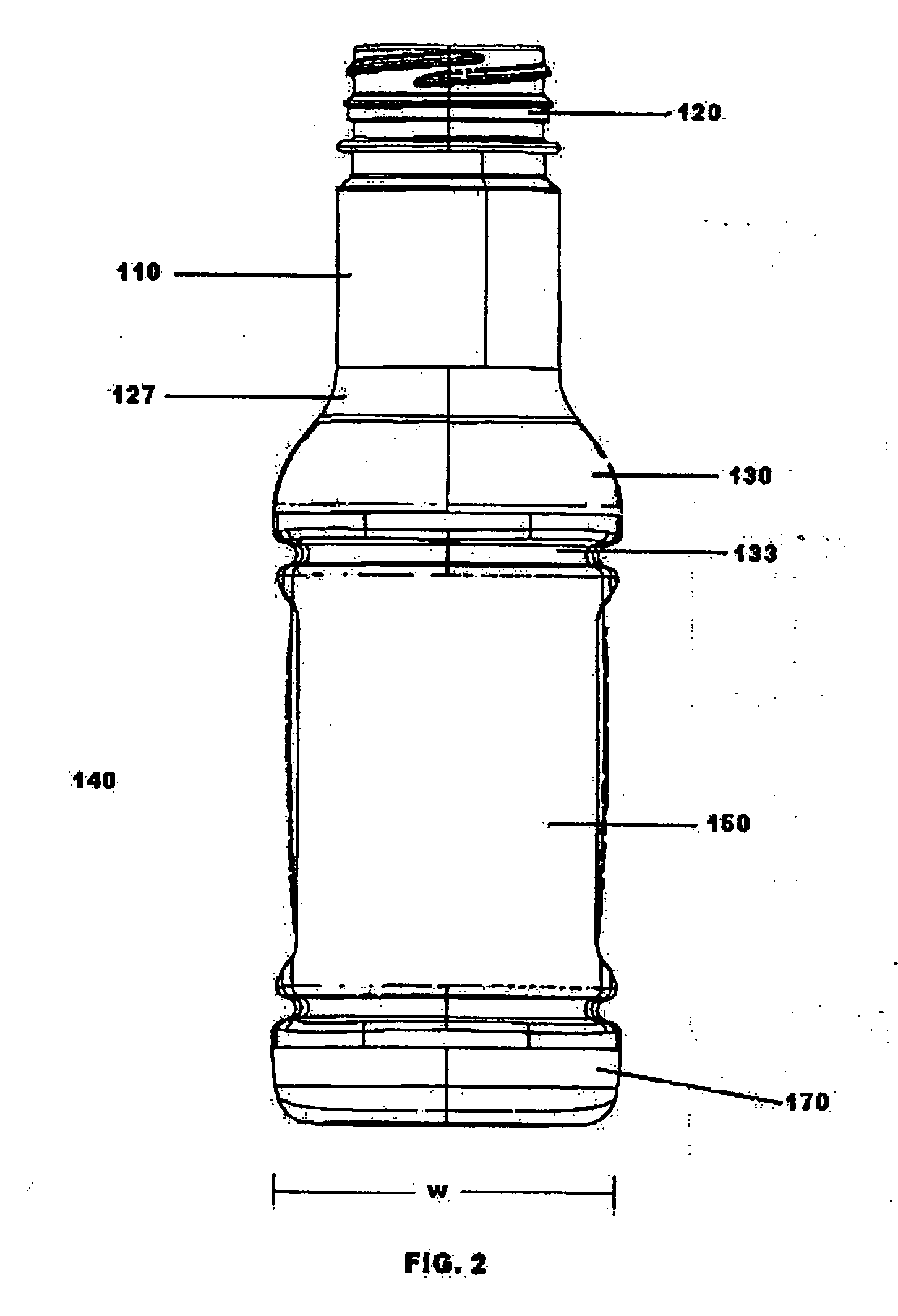

Oval container

InactiveUS20060070977A1Prevent excessive deformationPrevent bucklingLarge containersRigid containersPressure sensitiveEllipse

An oval plastic container. A cross-section of the container, taken perpendicular to the height of the container shows an oval or elliptical shape. Such a container has front and back sides. The container also has a left side and a right side. Given the oval shape of the body, the width of the container as measured from the left side to the right side, is less than the depth of the container, measured from front to back. The front and back of the container therefore have a relatively small radius of curvature, compared to the left and right sides. The front and / or the back of the container includes a relatively featureless panel. Such a panel is flat, apart from the curvature that results from the oval shape of the body. Such an area can be used for the application of a pressure-sensitive label. The oval shape of the body prevents the labeled surface from buckling during the cooling process. The left and right sides of the container may include structure such as ribbing, to prevent buckling or excessive deformation during cooling. Alternatively, the left and right sides of the container may include vacuum panels that may be drawn inward during cooling, without excessive deformation or buckling.

Owner:GRAHAM PACKAGING CO LP

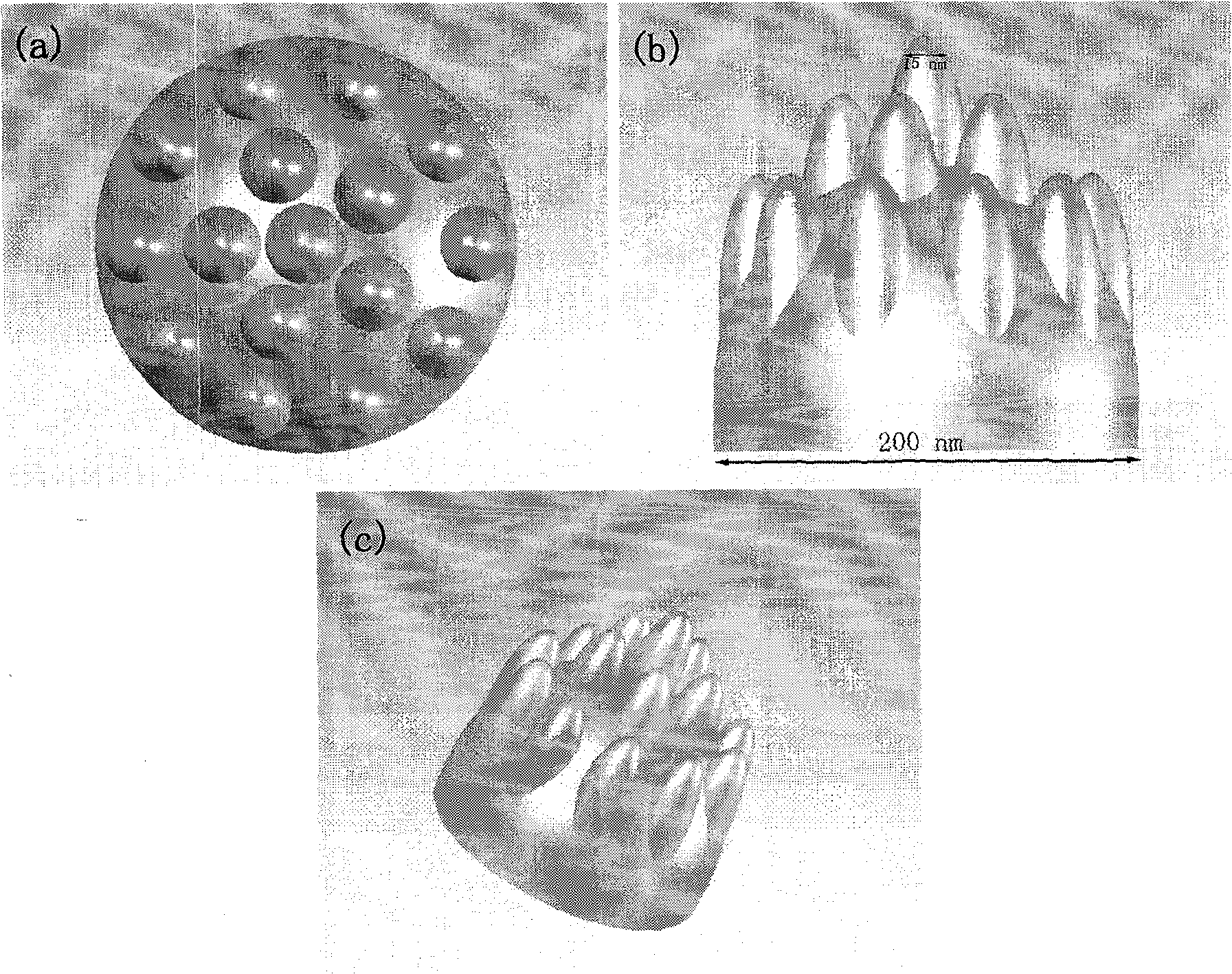

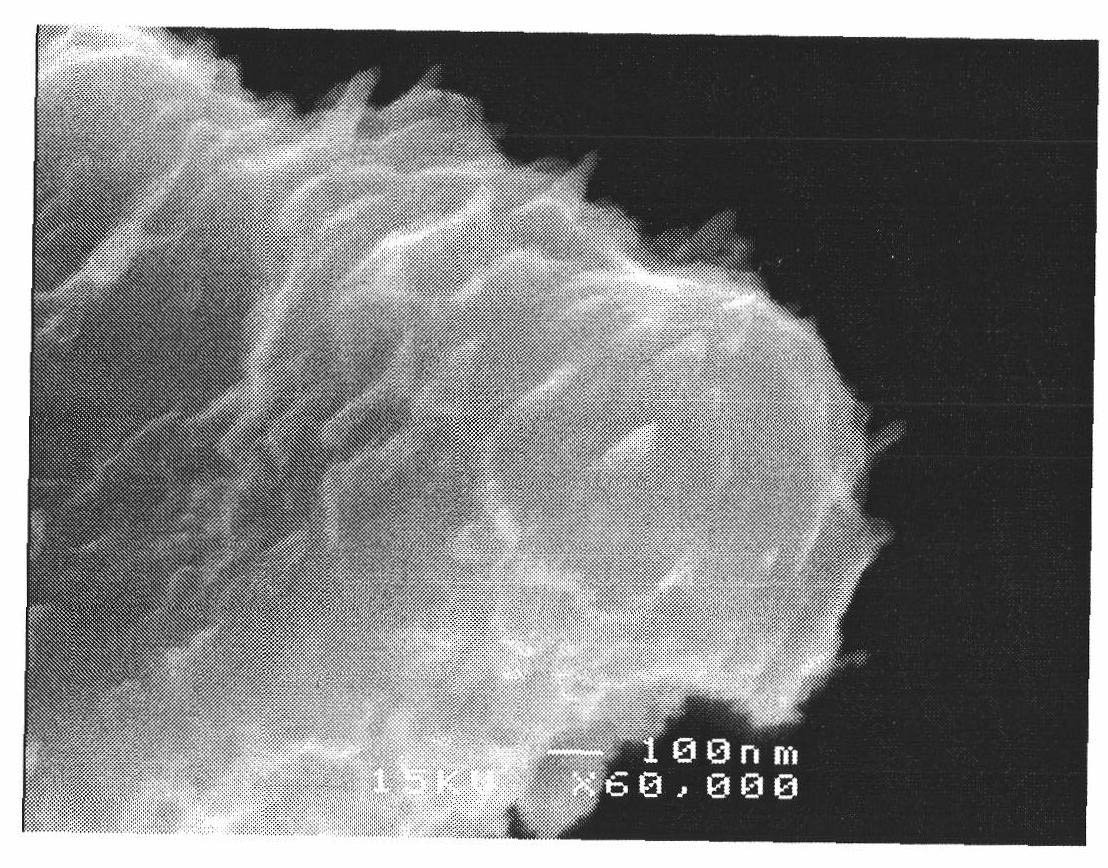

Non-aperture tip enhanced Raman scattering probe and manufacturing method thereof

ActiveCN101923054ASmall radius of curvatureHigh resolutionRaman scatteringAtomic force microscopyCarbon layer

The invention relates to a non-aperture tip enhanced Raman scattering probe and a manufacturing method thereof, belonging to the field of near-field Raman spectroscopy detection technology. The non-aperture tip enhanced Raman scattering probe is characterized in that the surface of the traditional Raman scattering probe is provided with 3-20 tiny tips, the diameter of the tiny tips is 5-25 nm, and the curvature radius of the tiny tips is 2-15 nm. In the invention, a scanning probe microscopy / atomic force microscopy (SPM / AFM) probe with a noble metal film layer is selected, a carbon layer is deposited on the noble metal film layer, and excess carbon layers are removed by washing after the impact of an argon ion beam. The manufactured non-aperture tip enhanced Raman scattering probe has great application potential in the fields of trace analysis, qualitative detection even single-molecule detection and the like.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

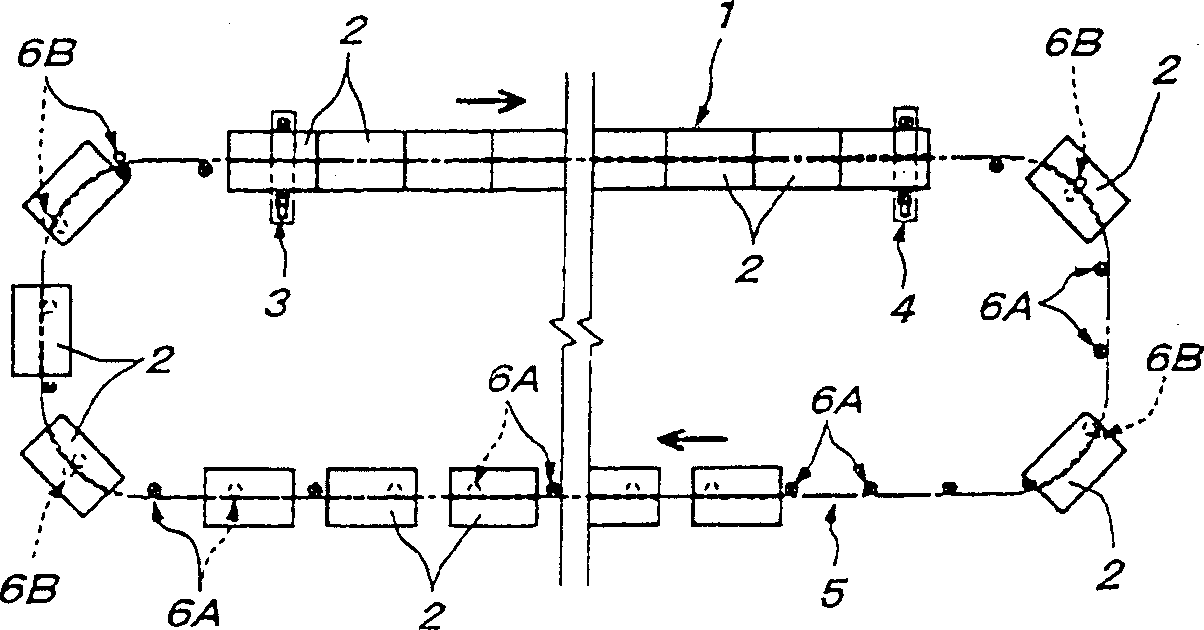

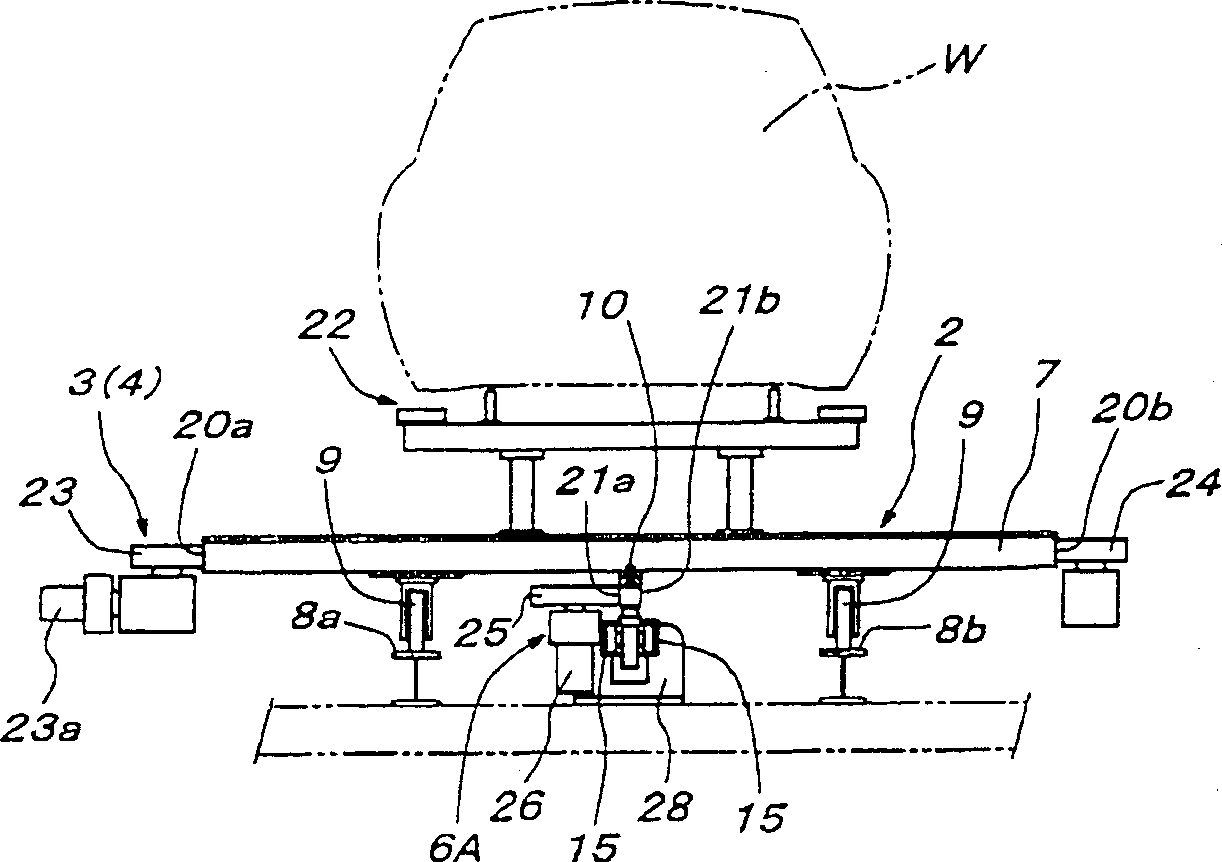

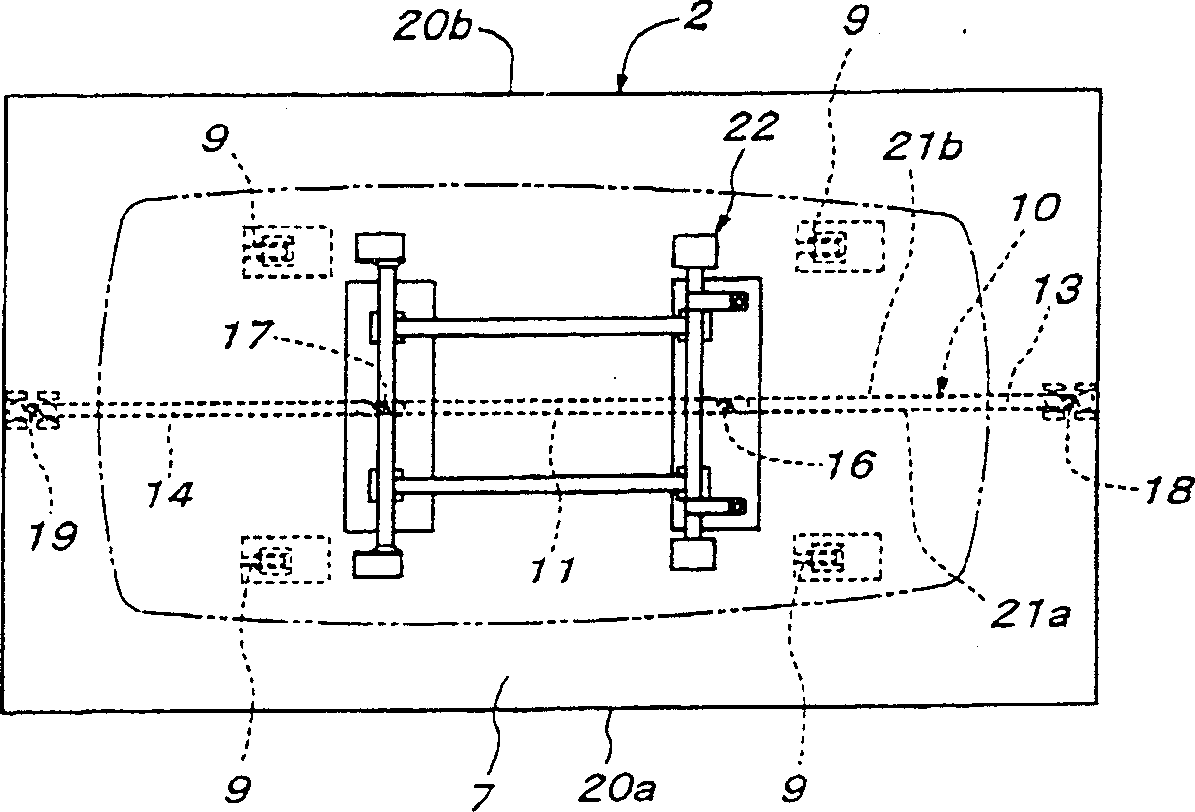

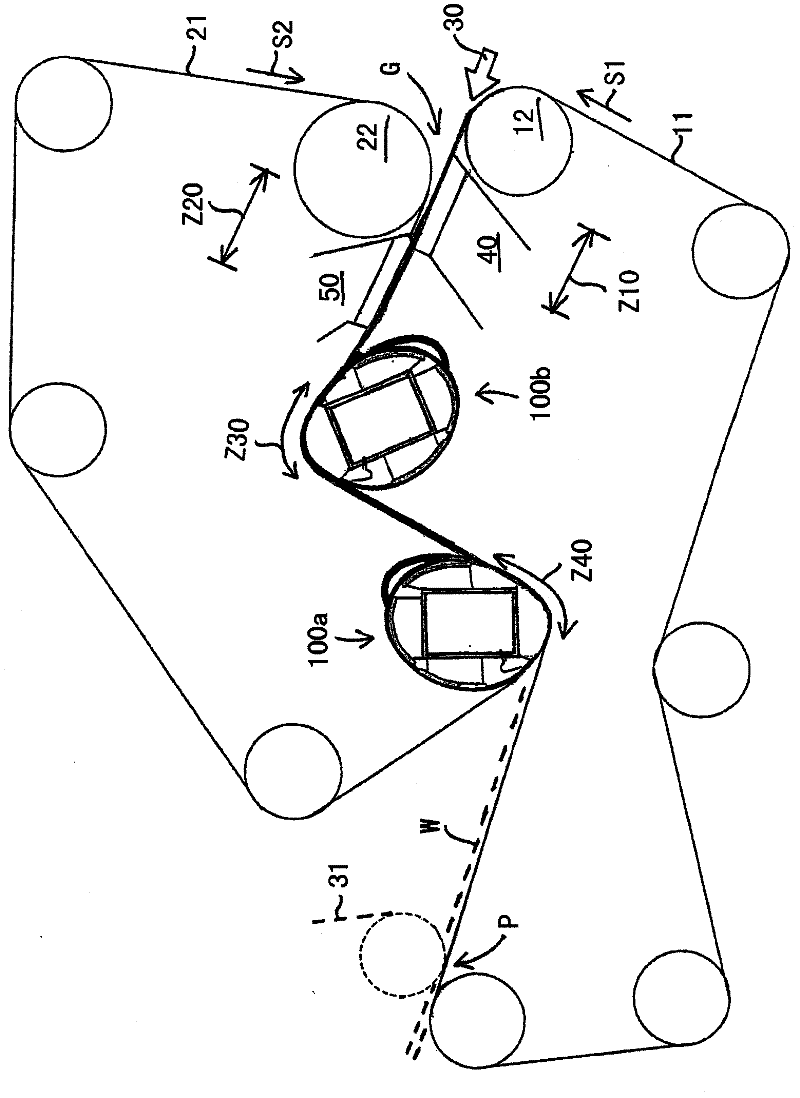

Vehicle conveyer

InactiveCN1370724ALow costSmall radius of curvatureMonorailsRailway componentsDrive wheelEngineering

The vehicle delivery device of the present invention includes a plurality of vehicles and a vehicle running line. Each vehicle includes: a vehicle floor having a main transmission friction surface, the friction surface being a side formed on or close to at least one of the left and right sides of the vehicle floor, which is parallel to the direction of travel of the vehicle; A rod extending along the centerline of the vehicle floor, the centerline being parallel to the direction of travel, the rod has a side forming a friction surface for an auxiliary drive. The running line includes a main conveyor line as a linear conveyor line or an auxiliary conveyor line. The main conveyor line is equipped with a transmission device used as a main driving force. drive wheel. The auxiliary conveying line is equipped with a plurality of transmission devices used as auxiliary driving force, and each transmission device includes a friction drive wheel for pressure contact with the friction surface of the vehicle. The transmissions are arranged at intervals in the direction of travel.

Owner:DAIFUKU CO LTD

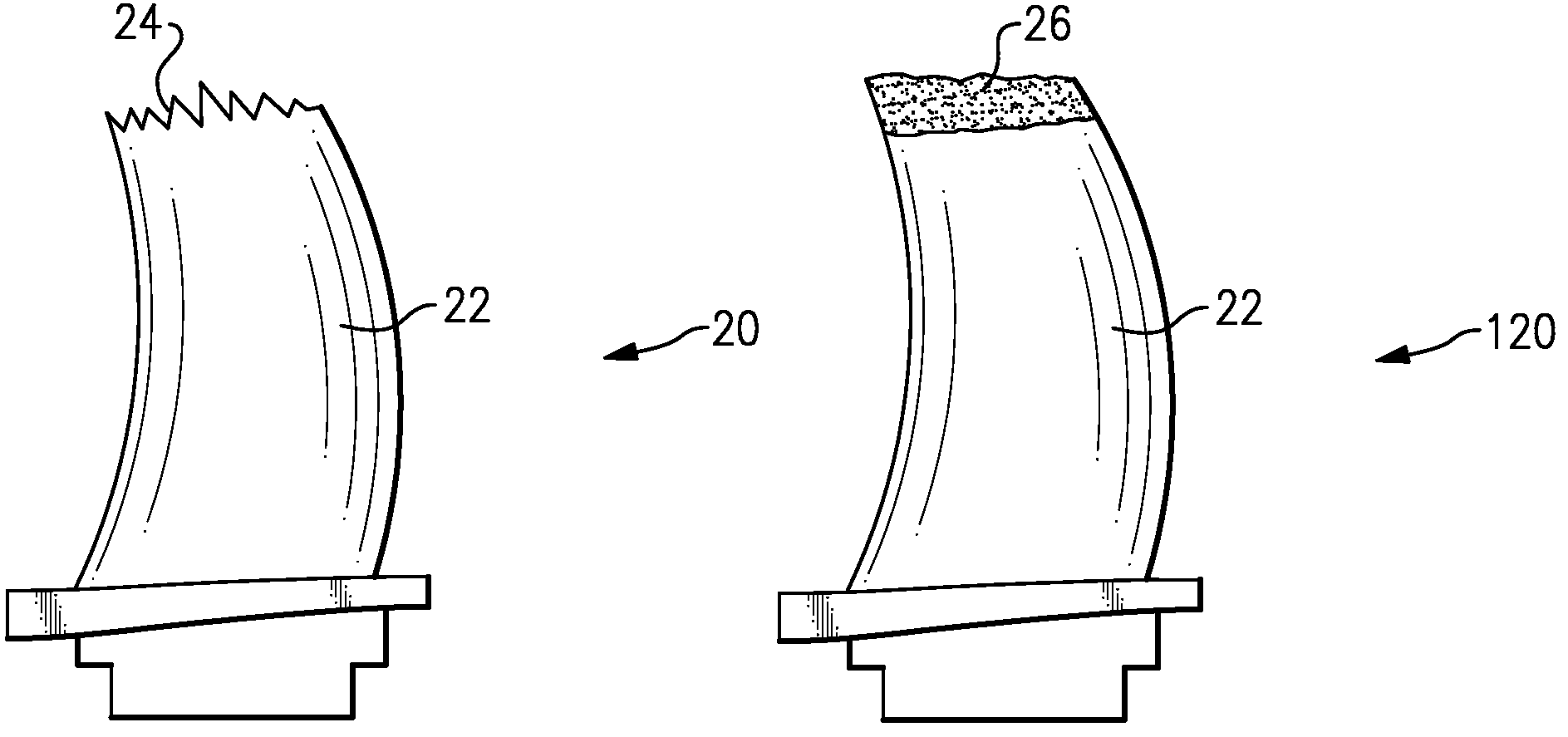

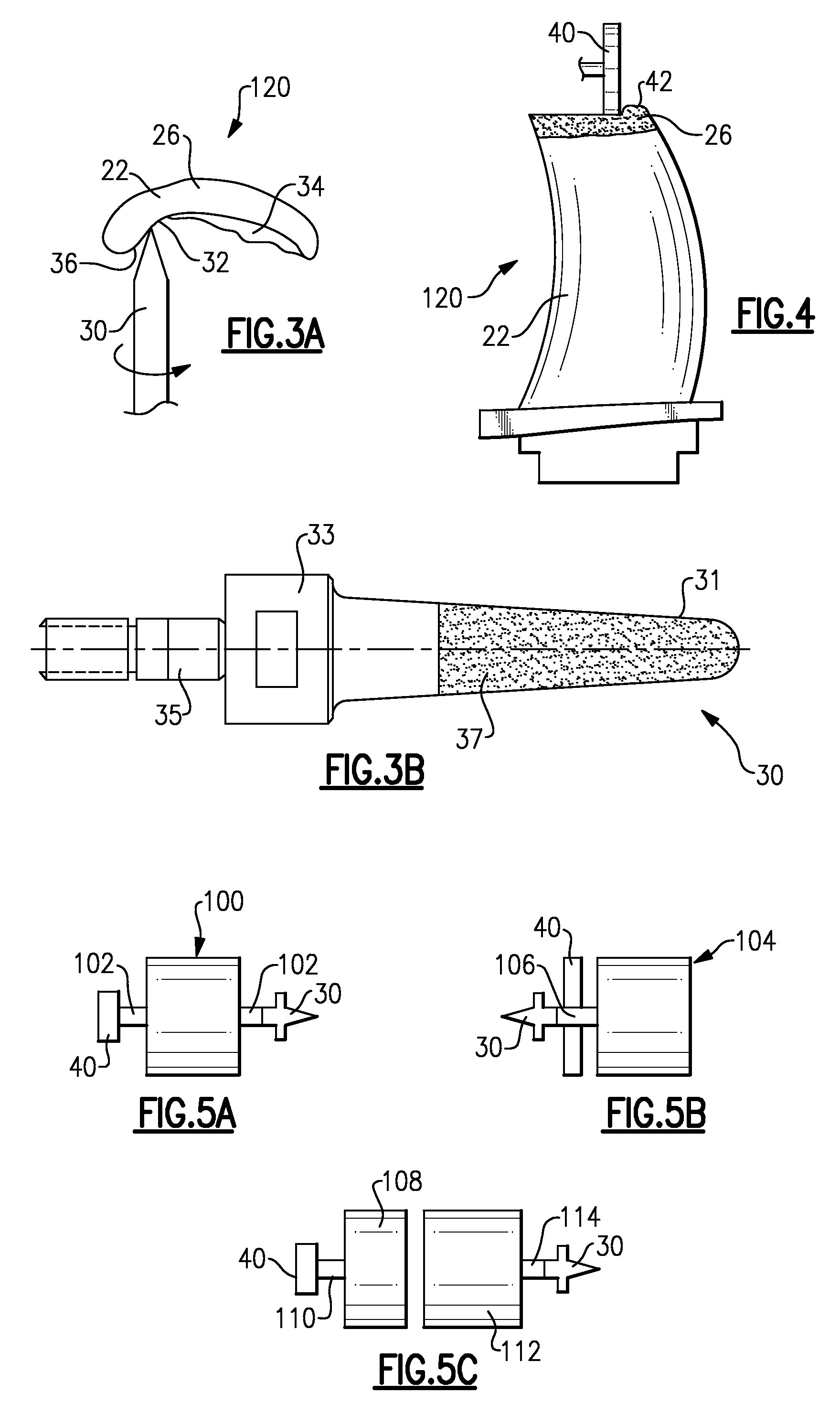

Method for restoring airfoil tip contour

ActiveUS7836594B2Small radius of curvatureBlade accessoriesMachines/enginesPulp and paper industryKnife blades

Owner:RTX CORP

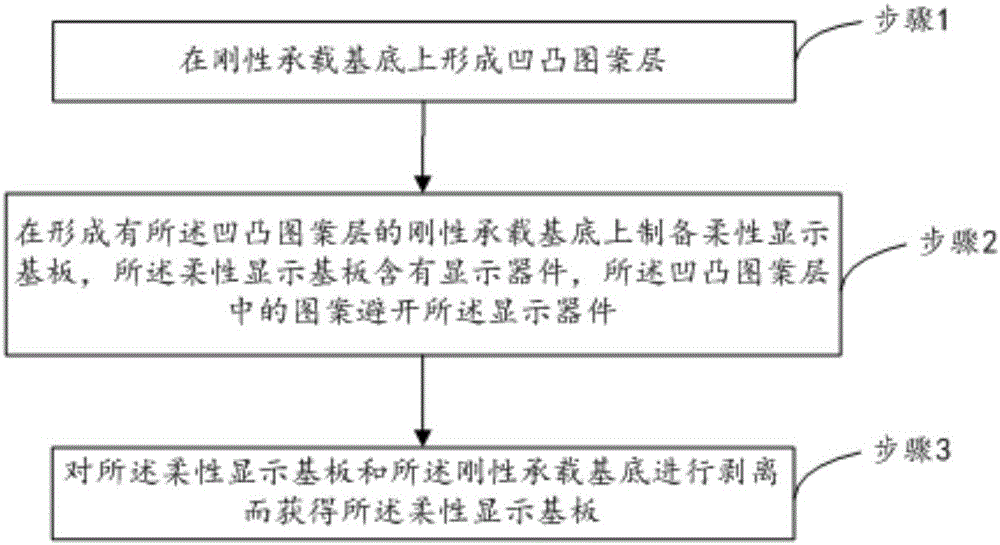

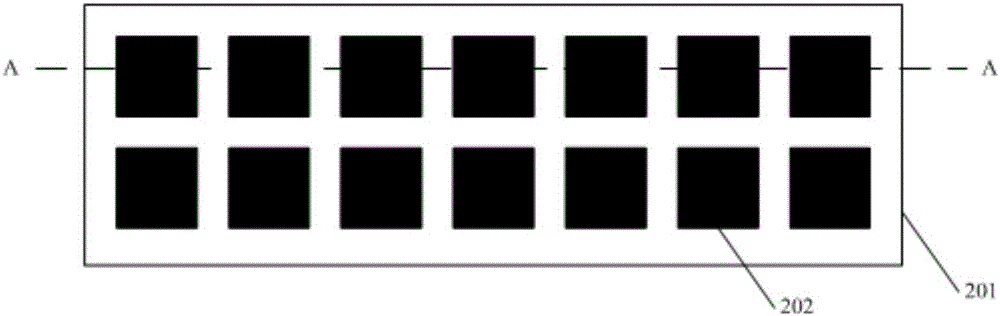

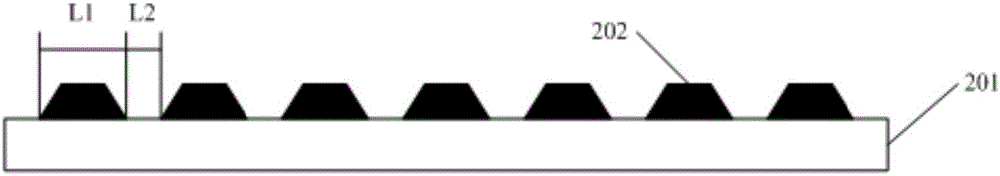

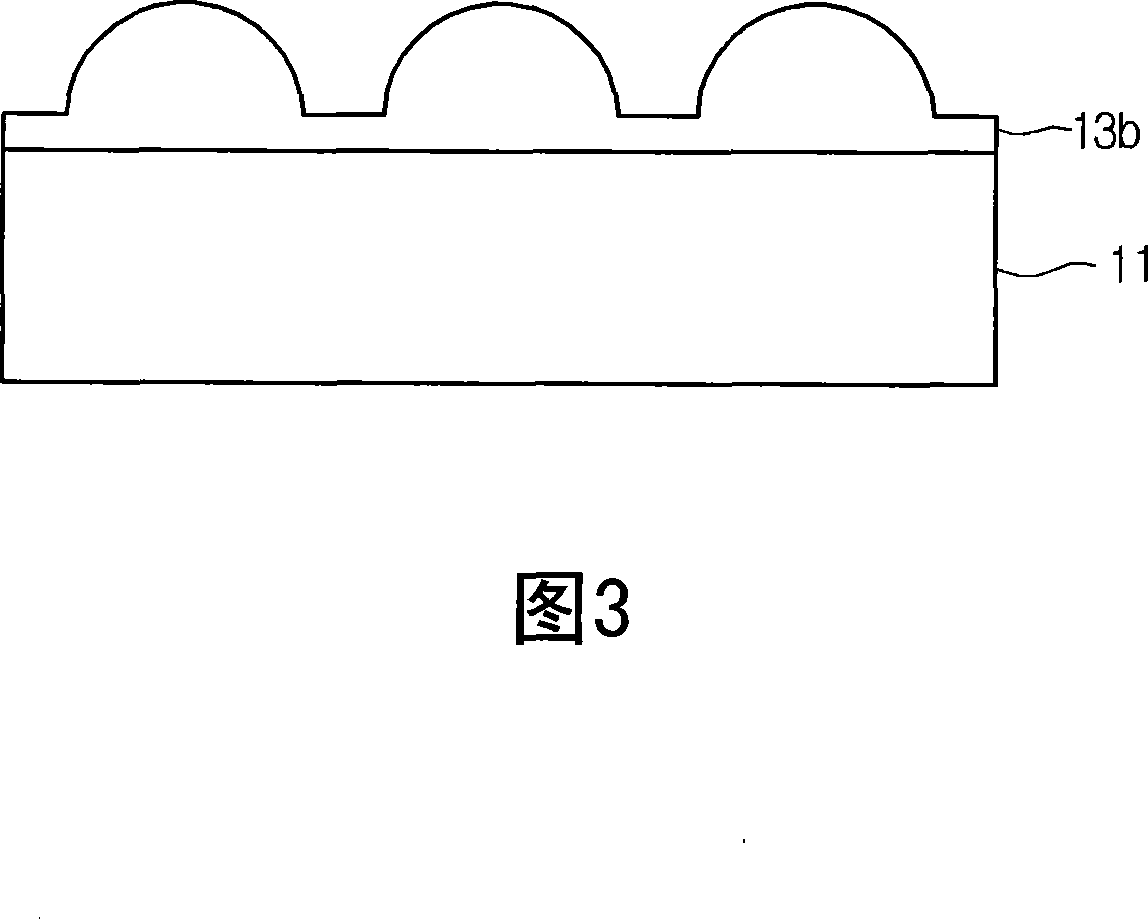

Preparation method for flexible display substrate

ActiveCN106129269AReduce thicknessSmall radius of curvatureSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceFlexible display

The invention discloses a preparation method for a flexible display substrate, relates to the technical field of the flexible display substrate, and solves the problem that a device on the flexible display substrate is damaged in peeling off the flexible display substrate and a rigid bearing substrate and the problem of relatively large radius of curvature of the flexible display substrate and the like. The preparation method comprises the steps of forming a concave-convex pattern layer on the rigid bearing substrate; preparing the flexible display substrate on the rigid bearing substrate where the concave-convex pattern layer is formed, wherein the flexible display substrate comprises a display device; the pattern in the concave-convex pattern layer avoids the display device; and peeling off the flexible display substrate and the rigid bearing substrate to obtain the flexible display substrate. The preparation method provided by the invention is used for preparing the flexible display substrate.

Owner:BOE TECH GRP CO LTD

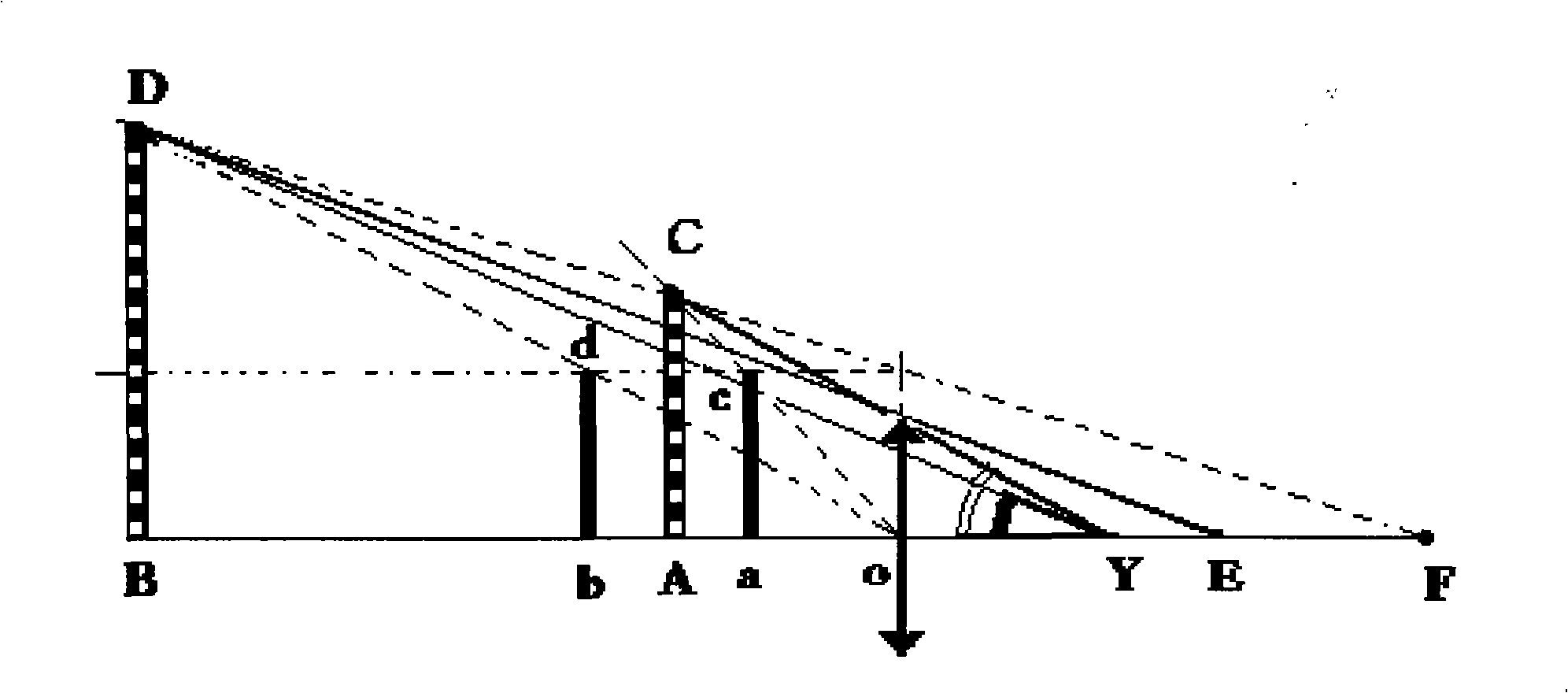

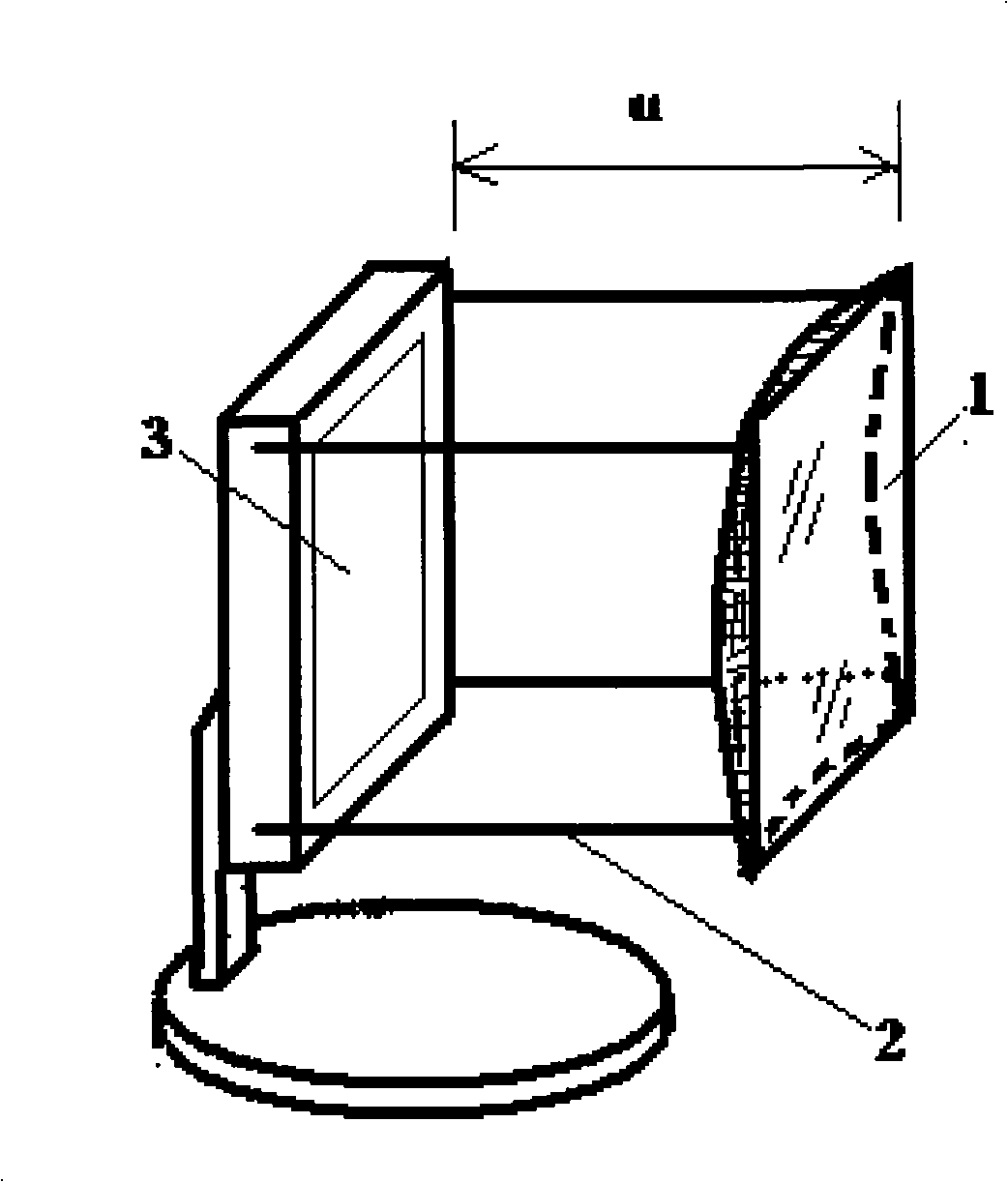

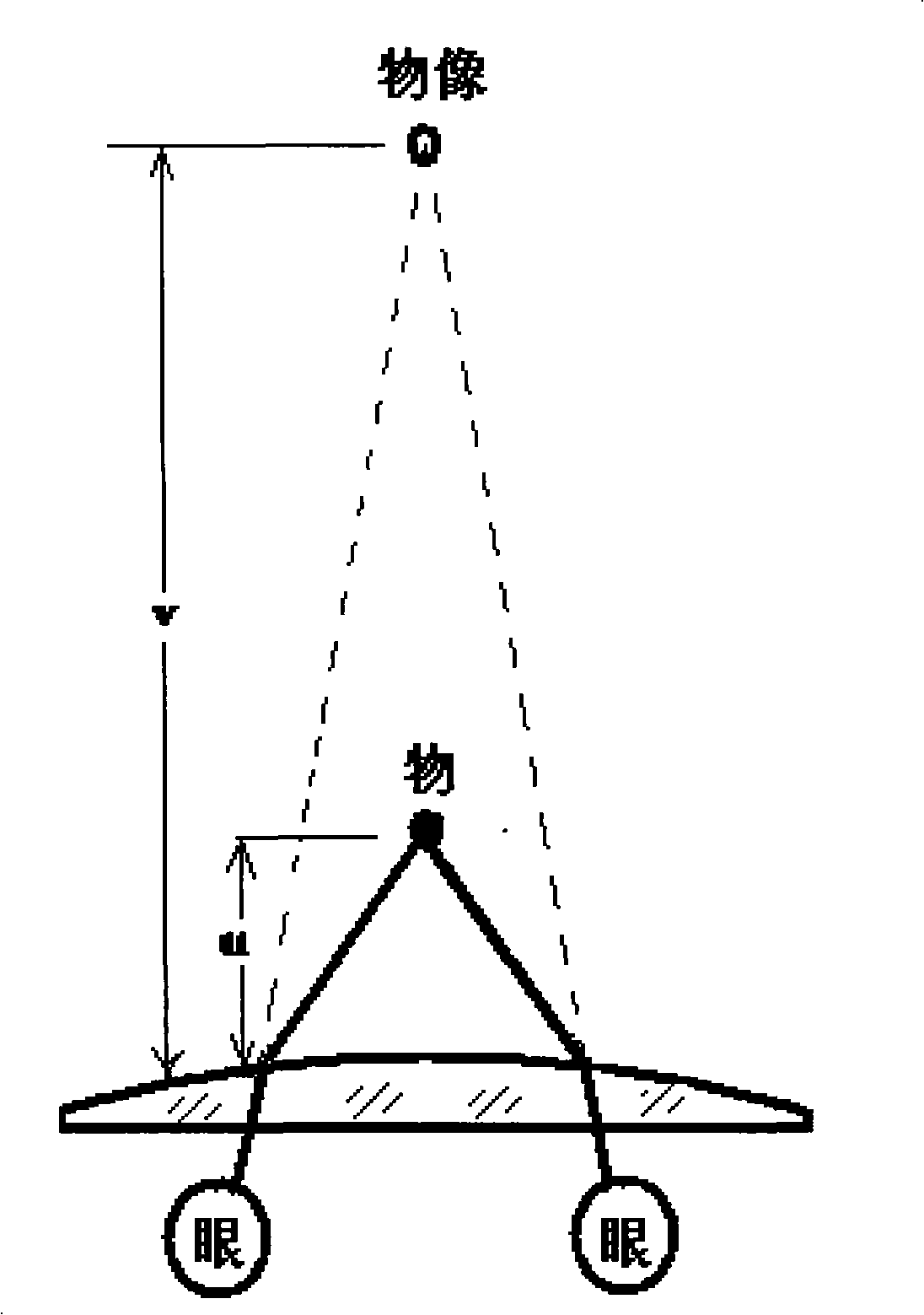

Apparatus for watching display screen

The invention relates to a device for watching display screens, and relates to the display and computer desk technical fields. The invention includes a display screen device or a computer desk (or a special member including the display screen device), which is characterized in that a convex lens for watching the same display screen with two eyes and a support for keeping a stable distance between the positions of the convex lens and the display screen are arranged on the display screen device or computer desk (or the special member including the display screen device), and the distance between the positions of the convex lens and the display screen is u which is some value more than f / (1+f) and less than 1.1. The device enables an observer to change from watching a nearby display screen to a distant display screen virtual image, and relaxes and adjusts the eyes with comfort and hardiness. The device is beneficial for reducing the eye fatigue caused by long-time watching the nearby display screen, and beneficial for watching for a long time as well as for watching by a presbyopia or a farsightedness.

Owner:王霖华

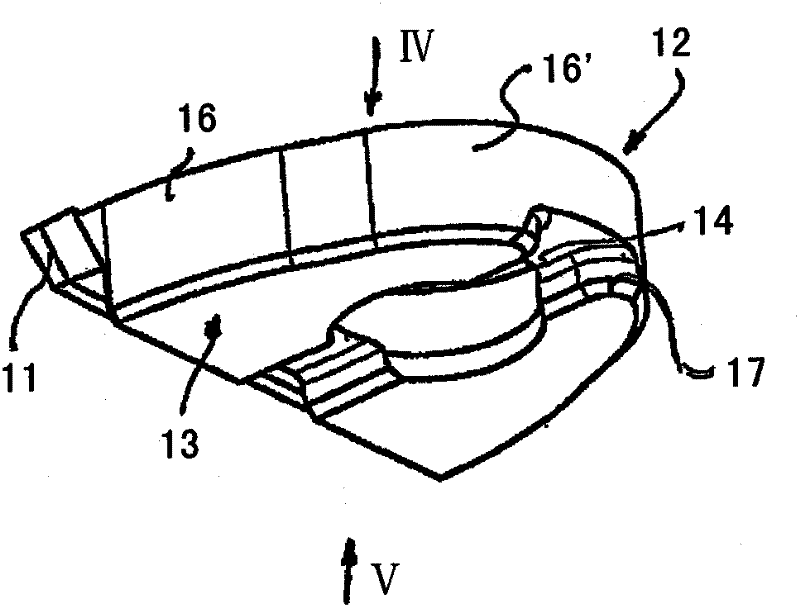

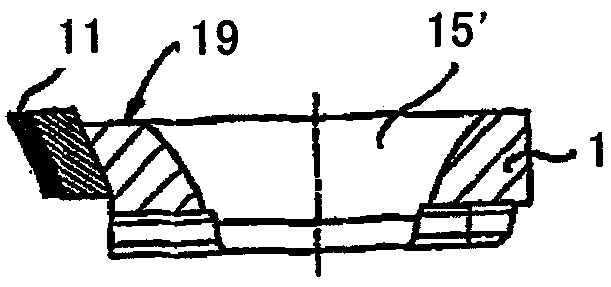

Milling tools and cutting elements for milling tools

The invention relates to a milling tool for machining non-metallic materials, in particular wood, wood-based materials and plastics, which has a carrier (3) into which a corresponding number of tools can be inserted in the radial direction on the circumferential side A plurality of cutting elements (1) in an extended recess (2), which can be screwed to the carrier (3) via holes (15), said cutting elements being plate-shaped and in cross-section Basically triangular in shape and provided with a cutting edge (11) on one side edge, it is characterized in that the cutting element (1) has the following features: a) the area (12) opposite the cutting edge (11) is inverted circle, b) a groove (14) is provided in the underside (13) extending substantially at right angles to the cutting edge (11), c) the hole (15) divides the groove (14) preferably into two regions , is also characterized by the following feature of the hollow slot (2): d) extends upwards in the radial direction from the bottom (21) of the hollow slot serving as a support surface for the cutting element (1) tab (22), which is associated with the groove (14), e) a radial threaded hole (23), which preferably divides the tab (22) into two regions , and f) the cutting element (1) is only characterized by its underside (13), the side wall (17 or 18) of the groove (14) and the A part of the area (12) is in contact with said cavity (2).

Owner:LEITZ GMBH & CO KG

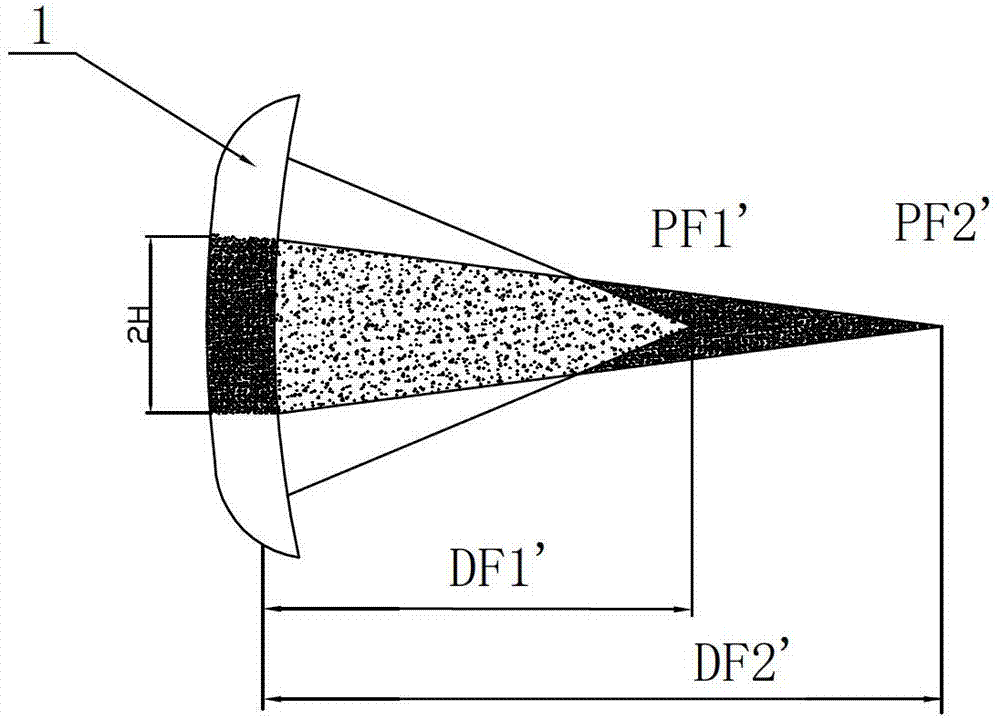

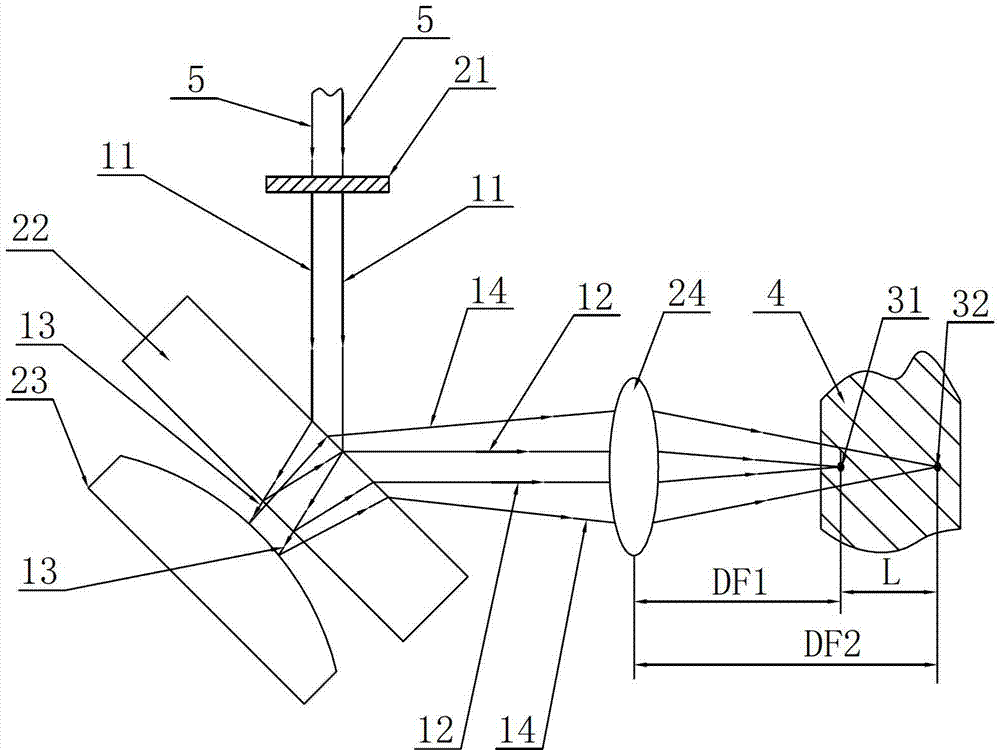

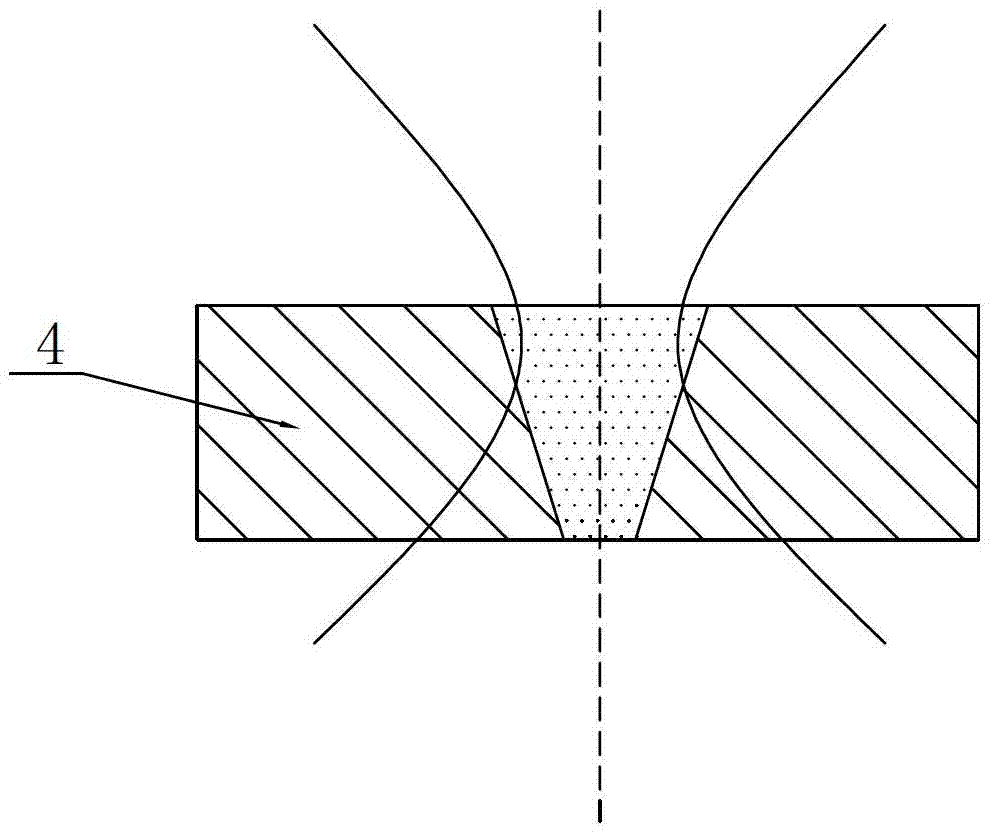

Bifocus laser processing system

InactiveCN103111755AFast processingImprove product qualityLaser beam welding apparatusLaser processingLight beam

The invention provides a bifocus laser processing system. The bifocus laser processing system comprises a spectroscope, a convex mirror and a focusing mirror. An incident beam is reflected through the spectroscope, and a second light beam is obtained; the second light beam is focused by the focusing mirror, and a first focus is formed; the incident beam is transmitted by the spectroscope, and a third light beam is obtained; the third light beam is reflected by the convex mirror, and then is transmitted by the spectroscope, and a fourth light beam is obtained; and the fourth light beam is focused by the focusing mirror, and a second focus is formed. According to the technical scheme, the first focus and the second focus are produced by the incident beam, and a focusing system with two focuses is formed. Distance between the first focus and the second focus can be changed by changing a curvature radius of the convex mirror, an energy ratio between the first focus and the second focus can be changed by adjusting a rotation angle of a wave plate, and processing speed and product quality are improved.

Owner:WUHAN DR LASER TECH CORP LTD

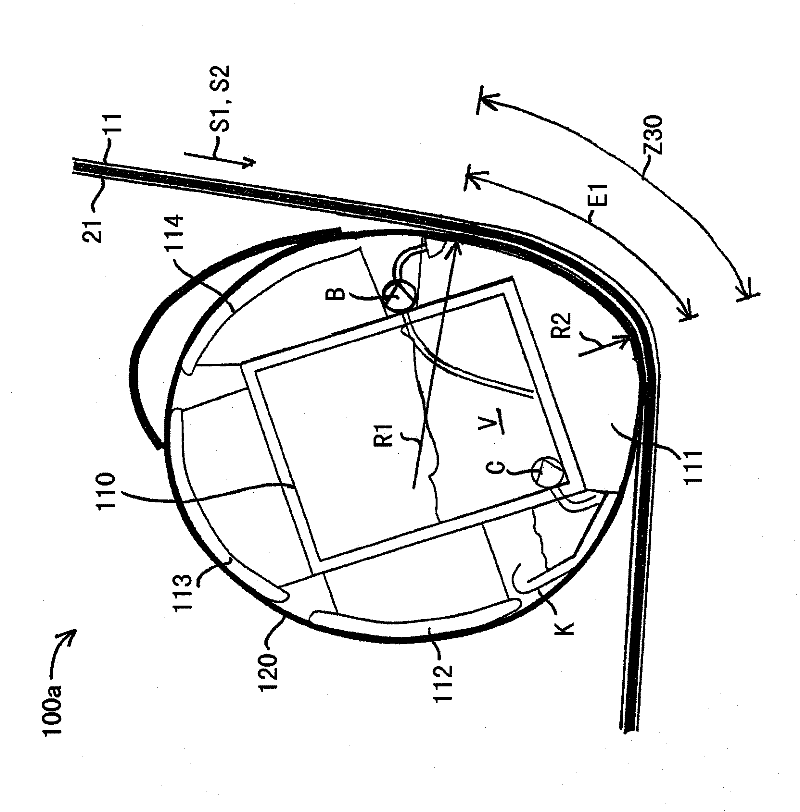

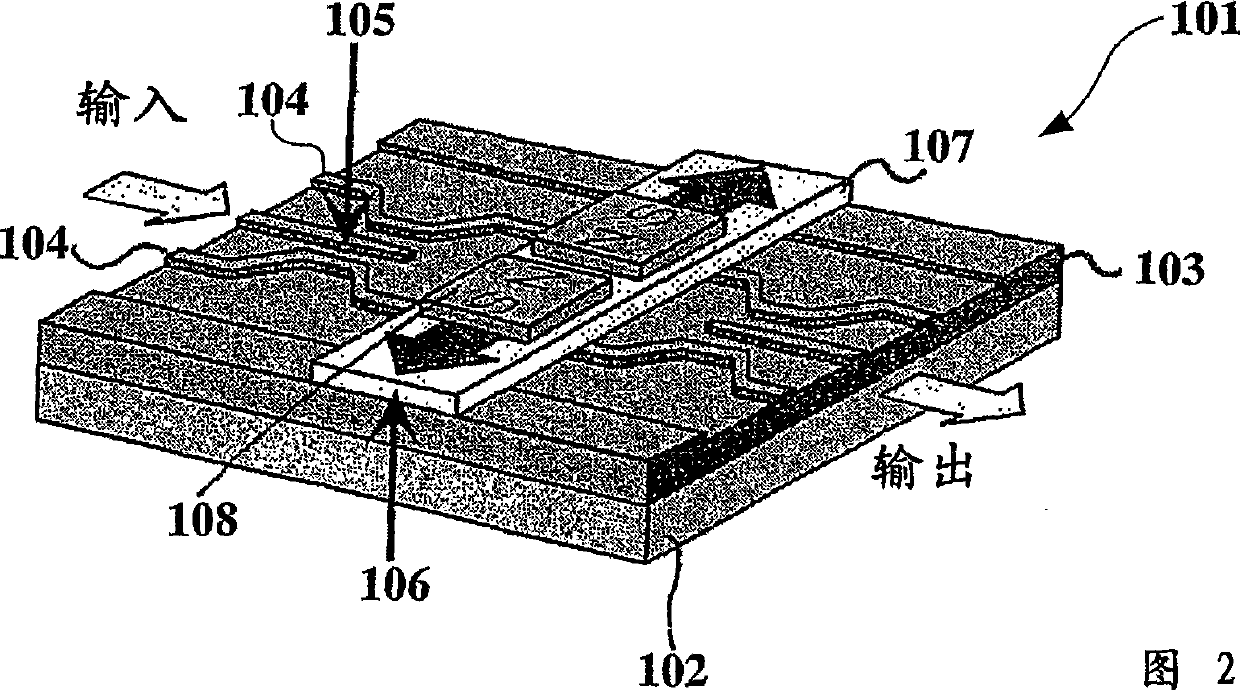

Forming section

ActiveCN102197177AExcellent quality and strength propertiesReduce splashMachine wet endWire loopDewatering

The forming section comprises two wire loops (11, 21) which form a twin- wire zone which comprises a dewatering element (40) performing initial dewatering and a dewatering device (100b) following it. The dewatering device (100b) comprises a stationary support shaft (110) on which are supported support elements (111, 112, 113, 114) around which circles an impermeable belt loop (120). The dewatering device (100b) further comprises a curvilinear dewatering zone (Z30) over which the wires (11, 21) travel supported by the belt loop (120). The degree of curvature of the curve of the curvilinear dewatering zone (Z30) increases in the travel direction of the belt (120) such that increasing dewatering pressure is applied to pulp suspension travelling between the wires (11, 21) on the curvilinear dewatering zone (Z30).

Owner:METSO PAPER INC

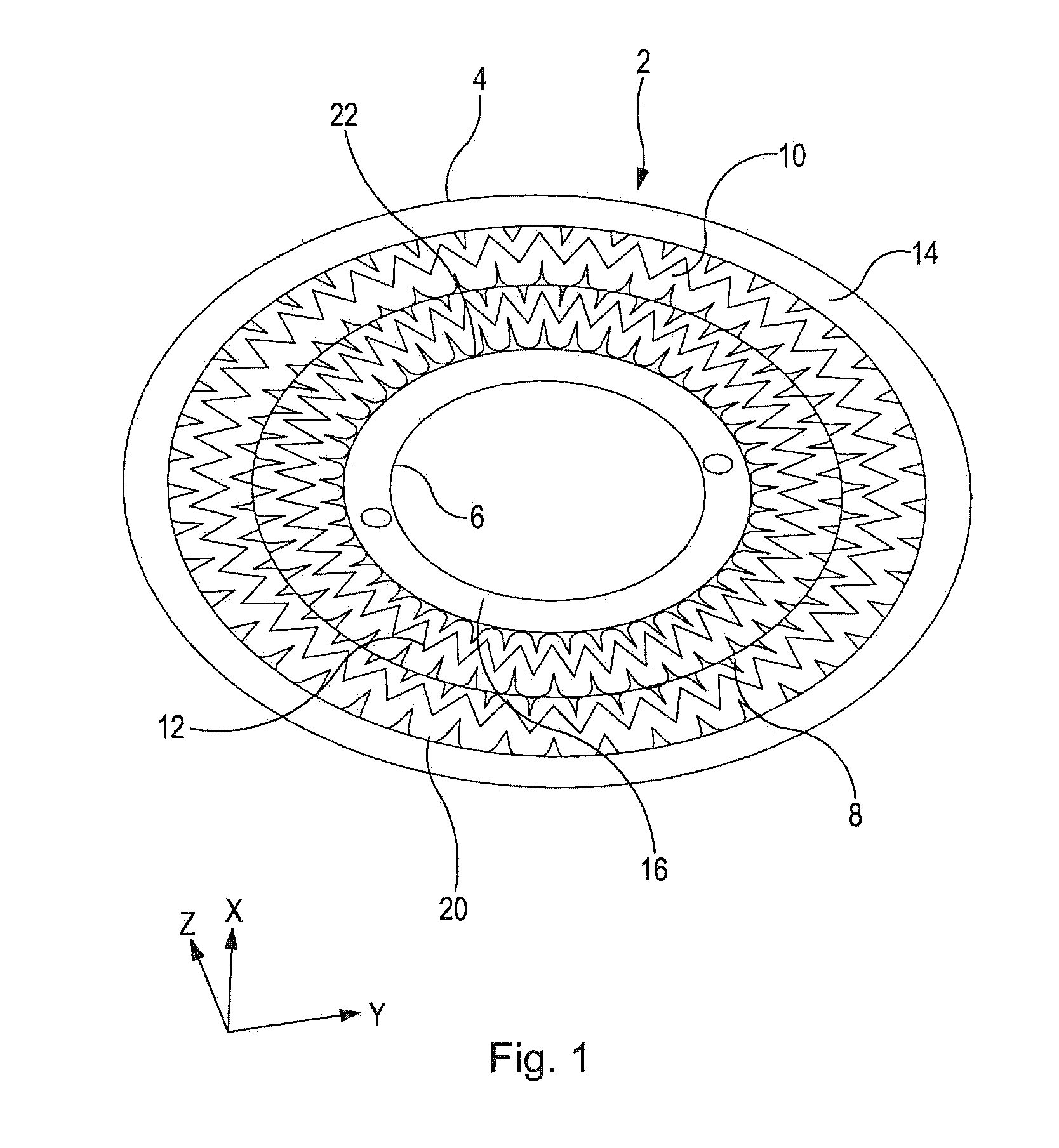

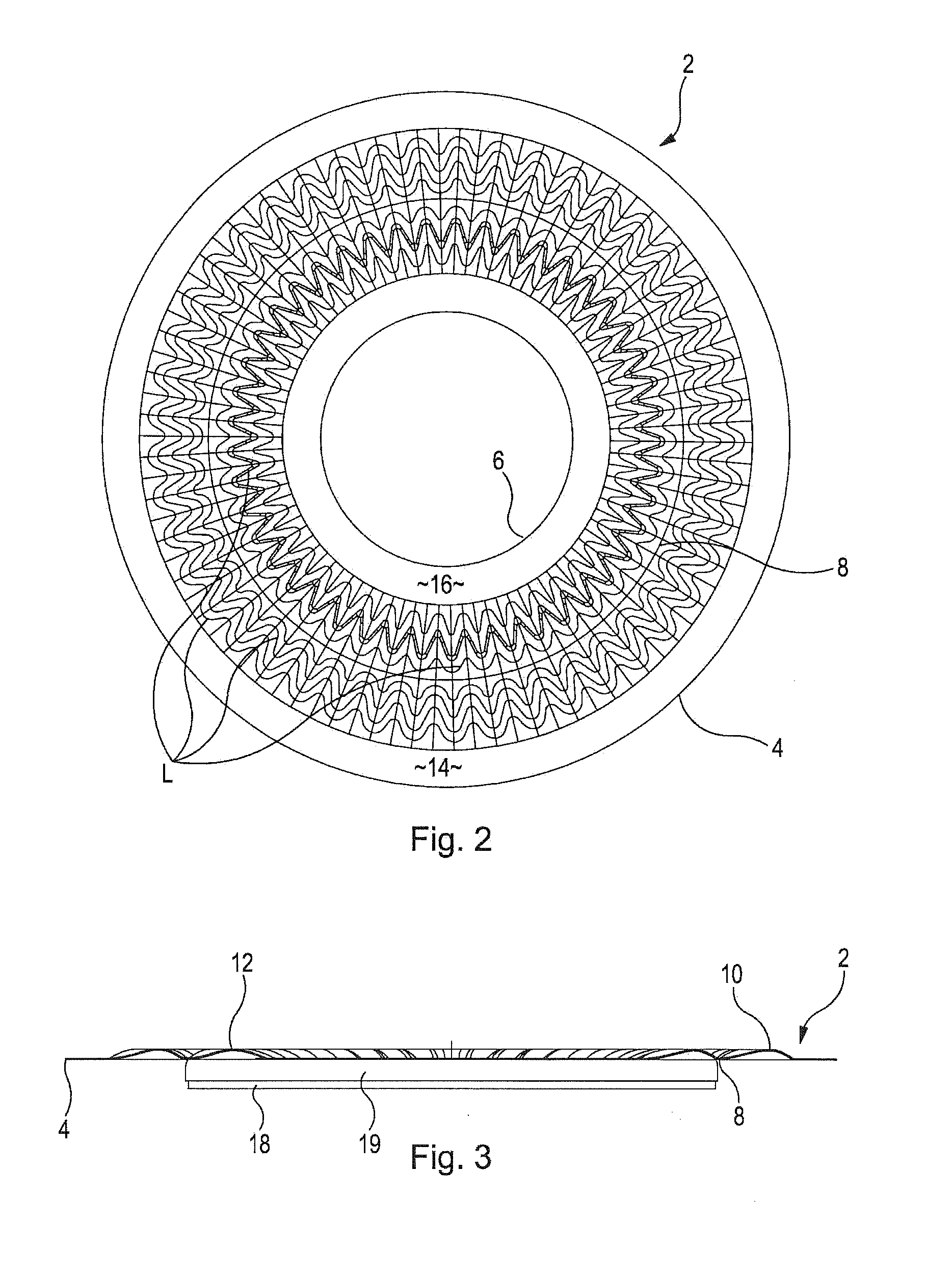

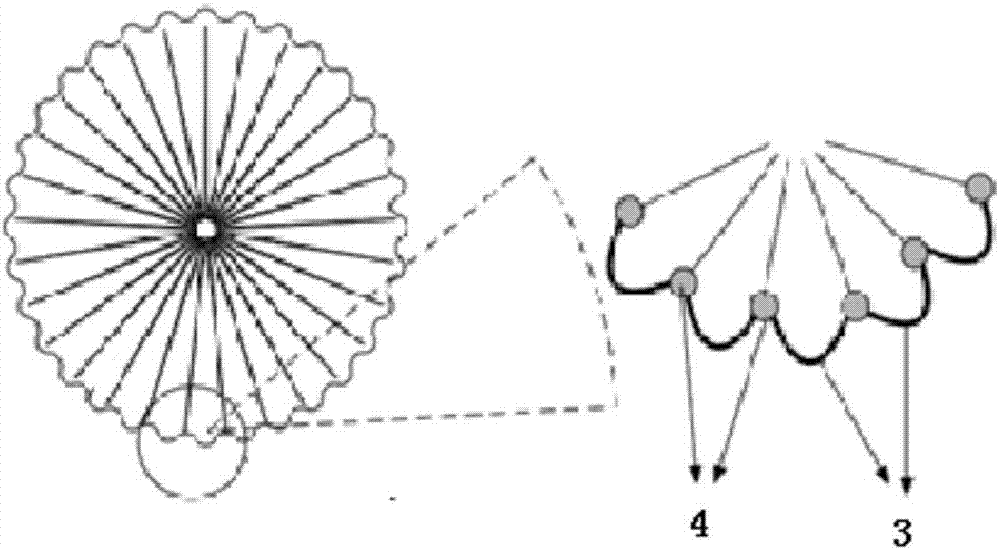

Electro acoustic diaphragm

ActiveUS20160014519A1Small radius of curvatureThinnerTransducer detailsNon-planar diaphragms/conesLoudspeakerEngineering

A diaphragm for a loudspeaker, wherein the diaphragm is formed generally in a closed loop around a central void, the loop lying in a plane, the diaphragm having an axis in a direction orthogonal to the plane along which axis the diaphragm is arranged to be driven in use, the diaphragm having inner and outer circumferential edges which are adapted, in use, to be fixed in position, wherein a substantial portion of the diaphragm between the inner and outer edges is shaped in the direction of the said axis so as to protrude from the general plane of the diaphragm in either or both directions along the axis, and wherein said shaped portion when viewed along the direction of the axis comprises at least one series of curves extending radially across substantially all of the driven area of the diaphragm.

Owner:GP ACCOUSTICS (UK) LIMITED

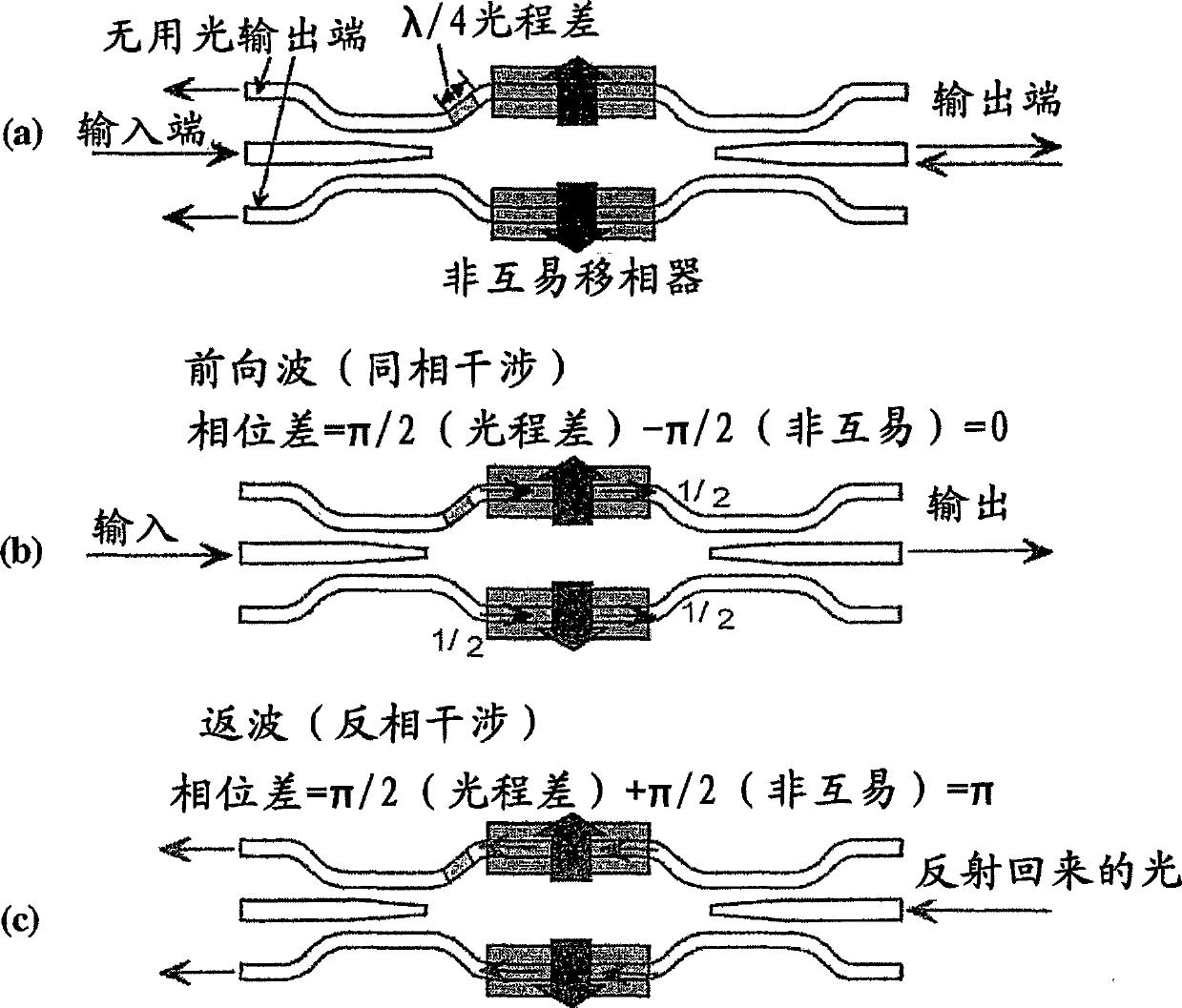

Optical isolator

InactiveCN101375200AShorten the lengthHigh refractive indexOptical waveguide light guideNon-linear opticsOptical isolatorRefractive index

An optical isolator is constituted by providing a substrate, a waveguiding layer lattice-matched to the substrate, and a non-reciprocal phase shifter, and a waveguide and a curved waveguide for guiding the waveguiding layer are formed in the waveguiding layer, and a branch coupler is also provided therein, furthermore, a refractive index of the waveguiding layer is made larger than 3.36 by changing a semiconductor composition.

Owner:TOKYO INST OF TECH +1

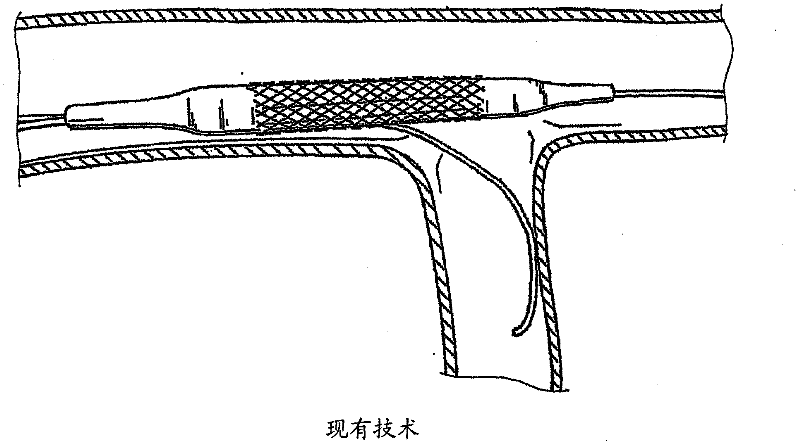

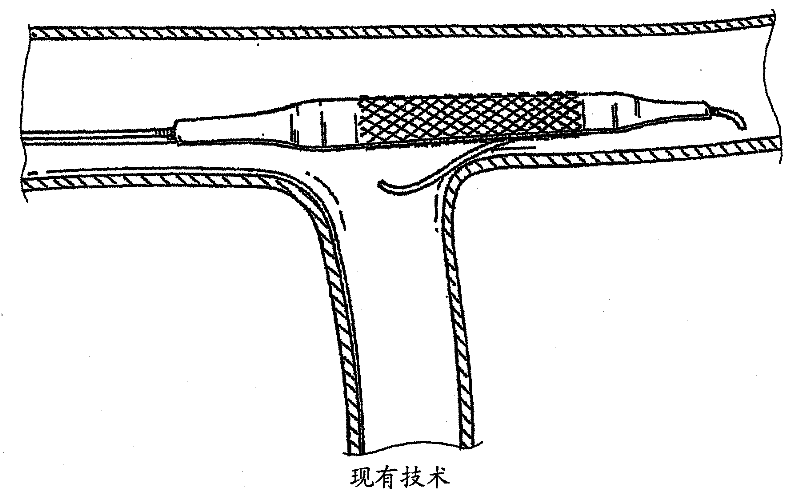

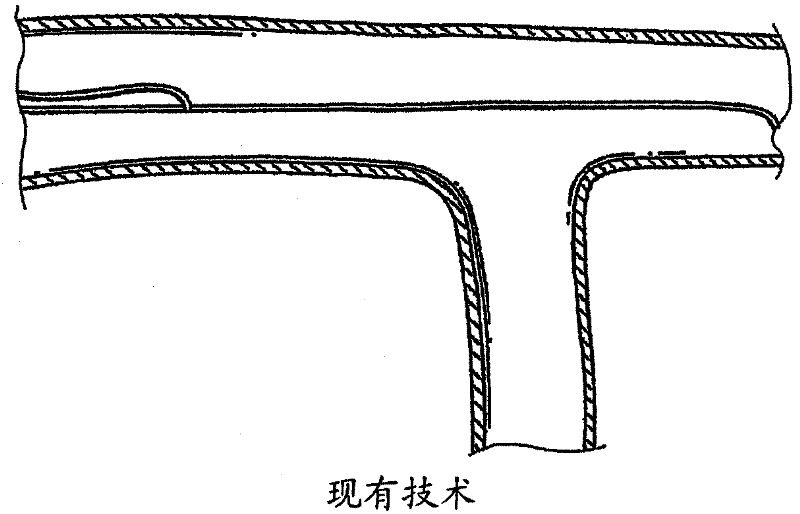

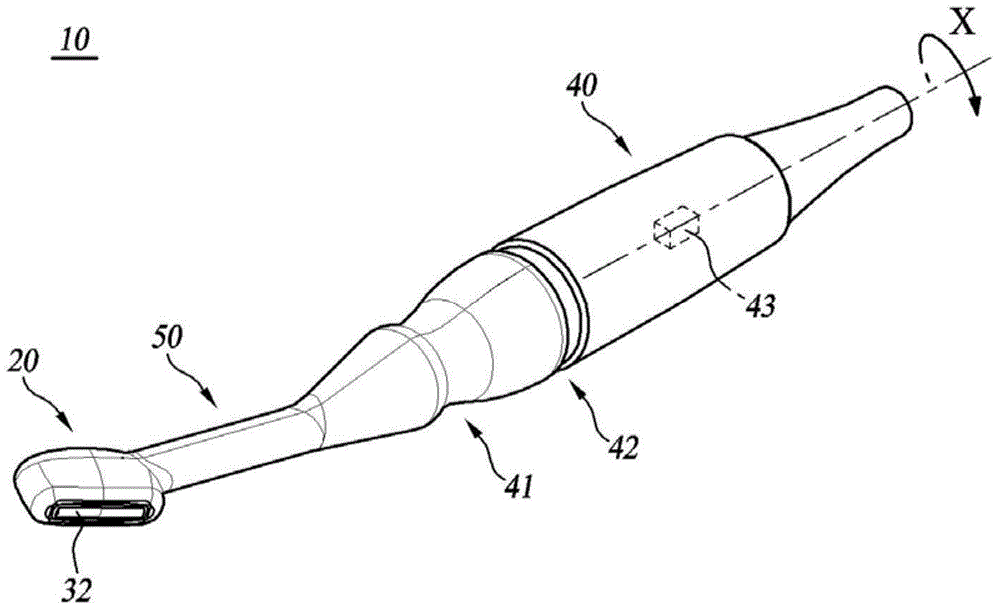

Navigation guide wire through an anatomical structure having branched ducts

InactiveCN102202717AEasy to operateQuick twist feedbackStentsGuide wiresAnatomical structuresDistal portion

A navigation guide wire (1 ) through an anatomical apparatus, for example a vascular system, unusually capable of being safely positioned proximate to bifurcations, comprises: - an elongated body (19) having a proximal end (21 ), a distal end (20), and a longitudinal extension along an axis (x-x) extending at least from said proximal end to said distal end; - at least one first proximal portion (4) having a predetermined first flexural rigidity (KfI ) capable of a first predetermined flexure in at least one plane comprising at least one portion of said longitudinal axis in order to allow a first curvature to said proximal portion when bending stressed, while ensuring a predetermined elastic return in a rectilinear position of the elongated body proximal portion when not subjected to stresses; - at least one second distal portion (3) having a predetermined second flexural rigidity (Kf2), the amount of which is equal to or higher than said first flexural rigidity of said at least one first proximal portion, capable of a predetermined flexibility of said second distal portion in order to obtain a second curvature when bending stressed in at least one plane comprising at least one portion of said longitudinal axis, while ensuring an elastic return to a rectilinear position of said distal portion of said elongated body when not subjected to stress; - at least one intermediate length (6), arranged between said first proximal portion and said second distal portion, having a third flexural rigidity (Kf3) essentially lower than said first flexural rigidity (KfI ) and said second flexural rigidity (Kf2), which allows a predetermined flexibility capable of a third curvature substantially more pronounced compared to said first curvature and second curvature, so as to allow a considerable direction change between said first proximal portion (4) and said second distal portion (3).

Owner:EVR MEDICAL S AR L

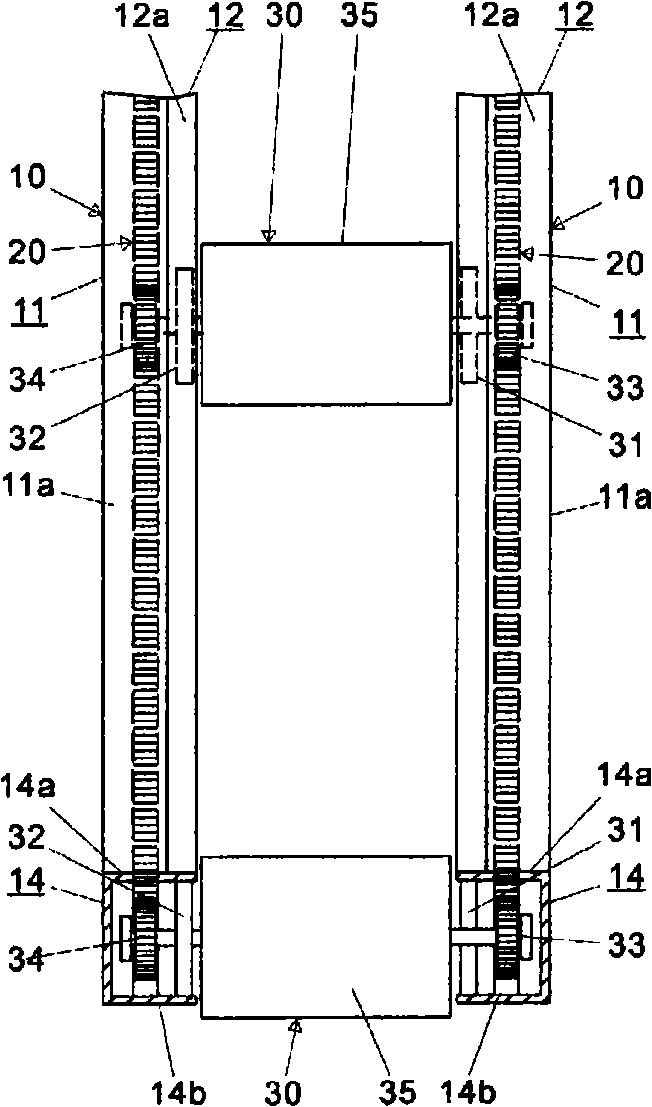

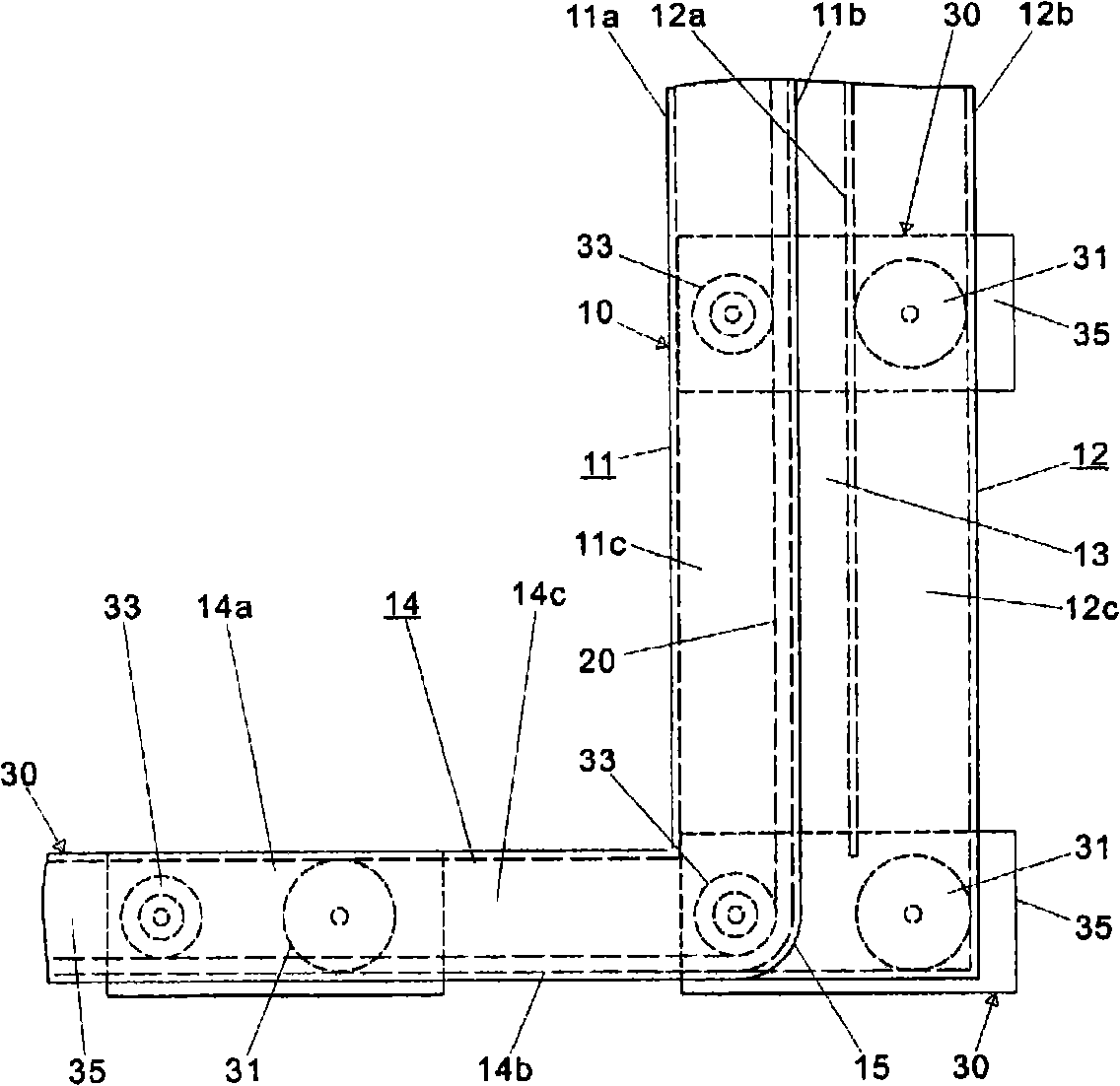

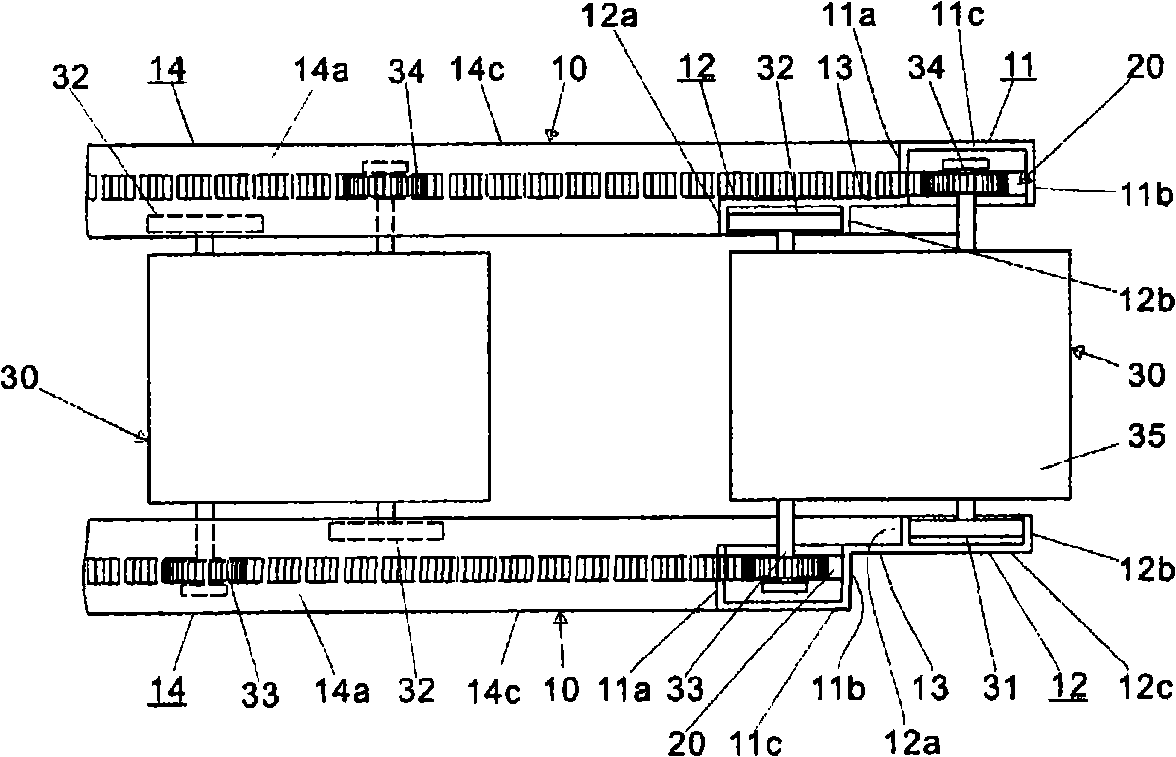

Horizontal conveyance mechanism for self-propelled carriage

ActiveCN101495357AReduce curve curvatureCompact structureMonorailsRailway system combinationsVehicle frameOperating energy

A conveyance mechanism having rails (10) horizontally and vertically laid in a building, racks (20) laid along the rails, wheels (31, 32) for traveling on the rail, and a self-propelled carriage (30) having pinions (33, 34) meshing with the racks and a drive section for the pinions and on which a load is placed. The rails have a curve section in which they change the direction from horizontal to vertical or from vertical to horizontal, and also have a vertical section continuing to the horizontal section. In the two sections above, the rails have rails (11) for the pinions, having the racks meshing with the pinions, and also have rails (12) for the travel wheels, installed in parallel with and separated from the rails for the pinions. The carriage have, on its left and right sides, the pinions meshing with the rails for the pinions and the travel wheels supported on the rails for the travel wheels. Also, the rails for the pinions and the rails for the travel wheels are arranged so that the carriage can move in a horizontal position in the curve section and the vertical section continuing to the curve section.

Owner:S & S ENG

Multi-focal laser processing system

InactiveCN103111757AFast processingImprove product qualityLaser beam welding apparatusLaser processingOptical axis

The invention provides a multi-focal laser processing system which comprises two or more than two optical element assemblies and a focus lens, wherein the optical element assemblies are sequentially connected with an optical path in series, an incident beam passes through two or more than two optical element assemblies which are sequentially connected with the optical path in series, is focused by the focus lens, and then acts on the focal point of an optical axis of a work piece to be processed. Each optical element assembly comprises a spectroscope and a convex mirror. The incident beam is reflected through the spectroscope to obtain a first incident beam which enters the next optical element assembly. The incident beam is transmitted through the spectroscope and a light beam is obtained, and the light beam is reflected through the convex mirror and transmitted through the spectroscope to obtain a second incident beam which enters the next optical element assembly. Through the adoption of the technical scheme of the multi-focal laser processing system, the incident beam forms a plurality of focuses through the multi-focal laser processing system, the number of the focuses is a multiple of 4, and therefore processing speed and quality of products are improved.

Owner:WUHAN DR LASER TECH CORP LTD

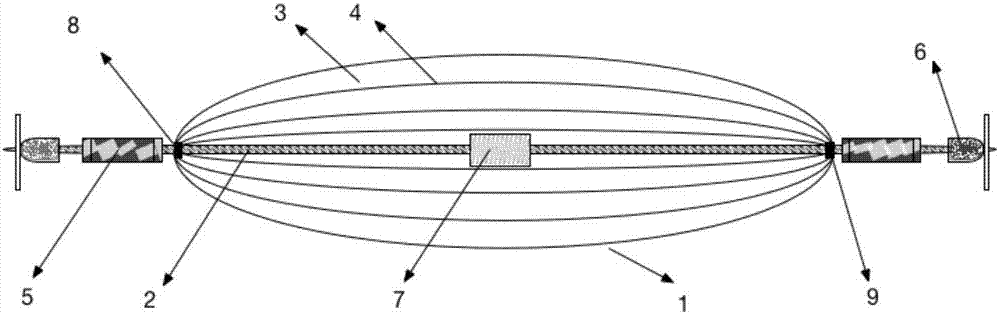

Reinforced stratospheric airship internally provided keel

The invention relates to a reinforced stratospheric airship internally provided with a keel. The reinforced stratospheric airship internally provided with a keel is mainly composed of the rigid truss support keel, an airship bag body, a solar cell module, an energy storage battery, a power propulsion system and an avionics system, wherein the airship bag body is formed by bump-type skin; a plurality of strip-shaped bumps are arranged on the bump-type skin; each strip-shaped bump is arranged in the length direction of the stratospheric airship; and the strip-shaped bumps are arranged along the outer circumference of the airship. According to the reinforced stratospheric airship internally provided with the keel,, the radius of curvature of the skin can be reduced, and a stress load, caused by pressure, of the skin of the airship can be reduced greatly so that the skin can withstand the overpressure state for a long time, and increment of the size of the airship is possible.

Owner:北京天恒长鹰科技股份有限公司

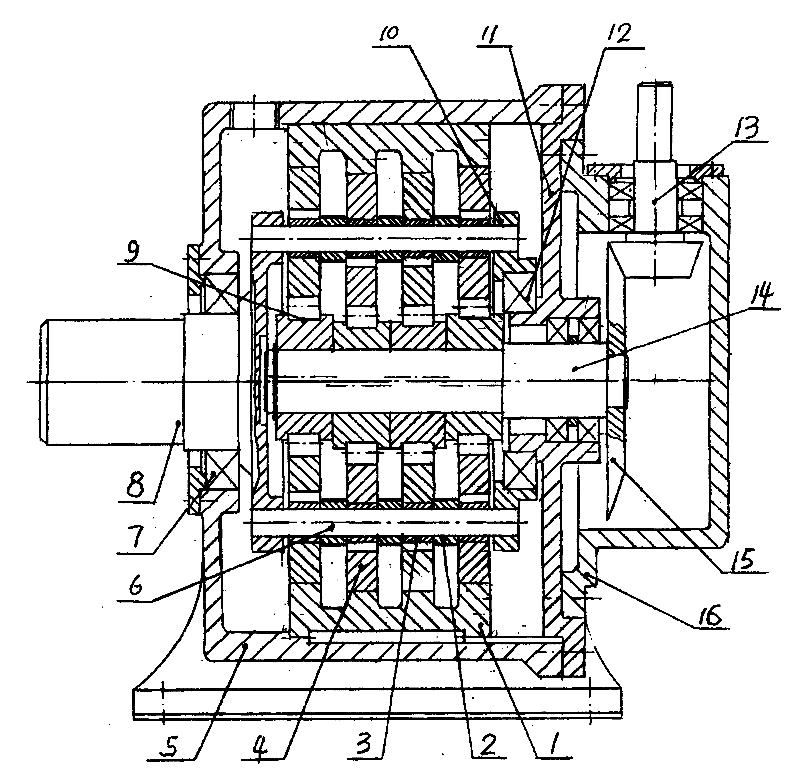

Reducer with bevel gear and hypocycloid in large transmission ratio for ore grinding machine

InactiveCN102192280ASmall radius of curvatureImprove contact strengthToothed gearingsReduction drivePhase difference

The invention relates to the technical field of reducing the speed of an ore grinding machine. A reducer with a bevel gear and a hypocycloid in large transmission ratio for an ore grinding machine is characterized by comprising a bevel gear pair and a cycloid transmission part; the bevel gear pair comprises driving and driven bevel gears and the cycloid transmission part is composed of a machine body, an input shaft, eccentric bearings, a cycloid gear, an inner cycloid gear ring, a W mechanism and bearings; the W mechanism comprises an output shaft, a column pin, a uniform loading disc and an annular plate; in the W mechanism, the output shaft is supported on an inner hole of the machine body through utilizing the bearing and an inner hole of the uniform loading disc is supported on the outer circle of a flange of an end cover through utilizing the bearing; in four single-eccentric bearings: the phase difference between the first bearing and the second bearing and the phase difference between the third bearing and the fourth bearing are 180 DEG and the phase of the second bearing is same as that of the third bearing. In the invention, the reducer has the beneficial effects as follows: (1) the hypocycloid gear is engaged by purely rolling, so that the bearing capability is improved by 2-3 times; (2) the length of the axial direction is reduced by 45-55% and the cost is reduced by 40-50%; (3) the reversed installation service life of the cycloid gear is doubled; and (4) the inertia force and the inertia moment are completely balanced in theory when the reducer is operated.

Owner:吴小杰

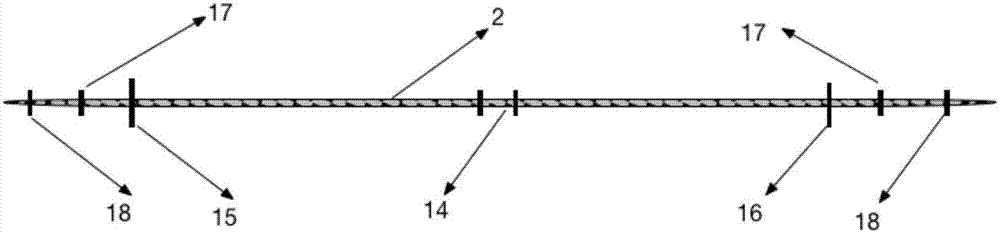

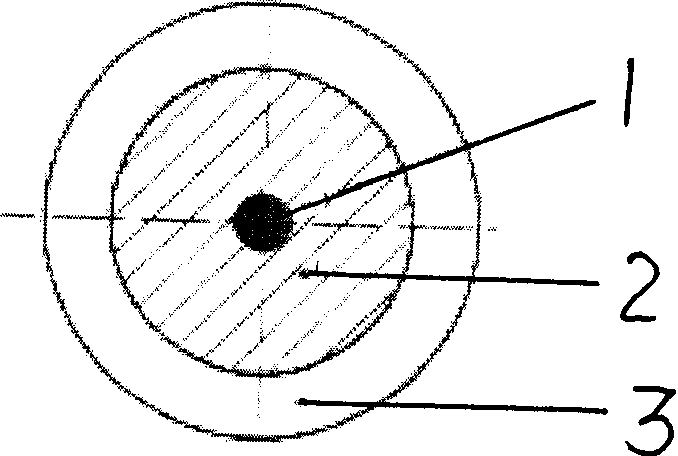

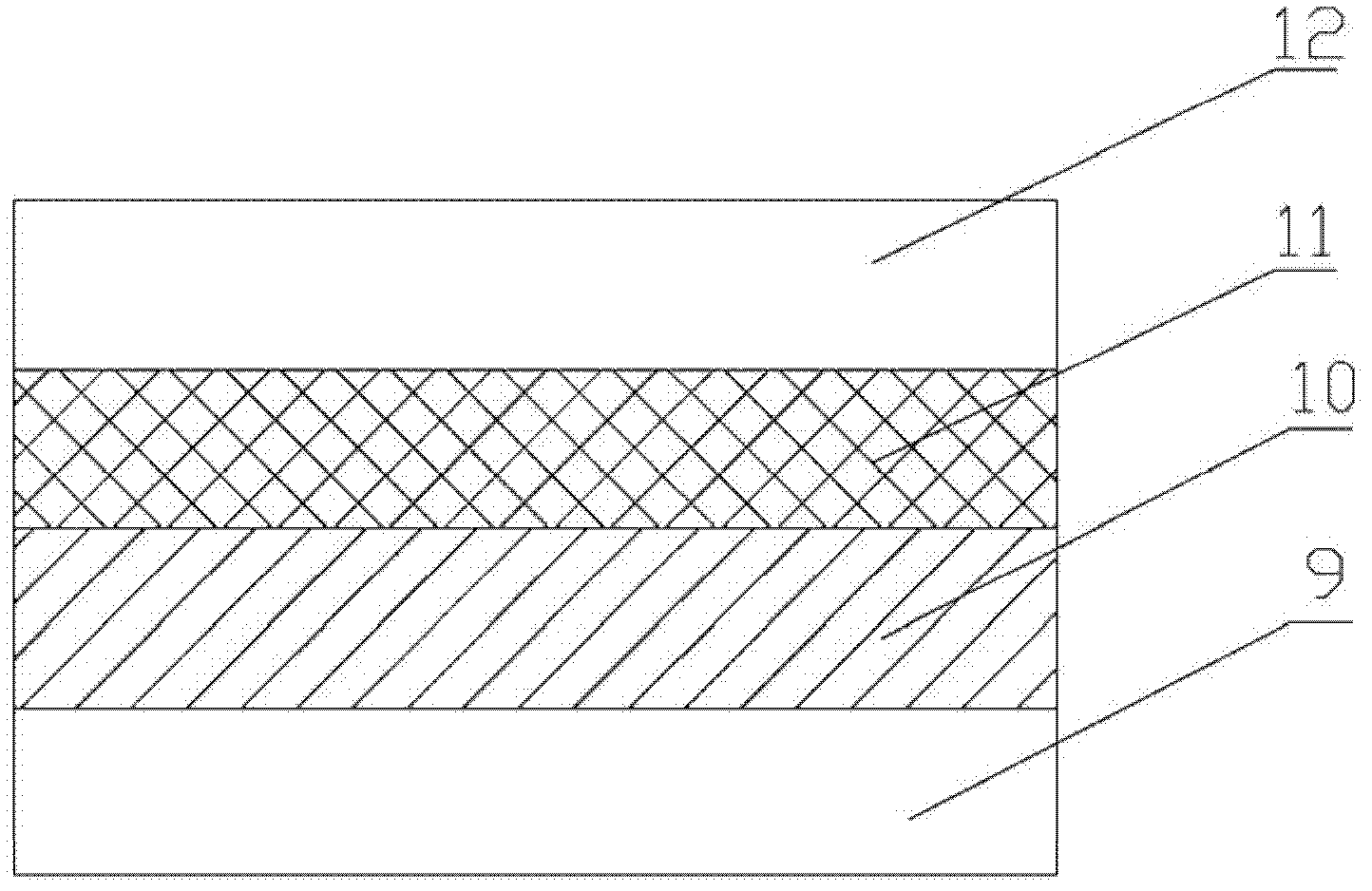

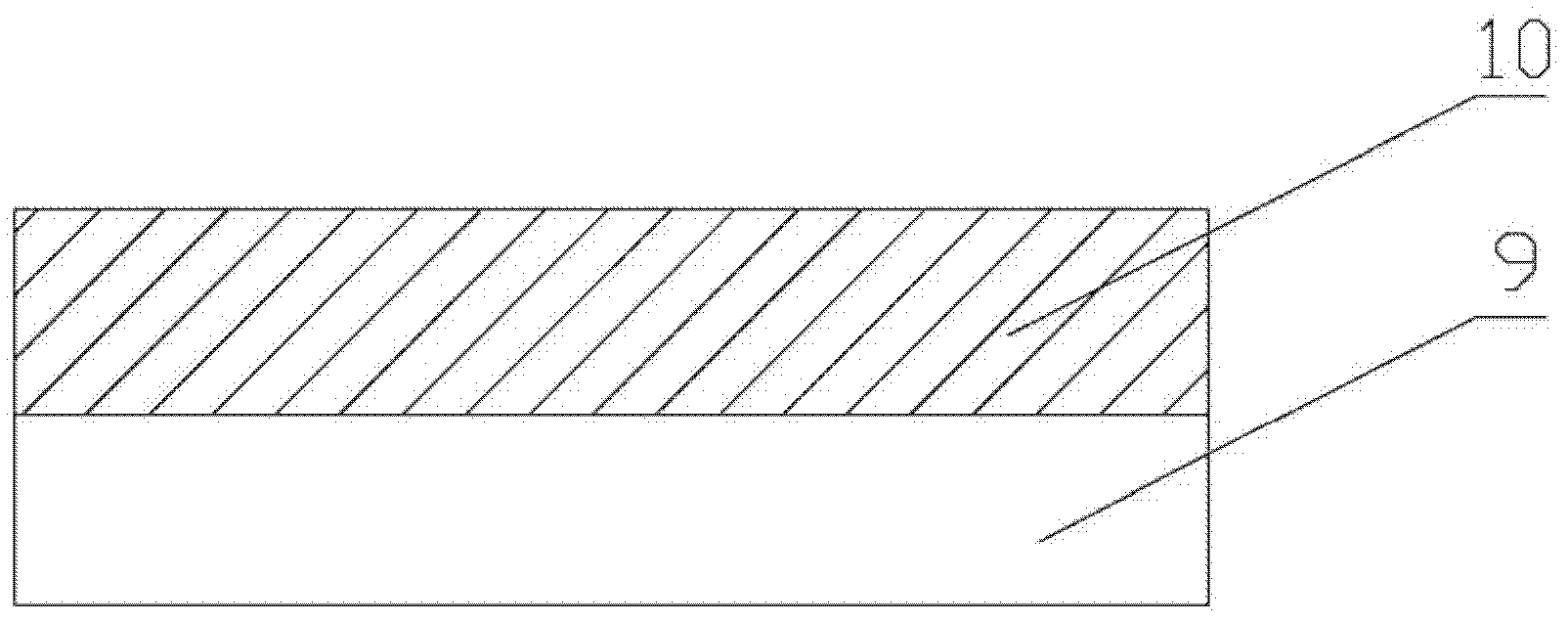

Optical cable, fiber reinforced plastics used thereby and preparation method thereof

InactiveCN101915970AReduce manufacturing costWell mixedFibre mechanical structuresYarnTerminal equipment

The invention relates to an optical fiber used in an outdoor system and an indoor system of a fiber-to-the-x (FTTx) network project in a communication network, fiber reinforced plastics used by the optical cable and a preparation method of the fiber reinforced plastics. As for the optical cable, at least one optical fiber is coated with a reinforced sheath which is the fiber reinforced plastics and is externally coated with a protecting jacket. The fiber reinforced plastics comprise the following components in parts by weight: 13-25 parts of light-cured resin and 75-87 parts of fiber yarn. The preparation method of the fiber reinforced plastics has the following steps: a, placing the light-cured resin in a constant temperature cabinet at the temperature of 70-90 DEG C for 1-2h; b, placing the light-cured resin and the fibre yarn in a solution tank for evenly mixing; c, pulling and extruding into a formed rod piece by a pultrusion module; and d, placing the formed rod piece in an ultraviolet curing oven for curing for 0.3-12s. The invention improves the safety protection performance of communication facilities and user terminal equipment; and the optical cable with fine diameter and small radium of curvature can satisfy the special requirements of easy branching, easy access and convenient construction in the FTTx network project.

Owner:上海晓宝增强塑料有限公司

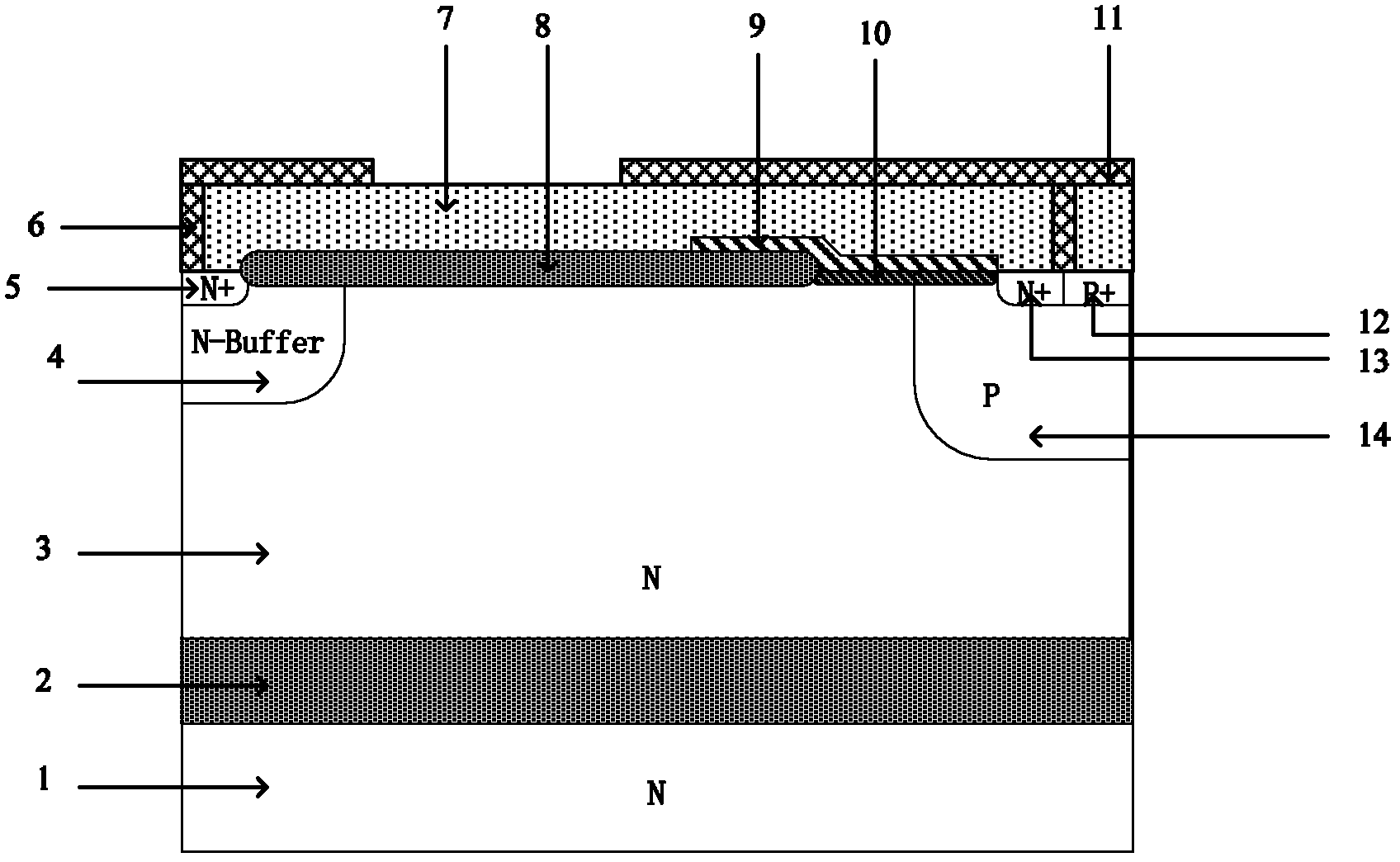

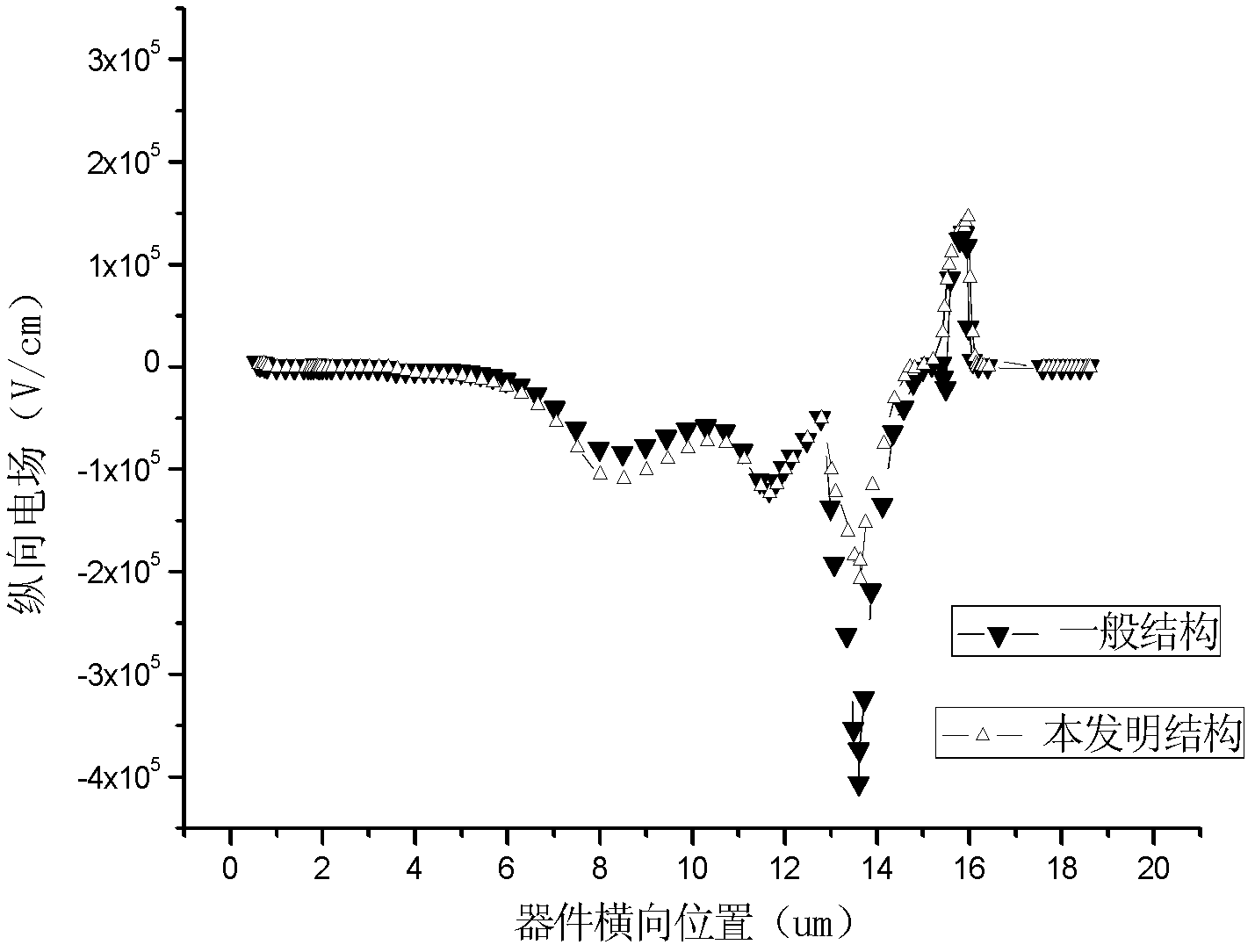

N-type silicon-on-insulator transverse double-diffusion field effect transistor

InactiveCN102437192ASmall radius of curvatureReduce electric field strengthSemiconductor devicesDouble diffusionElectrical field strength

Owner:SOUTHEAST UNIV

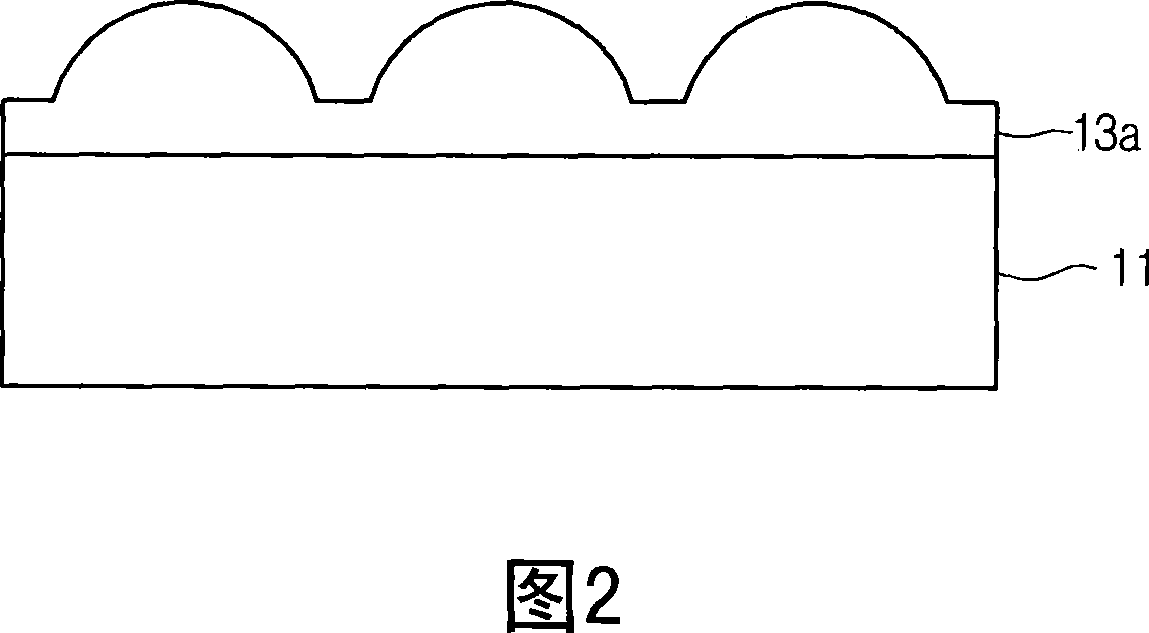

Method for fabricating image sensor

InactiveCN101211815AHigh sensitivitySmall sizeSolid-state devicesSemiconductor/solid-state device manufacturingHeat treatedMaterials science

The present invention provides a method of manufacturing an image sensor. In this method, a low temperature oxide layer is formed on the color filter layer, and a photoresist pattern is formed on the low temperature oxide layer. Subsequently, heat treatment is performed on the photoresist pattern to form sacrificial microlenses. The sacrificial microlenses and the low temperature oxide layer are etched to form preliminary microlenses in the low temperature oxide layer. The preliminary microlenses are etched to form microlenses having a reduced radius of curvature compared to the preliminary microlenses. According to the method of manufacturing an image sensor of the present invention, the sensitivity of the image sensor is improved, and the light convergence distance is reduced, so that the size of the image sensor can be reduced.

Owner:DONGBU HITEK CO LTD

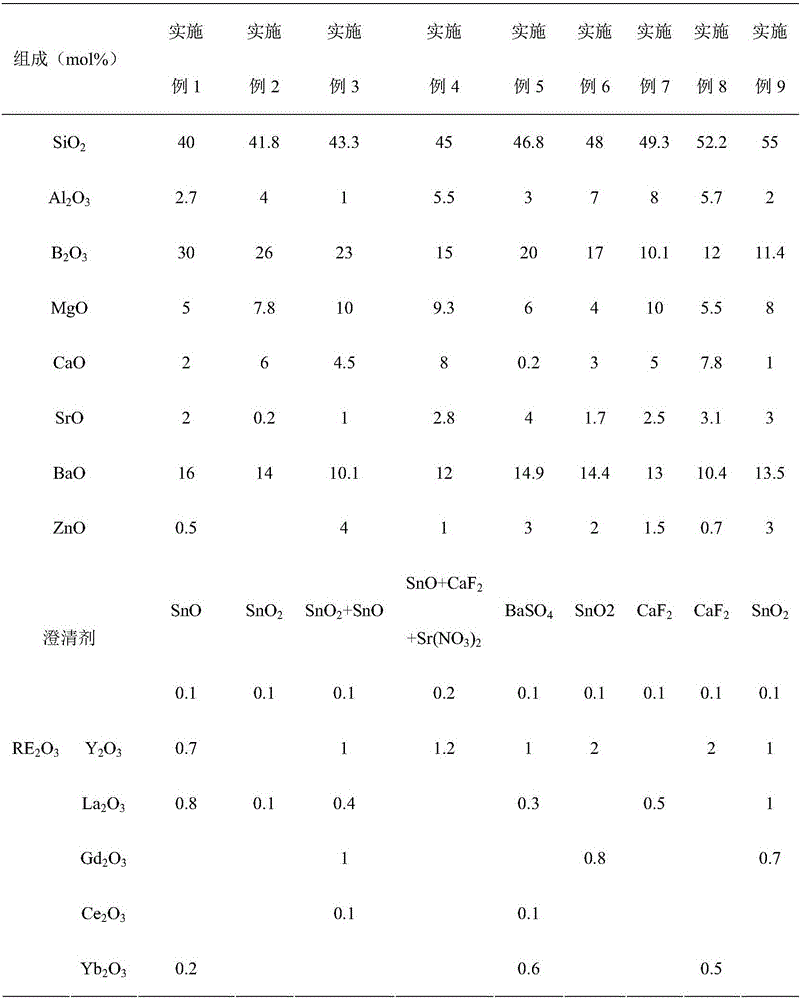

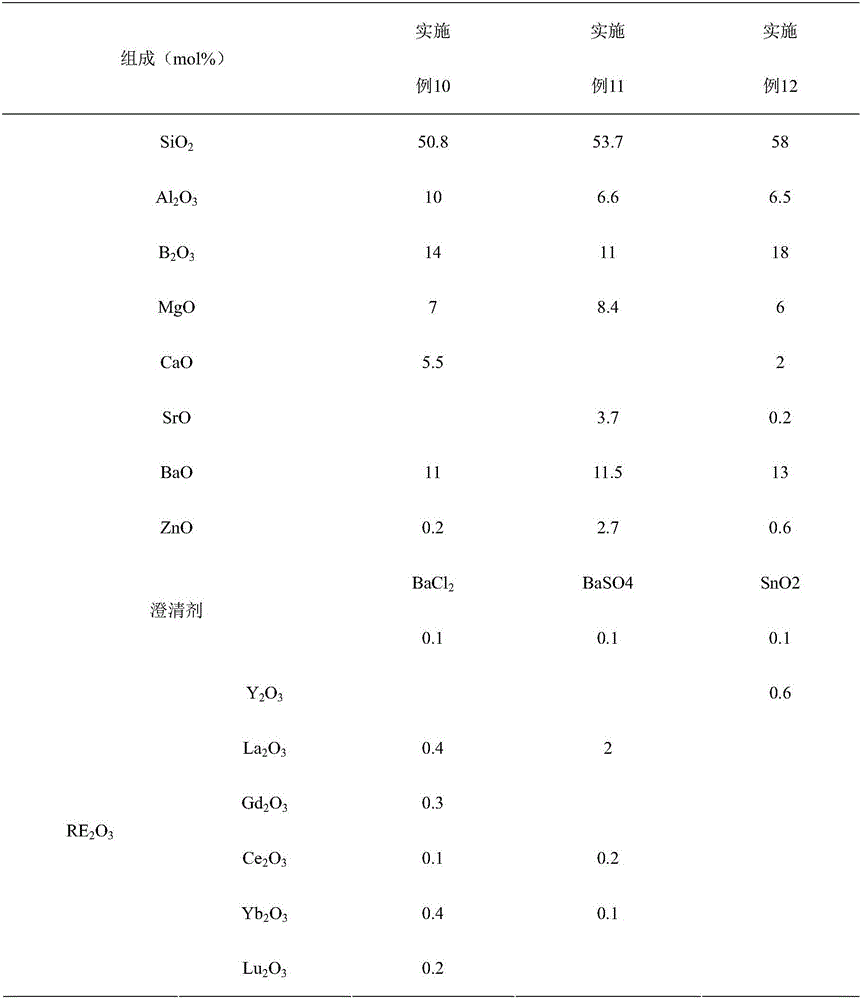

Composition used for preparing aluminum borosilicate glass, aluminum borosilicate glass, preparation method and application of aluminum borosilicate glass

The invention provides a composition used for preparing aluminum borosilicate glass, the aluminum borosilicate glass, and a preparation method and an application of the aluminum borosilicate glass. The composition used for preparing the aluminum borosilicate glass comprises 40-58mol% of SiO2, 10-30mol% of B2O3, 1-10mol% of Al2O3, 4-10mol% of MgO, 0-8mol% of CaO, 0-4mol% of SrO, 10.1-16mol% of BaO, 0-4mol% of ZnO and 0.1-3mol% of RE2O3. The SiO2 content of the composition is low, the B2O3 content and the BaO content of the composition are high, and the glass prepared through using the composition has the advantages of low brittleness and strong flexibility.

Owner:DONGXU OPTOELECTRONICS TECH CO LTD

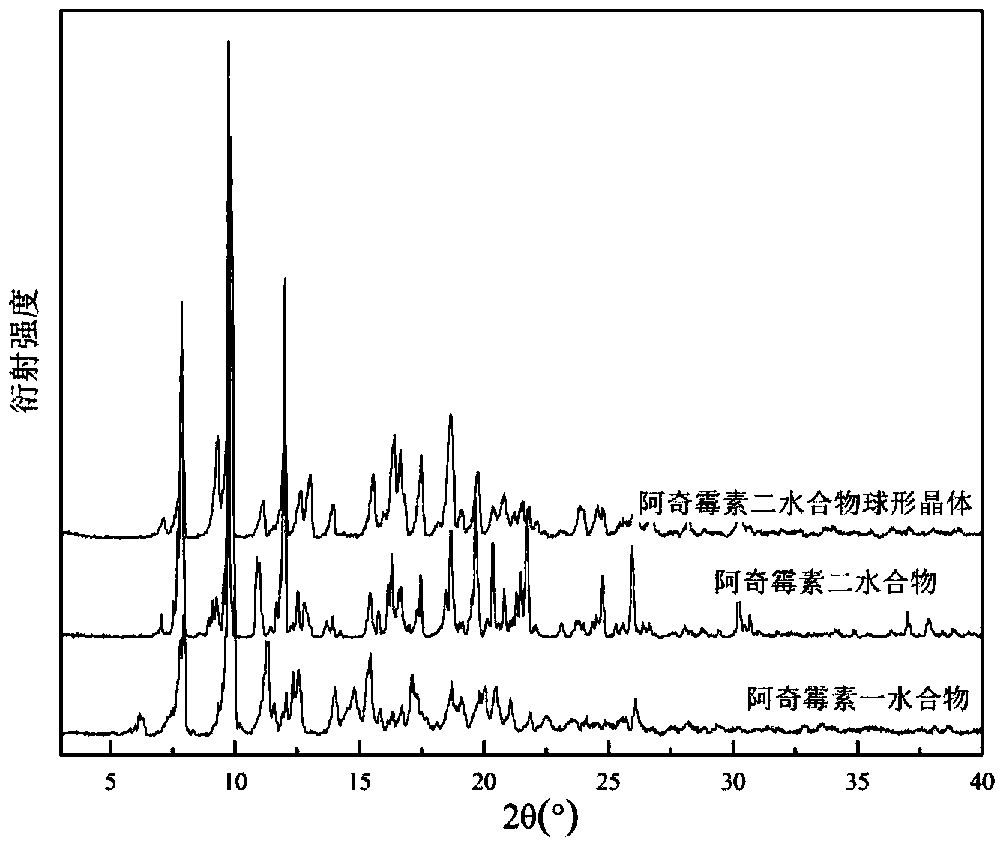

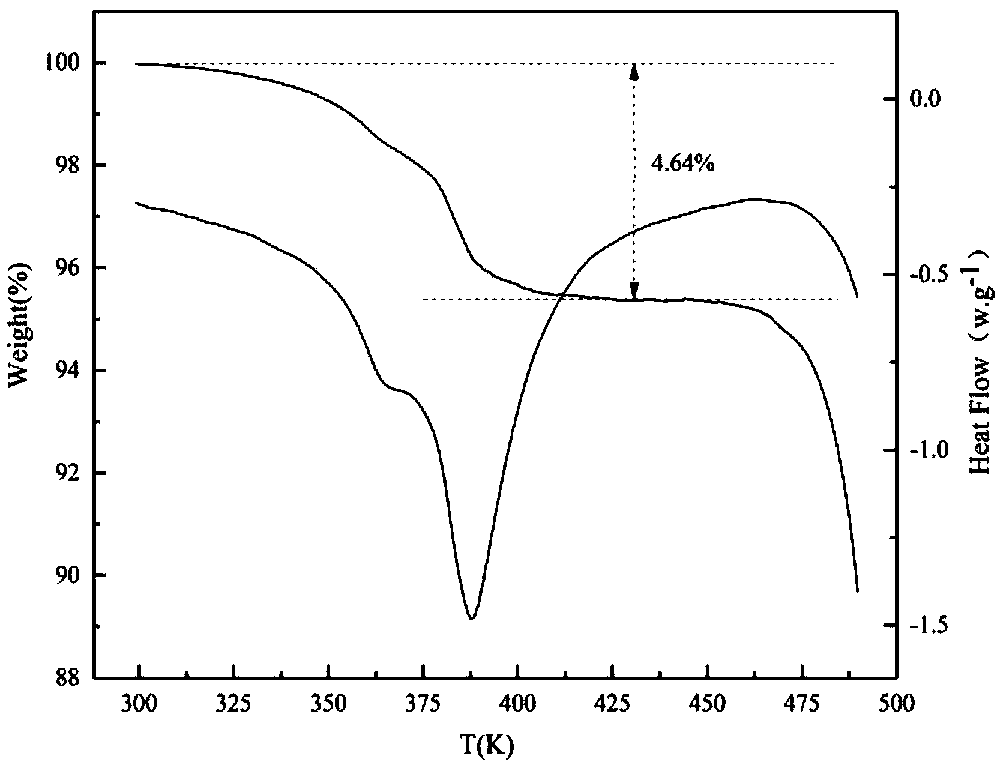

Dihydrate azithromycin sphaerocrystal and preparation method thereof

ActiveCN108690106ALarge granularityImprove liquiditySugar derivativesOrganic chemistry methodsAzithromycinGranularity

The invention relates to a dihydrate azithromycin sphaerocrystal and a preparation method thereof. The sphaerocrystal is high in circular degree and large in particle size, has the diameter reaching to 0.5mm to 4mm, is good in fluidity, and has an angle of repose being 17 degrees to 23 degrees. The method comprises the steps of adding azithromycin solids into a mixed solvent of a good solvent anda bridging agent, then heating to 20 DEG C to 40 DEG C, fully dissolving the solids, adding water for crystallizing under the stirring action, after adding water, growing the grain for 30 to 90min atconstant temperature, then filtering a crystal mush, vacuum drying a filter cake at 50 to 60 DEG C to constant weight to obtain the dihydrate azithromycin sphaerocrystal. The particle size of the product is uniform, the particle size can reach 0.5 to 4mm, the angle of repose is 17 degrees to 23 degrees, and the fluidity is good. The dihydrate azithromycin sphaerocrystal provided by the invention is simple in process flow, has low requirement on equipment, is large in product particle size, high in purity and good in fluidity, can be directly used for tableting, and is easy to realize industrial production.

Owner:TIANJIN UNIV

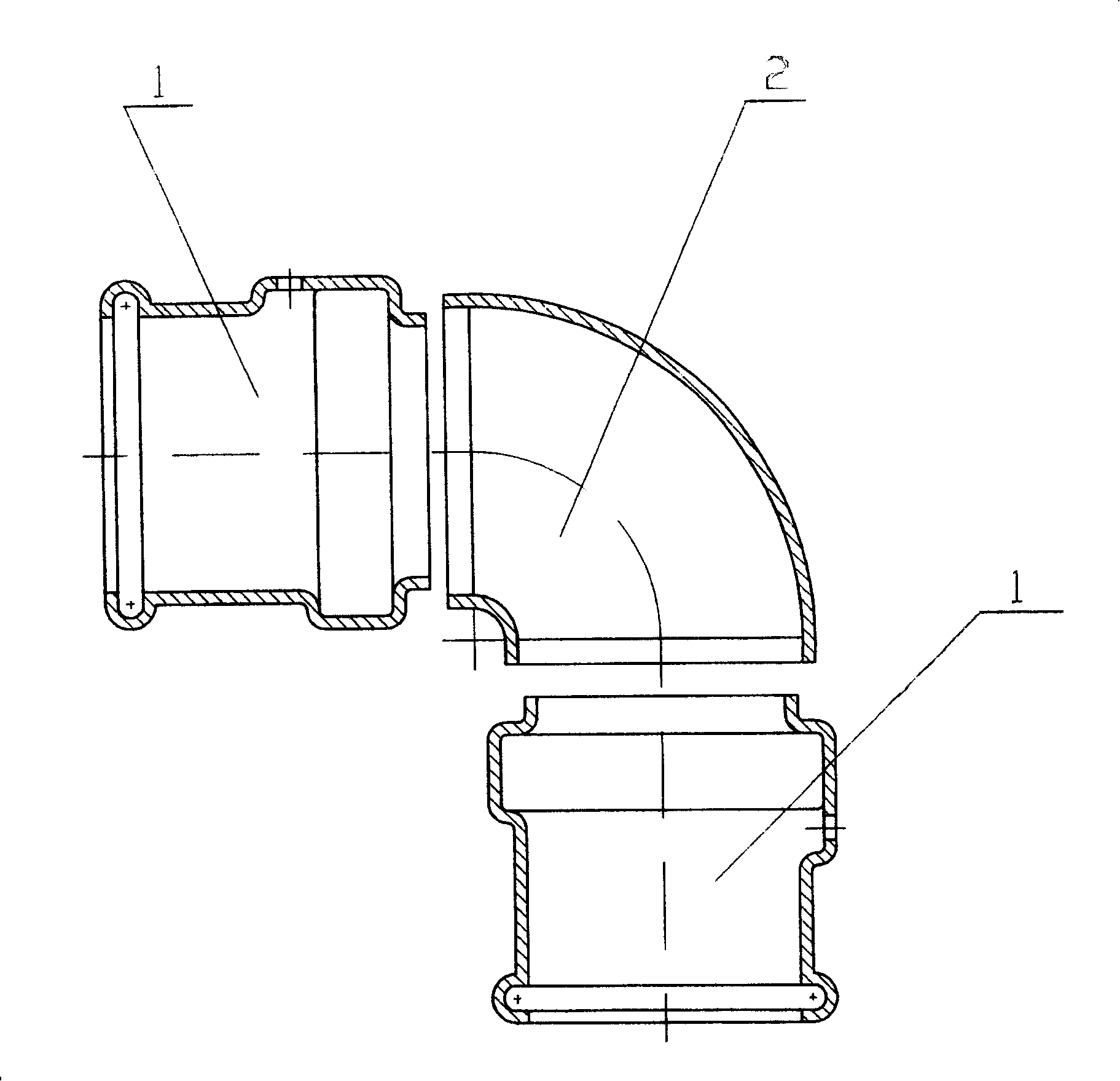

Manufacturing method with curvature thin wall stainless steel pipe fittings

InactiveCN101158430ASmall radius of curvatureSmall sizeNon-disconnectible pipe-jointsSiphonsPipe fittingPrecision casting

The present invention relates to a manufacturing method for a thin-walled stainless steel pipe fitting with a bending part, and is used for the production of the thin-walled stainless steel pipe fittings such as elbows and overhead pieces, etc. The pipe fitting is divided into a socket part (1) of two ends connected with a tube and a central bending part (2). The socket part (1) is produced by adopting the pressure-expansion forming of the thin-walled stainless steel pipe fitting. The bending part (2) is produced by adopting precision casting technique of stainless steel. The socket part (1) and the bending part (2) are combined and welded into a whole by welding, thereby reducing the dimensions of the pipe fittings and having low cost and beautiful appearance.

Owner:阎金波

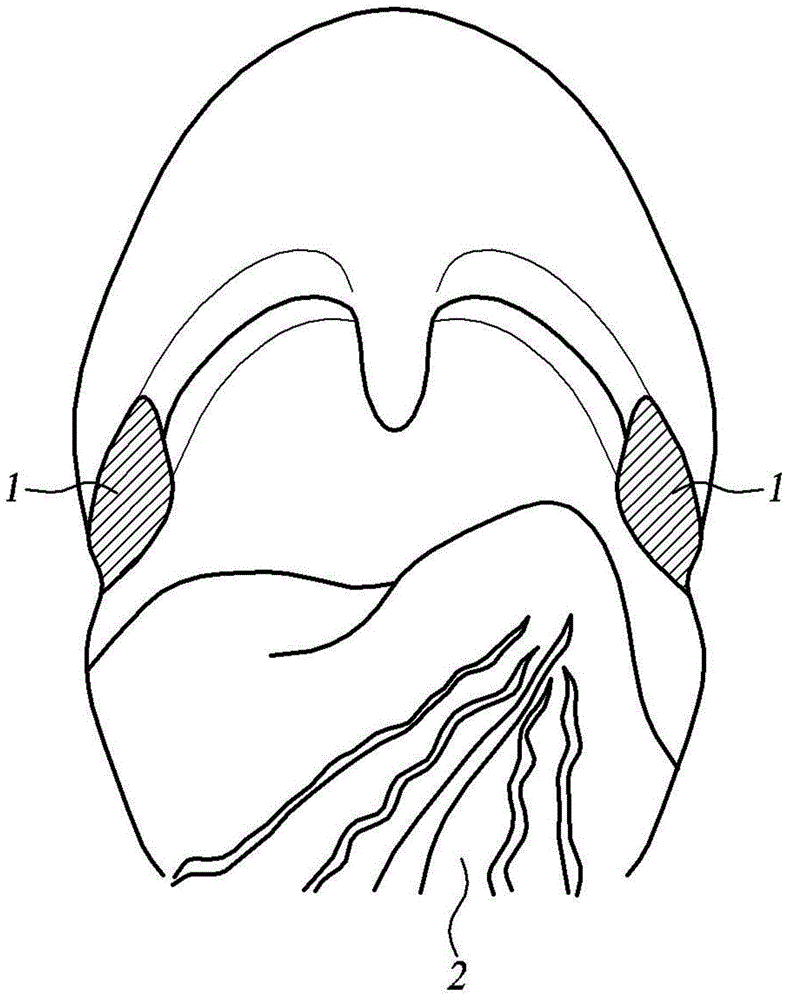

Ultrasonic probe

InactiveCN104968281AReduce the cross-sectional areaEasy to insertUltrasonic/sonic/infrasonic diagnosticsMaterial analysis using sonic/ultrasonic/infrasonic wavesBiomedical engineeringUltrasound probe

One embodiment of the present invention provides an ultrasonic probe for otolaryngology, comprising: a handle part enabled to be grasped by the hand of a user; a lens part inserted into the oral cavity to make contact with the skin therein and having a fixed curvature radius; a head part including the lens part on one side thereof and having rounded edges; and a connection part for connecting the head part and the handle part and forming a first angle with the head part.

Owner:ALPINION MEDICAL SYST +1

Square lithium secondary battery

ActiveUS8927127B2Improve reliabilityReducing capacityFinal product manufactureSmall-sized cells cases/jacketsLithiumBiomedical engineering

A square lithium secondary battery includes a wound body in which a collective sheet in which a positive electrode sheet and a negative electrode sheet overlap each other with a first separator interposed therebetween is wound while a second separator is put inside the collective sheet. An active material mixture layer on one or both surfaces of at least one of the positive electrode sheet and the negative electrode sheet includes a region with a plurality of openings and a region with no opening. At least a bent portion of the collective sheet is covered with the region with the plurality of openings.

Owner:SEMICON ENERGY LAB CO LTD

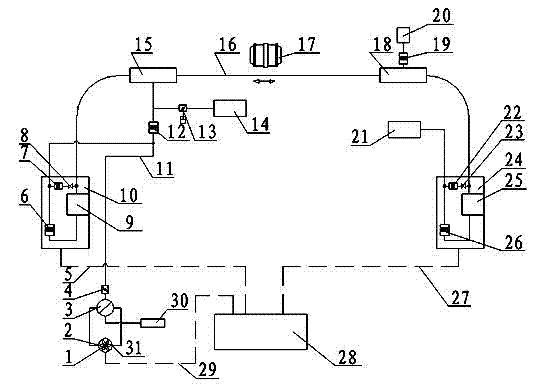

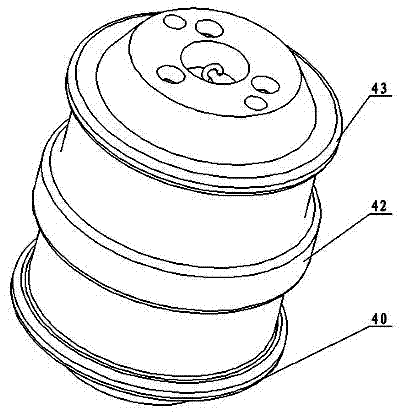

Pneumatic pipeline transmission container and intelligent pipeline transmission system

ActiveCN103964204ASmall radius of curvatureConvenient queryConveyorsSealingTransmission systemEngineering

The invention relates to a pneumatic pipeline transmission container which is characterized by comprising a sample box seat and a sample box cover, wherein the sample box seat and the sample box cover are assembled together to be cooperatively used; each of the sample box seat and the sample box cover comprises an opening end and a closed end, and is of a hollow barrel-shaped structure; a first annular bulge is arranged on the outer edge of the closed end of the sample box seat; a second annular bulge which is encircled by a circle and extends in an axial direction is arranged on the outer edge of the opening end of the sample box cover, and a third annular bulge is arranged on the outer edge in the circumferential direction of the closed end of the sample box cover; a gap between the second annular bulge and the inner wall of a pipeline is 3-4mm, and the gap between each of the first annular bulge and the third annular bulge and the inner wall of the pipeline is 6-7mm. The invention further relates to an intelligent pipeline transmission system which is characterized by comprising a transmission pipeline, a first transmit-receive unit and a second transmit-receive unit, wherein the first transmit-receive unit and the second transmit-receive unit are positioned at the two ends of the transmission pipeline. The pneumatic pipeline transmission container operates in the transmission pipeline.

Owner:济南海鹰机电制造有限公司

Network cable skin strength-bearing material

A network cable skin strength-bearing material relates to skin strength-bearing materials and solves the problems that the skin strength-bearing materials used by the existing air-inflating structure including a stratospheric airship are large in weight and low in bearing capacity, the inner portion of the materials cannot bear high pressure, the shape can not be controlled easily and the like. The network cable skin strength-bearing material comprises a membrane layer, a network cable layer and an adhesive tape layer, wherein the network cable layer is one of six weaving structures weaved by fiber tows. The network cable skin strength-bearing material has the advantages of being light, large in rigidity, strong in bearing strength and capable of bearing larger effective loading, and the equivalent elastic modulus of the material is larger than that of a film with the same thickness. As a soft composite material, the material can meet high configuration requirements of aircrafts and can be conducted with efficient folding without losing mechanical property. The network cable skin strength-bearing material can be used in the field of aerospace and the like and is particularly suitable for outer surfaces of aviation spacecrafts with large dimension.

Owner:HARBIN INST OF TECH

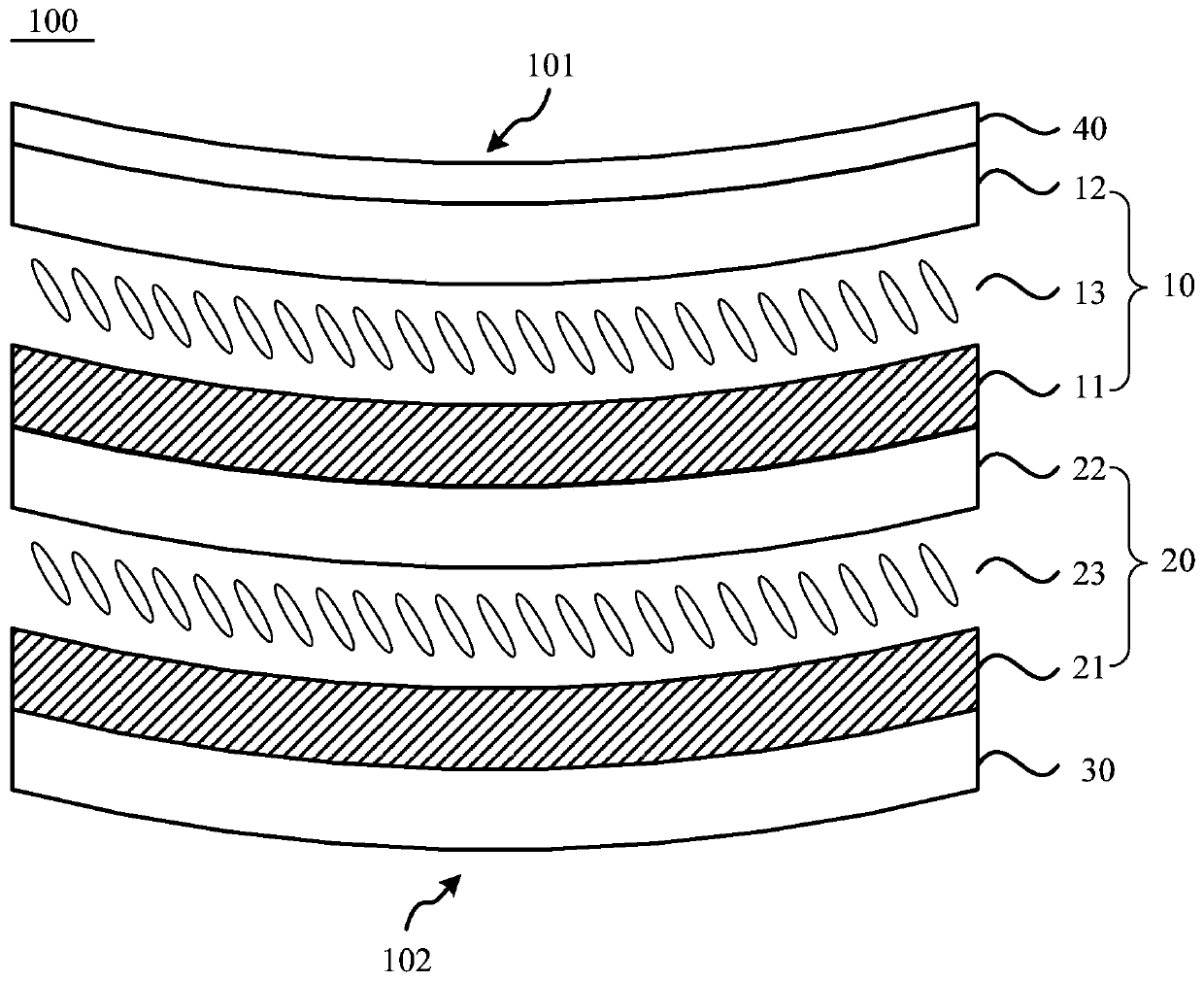

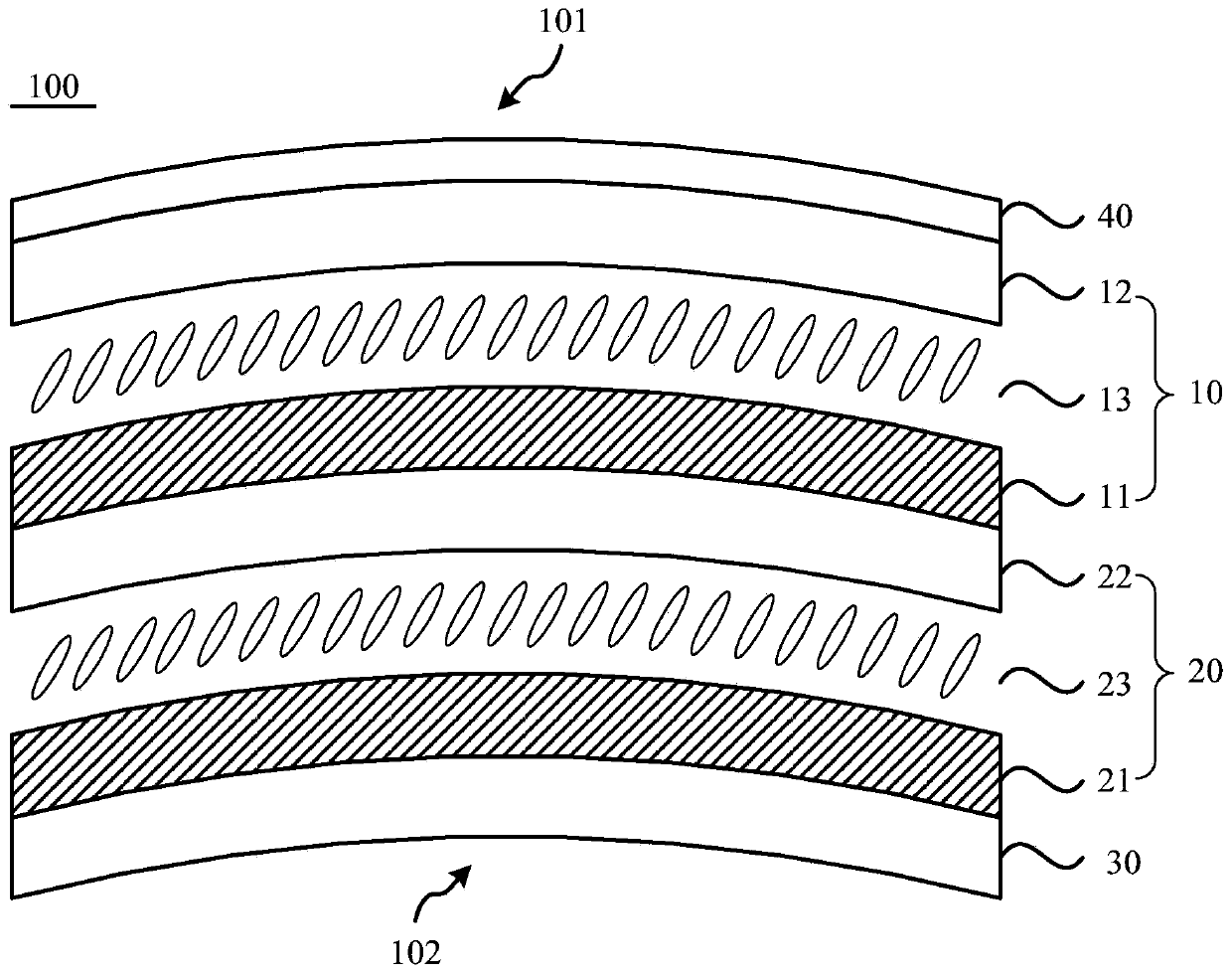

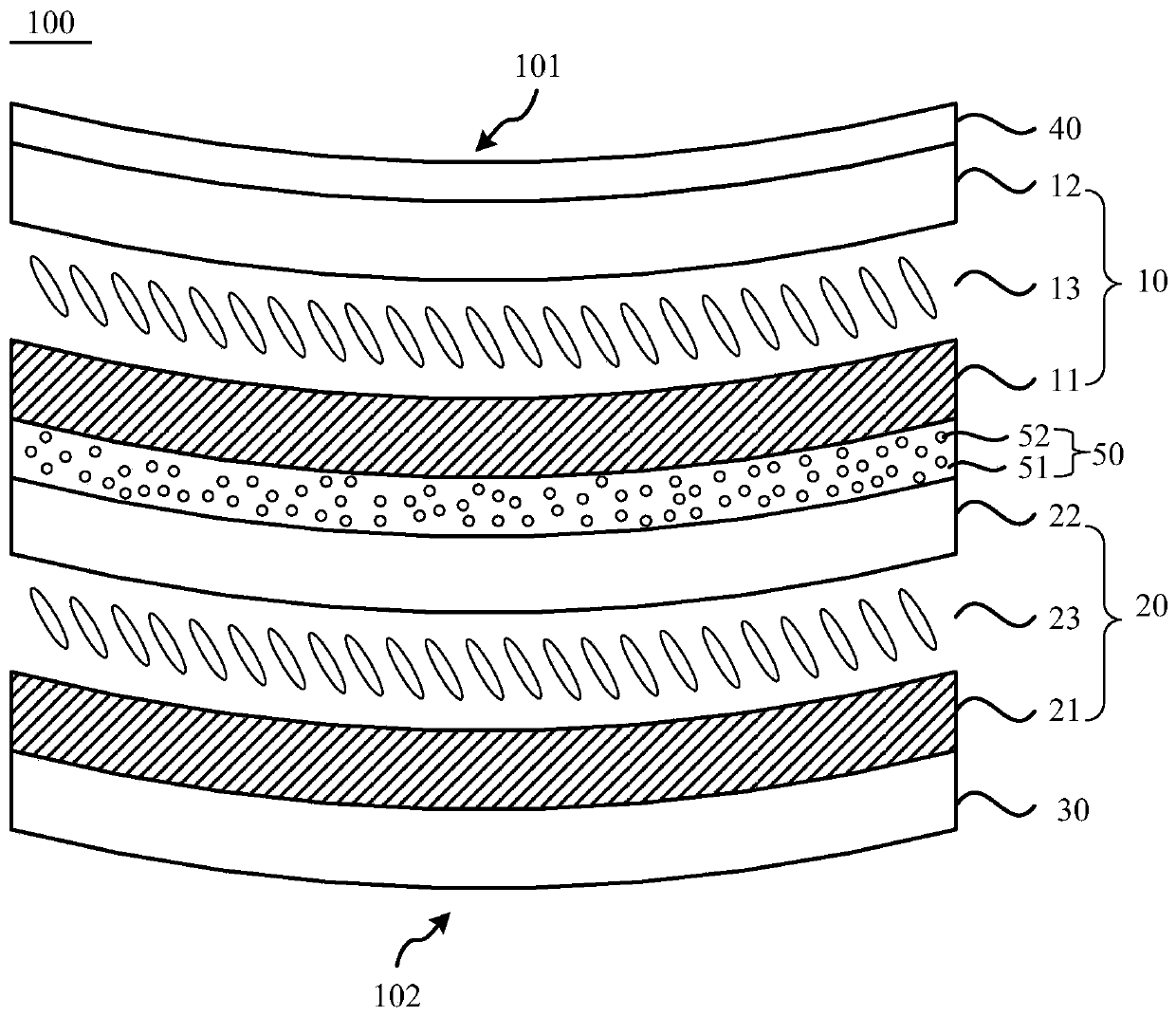

Curved liquid crystal display device and method for making the same

PendingCN110308580ASmall radius of curvatureLarge radius of curvatureNon-linear opticsLiquid-crystal displayEngineering

The embodiment of the invention provides a curved liquid crystal display device and a method for making the same. A first array substrate and a first opposite substrate of a first liquid crystal display panel is set as glass substrates and a second opposite substrate and a second array substrate of a second liquid crystal display panel are set as flexible substrates, so that the structure of the curved liquid crystal display device is simplified, the product yield is improved, and the cost of the curved liquid crystal display device is lowered. Besides, the bent first liquid crystal display panel and the bent second liquid crystal display panel form an accurate alignment relationship, thereby improving the uneven display of the curved liquid crystal display device and improving the displayeffect of the curved liquid crystal display device.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

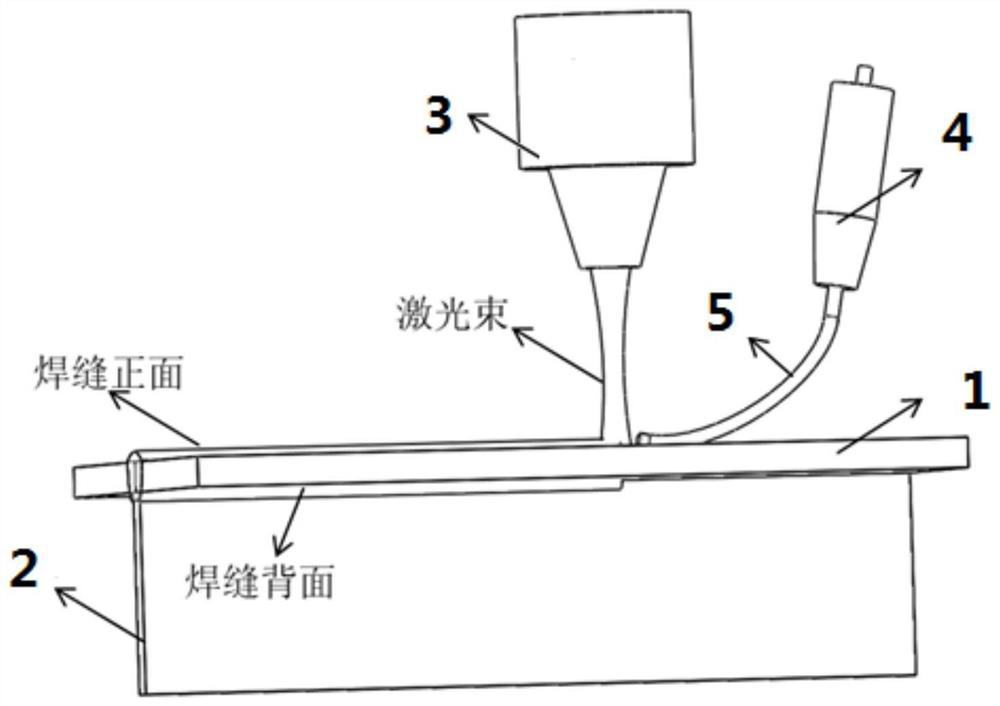

Laser oscillation filler single-side welding double-side forming welding method for thick framework T-shaped structure

ActiveCN111673219AMeet defect-free weldingAchieve weldingSolder feeding devicesSoldering auxillary devicesFillet weldEngineering

The invention relates to the field of material processing engineering, in particular to a laser oscillation filler single-side welding double-side forming welding method for a thick framework T-shapedstructure. The laser oscillation filler single-side welding double-side forming welding method aims to solve the technical problems that by using an existing T-shaped structure welding method, the stability is poor, the efficiency is low, and welding of thick framework curve welds is difficult. The method comprises the steps that firstly, the to-be-welded end face of a framework and a to-be-welded area of skin are processed; secondly, the framework is placed and fixed; thirdly, a laser gun is adjusted, and calibrating is carried out; fourthly, the walking path is adjusted; fifthly, the skin is assembled; and sixthly, the laser oscillation filler welding parameters are set, and welding is carried out. By the adoption of the laser oscillation filler single-side welding double-side forming welding method, laser oscillation filler welding is adopted, the effect of synchronous forming of the back face of the skin and the two sides of the framework is achieved through skin front face welding, and only one-time welding is needed to achieve synchronous forming of fillet welds of the two sides of the framework, achieve the purpose of improving the welding efficiency manyfold and guaranteethe consistency and stability of the forming process. The welding method is used for complex curve weld welding of the thick framework T-shaped structure formed by the skin-framework.

Owner:HARBIN WELDING INST LTD

N type silicon on insulator transverse insulated gate bipolar device

InactiveCN102437181ASmall radius of curvatureReduce electric field strengthSemiconductor devicesElectrical field strengthBody contact

The invention provides an N type silicon on insulator (SOI) transverse insulated gate bipolar device which comprises an N type substrate. A buried oxide is provided on the N type substrate. An N type epitaxial layer is provided on the buried oxide. The N type epitaxial layer is provided with an N type buffer well and a P type body region inside. The N type buffer well is provided with a P type positive area inside. The P type positive area is provided with an N type positive area and a P type body contact area inside. A surface of the N type epitaxial layer is provided with a gate oxide layer and a field oxide layer in a certain scope. An upper surface of the gate oxide layer is provided with a polysilicon gate. A surface of the device is provided with a passivation layer and a metal level in a certain scope. The device is characterized in that: the N type epitaxial layer is provided with a P type well area, the P type well area and the P type body region form steeped P type doping, dosage concentration of the P type well area is lower than dosage concentration of the P type body area, one side of the P type well area is tangent to the field oxide layer, and the other side of the P type well area presses against the P type body area. According to the above structure, electric field intensity and impact ionization rate of a beak position can be substantially reduced, thus an output characteristic is effectively improved.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com