Network cable skin strength-bearing material

A cable net and skin technology, applied in the direction of layered products, etc., can solve the problems of heavy weight of the skin bearing material, difficult shape control, inability to withstand high pressure, etc., to achieve high rigidity and meet the requirements of wing shape stability , the effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

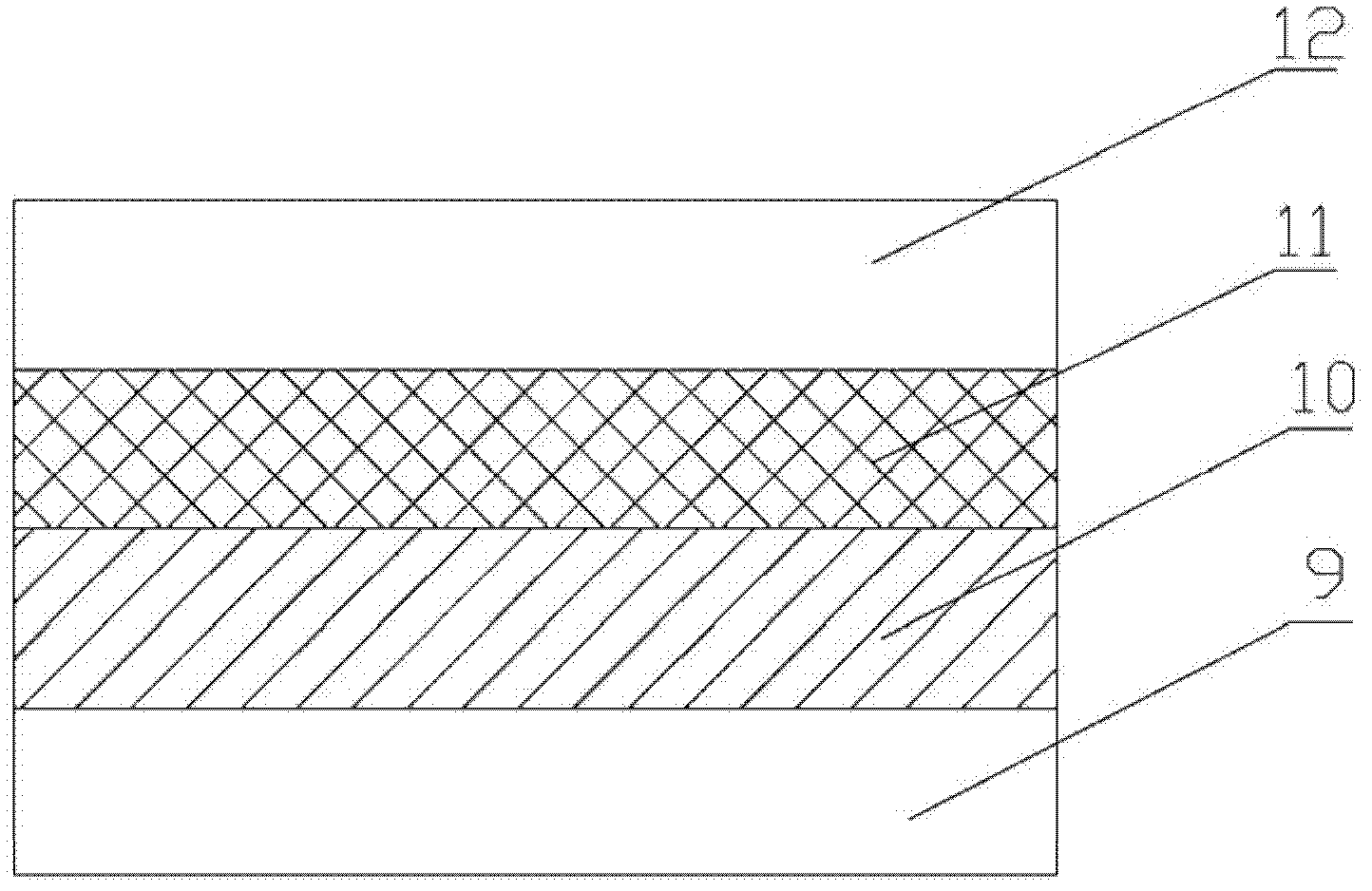

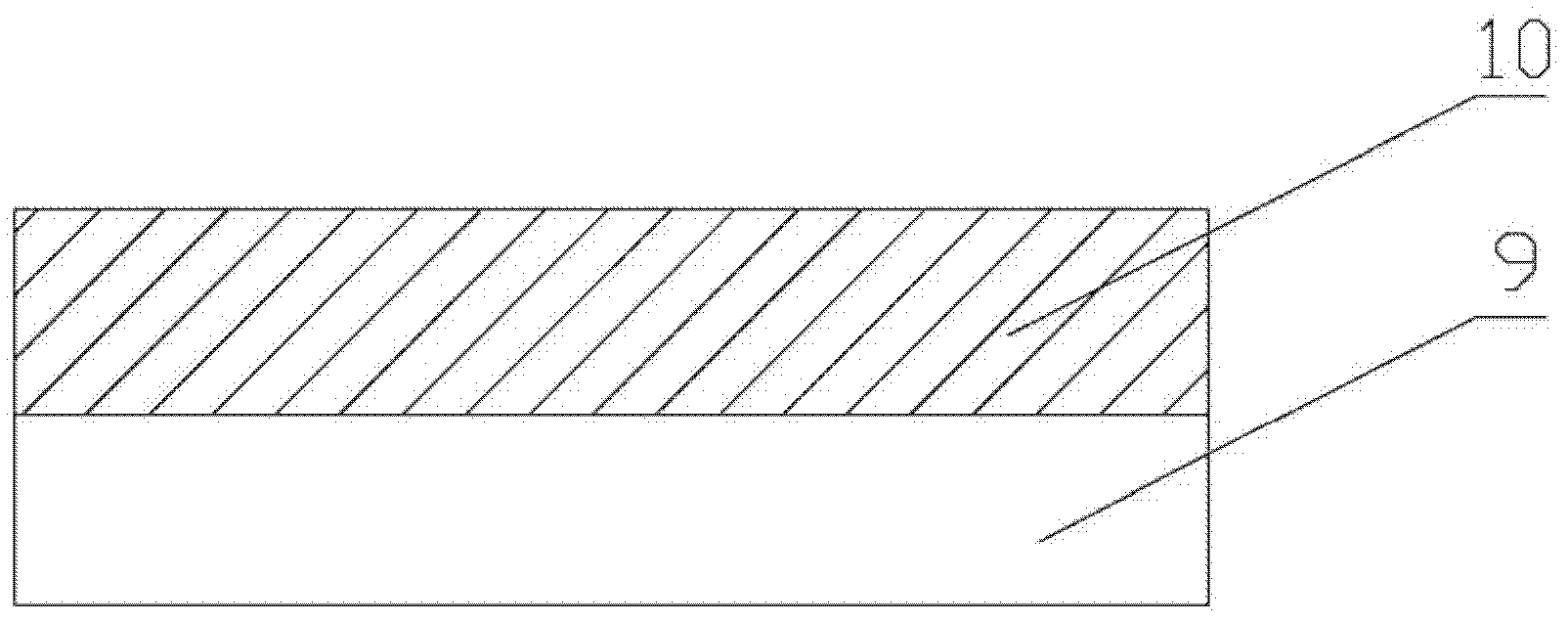

[0028] Specific Embodiment 1: The load-bearing material of the cable-net skin in this embodiment includes a film layer 9, a cable-net layer 10 and a tape layer 11, the cable-net layer 10 is arranged on the film layer 9, and the tape layer 11 is arranged on the cable-net layer 10, a film layer-cable net layer-tape layer structure is formed, the film layer 9 and the cable net layer 10 are bonded by the tape layer 11, and the cable net layer 10 is woven from fiber tow.

[0029] The cable-net skin load-bearing material of this embodiment has the characteristics of light weight, high rigidity and strong bearing capacity, and can carry a larger payload, and its equivalent elastic modulus is larger than that of a film with the same thickness. As a flexible composite material, it can meet the requirements of aircraft with high configuration requirements, and can also be folded efficiently with little loss of mechanical properties. In addition, limited to the internal pressure requirem...

specific Embodiment approach 2

[0030] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the cable net skin load-bearing material also includes a second film layer 12, and the second film layer 12 is arranged on the tape layer 11 to form a film layer- Cable net layer-tape layer-film layer structure, the second film layer 12 and the tape layer 11 are bonded by epoxy resin. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0031] Specific embodiment three: this embodiment is different from specific embodiment one or two in that: the film layer is a polyurethane film (also known as PU film, polyurethane film) or polyester film ( Also known as polyethylene terephthalate film, PET film) or polyimide film. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com