Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63results about How to "No loss of mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano Al2O3 composite corona-resistant polyimide film

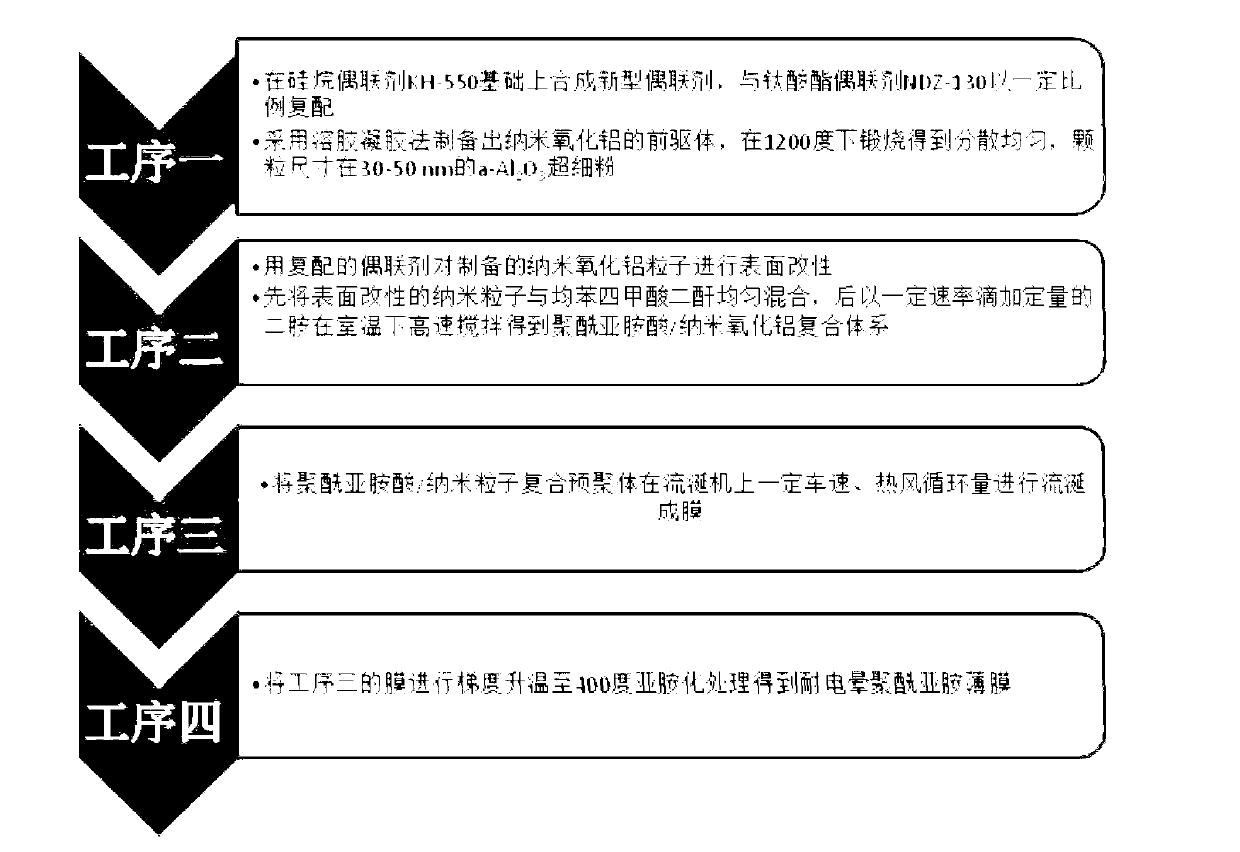

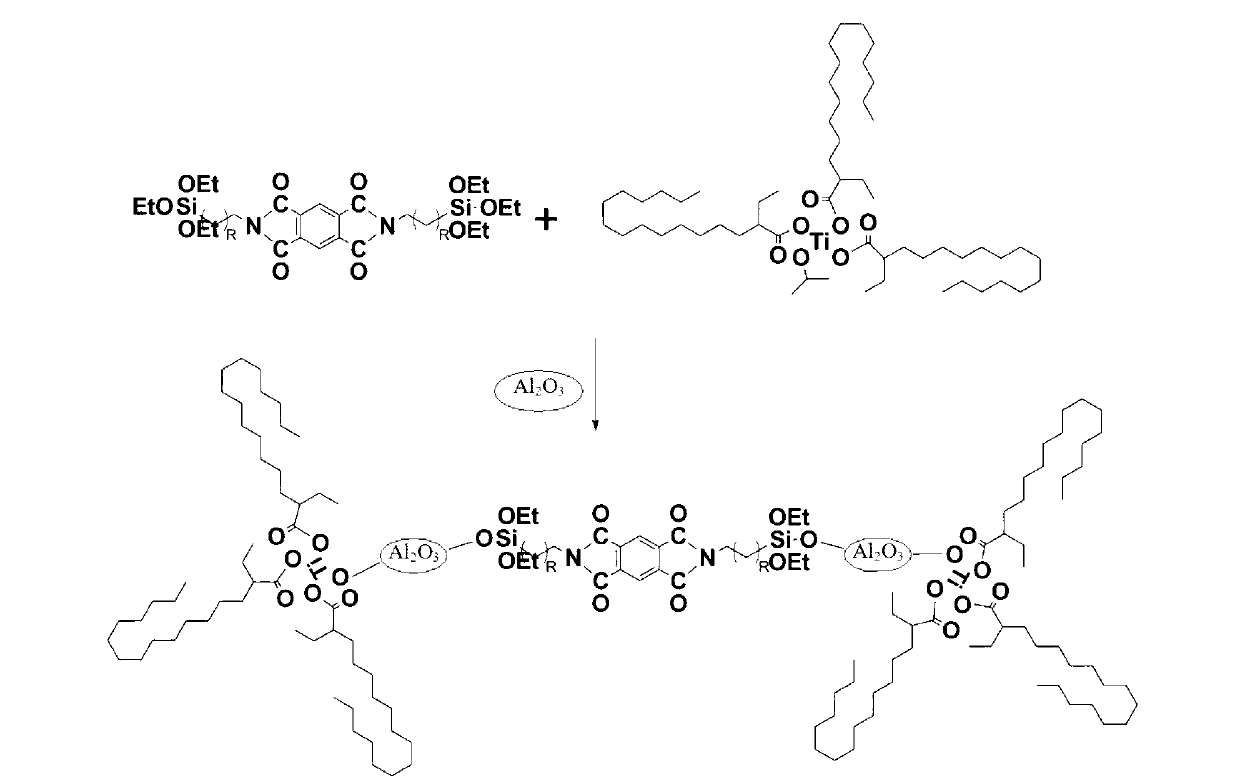

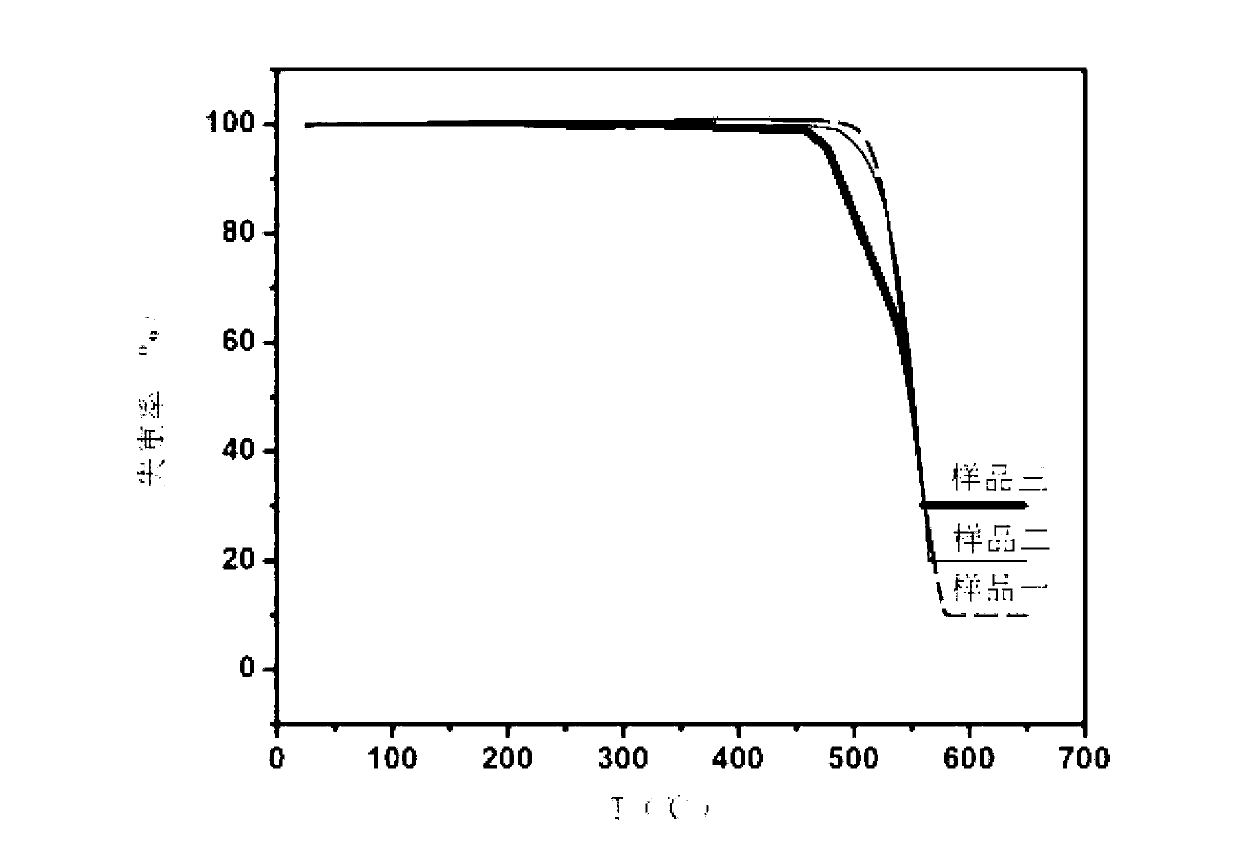

The invention relates to a corona-resistant polyimide film containing high-concentration nano metal oxide, which comprises the following main components: benzenetetracarboxylic anhydride, 4, 4'-diamino diphenyl ether and nano-scale aluminum oxide, wherein the particle size of the nano-scale metal oxide is in the range from 30nm to 50nm. The film provided by the invention has the following outstanding advantages that a novel coupling agent is synthesized and is compounded with titanate coupling agent NDZ-130 to conduct surface modification on prepared alpha-Al2O3, thus the modified nano-particles can be steadily and uniformly dispersed in the substrate polyimide film with relatively high mass percentage (can reach 30wt%). By adoption of the above novel technical scheme of the invention, the technical problem that high-concentration nano-metal oxide is very difficultly doped uniformly in the corona resistant polyimide film according to the prior art is solved well, and meanwhile the mechanical strength of the film is kept from dropping.

Owner:UNIV OF SCI & TECH BEIJING

Pulp distance varying mechanism of wind power generator

InactiveCN101392726AQuick responseAvoid adaptationWind motor controlMachines/enginesPower componentWind force

The invention discloses a variable-pitch mechanism for an aerogenerator, which comprises a wheel hub, a power component, a plurality of variable-pitch bearings, wherein the wheel hub consists of a curved surface formed by the axes around the wheel hub, a front cover and a back cover which are vertical to the axes of the wheel hub; the outer circle of the variable-pitch bearing is fixedly connected with the curve surface of the wheel hub, and the variable-pitch bearing is evenly distributed on the curve surface of the wheel hub. The device also comprises a screw-driven component, a synchronous mounting rack, a connecting piece and a rotating component, wherein the screw-driven component is rotationally matched with central holes of the front cover and the back cover, and the screw-driven component is connected with the power component; the screw-driven component is fixedly connected with the synchronous mounting rack; the synchronous mounting rack is rotationally connected with each connecting piece, each connecting piece is evenly distributed on the circumference taking the center of the synchronous mounting rack as circle center, and circumference plane is vertical to the axes of the wheel hub; and the connecting piece is also rotationally connected with the rotating component, and the rotating component is fixedly connected with the inner circle of the variable-pitch bearing.

Owner:宁波欣达(集团)有限公司

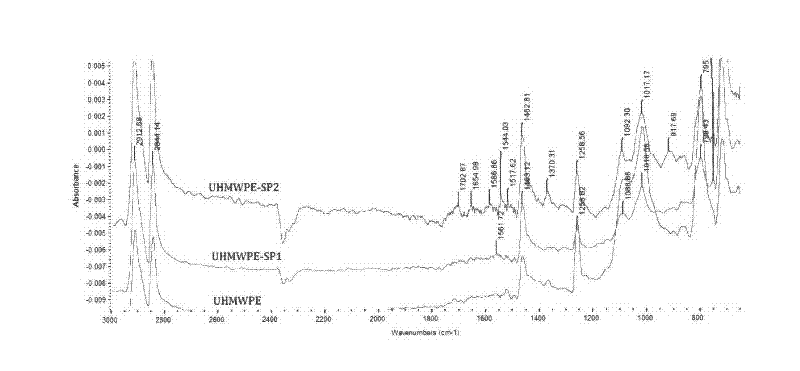

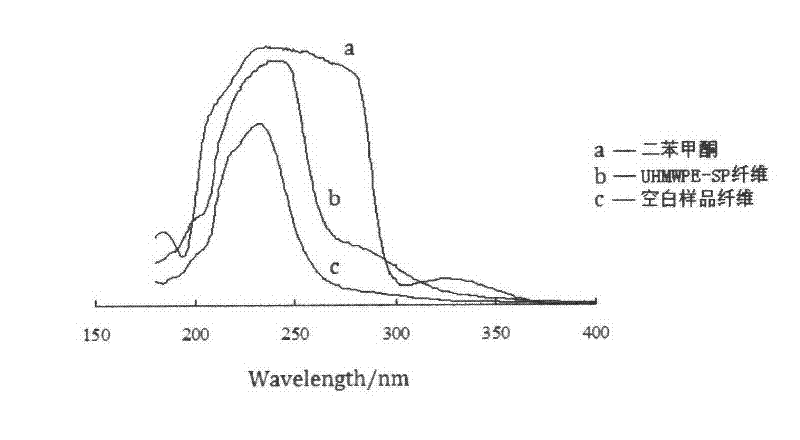

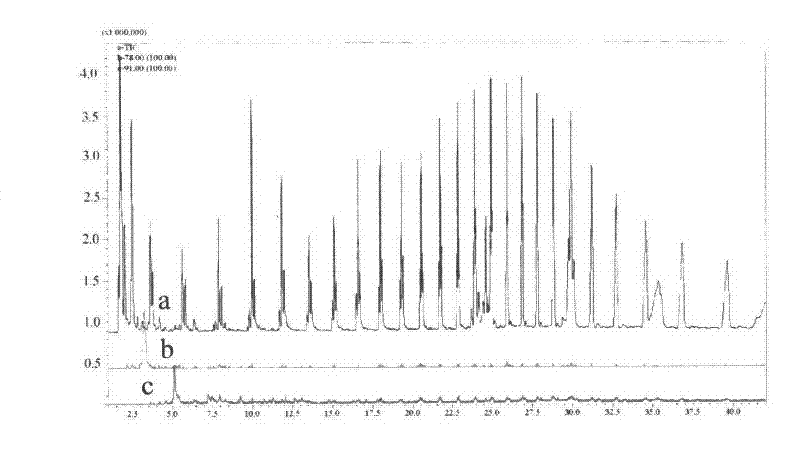

Method for polymerizing and grafting polyethylene surface light-initiated controllable free radical with ultrahigh molecular weight

The invention discloses a method for polymerizing and grafting a polyethylene surface light-initiated controllable free radical with ultrahigh molecular weight. The method comprises the following steps of: putting a pretreated polyethylene substrate with ultrahigh molecular weight into a photosencitizer solution; radiating with ultraviolet rays to form a surface photosensitive group; soaking in a riveted monomer solution for reacting; initiating the grafting reaction of the light-initiated riveting monomer through ultraviolet radiation; treating the grafted polyethylene substrate with ultrahigh molecular weight by using a light-initiated transfer terminator; and forming an active tail end which can be used for initiating through ultraviolet rays on treated substrate, wherein the active tail end has high initiation performance, is controllable, and can be used for further initiating controllable free radical polymerizing and grafting of other active monomers, so that the bonding performance and hydrophilicity of the polyethylene substrate with ultrahigh molecular weight are greatly improved.

Owner:SHANGHAI RES INST OF CHEM IND +2

Rubber composition of low-temperature resistant environmentally-friendly chlorinated polyethylene and preparation method thereof

The present invention relates to a rubber composition of low-temperature resistant environmentally-friendly chlorinated polyethylene. The rubber composition comprises the following raw materials in parts by weight: 100 parts of chlorinated polyethylene; 5-40 parts of carbon black; 10-130 parts of a plasticizer creat E2; 30-60 parts of an inorganic filler; 5-20 parts of light magnesium oxide; 2-10 parts of calcium stearate; 1-3 parts of paraffin wax; 3-5 parts of polyethylene wax; 1-3 parts of an antioxidant RD; 10-40 parts of a plasticizer; 1-4 parts of a vulcanizing agent EataVulc PT75; and 1-4 parts of a promoter EataAccel 903. Compared with a traditional CPE formula, all the raw materials in the present invention are environmentally friendly, and satisfy ROHS and REACH requirements; and a novel thiadiazole vulcanizing agent PT-75 and a promoter 903 are used, so that the vulcanization rate is significantly improved, and vulcanization can be performed on CPE at a lower temperature.

Owner:NANJING ORIENTLEADER TECH CO LTD

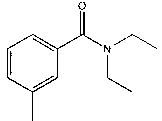

One-bath dyeing and anti-mosquito finishing method of aramid fiber disperse dye

InactiveCN103184697AGood mosquito repellentBright colorFibre typesDry-cleaning apparatus for textilesDisperse dyeAramid

The invention discloses a one-bath dyeing and anti-mosquito finishing method of aramid fiber disperse dye, belonging to the technical field of the dyeing and after finishing of polyamide fiber or textile. According to the invention, diethyltoluamide is used as a disperse dye aramid fiber dyeing carrier to promote the dyeing of the disperse dye aramid fiber textile and realize certain anti-mosquito function of the aramid fiber textile. The process flow comprises the steps of aramid fiber pretreatment, one-bath dyeing, anti-mosquito finishing and reduction clearing. Through the dyeing and the anti-mosquito finishing aramid fiber provided by the invention, the aramid fiber can obtain relatively high dye uptake and good dyeing effect as well as certain anti-mosquito ability. The method disclosed by the invention has wide applicability, simple technology, low treatment cost and high industrial application value.

Owner:SICHUAN UNIV

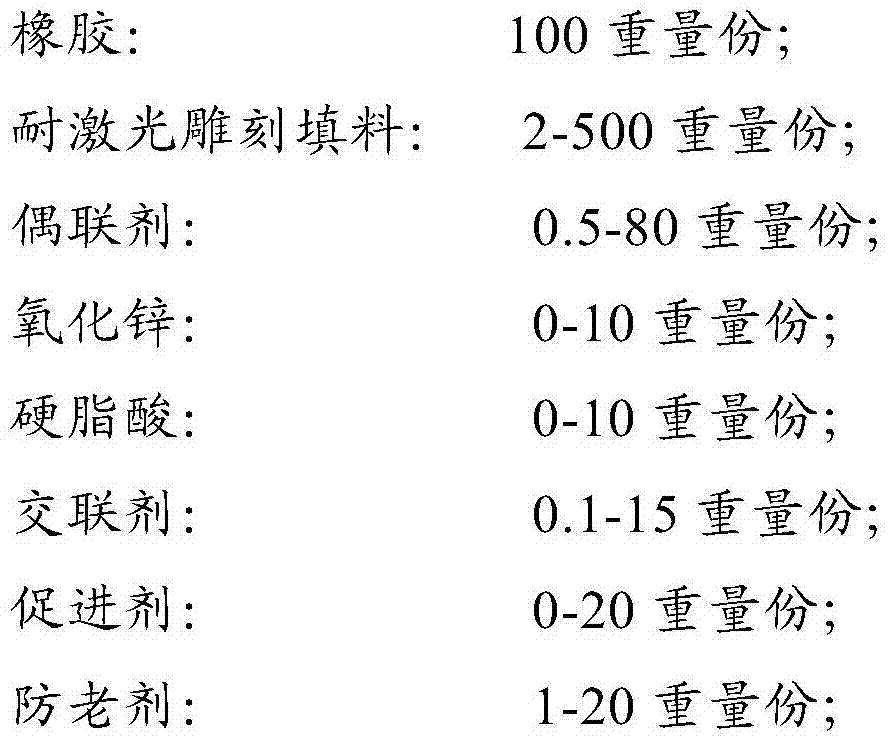

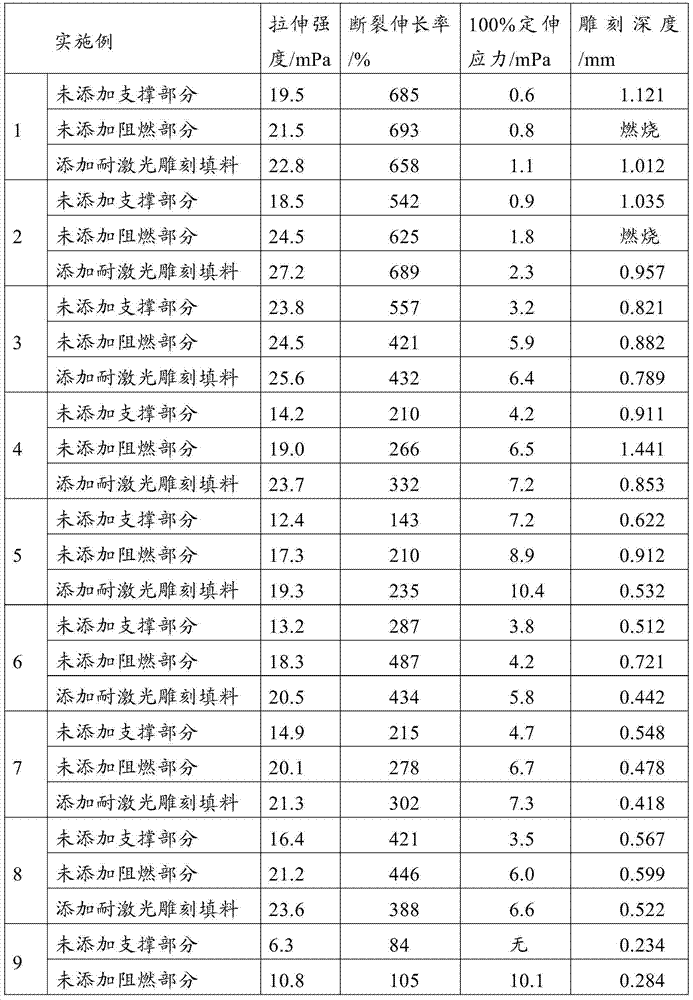

Rubber composite material for laser engraving

ActiveCN104211996AResistant to laser engravingNo loss of mechanical propertiesCompound aLaser engraving

The invention relates to a rubber composite material for laser engraving, and aims to provide a rubber composite material for laser engraving having excellent routine physical and mechanical performances and excellent laser engraving resistance. The rubber composite material with excellent laser engraving resistance is prepared by compounding a dual-component laser engraving resistant filler with a polymer material (rubber). The dual-component laser engraving resistant filler comprises a flame retardation component and a supporting component, so the rubber composite material has excellent routine physical and mechanical performances and has excellent laser engraving resistance.

Owner:中国印刷科学技术研究所

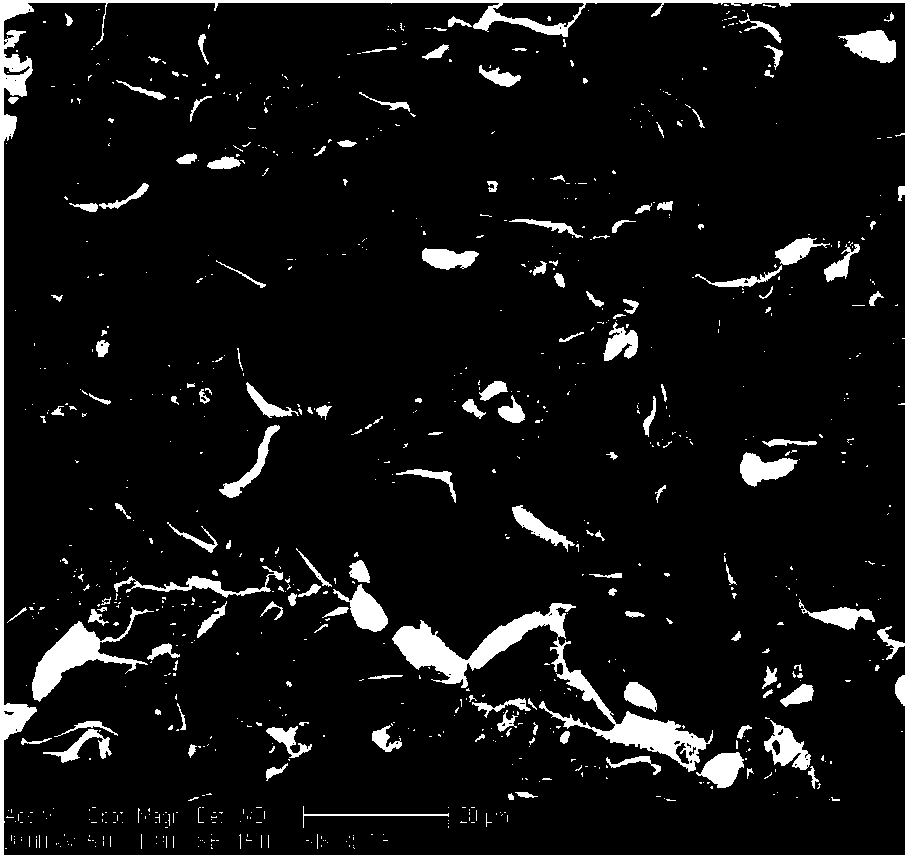

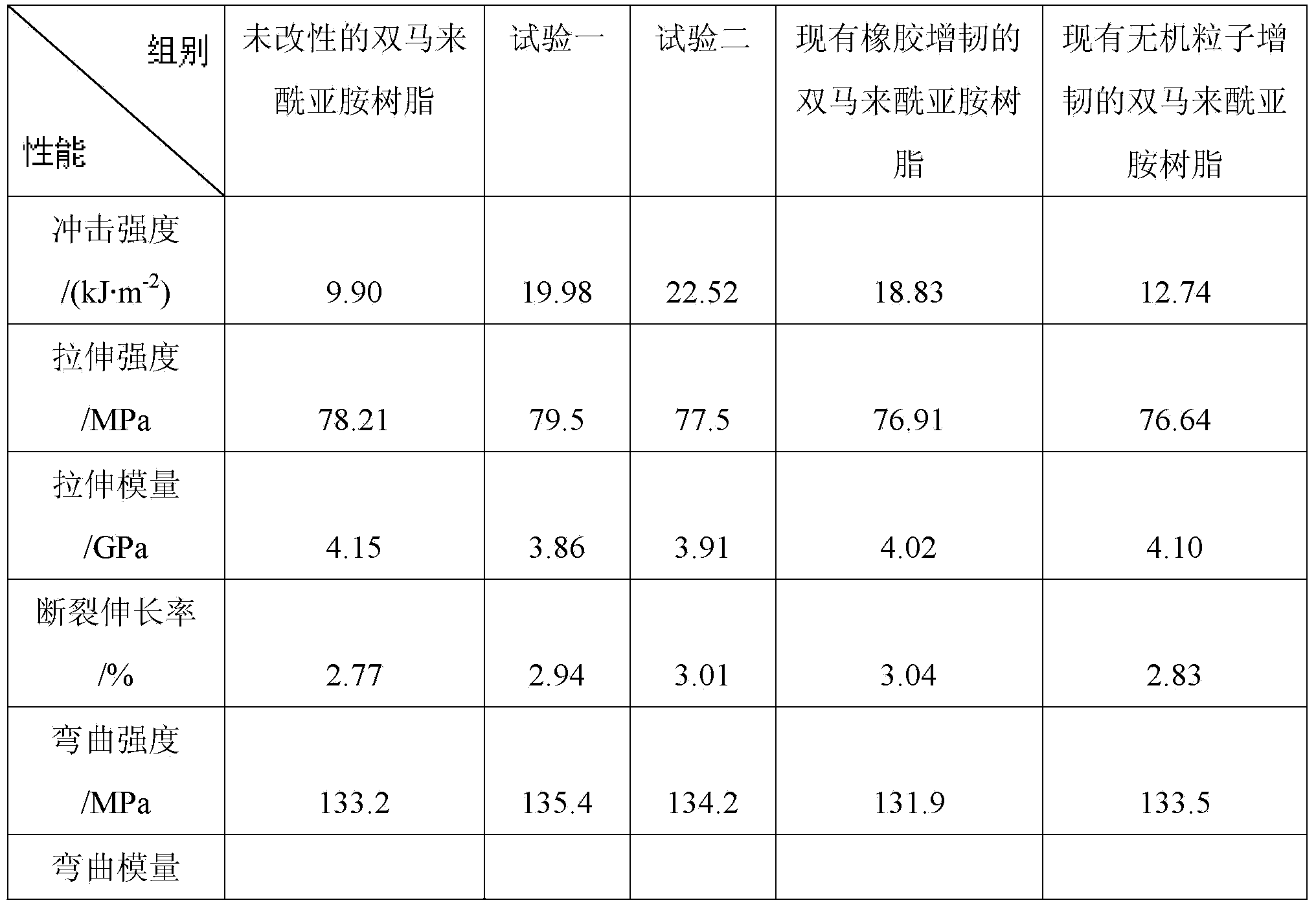

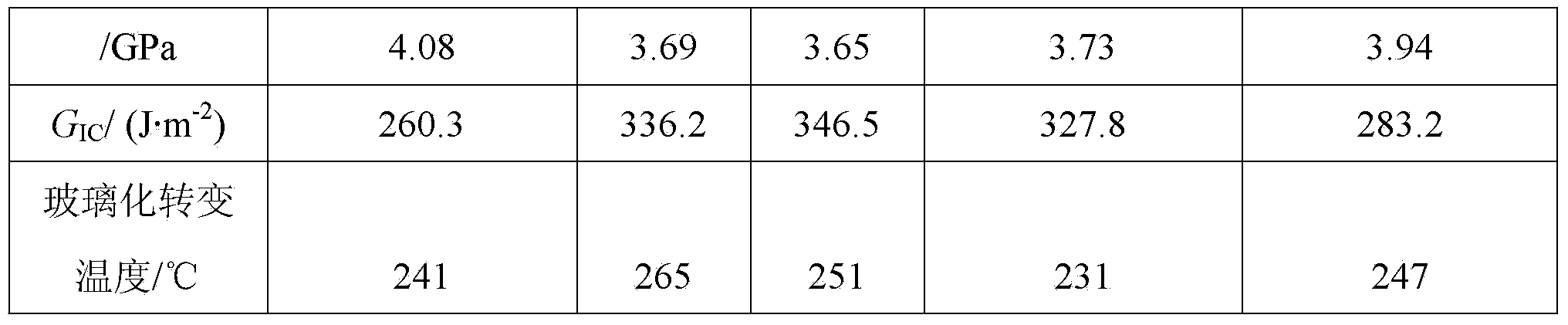

Toughening modification method for bismaleimide resin

InactiveCN103467987ANo loss of mechanical propertiesImprove toughnessAdhesivesPolymer scienceAdhesive

The invention provides a toughening modification method for bismaleimide resin, and relates to the bismaleimide resin field, in particular to a method for toughening modification of bismaleimide by combining diallyl bisphenol A, vinyl-terminated nitrile butadiene rubber and SiC crystal whiskers. The toughening modification method aims to solve the problem that an existing method for toughening the bismaleimide resin enhances the toughness of the bismaleimide resin at the cost of sacrificing other properties. According to the toughening modification method, the diallyl bisphenol A, the vinyl-terminated nitrile butadiene rubber and the bismaleimide resin are subjected to copolymerization, and then silicon carbide crystal whiskers are added into the system for blending to obtain modified bismaleimide resin. The modified bismaleimide resin prepared through the toughening modification method can be used as matrix resin of a composite material or subject resin of an adhesive.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

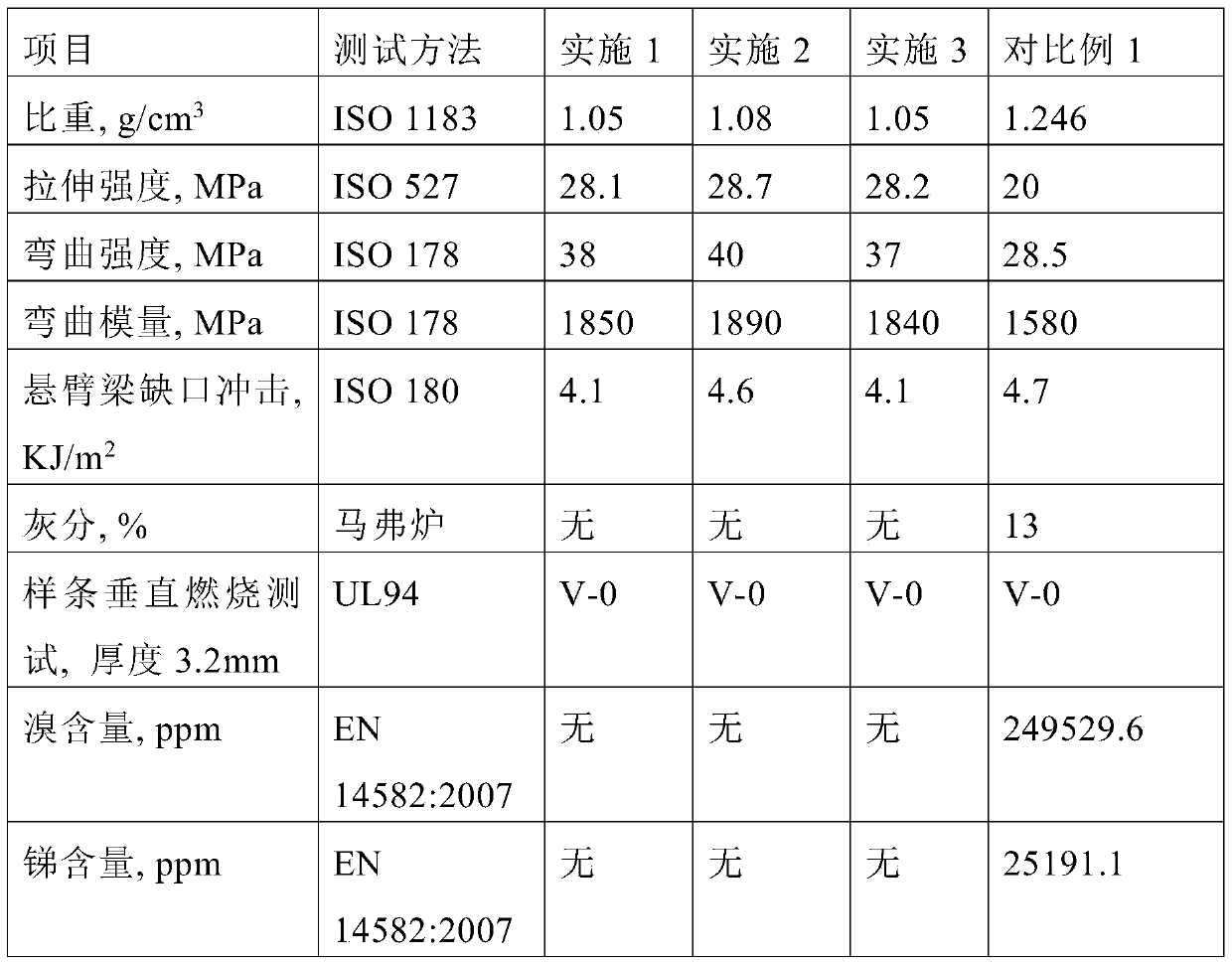

Halogen-free environment-friendly flame-retardant polyolefin master batch for replacing bromine-containing flame retardant and preparation method of master batch

InactiveCN105504519ANo loss of mechanical propertiesReduced impact resistanceHigh humidityPolyolefin

The invention relates to a halogen-free environment-friendly flame-retardant polyolefin master batch for replacing bromine-containing flame retardant and a preparation method of the master batch. The master batch is prepared from, by weight, 90-100 parts of carrier resin, 200-420 parts of halogen-free flame retardant, 1.5-3 parts of a cladding treatment agent, 65-100 parts of a synergistic agent and 0.1-0.5 part of antioxidant. The preparation method comprises the steps of sufficiently treating the halogen-free flame retardant with the cladding treatment agent, then uniformly mixing the halogen-free flame retardant with the carrier resin, the synergistic agent and the antioxidant, then conducting extraction through a double-screw extruder or a mixer, and cutting the product into granules, so that the halogen-free environment-friendly flame-retardant polyolefin master batch is obtained. Compared with the prior art, the product prepared through the preparation method has more excellent flame retardancy, environmental protection performance and processability, is free of corrosion or precipitation and resistant to high temperature and high humidity, has universality and is quite applicable to shells of small household appliances and electronic and electric products, shells of printed circuit boards, shells of motors, shells of electric control centers and the like.

Owner:SHANGHAI JIEMIAN NEW MATERIAL TECH CO LTD

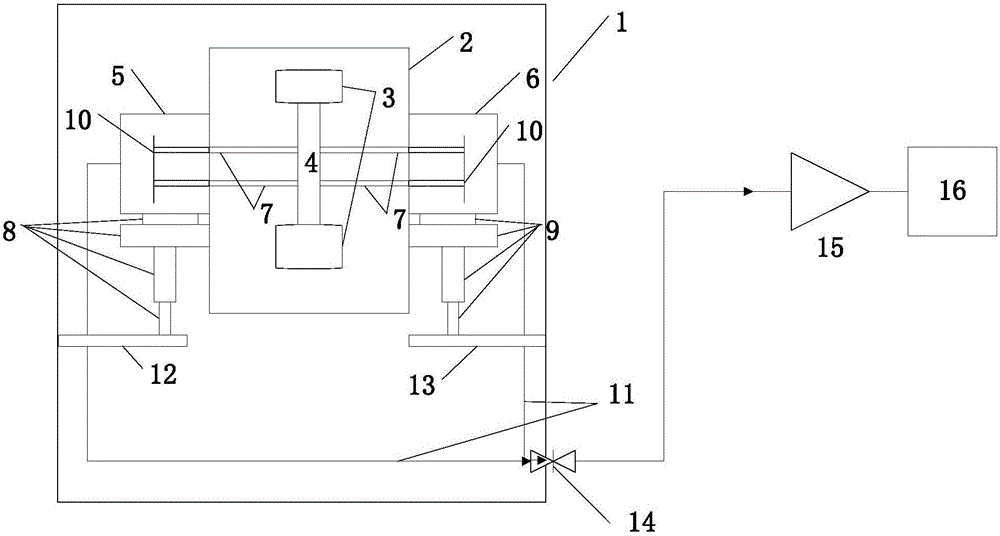

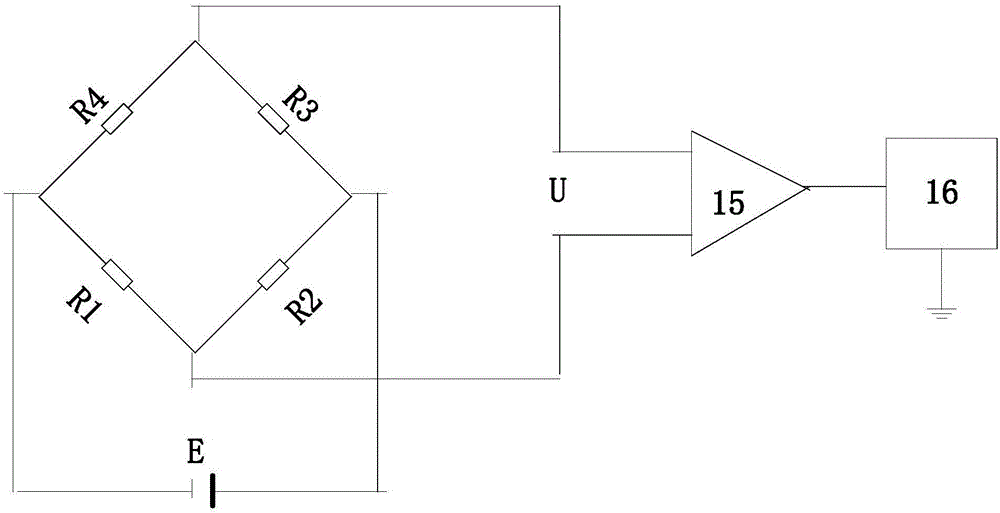

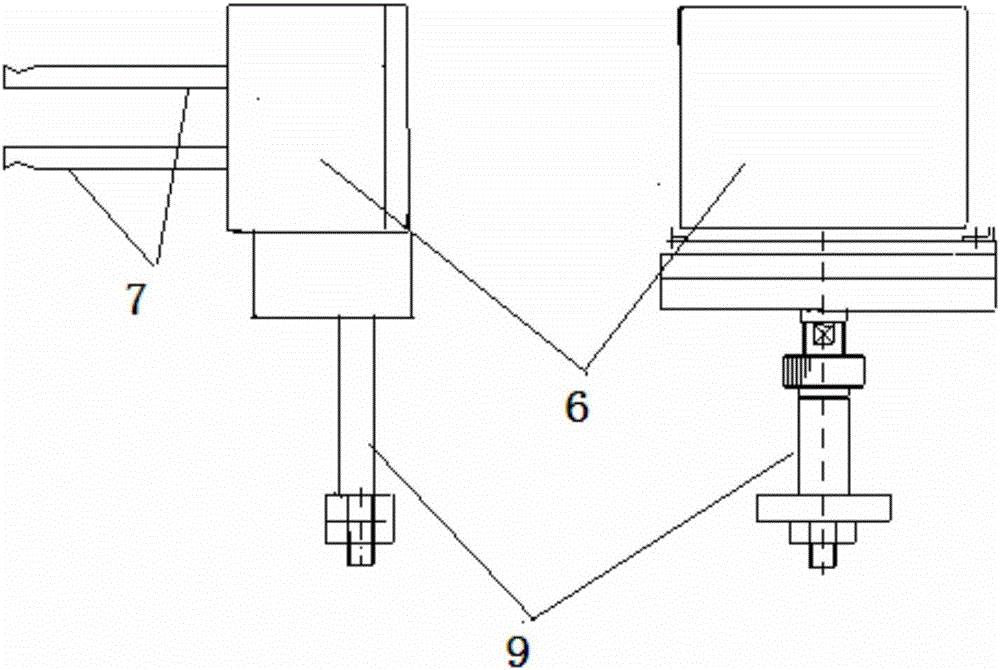

Direct contact type stretching deformation measuring system and method in high-temperature oxygen-free environment

ActiveCN106017298ANo loss of mechanical propertiesAvoid excessive heatMaterial strength using tensile/compressive forcesElectrical/magnetic solid deformation measurementStrain gaugeSignal amplification

The invention provides a direct contact type stretching deformation measuring system in a high-temperature oxygen-free environment, and relates to the field of stretching deformation measurement in the high-temperature oxygen-free environment. The system comprises an environment casing, a radiation furnace, stretching clamps, a stretching sample, a first extensometer water cooling box, a second extensometer water cooling box, extensometer transmission rods, a first support adjusting device, a second support adjusting devices, elastic components and foil gauges, a signal line, a first fixed plate, a second fixed plate, an aviation plug, a signal amplification converter and a display. A direct contact type measuring method can be used to transmit deformation of the sample to the elastic components accurately, and the sensitivity is higher; and the test temperature can reach 2000 DEG C, the elastic components and foil gauges are kept below 50 DEG C always, and an extensometer can be calibrated in normal temperature and used in the high temperature environment.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Outdoor fluorescent wood-plastic floorboard and preparation method thereof

The invention discloses an outdoor fluorescent wood-plastic floorboard. The preparation method comprises the following steps: adding a luminous pigment into the wood-plastic floorboard raw materials, wherein the luminous pigment is an organic modified fluorescent material; mixing, treating by a melt plasticizing facility, and carrying out molding formation to obtain the integrally-luminous fluorescent wood-plastic floorboard; or mixing the organic modified fluorescent material used as the luminous pigment with a wood-plastic floorboard coextrusion material, adding the mixture into a side extrusion hopper of a coextruder, coextruding with the raw materials of the main extruder wood-plastic floorboard, and carrying out mold extrusion formation to obtain a surface coextruded wood-plastic floorboard, thereby obtaining the surface-luminous fluorescent wood-plastic floorboard. The invention also discloses a preparation method of the outdoor fluorescent wood-plastic floorboard. The method disclosed by the invention can be used for preparing the fluorescent wood-plastic product with uniform color, favorable durability and favorable luminescence, and the fluorescent wood-plastic product has the effects of dim light indication and decoration.

Owner:SHANDONG XIAGUANG INDAL

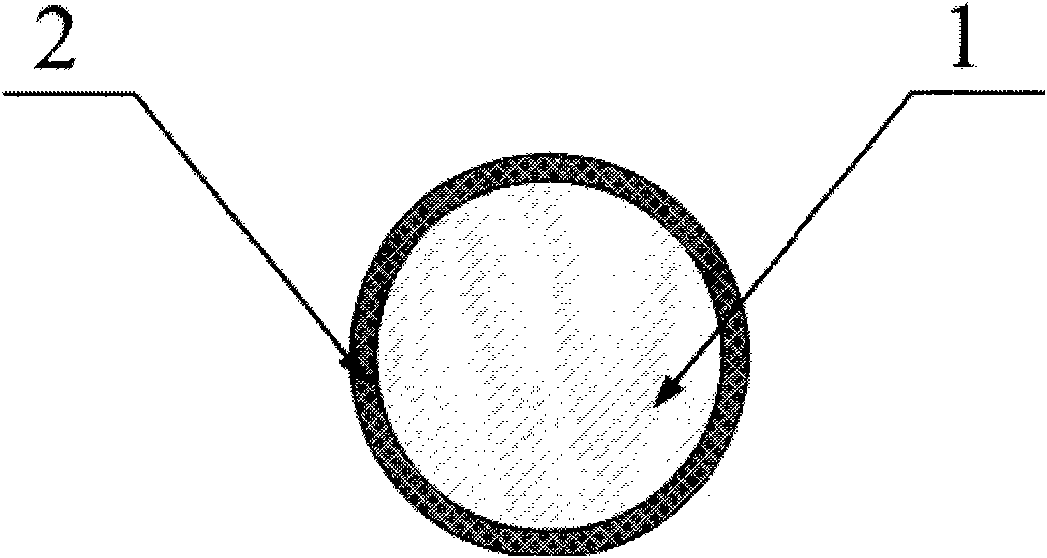

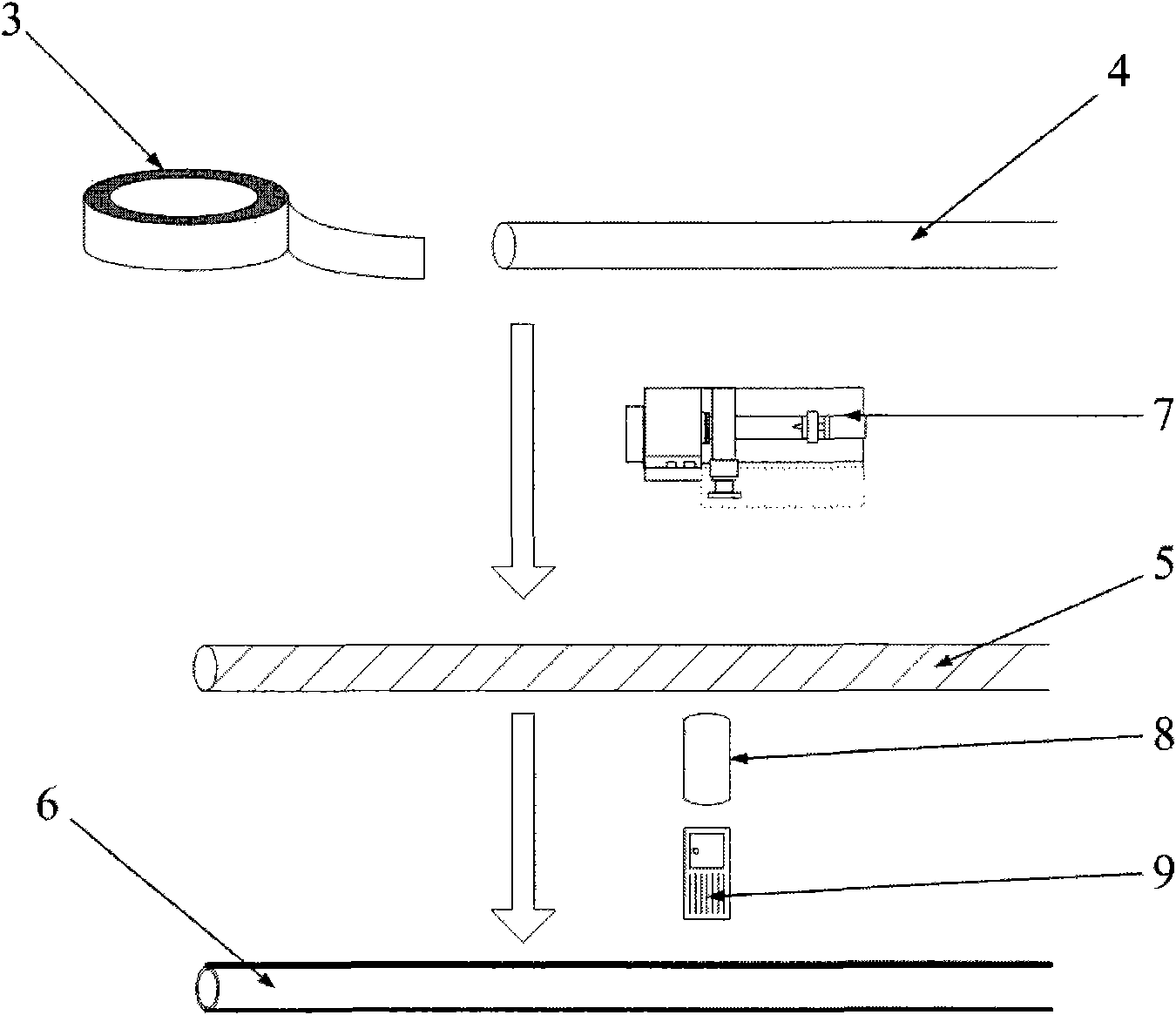

Poly (ether ether ketone) film lapping-high temperature sintering insulating conductor and manufacturing process thereof

InactiveCN101667470AMeet the requirements of "green manufacturing"Control speedPlastic/resin/waxes insulatorsInsulated cablesPoly ether ether ketoneElectrical conductor

The invention belongs to the field of insulating conductors, in particular to a poly (ether ether ketone) film lapping-high temperature sintering insulating conductor and a manufacturing process thereof, which aim to solve the problem that the prior insulating conductor has reduced insulativity after working for a long time under a nuclear environment. The conductor consists of an inner conductor(1) and an insulating layer (2) closely attached to the inner conductor (1), wherein the diameter of the inner conductor (1) is between 0.8 and 40mm; and the thickness range of the insulating layer (2) of the insulating conductor is between 0.05 and 0.8mm. The invention also provides a process for manufacturing the conductor, which comprises five steps of aligning the inner conductor, processing the surface of the inner conductor, coating a film, fusing the film and cooling. The insulating conductor and the process have the advantages of high temperature resistance, radiation resistance, hightemperature hydrolyzation resistance, good consistency of the insulating layer material, no toxic substance generation in a sintering process, simple process, and suitability for all kinds of manufacturing, and for insulating layer manufacturing of full wire diameter conductors.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

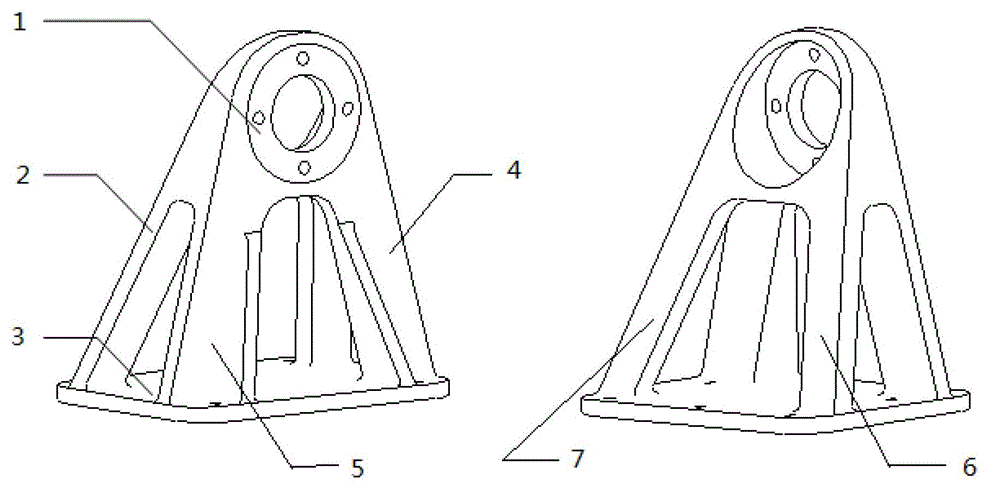

Novel flywheel support structure for spacecraft

ActiveCN102720801ASimple structureImprove mechanical propertiesVibration suppression adjustmentsMomentumFlywheel

The invention discloses a novel flywheel support structure for a spacecraft. The novel flywheel support structure for the spacecraft comprises a first mounting part, a main bearing structure, and a second mounting part. The flywheel support is designed according to the design concept of structural optimization, and allows for light weight of a flywheel while having better performances than the original design performances. The flywheel support provides moving parts, such as reaction flywheels, momentum wheels and torque compensation wheels, with stable mounting base, guarantees safety and reliability of crafts in satellite launching phase and orbiting respectively, can also satisfy heat transfer requirement and mechanical conditions for controlling subsystem flywheels (or reaction momentum wheels and torque compensation wheels) in operation, has the advantages of light weight, simple structure and low manufacturing cost and is highly universal.

Owner:SHANGHAI SATELLITE ENG INST

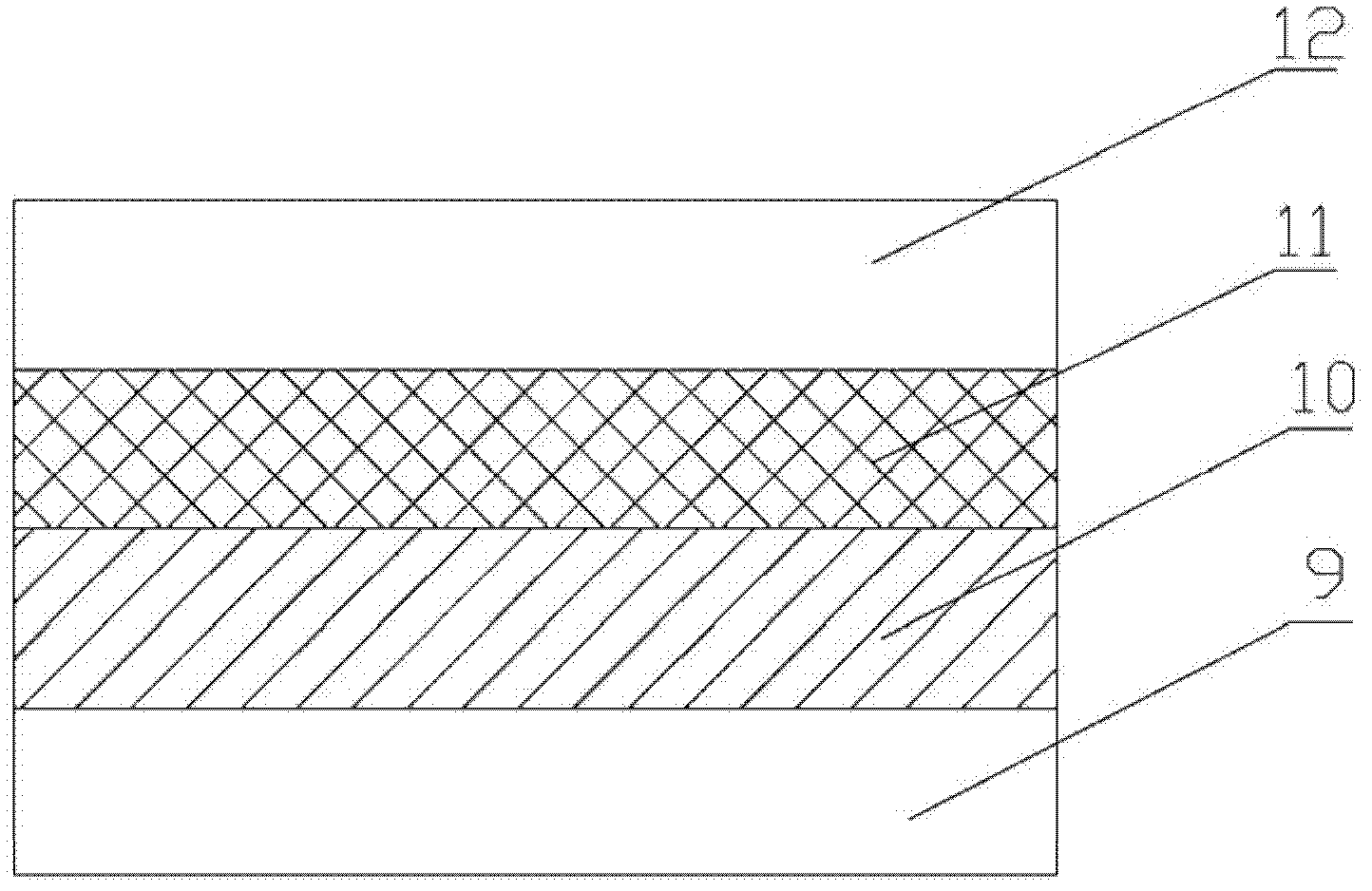

Network cable skin strength-bearing material

A network cable skin strength-bearing material relates to skin strength-bearing materials and solves the problems that the skin strength-bearing materials used by the existing air-inflating structure including a stratospheric airship are large in weight and low in bearing capacity, the inner portion of the materials cannot bear high pressure, the shape can not be controlled easily and the like. The network cable skin strength-bearing material comprises a membrane layer, a network cable layer and an adhesive tape layer, wherein the network cable layer is one of six weaving structures weaved by fiber tows. The network cable skin strength-bearing material has the advantages of being light, large in rigidity, strong in bearing strength and capable of bearing larger effective loading, and the equivalent elastic modulus of the material is larger than that of a film with the same thickness. As a soft composite material, the material can meet high configuration requirements of aircrafts and can be conducted with efficient folding without losing mechanical property. The network cable skin strength-bearing material can be used in the field of aerospace and the like and is particularly suitable for outer surfaces of aviation spacecrafts with large dimension.

Owner:HARBIN INST OF TECH

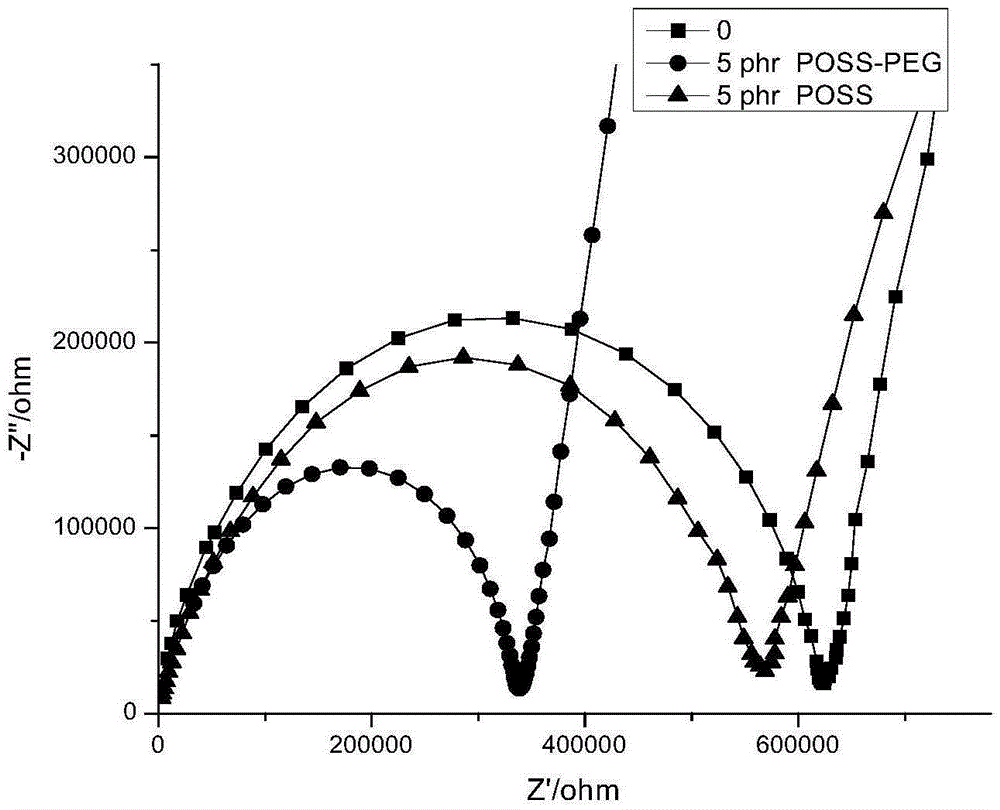

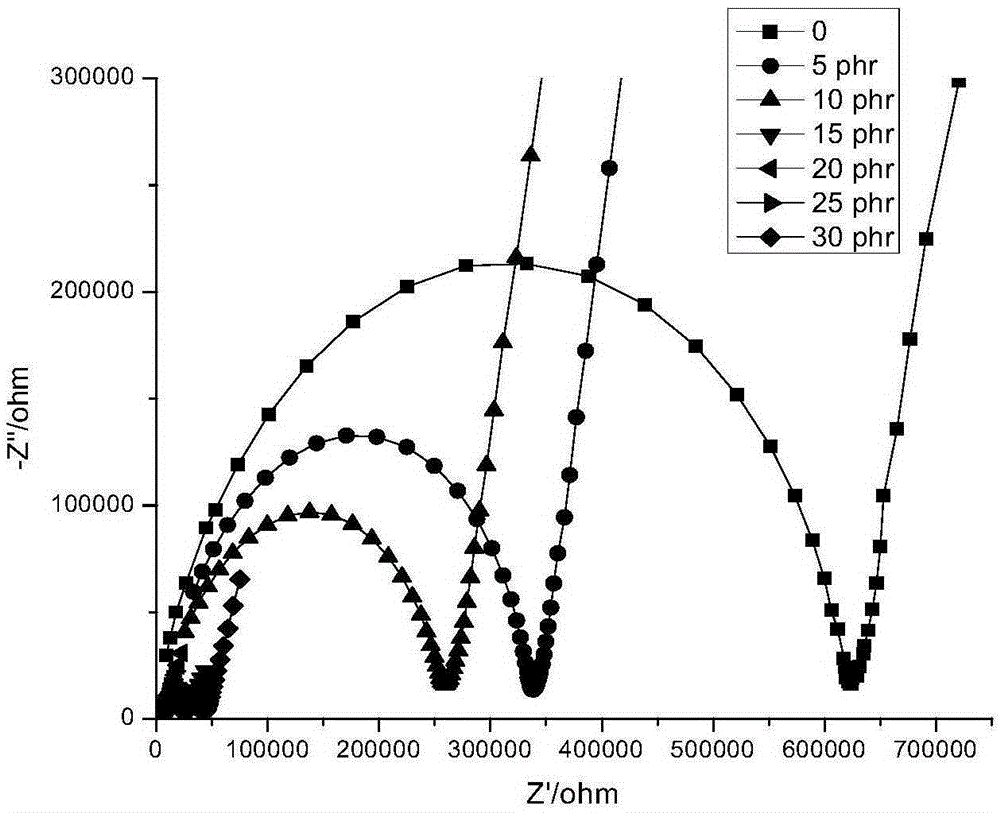

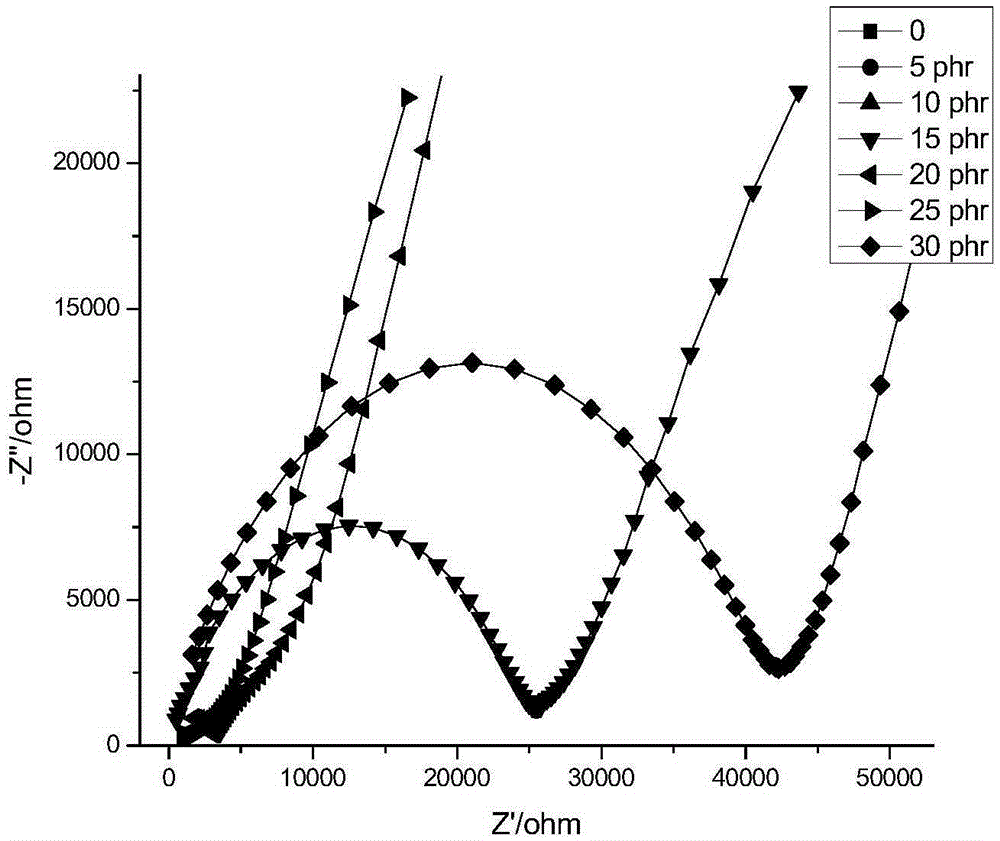

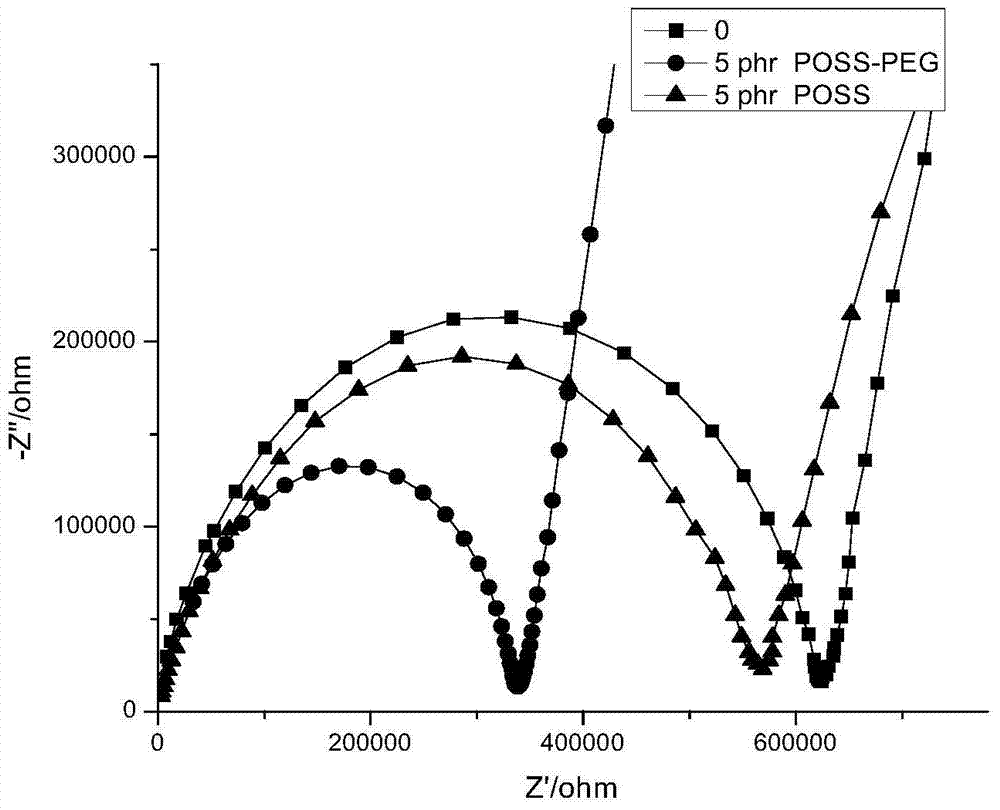

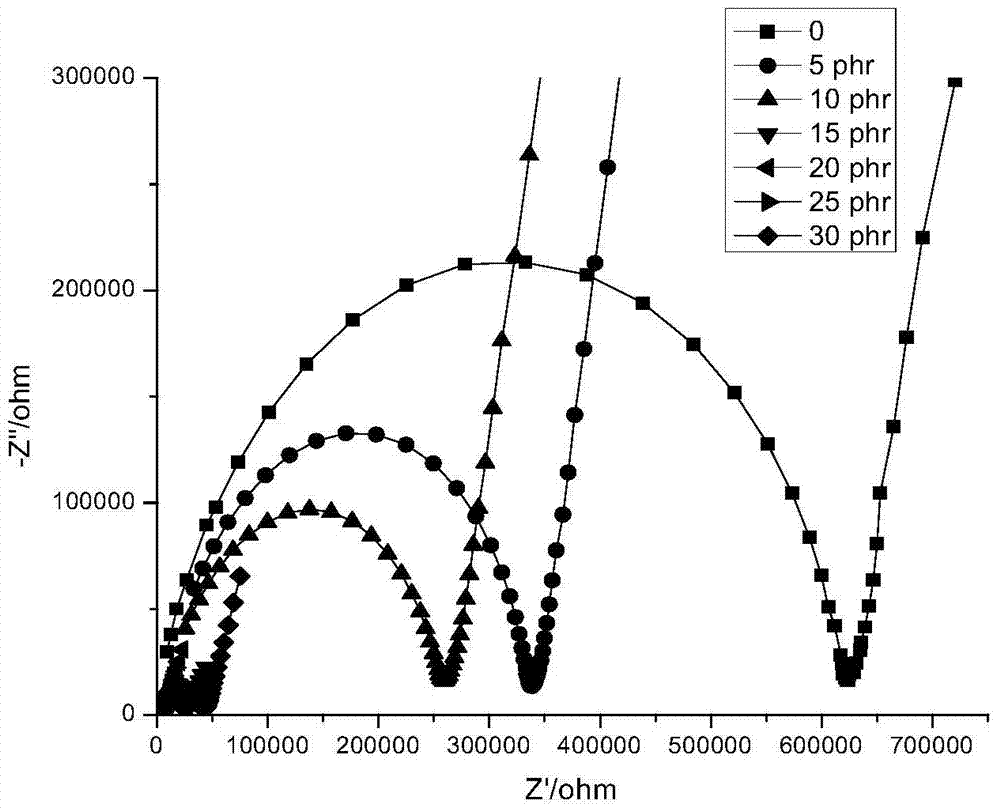

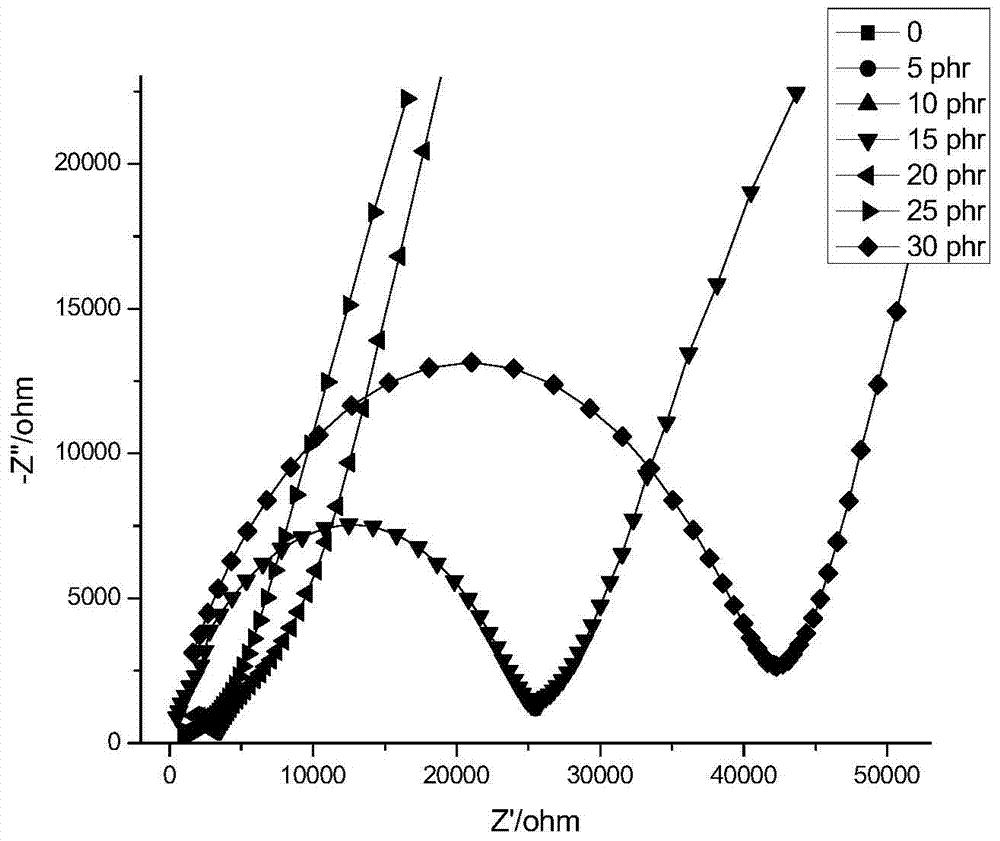

Composite all-solid-state polymer electrolyte material and preparation method thereof

InactiveCN105280952AImprove ionic conductivityReduce crystallinityFinal product manufactureElectrolyte accumulators manufacturePolymer substrateElectrical resistivity and conductivity

The invention relates to a composite all-solid-state polymer electrolyte material and a preparation method thereof. The raw materials comprise the following constituents based on mass: 10-30 parts of carboxyl nitrile rubber, 70-90 parts of epoxidized natural rubber, 30-50 parts of lithium perchlorate salt and 5-30 parts of epoxidized low-polymer cage type silsesquioxane-carboxyl-terminated polyethylene glycol grafted copolymer. According to the preparation method, the composite all-solid-state polymer electrolyte is obtained by dissolving the above raw materials in a tetrahydrofuran solvent, carrying out a solution casting method and evaporating the solvent. Compared with the prior art, the composite, the adopted polymer substrate and a filler are matched, so that the composite all-solid-state polymer electrolyte material has the advantages of relatively high room-temperature conductivity; when 25 parts of filler is added, the conductivity at a room temperature reaches maximum and is 2.571*10<-5> S.cm<-1>; and moreover, the material is easy to prepare, is low in cost, is environment friendly, and has potential application value in industrial manufacturing of a lithium battery.

Owner:SHANGHAI JIAO TONG UNIV

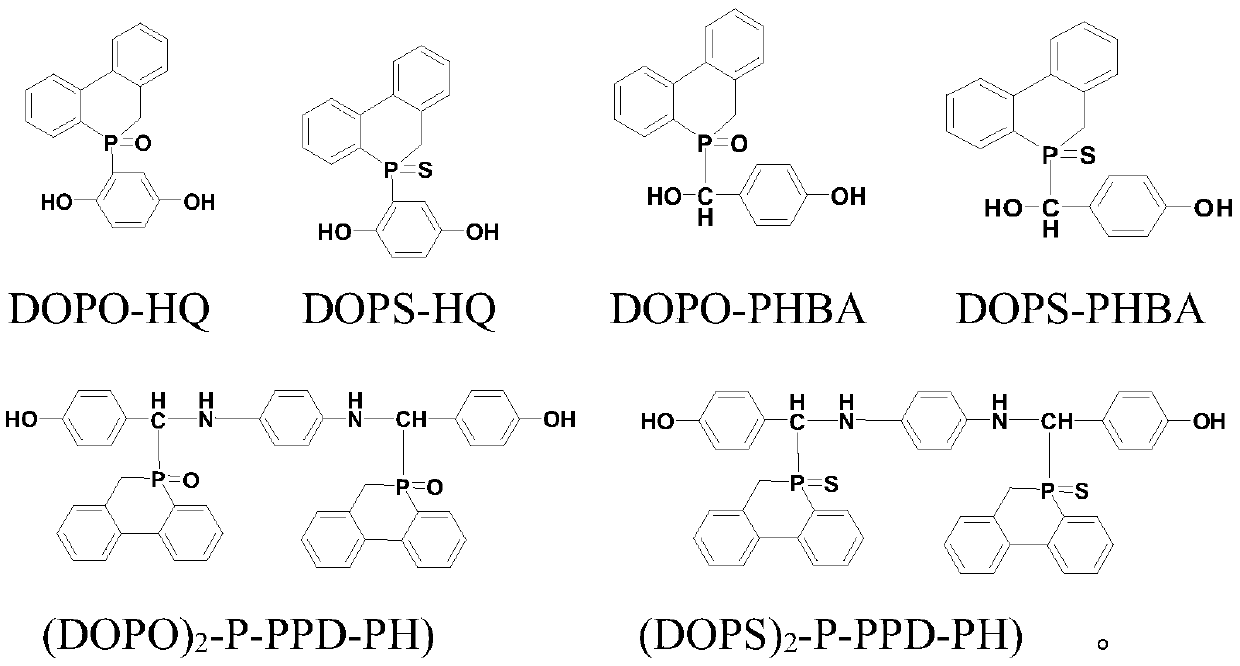

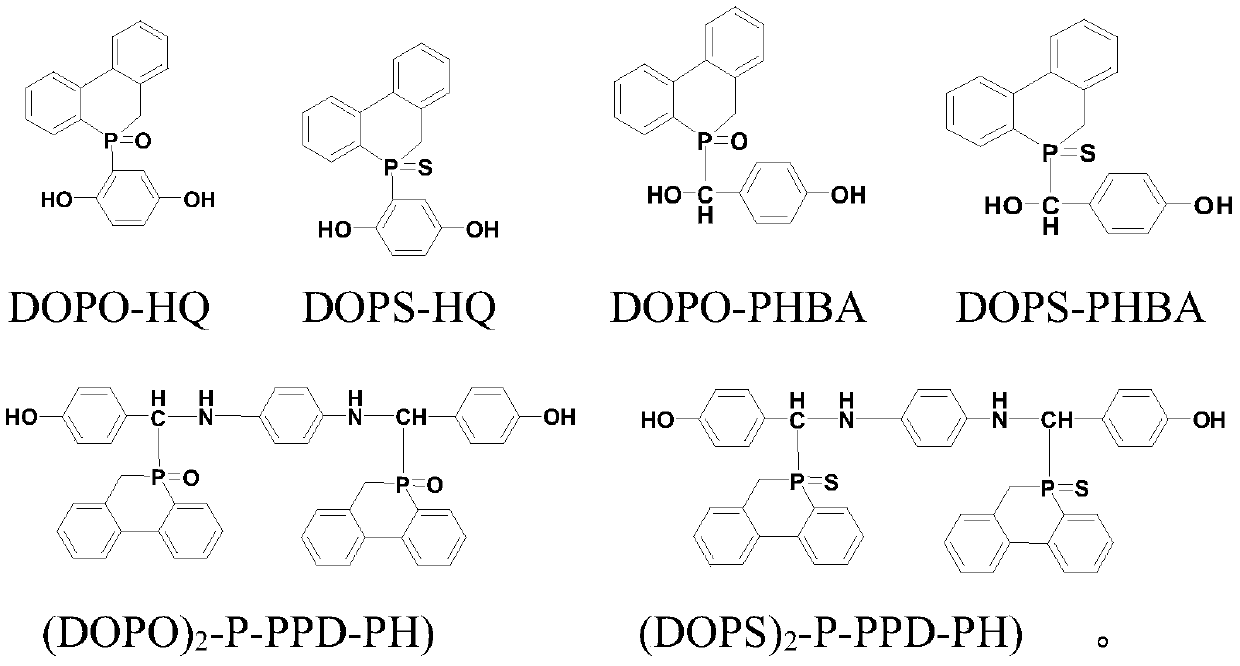

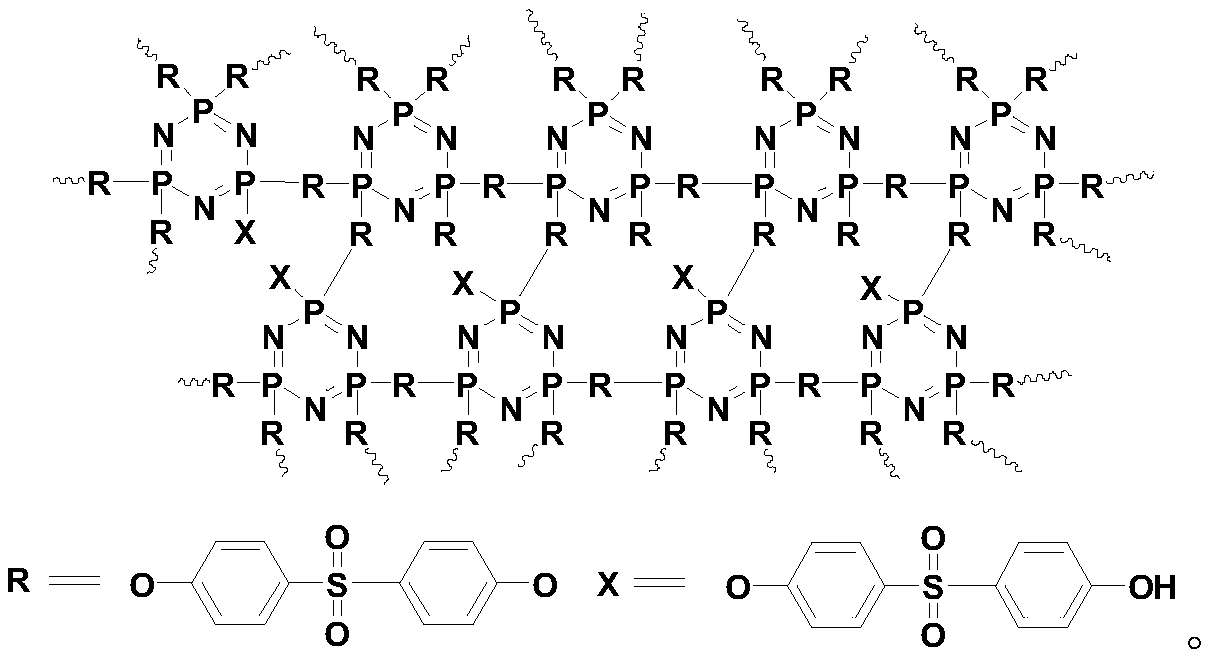

Phosphaphenanthrene and polyphosphazene double-base synergistic flame-retardant acrylonitrile-butadiene-styrene copolymer composite material and preparation method thereof

InactiveCN111363295AGood flame retardant performanceGood interface compatibilityFireproof paintsLarge containersPhosphazeneFlame resistance

The invention belongs to the field of acrylonitrile-butadiene-styrene copolymer composite materials, and particularly relates to a phosphaphenanthrene and polyphosphazene double-base synergistic flame-retardant acrylonitrile-butadiene-styrene copolymer composite material and a preparation method thereof. The phosphaphenanthrene and polyphosphazene double-base synergistic flame-retardant acrylonitrile-butadiene-styrene copolymer composite material is prepared from, by mass, 80 to 95 parts of an acrylonitrile-butadiene-styrene copolymer, 2 to 5 parts of a gas-phase flame retardant, 2 to 5 partsof a a condensed-phase flame retardant, 5 to 10 parts of bulking agent and 0.5 part of an antioxidant. Due to the synergistic effect of the gas-phase flame retardant and the condensed-phase flame retardant, the gas-phase flame retardant is mainly used for gas-phase flame retardance, and the condensed-phase flame retardance is weak. The condensed-phase flame retardant is mainly used as a condensedphase, so that the gas-phase flame retardant is made up; and by mixing the gas-phase flame retardant, the liquid-phase flame retardant and the acrylonitrile-butadiene-styrene copolymer, the flame-retardant material has more excellent flame retardancy and excellent interfacial compatibility, so that the mechanical properties of the polymer flame-retardant material are not reduced and are enhanced.

Owner:GUIZHOU MINZU UNIV

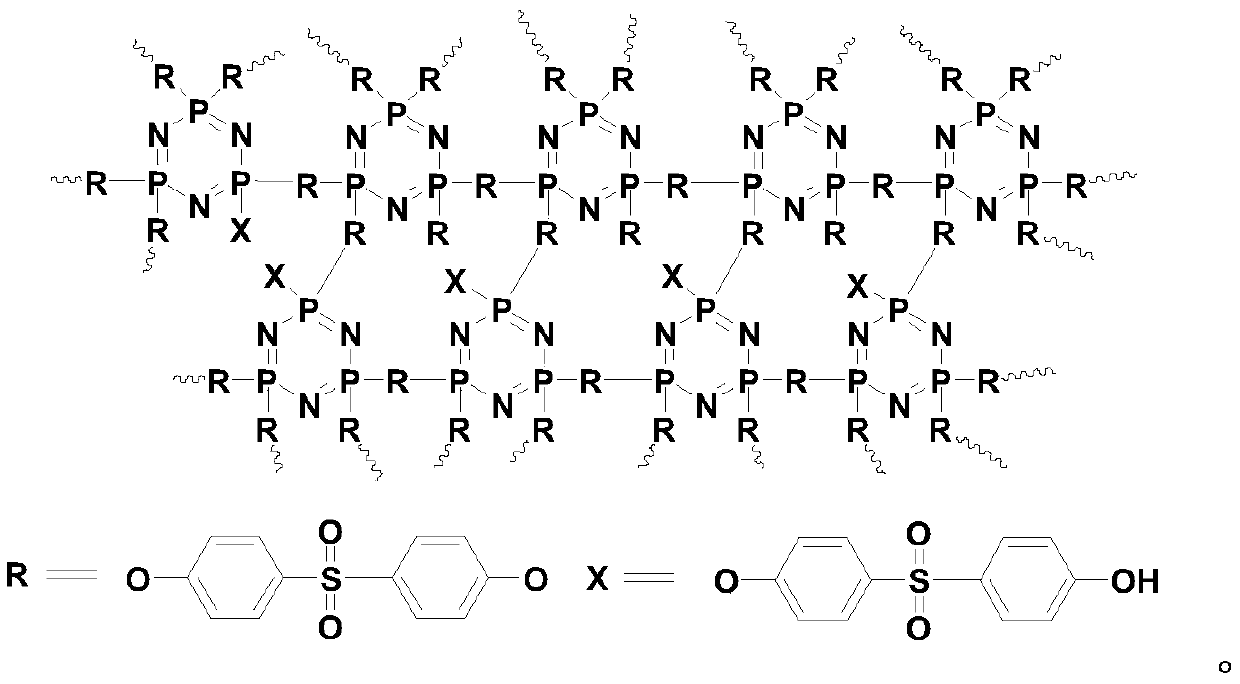

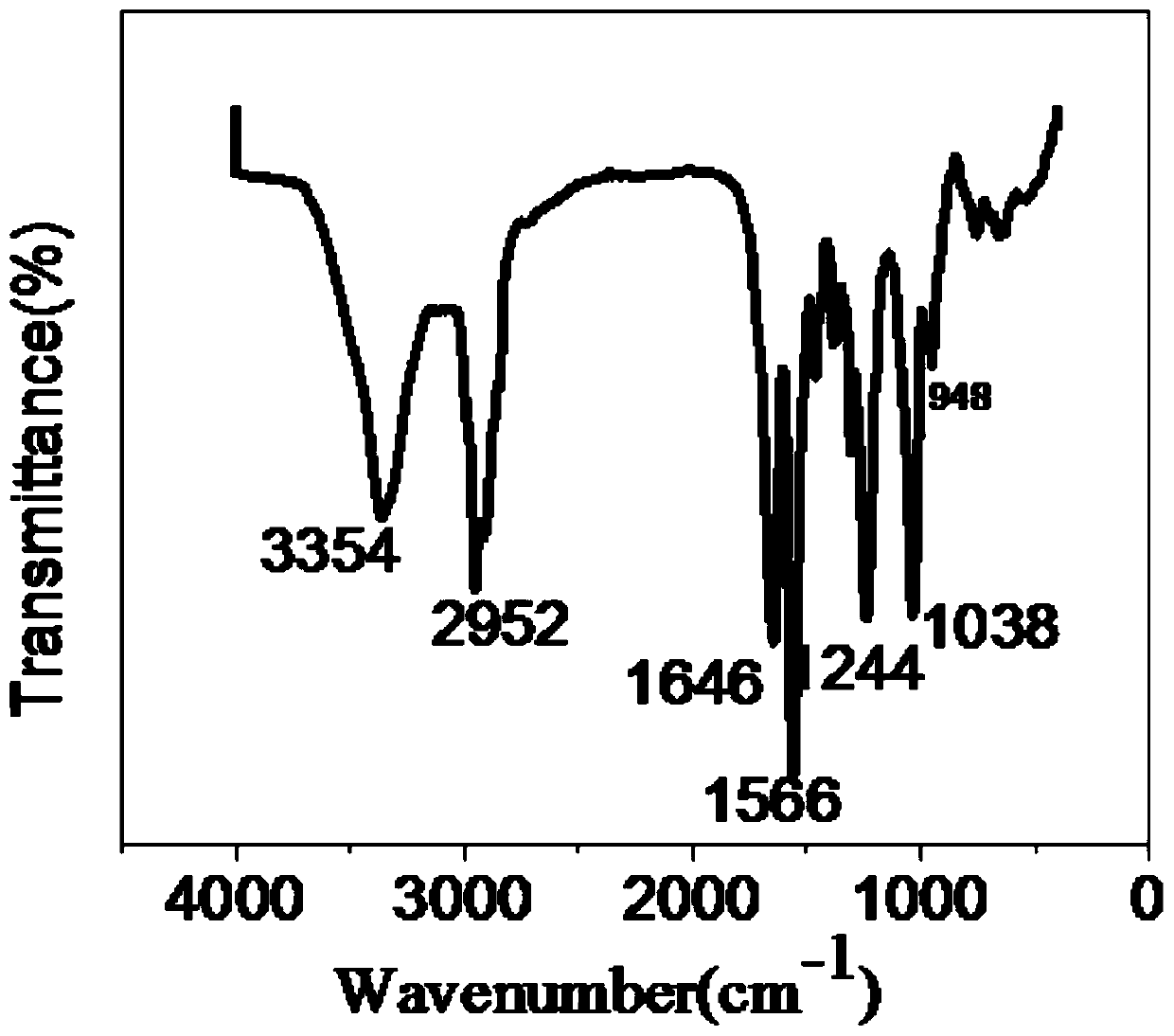

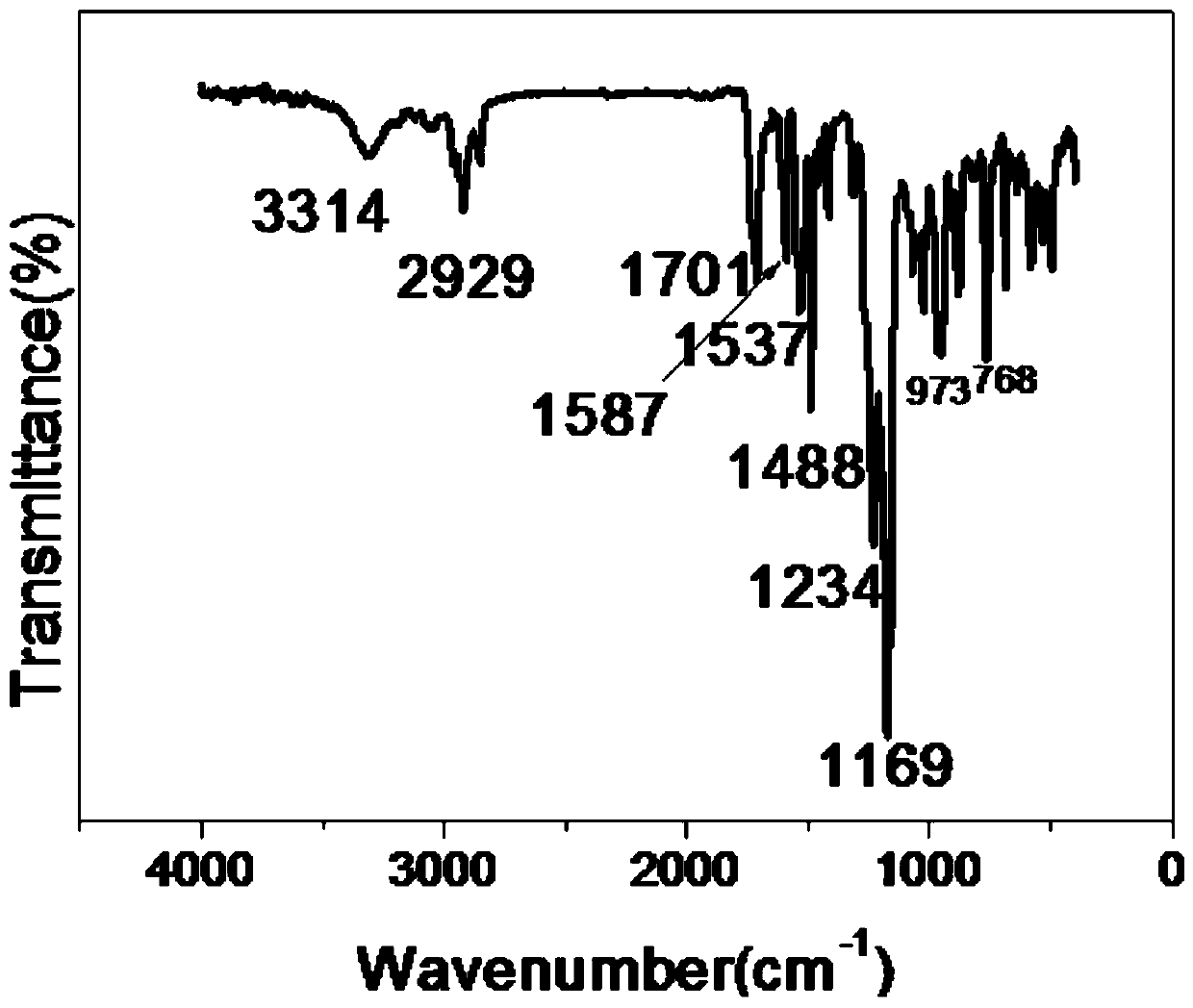

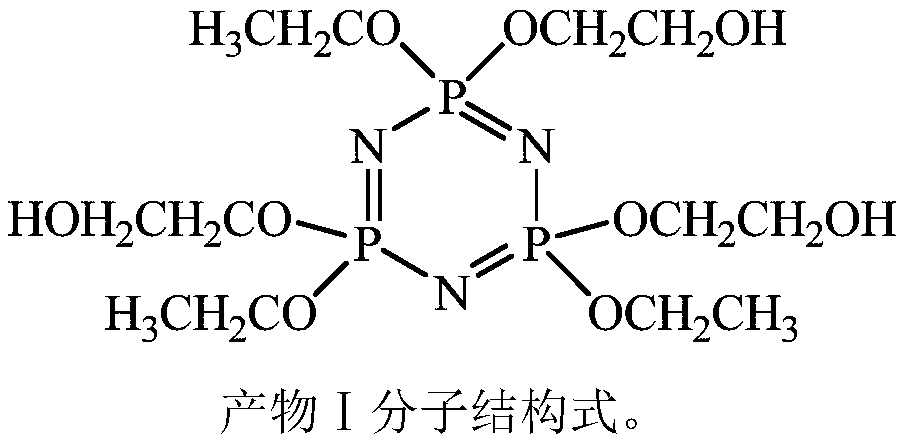

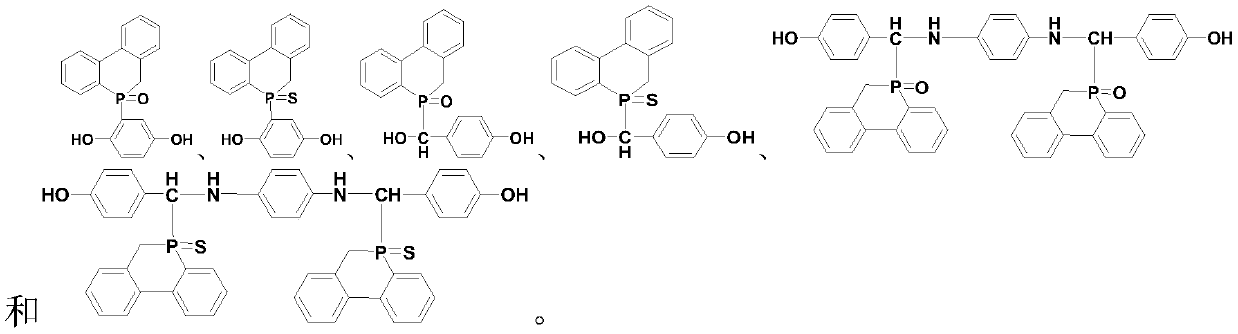

Preparation method of phosphonitrile polymeric flame retardant

InactiveCN110204672AImprove thermal performanceNo loss of mechanical propertiesGroup 5/15 element organic compoundsThermoplastic polyurethaneChloride

The invention provides a preparation method of a phosphonitrile polymeric flame retardant. According to the method, from a molecule design angle, two specific substituent groups are introduced on phosphonitrilic chloride trimer, a ring phosphonitrile derivative with polyhydroxyl is obtained, and through a polyaddition reaction of the derivative and isocyanate, the polymeric flame retardant with aphosphonitrile ring is synthesized. The phosphonitrile polymeric flame retardant is used for flame-retardant modification on materials such as polyurethane and is efficient and environmentally friendly, and the compatibility of the flame retardant and the materials is good. According to the technical scheme, aryloxy or alkoxy and ethylene glycol single sodium with different molar ratios are used as nucleophilic agents, two or more hydroxyl functional groups are introduced to the phosphonitrilic chloride trimer and further react with diisocyanate, and phosphonitrile polyurethane is synthesized.The phosphonitrile polyurethane is used as the polymeric flame retardant for modifying thermoplastic polyurethane (TPU), the LOI value of modified TPU reaches 27.7%, and the flame-retardant level reaches UL94V-0.

Owner:BEIJING UNIV OF CHEM TECH

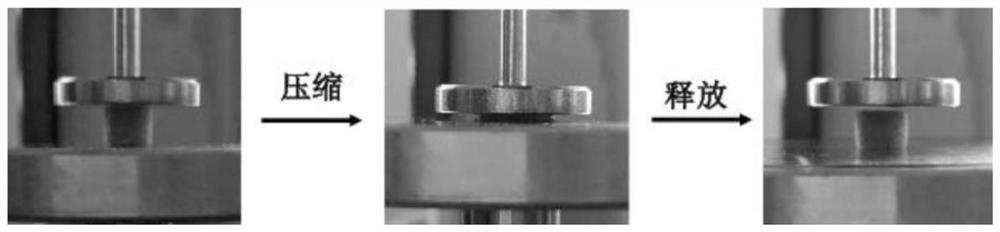

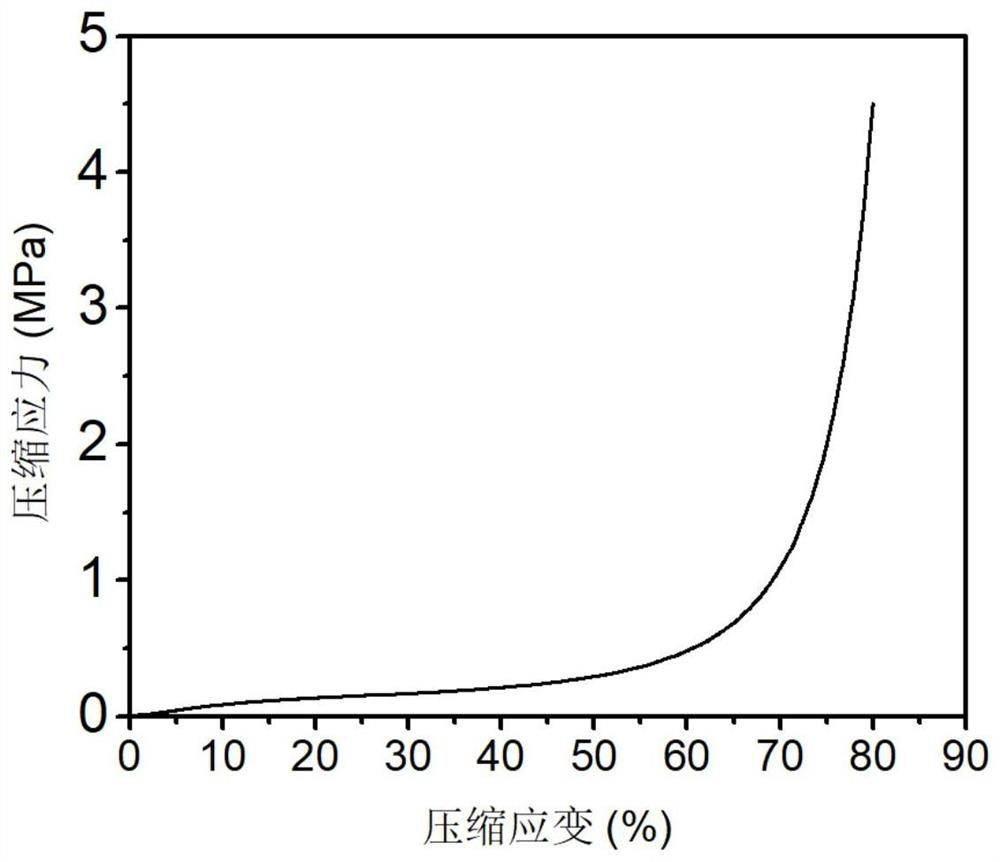

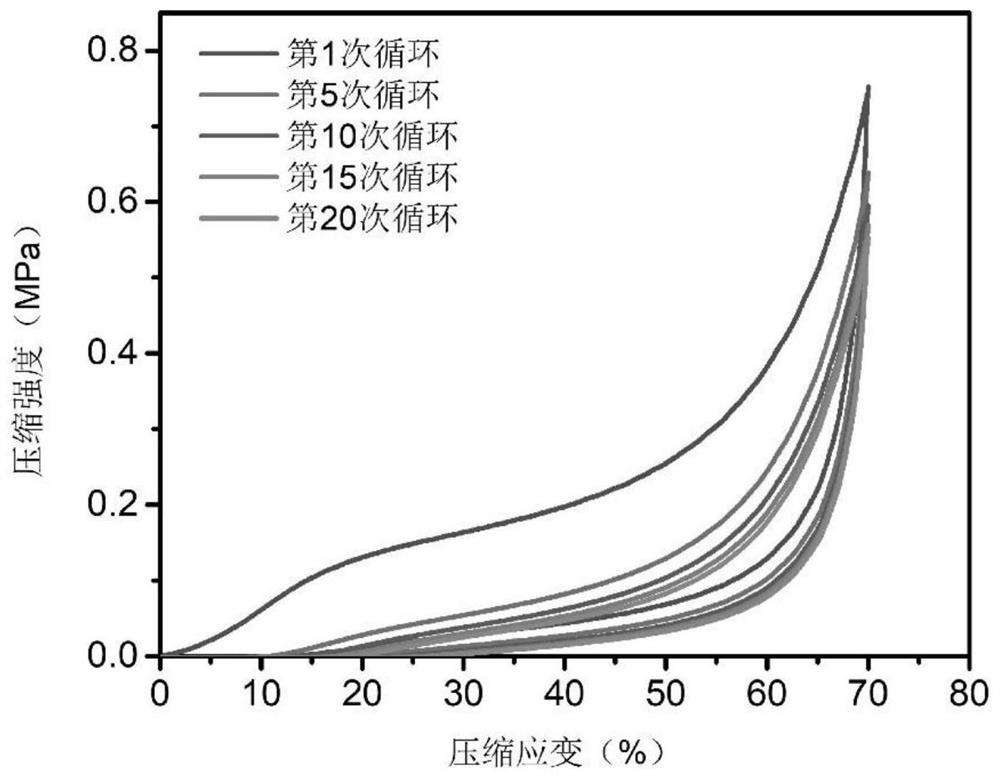

Preparation method of high-elasticity and high-strength double-crosslinked porous hydrogel

The invention discloses a preparation method of high-elasticity high-strength double-crosslinking porous hydrogel, which comprises the following steps: preparing acrylic acid, a hydrophilic monomer, achemical crosslinking agent, an initiator and a solvent into a prepolymer solution; adding a pore-foaming agent into the pre-polymerization solution until the pre-polymerization solution is in a saturated filling state; transferring the saturated filled prepolymer solution into ultraviolet to initiate polymerization to obtain chemical cross-linked hydrogel; and soaking the chemically crosslinkedhydrogel in an iron ion solution, and carrying out physical crosslinking to obtain the double-crosslinked porous hydrogel. The method is simple and easy to implement and is free of special equipment;the porous hydrogel prepared through the method has the characteristics of high elasticity and high strength; in addition, the original mechanical strength of the porous hydrogel can be rapidly recovered under the room temperature condition after the porous hydrogel is fatigued and the good anti-fatigue characteristic is achieved. The product has important application prospects in the fields of artificial muscle, environment treatment materials, flexible electronics and the like.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

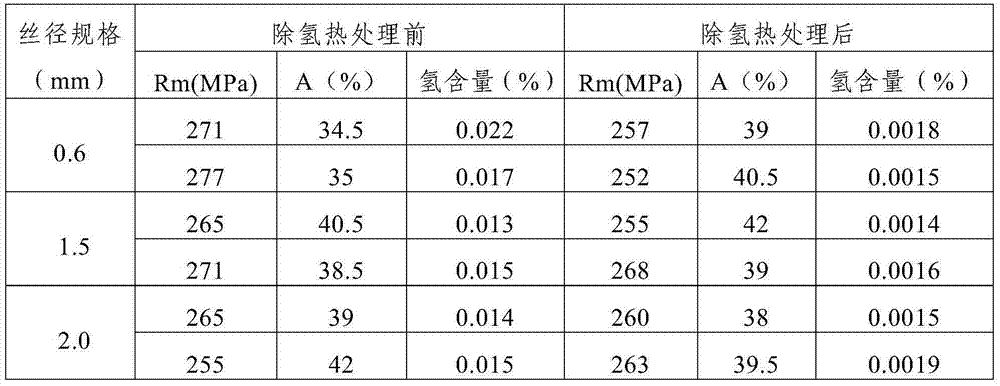

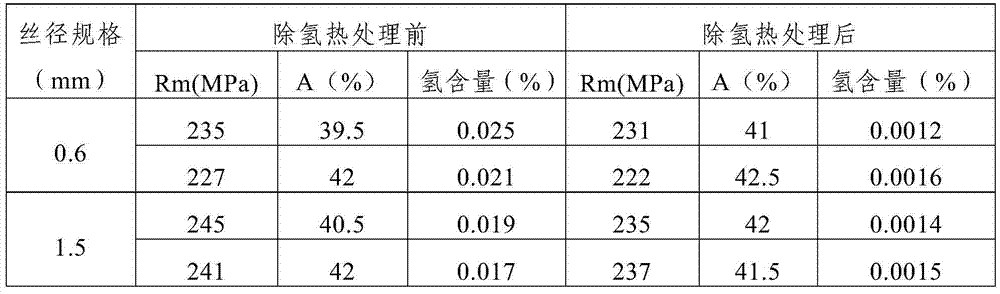

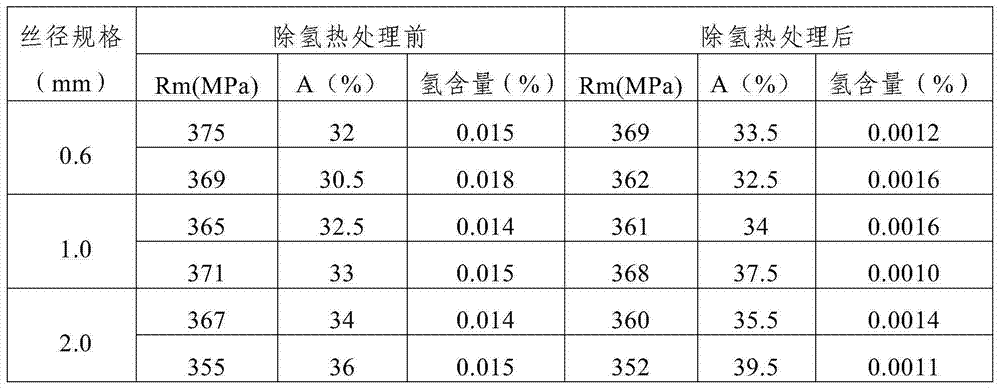

Thermal treatment method for hydrogen removing of titanium wires

ActiveCN103484804AGuaranteed mechanical propertiesReduce hydrogen contentFurnace typesHeat treatment furnacesHydrogenThermal insulation

The invention provides a thermal treatment method for hydrogen removing of titanium wires. The thermal treatment method comprises the following steps: under a vacuum condition, raising the temperature of the titanium wires to (Trs-30)-(Trs-10) DEG C, and performing thermal insulation for 30-90 min; then, raising the temperature to (Trs+10)-(Tre-10) DEG C, and performing thermal insulation for 90-180 min; finally, raising the temperature to Tre-(Tre+30) DEG C, and performing thermal insulation for 60-90 min, wherein the Trs represents the recrystallization temperature of the titanium wires, the Tre represents the recrystallization termination temperature of the titanium wires, and Trs and Tre both adopt the unit of DEG C; the titanium wires are pure titanium wires or titanium alloy wires. According to the thermal treatment method, a multi-stage heat-insulating system is adopted for thermal treatment for hydrogen removing, and an excellent hydrogen removing effect is achieved while the mechanical properties of the titanium wires are not damaged. The thermal treatment method is simple, unique in design and obvious in hydrogen removing effect.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Flame-retardant toughened polylactic acid-based composite material as well as preparation and application thereof

PendingCN111763412AGood compatibilityNo loss of mechanical propertiesFire retardantCompatibilization

The invention belongs to the technical field of flame-retardant toughened modified polymers, and particularly relates to a flame-retardant toughened polylactic acid-based composite material and a preparation method thereof. The composite material comprises a polylactic acid matrix and a modified flame retardant; the modified flame retardant comprises a polylactic acid modified reactive halogen-free flame retardant; the reactive halogen-free flame retardant is a halogen-free flame retardant with the surface containing reactive groups. The invention also provides a preparation method of the composite material. The preparation method comprises the following steps of: 1) mixing a reactive flame retardant with polylactic acid, and carrying out melt blending extrusion to obtain a polylactic acid-modified reactive flame retardant; and (2) carrying out melt blending extrusion on the product obtained in the step (1) and a polylactic acid matrix to obtain the flame-retardant toughened polylacticacid-based composite material. According to the polylactic acid-based composite material provided by the invention, the compatibility between the flame retardant and the polylactic acid matrix is effectively improved, the flame retardant efficiency of the material is high, the mechanical property of the material is relatively good, the process of the material is easy to master, green and environment-friendly; the production cost of the material is low; and the mass production of the material is easy to realize.

Owner:GUIZHOU MATERIAL IND TECH INSTITUE

Biocompatible water-soluble composition and use thereof

ActiveCN102989045AExcellent penetration and wettabilityNo loss of mechanical propertiesAntipyreticAnalgesicsPolyolBiocompatibility

The invention relates to a biocompatible water-soluble composition which is prepared from the following ingredients in mass percentage: 0-60% of water-soluble amino acid, 2.5%-60% of D-panthenol, 0%-5% of a moisturizing-conditioning agent, 2.5%-20% of a polyalcohol moisturizing agent and 30%-80% of water, wherein in the case that water-soluble amino acid is contained, the total content of water-soluble amino acid and D-panthenol is not less than 5%; and in the case that water-soluble amino acid is not contained, the content of D-panthenol is not less than 5%. The invention further relates to the use of the composition as a penetrating lubricant for medical or contraceptive rubber film products. The composition disclosed by the invention is excellent in penetrating and wetting properties, lubricating and moisturizing properties, and biocompatibility, so that the rubber films present transparent and moist appearances, and can be integrally wetted in the surrounding in a forming-curling state; the whitening and the mechanical performance degradation of rubber due to long-time contact are avoided; and the advantages of wettability, lubrication, no crystallization and the like can still be kept in a drying environment.

Owner:GUANGZHOU GONGHE MEDICINE TECH

Fluorescence wood plastic decorative board and preparation method

This invention discloses a kind of fluorescence wood plastic decorative board and preparing method thereof, the key technical point is adopting organic modification treated fluorescence material as luminous pigment, and adding it to wood plastic compound material, then plasticize and mix and fix pattern by mold, then the fluorescence wood plastic decorative board is got. This preparing method can solve the compatibility of inorganic luminous pigment and wood plastic, and the blackening problem of luminous pigment during wood plasticized material process, the prepared fluorescence wood plastic decorative board has even tint, good mechanical performance and luminous performance, and can be widely applied to building indoor and outdoor decoration for weak light indication and beautification.

Owner:SHANDONG XIAGUANG INDAL

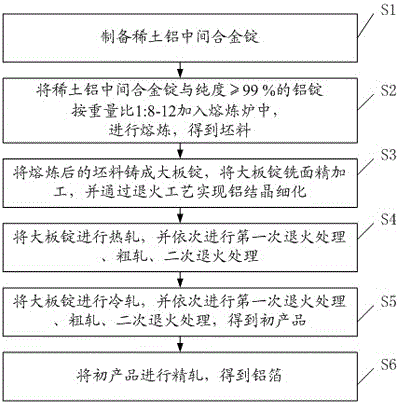

Aluminum foil applicable to lithium ion battery and preparation method for aluminum foil

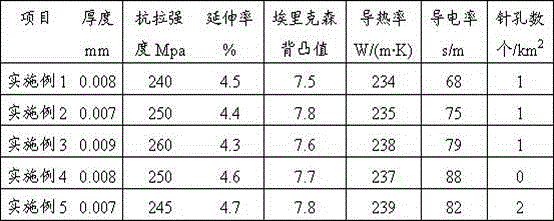

ActiveCN105977494AIncreased strength and mechanical performance indicatorsLower bandgapElectrode rolling/calenderingMaterial nanotechnologyRare-earth elementThermal conductivity

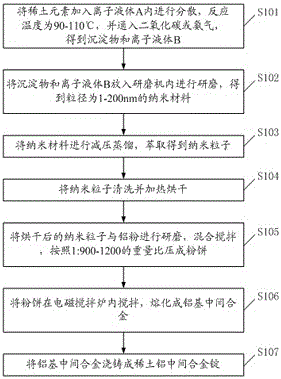

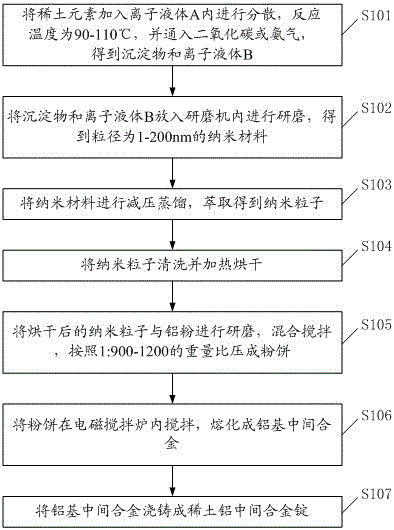

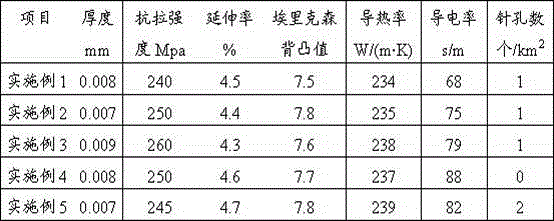

The invention discloses a preparation method for an aluminum foil applicable to a lithium ion battery. The preparation method comprises the steps of 1, grinding rare earth elements to obtain a nanometer rare earth material with the particle diameter of 1-200nm, enabling the nanometer rare earth material to be ground, mixed and stirred with aluminum powder, pressing the mixture into pressed powder, and then melting the pressed powder and casting to obtain a rare earth aluminum intermediate alloy ingot; 2, adding the rare earth aluminum intermediate alloy ingot and the aluminum ingot into a smelting furnace to be smelted to obtain a blank material; 3, performing cast rolling on the smelted blank material to obtain an aluminum plate blank material; 4, performing annealing and heat treatment on the aluminum plate blank material; 5, performing continuous cold rolling on the aluminum plate blank material to obtain a primary product; and 6, performing finish rolling on the primary product to obtain the aluminum foil. Correspondingly, the invention also discloses the aluminum foil prepared by the method. The aluminum foil is high in intensity, thermal conductivity and electric conductivity, good in mechanical performance and resistant to electrochemical corrosion.

Owner:佛山金兰铝厂有限公司

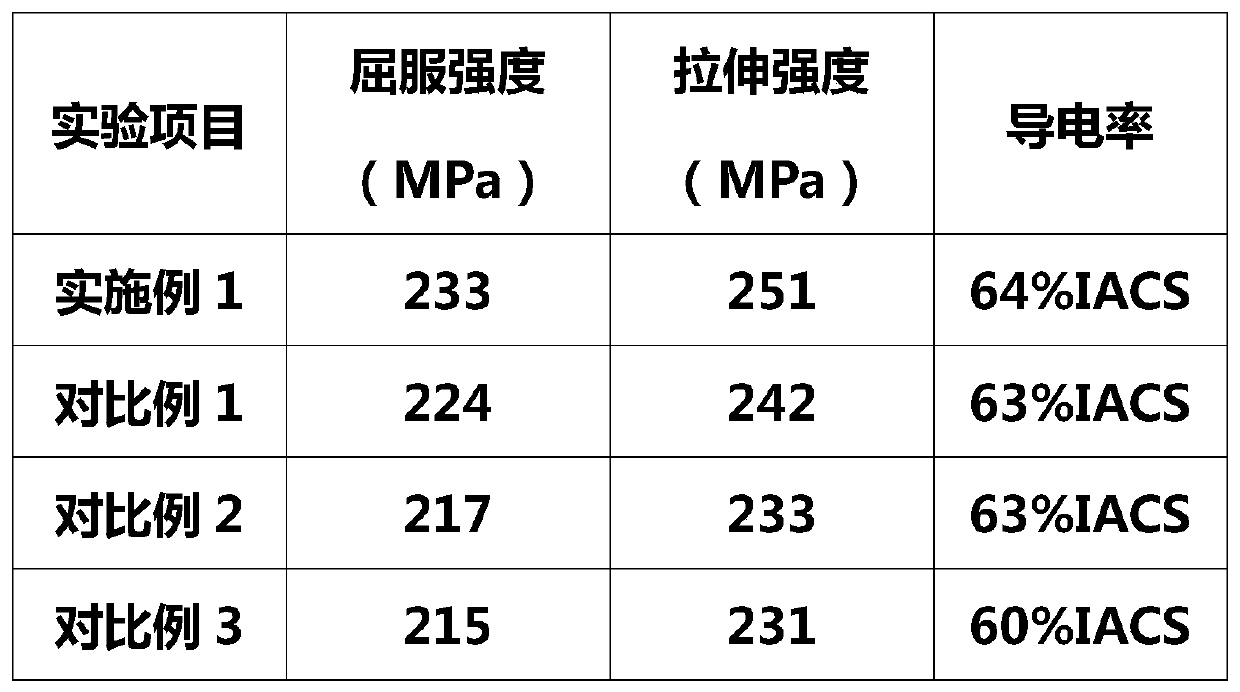

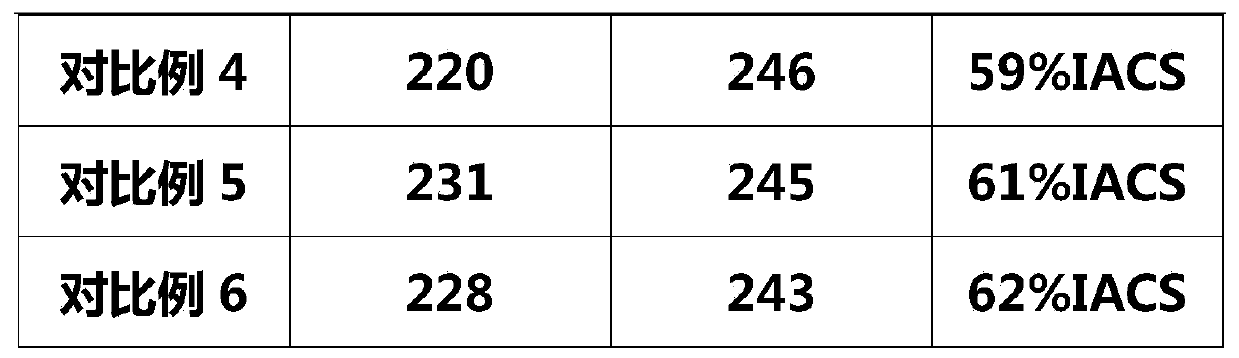

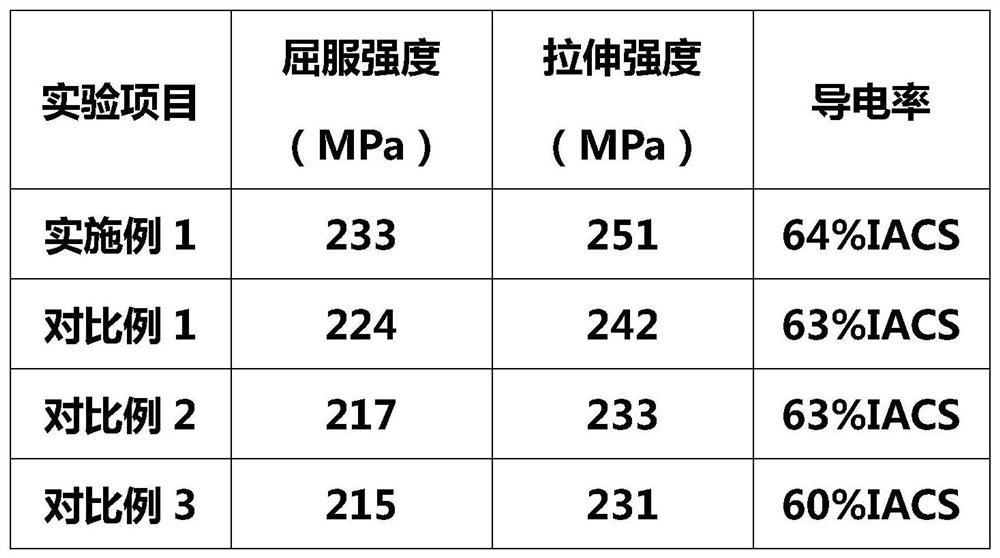

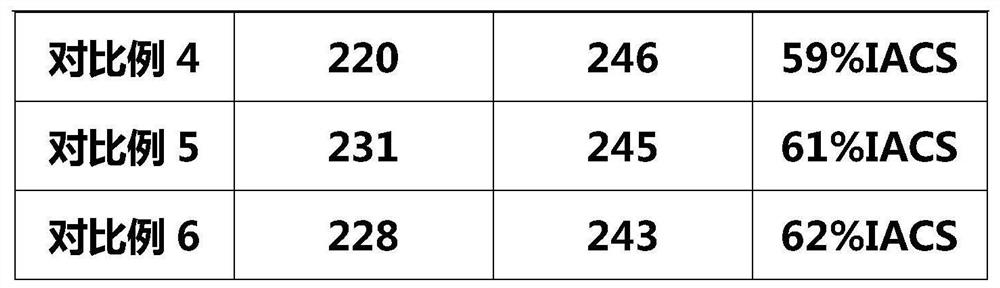

High-conductivity aluminum alloy and heating processing technology thereof

ActiveCN111575557ANo loss of mechanical propertiesImprove conductivityConductive materialMetal/alloy conductorsMechanical propertyHeat treated

The invention discloses a high-conductivity aluminum alloy. The high-conductivity aluminum alloy comprises the following components of, in percentage, 0.34%-0.45% of Si, smaller than or equal to 0.12%of Fe, 0.08%-0.18% of Cu, 0.54%-0.76% of Mg, smaller than or equal to 0.05% of Zn, smaller than or equal to 0.05% of Cr and the balance Al and other inevitable impurity elements, the total componentcontents of Mg and Si are smaller than or equal to 1.05%, the mass ratio of Mg to Si is 1.6 to 1.7, the total component contents of Cu and Zn are 0.12%-0.18%, and Cu / Zn is larger than or equal to 2.8and smaller than or equal to 3.4. According to the high-conductivity aluminum alloy and the heating processing technology thereof, on the basis of common elements, the proportion content of the elements is optimized, meanwhile, a heat treatment method is coordinated, it is guaranteed that the mechanical property is not greatly reduced while the conductivity is improved, the cost is reduced, and the application prospect is achieved.

Owner:福建祥鑫股份有限公司

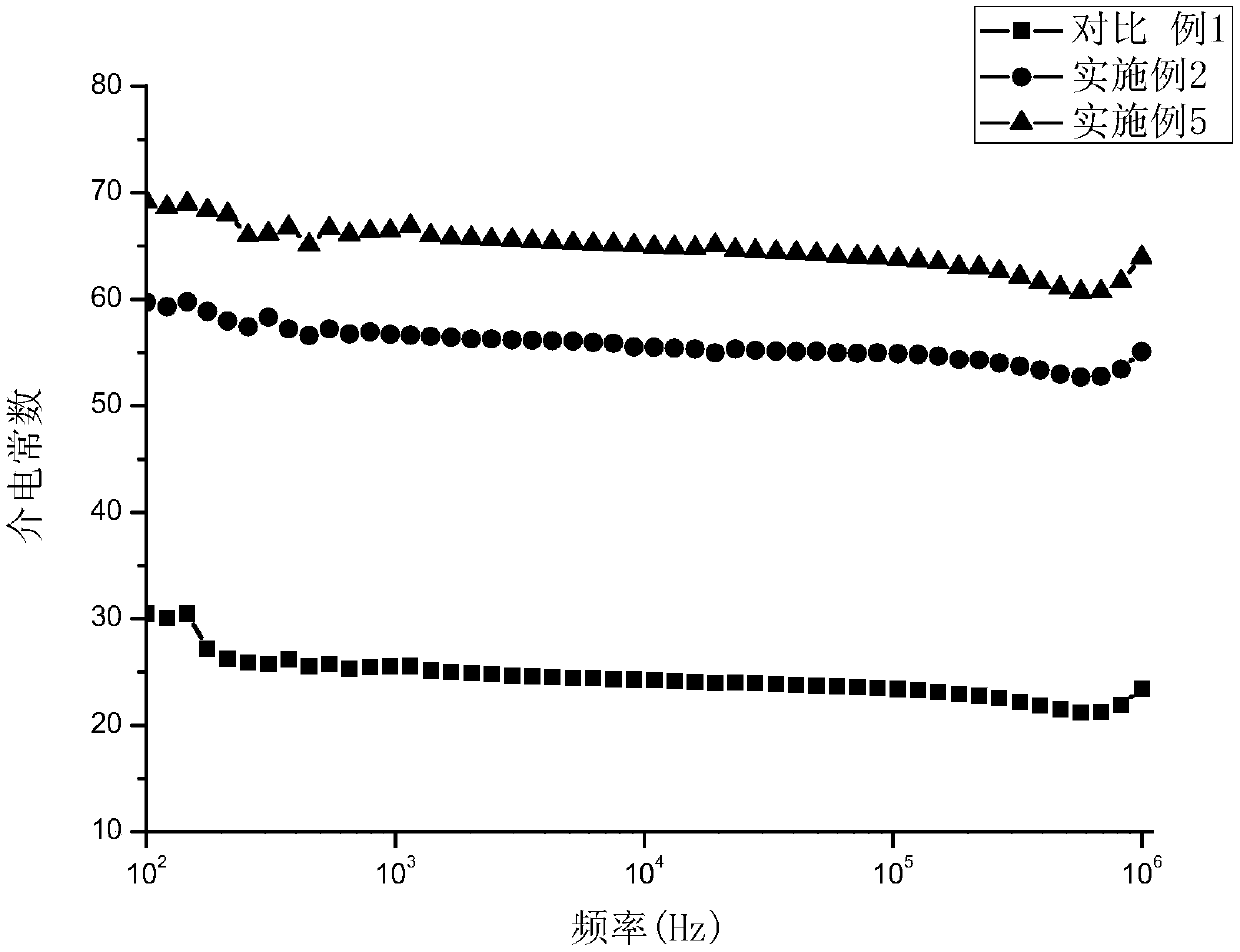

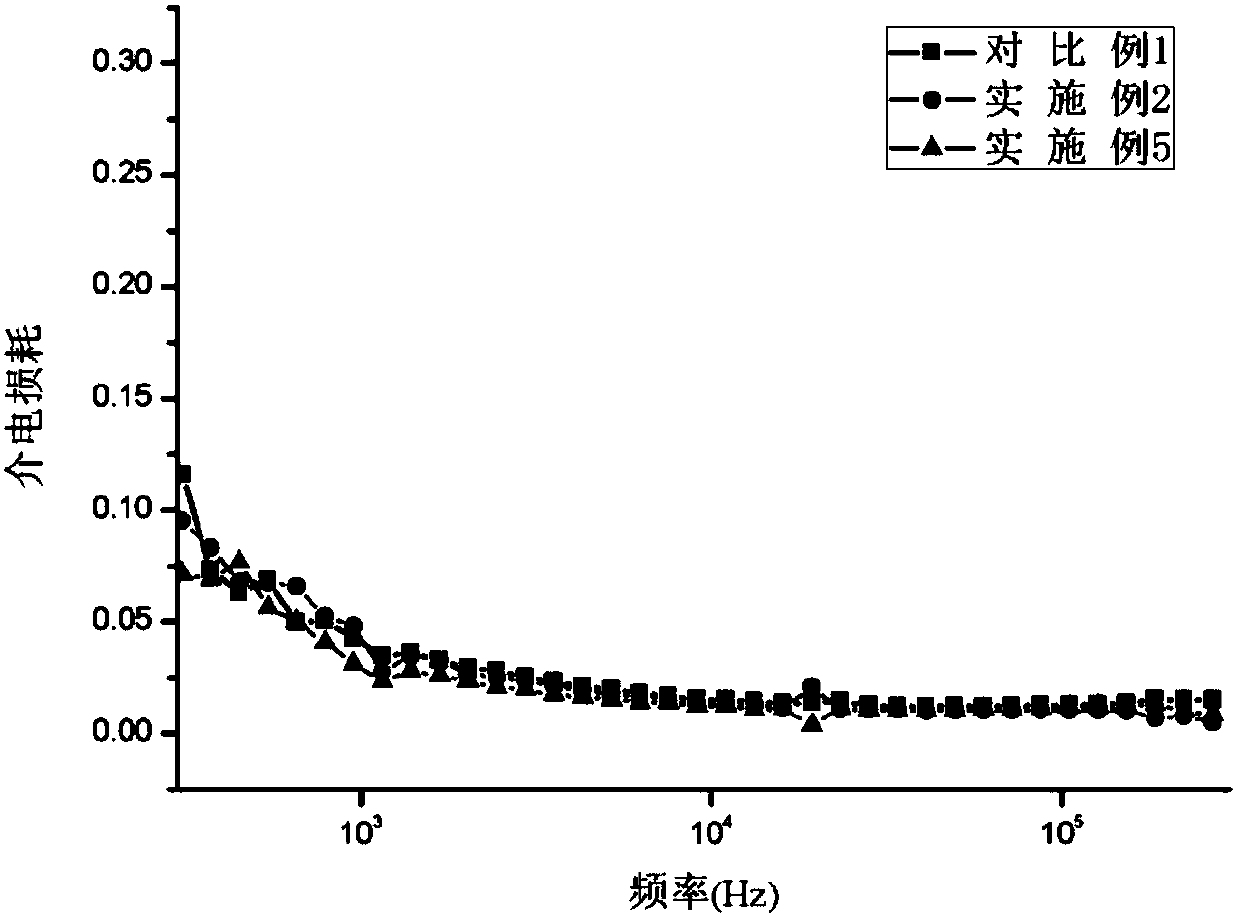

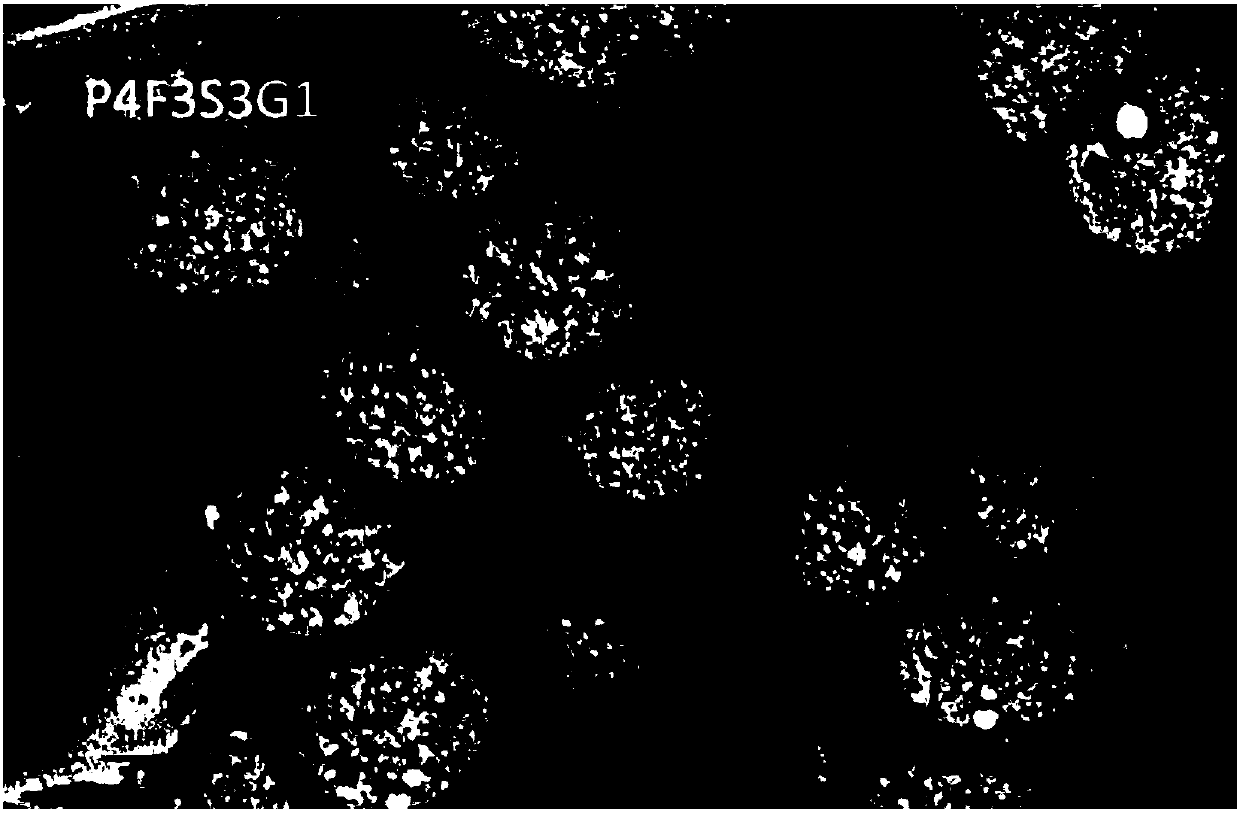

Carbon-based dielectric elastomer based on core-shell dynamic vulcanization and preparation method

The invention discloses a carbon-based dielectric elastomer based on core-shell dynamic vulcanization and a preparation method. Multiple core-shell structures of core rubber completely coated and crosslinked by shell rubber are formed in a plastic continuous phase through dispersion; carbon-based conductive filler in the dielectric elastomer is selectively dispersed in the core rubber and coated with the shell rubber to form dispersed micron-size micro-capacitors; the dielectric constant of the carbon-based dielectric elastomer within the frequency range of 101-106 Hz is kept at 55 or above and dielectric loss can be kept at 0.1 or below. The dielectric constant of the dielectric elastomer is increased significantly while the low dielectric loss is kept in the wideband range, and the prepared dielectric elastomer can be widely applied to medical equipment, energy storage, biomimetic materials, aviation machinery, robots and other fields.

Owner:SOUTH CHINA UNIV OF TECH

Double-base synergistic flame-retardant polyformaldehyde composite material and preparation method thereof

InactiveCN111218089AImprove flame retardant performanceImprove adhesionPolyoxymethylenePolyphosphazene

The invention discloses a double-base synergistic flame-retardant polyformaldehyde composite material. The composite material comprises, by mass, 80-95 parts of polyformaldehyde, 2-5 parts of a gas-phase flame retardant, 2-5 parts of a condensed-phase flame retardant, 5-10 parts of a compatibilizer and 0.5 part of an antioxidant. A preparation method of the composite material comprises the following steps: S1, drying polyformaldehyde, the gas-phase flame retardant, the condensed-phase flame retardant, the compatibilizer and the antioxidant at 75-85 DEG C, and uniformly mixing to obtain a mixture; and S2, carrying out blending extrusion processing on the mixture obtained in step S1 through a double-screw extruder at 160-175 DEG C, cooling to room temperature, and sequentially carrying out traction and dicing to obtain the phosphaphenanthrene and polyphosphazene double-base synergistic flame-retardant polyformaldehyde composite material. The modified polyformaldehyde material has the advantages of favorable flame retardancy, favorable compatibility between the flame retardant and a matrix and favorable mechanical properties. In addition, the preparation method is simple.

Owner:KANGMINGYUAN GUIZHOU SCI & TECH DEV CO LTD

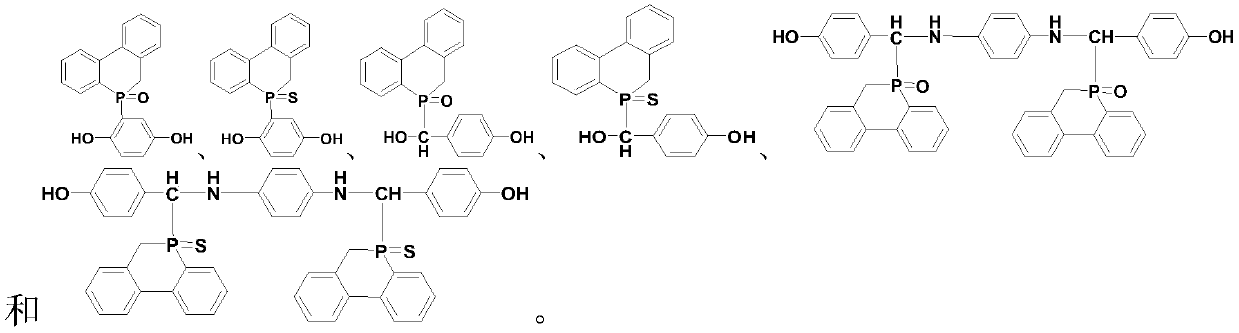

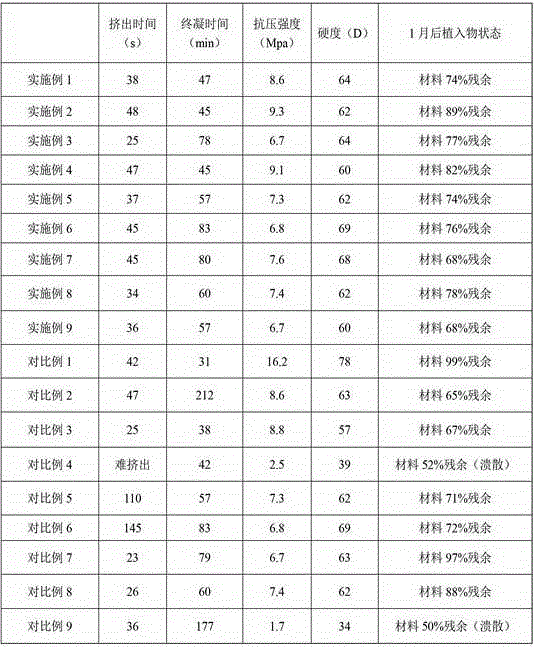

Injectable biological calcium salt compound bone cement and preparation method thereof

ActiveCN105770986AHigh mechanical strengthPlay a lubricating roleTissue regenerationProsthesisAbsorption capacityCell-Extracellular Matrix

The invention discloses injectable biological calcium salt compound bone cement and a preparation method thereof.The bone cement is composed of powder and liquid, the powder comprises a component A and a component B, and the component A is prepared from alpha-calcium sulfate hemihydrates, calcium phosphate and an enhancer.The component B is prepared from a bone extracellular matrix and a water-resistant lubricant.A calcium sulfate-calcium phosphate-powdery cancellous bone extracellular matrix basic system is adopted, but the amount of calcium phosphate in the system is further reduced, calcium phosphate is replaced with the calcium enhancer, the calcium enhancer can enhance the overall mechanical strength of the material like calcium phosphate, and the degradation and absorption capacity is superior to that of calcium phosphate.The water-resistant lubricant to which calcium ingredients are added can lubricate the whole material during stirring injection, injection is convenient, and the biological property, mechanical property and injectable performance of an existing calcium bone cement material can be improved.

Owner:GUANGZHOU ANZE REGENERATIVE MEDICINE TECH CO LTD

Fluorescent wood-plastic external wall board and preparation method thereof

InactiveCN106366497AUniform colorImprove luminous performanceLuminescent compositionsSurface layerFluorescence

The invention relates to a fluorescent wood-plastic external wall board. Raw materials of the fluorescent wood-plastic external wall board further include a luminous pigment, the luminous pigment is prepared by directly and physically mixing a fluorescent material subjected to organic modification treatment and then performing forming through a fusing-plasticizing device and a mouth mold or is prepared by adopting the fluorescent material subjected to organic modification treatment as a fluorescent pigment, co-extruding and mixing the fluorescent pigment and a wood-plastic wall board, adding the mixture to a lateral extrusion machine of a coextrusion machine for coextrusion with the coextrusion machine and performing plasticizing, mixing and mouth mold forming. The invention further discloses a preparation method. By the adoption of the preparation method, a surface-layer luminous wood-plastic product uniform in color and luster, good in durability and having good luminous property can be prepared, and the effects of weak light indication, decoration and beautifying are played.

Owner:SHANDONG XIAGUANG INDAL

Aluminum foil suitable for lithium ion battery and preparation method thereof

ActiveCN105951006AGuaranteed diffusionHigh strengthElectrode carriers/collectorsRare-earth elementIngot

The invention discloses a preparation method of aluminum foil suitable for a lithium ion battery. The method includes the steps that firstly, rare earth elements are ground to obtain a nano rare earth material with the grain size being 1-200 nm, the nano rare earth material and aluminum powder are ground, mixed and stirred and then pressed into a powder cake, and then the powder cake is melted and cast into a rare earth aluminum intermediate alloy ingot; secondly, the rare earth aluminum intermediate alloy ingot and an aluminum ingot are added into a smelting furnace to be smelted, and a blank is obtained; thirdly, the blank is cast into a large slab ingot, finish face milling is conducted, and aluminum crystal refining is achieved through an annealing process; fourthly, the large slab ingot is hot-rolled, annealed for the first time, roughly rolled and annealed for the second time; fifthly, the large slab ingot is cold-rolled, annealed for the first time, roughly rolled and annealed for the second time, and a primary product is obtained; and sixthly, the primary product is finely rolled to obtain the aluminum foil. Correspondingly, the invention discloses the aluminum foil prepared through the method. The aluminum foil is high in strength, heat conductivity and electric conductivity, good in mechanical performance and resistant to electrochemical corrosion.

Owner:佛山金兰铝厂有限公司

A composite all-solid polymer electrolyte material and its preparation method

InactiveCN105280952BImprove ionic conductivityNo loss of mechanical propertiesFinal product manufactureElectrolyte accumulators manufacturePolymer sciencePolyethylene glycol

The invention relates to a composite all-solid polymer electrolyte material and a preparation method thereof. The raw materials include the following components in parts by mass: 10-30 parts of carboxylated nitrile rubber; 70-90 parts of epoxidized natural rubber; 30-50 parts of lithium salt; 5-30 parts of epoxidized oligomer clathrate silsesquioxane-terminal carboxylated polyethylene glycol graft copolymer. In the invention, the above raw materials are dissolved in tetrahydrofuran solvent at room temperature, a solution casting method is adopted and the solvent is evaporated to obtain a composite all-solid polymer electrolyte. Compared with the existing technology, due to the combination of the polymer matrix and the filler used, it has the advantage of higher room temperature conductivity. When the filler is added to 25 parts, the conductivity at room temperature reaches the maximum, which is 2.571×10‑5S cm-1; and the material is easy to prepare, environmentally friendly, and low-cost, and has potential application value in the industrial production of lithium batteries.

Owner:SHANGHAI JIAO TONG UNIV

A kind of high conductivity aluminum alloy and its heat treatment process

ActiveCN111575557BNo loss of mechanical propertiesImprove conductivityConductive materialMetal/alloy conductorsMechanical propertyHeat treated

The invention discloses a high-conductivity aluminum alloy. The high-conductivity aluminum alloy comprises the following components of, in percentage, 0.34%-0.45% of Si, smaller than or equal to 0.12%of Fe, 0.08%-0.18% of Cu, 0.54%-0.76% of Mg, smaller than or equal to 0.05% of Zn, smaller than or equal to 0.05% of Cr and the balance Al and other inevitable impurity elements, the total componentcontents of Mg and Si are smaller than or equal to 1.05%, the mass ratio of Mg to Si is 1.6 to 1.7, the total component contents of Cu and Zn are 0.12%-0.18%, and Cu / Zn is larger than or equal to 2.8and smaller than or equal to 3.4. According to the high-conductivity aluminum alloy and the heating processing technology thereof, on the basis of common elements, the proportion content of the elements is optimized, meanwhile, a heat treatment method is coordinated, it is guaranteed that the mechanical property is not greatly reduced while the conductivity is improved, the cost is reduced, and the application prospect is achieved.

Owner:福建祥鑫股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com