Nano Al2O3 composite corona-resistant polyimide film

A technology of polyimide film and corona resistance, which is applied in the fields of chemical products and its preparation, corona-resistant polyimide film and its preparation, and can solve the problem of poor film yield, corona resistance and uniformity, dispersion Poor effect and other problems, to achieve the effect of good electrical performance, narrow size distribution, and uniform particle dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

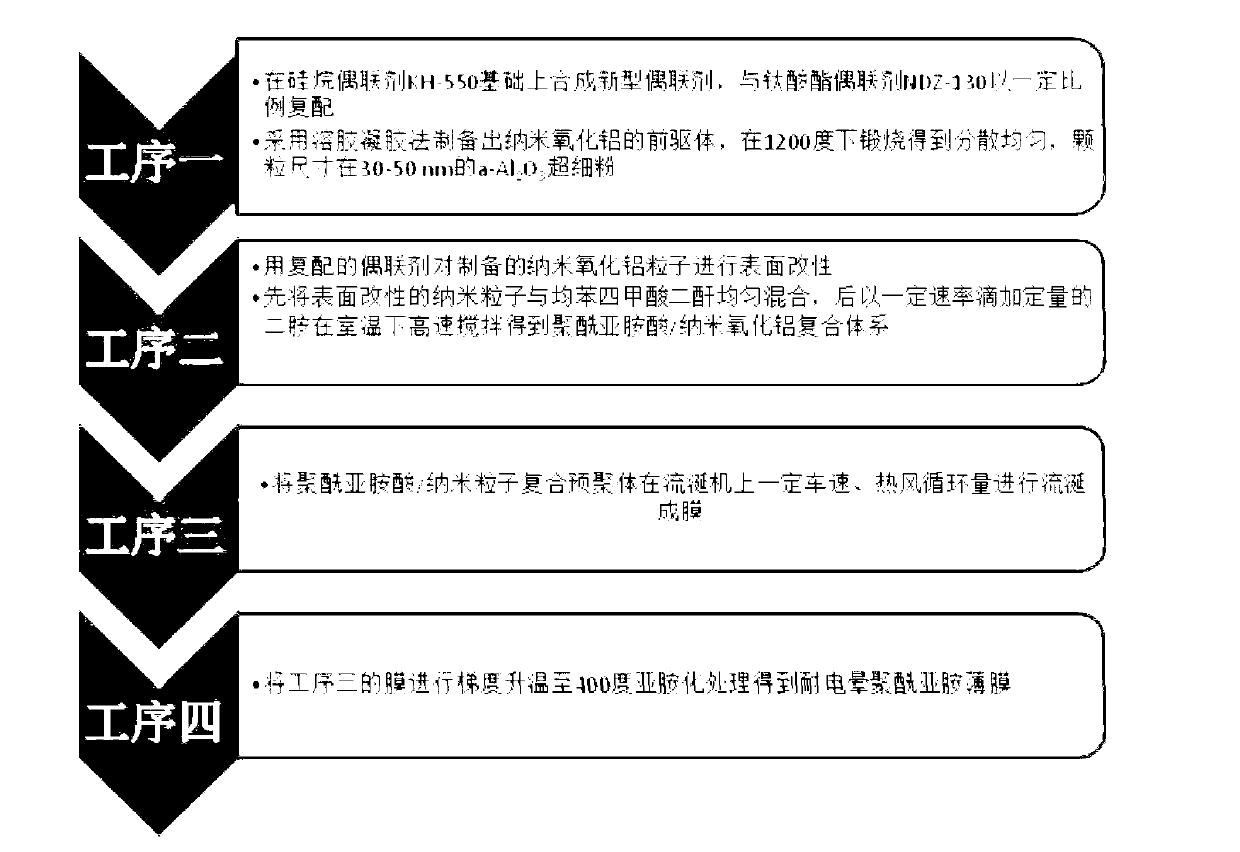

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: The main components of the corona-resistant polyimide film are: pyromellitic dianhydride, 4.4'-diaminodiphenyl ether and a certain mass fraction of surface-modified nano-alumina particles. The size of the nanoparticles is between 30-50nm. The specific ratio is: the mass ratio of pyromellitic dianhydride to 4.4'-diaminodiphenyl ether is 1:1.1, and the surface-modified nano-alumina particles added account for 0.15 of the total mass. The specific preparation method of this polyimide film containing nano-alumina anti-corona is as follows:

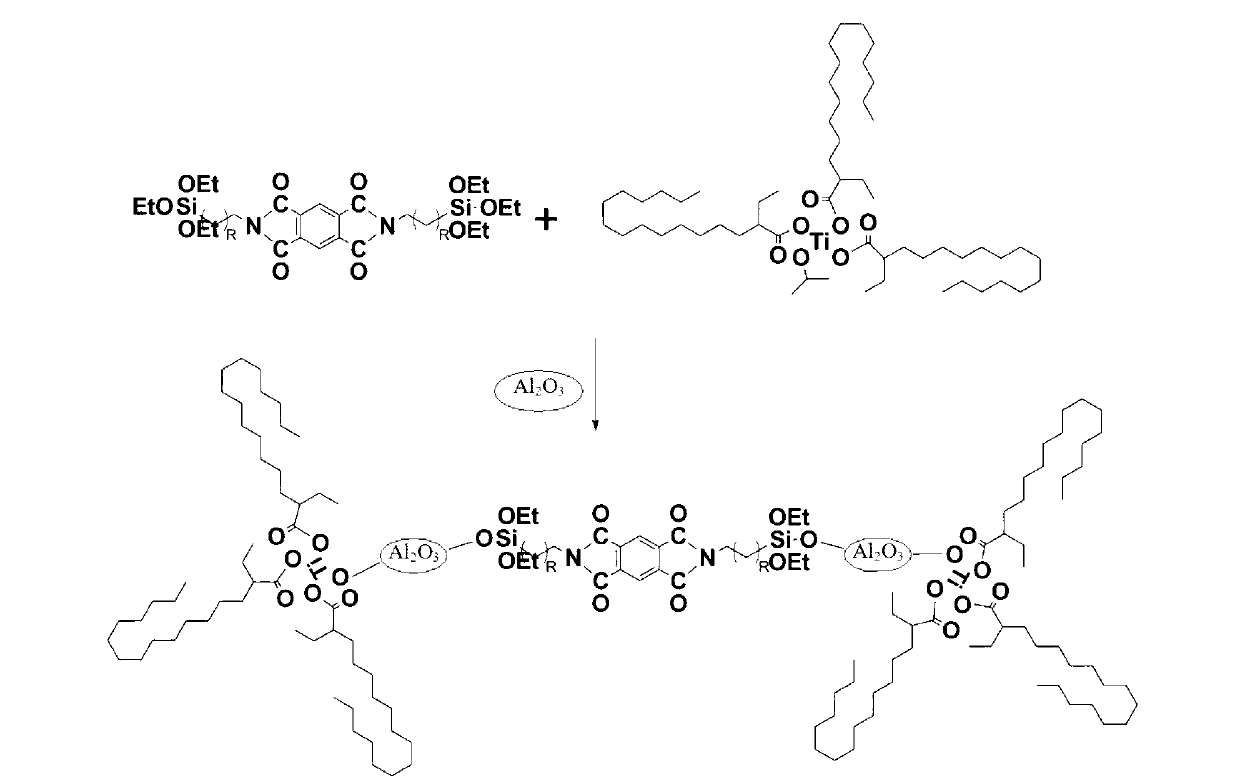

[0031] (1) Synthesis of new coupling agent—take 20g of silane coupling agent KH-550 and 9.8g of pyromellitic dianhydride in a flask, add a small amount of water-carrying agent, and heat up to 150°C for 2 hours. The reaction product was extracted with n-butanol, and then vacuum filtered to obtain the product.

[0032] (2) Preparation of nano-alumina particles—dilute ammonia water (made by diluting 28% concentrated ammonia ...

Embodiment 2

[0037] Embodiment two: with the anti-corona polyimide film of a kind of high concentration nano-alumina of embodiment one, its difference is that the massfraction of the nano-alumina particle that adds surface modification is 0.2.

Embodiment 3

[0038] Embodiment 3: a kind of corona-resistant polyimide film with high concentration of nano-alumina as in Embodiment 1, the difference lies in that the mass fraction of added surface-modified nano-alumina particles is 0.3.

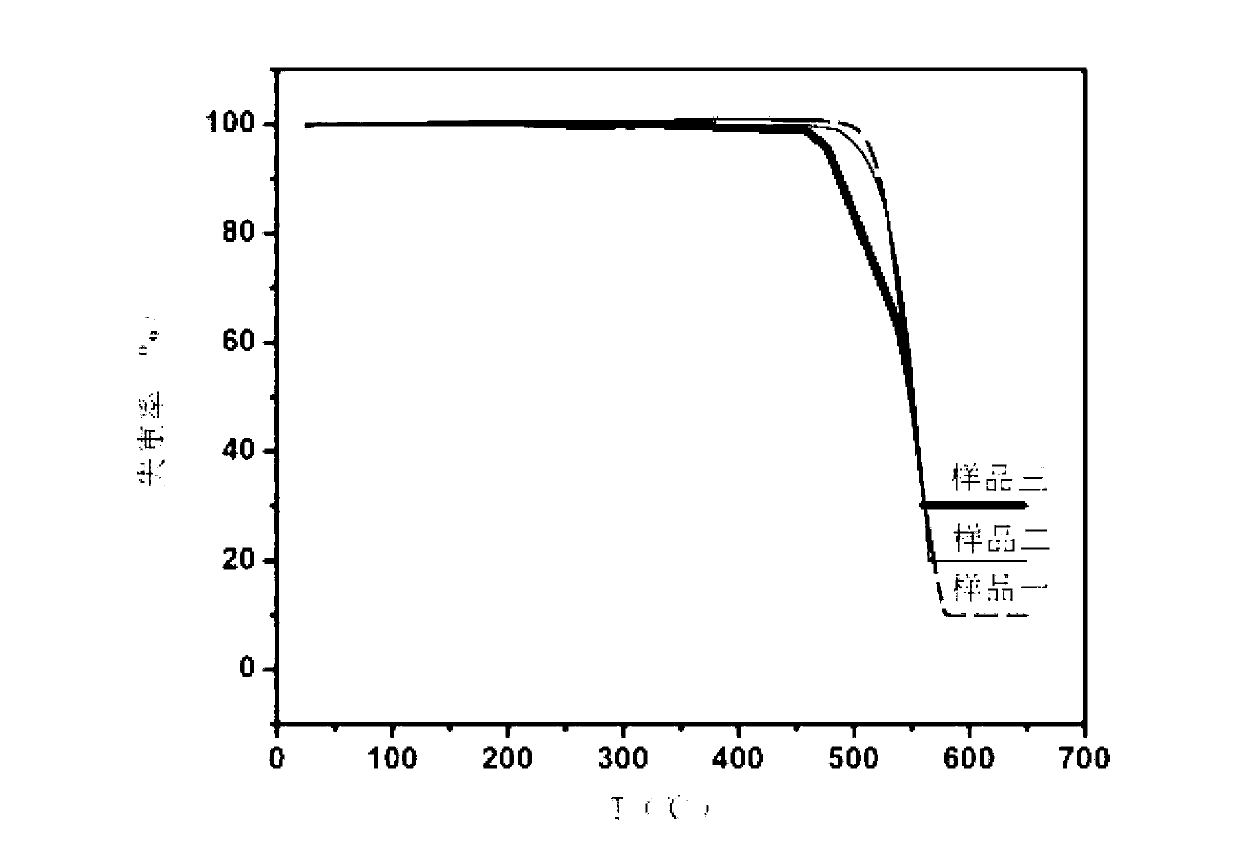

[0039] The following table shows various performance characterization values of the films prepared in the three specific examples.

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com