Direct contact type stretching deformation measuring system and method in high-temperature oxygen-free environment

A high-temperature anaerobic, tensile deformation technology, applied in the direction of electric/magnetic solid deformation measurement, measurement devices, electromagnetic measurement devices, etc., can solve the problems of many limitations and the inability to calibrate non-contact high-temperature extensometers, etc., to achieve guaranteed Measurement accuracy, no loss of mechanical properties, and the effect of eliminating heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

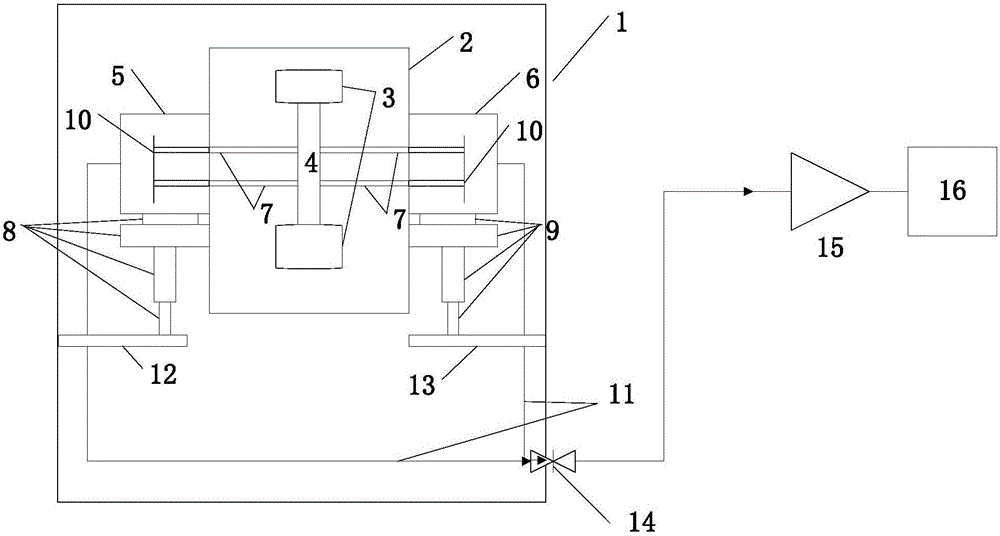

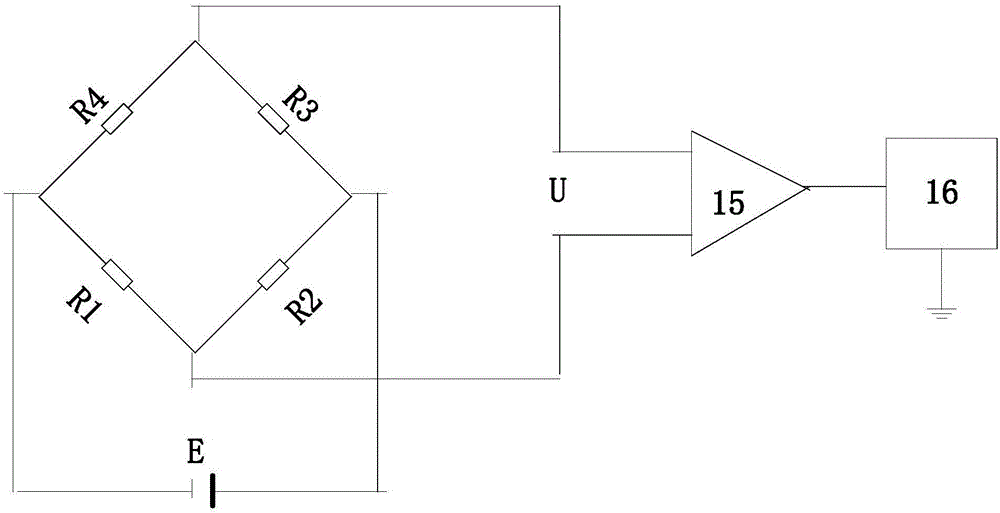

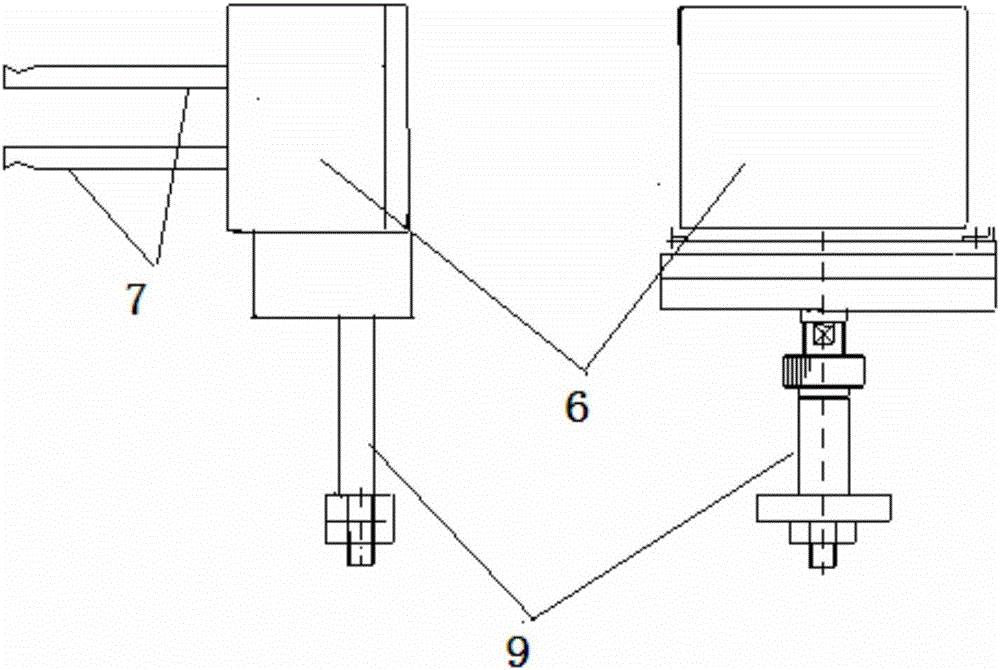

[0037] Such as figure 1 Shown is a schematic diagram of a high-temperature tensile performance testing system. It can be seen from the figure that a direct-contact tensile deformation measurement system in a high-temperature anaerobic environment includes an environmental chamber 1, a radiation furnace 2, a tensile fixture 3, and a tensile sample 4 , the first extensometer water cooling box 5, the second extensometer water cooling box 6, the extensometer transmission rod 7, the first support adjustment device 8, the second support adjustment device 9, the elastic element and the strain gauge 10, the signal line 11, the first Fixed plate 12, second fixed plate 13, aviation plug 14, signal amplification converter 15 and display 16;

[0038] Radiation furnace 2, tensile fixture 3, tensile sample 4, first extensometer water cooling box 5, second ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com